Can One Vacuum Cooler Handle All Your Baked Goods?

You have a perfect sourdough, a delicate sponge cake, and flaky croissants all coming out of the oven. But they all need different cooling. You worry that a single machine will ruin at least one of them. It is a big risk for your production.

Yes, a modern vacuum cooler can handle everything. The key is its programmable software. By creating custom "recipes" for each product—adjusting cooling speed, pressure steps, and final temperature—you can perfectly cool bread, cakes, and pastries in one versatile machine.

As the person responsible for engineering these systems at Allcold, I talk to bakers every day. The most common question I get is, "Mila, will your machine destroy my croissants?" It is a fair question. The answer lies in understanding that a vacuum cooler isn’t a blunt instrument; it is a precision tool. Let me show you how we tune it for each of your masterpieces.

How Do You Keep Crusty Bread Crispy, Not Soggy?

You pull a beautiful, dark-baked sourdough from the oven. It "sings" on the rack, a sign of a perfect crust. But two hours later, that crust has turned leathery and tough. All that hard work feels wasted.

Vacuum cooling creates a superior, longer-lasting crust. By rapidly pulling steam out of the loaf, we prevent moisture from the crumb from migrating to the surface. This "flash-off" effect results in a thinner, crispier crust that stays crunchy for hours, not minutes.

Engineering the "Aggressive Cooling Curve1"

For a buyer like Norman, who is sensitive to quality, the crust is a major selling point. He needs to know his product will still be premium quality when it reaches his customers. To achieve this, we use what we call an "Aggressive Cooling Curve1."

This is the simplest and fastest type of vacuum cooling, perfect for robust products with strong gluten structures. Here’s what’s happening inside the Allcold machine:

- Linear Pressure Drop2: Once the door is sealed, the vacuum pump (we use powerful and reliable Busch or Leybold pumps) starts pulling air and water vapor out of the chamber at a constant, high speed. The pressure drops in a straight line from atmospheric pressure (around 1000 mbar) down to the target pressure (e.g., 20 mbar).

- Rapid Evaporation3: As the pressure drops, the boiling point of the water inside the bread also drops. The water turns to steam and is instantly removed. This entire process takes only 3 to 5 minutes for products like baguettes.

- The "Flash-Off" Finish: In the final stage, the machine pulls the pressure slightly lower than what is required for the target temperature. This forces any remaining surface moisture to evaporate instantly, effectively "case-hardening" the crust. This creates a microscopic barrier that helps protect the crust from ambient humidity later.

For a technical decision-maker like Carlos, the specific parameters are key. He wants to see the data. Here’s how we might set up the Siemens PLC for different types of crusty breads:

| Feature | Artisan Sourdough Loaf | Thin Baguette |

|---|---|---|

| Primary Goal | Preserve open crumb, thick crust | Maximum crispness, thin crust |

| Cooling Time | 6-8 minutes | 3-5 minutes |

| Cooling Curve | Linear, Aggressive | Linear, Very Aggressive |

| Final Target Pressure | ~25 mbar (for 22°C core) | ~20 mbar (for 18°C core) |

| VFD Pump Speed | 90% capacity | 100% capacity |

| Resulting Texture | Chewy crumb, thick crunchy crust | Airy crumb, shatter-crisp crust |

This aggressive approach works wonders for crusty bread, but it would be a disaster for a more delicate product.

Why Do Cakes Collapse Under Vacuum?

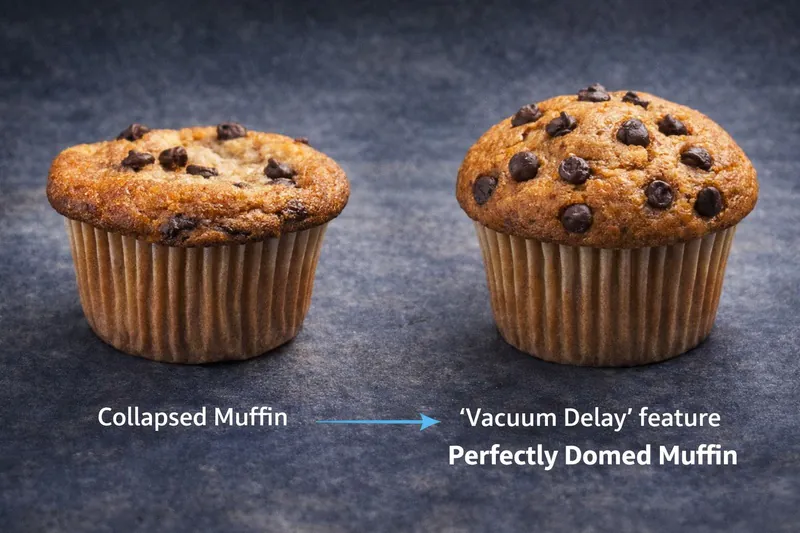

You bake a beautiful batch of muffins or a perfect sponge cake. You put it in a standard vacuum cooler, and it looks fine for a minute. Then, suddenly, it implodes, shrinking into a dense, gummy puck. This is a baker’s nightmare.

Cakes collapse because their delicate structure, often based on egg foam, cannot withstand the explosive force of rapid water evaporation. You must use a vacuum cooler with a "Vacuum Delay" or "Step-Cooling" function to allow the crumb to set before deep cooling begins.

The "Gentle Touch" of Step-Cooling

For a procurement manager like Sophia, who is responsible for the quality of thousands of pastries for a fast-food chain, consistency is everything. A single collapsed batch is a major failure. This is why we developed our "Soft Air4" and "Vacuum Delay5" protocols.

Unlike the aggressive, linear pull for bread, cooling cakes is a multi-stage process. Here is the logic programmed into our control system:

- Initial Stabilization Pause: The machine pulls the pressure down, but instead of going all the way, it pauses at a pre-set level, for example, 500 mbar. At this pressure, some water begins to evaporate, but gently. This initial, slow evaporation allows the cake’s internal structure (the coagulated proteins and starches) to firm up and gain strength. It is like letting a fragile building settle before putting a heavy load on it.

- Stepped Pressure Reduction: After a programmed delay (e.g., 60 seconds), the system continues to lower the pressure, but in controlled steps. It might go from 500 mbar to 300 mbar, pause again, then go to 100 mbar, and so on. We can program up to 10 different steps. The Variable Frequency Drive6 (VFD) on the pump motor is crucial here, as it allows us to precisely control the speed of evacuation at each stage.

- Final Cooling: Only when the product’s structure is stable does the machine pull down to the final target pressure (e.g., 35 mbar) to reach the desired core temperature.

Let’s compare the cooling curves. It paints a clear picture:

| Parameter | Aggressive Bread Cooling | Gentle Cake Cooling |

|---|---|---|

| Structure Type | Strong Gluten Network | Fragile Egg/Fat Foam |

| Cooling Logic | Linear (One Stage) | Stepped (Multiple Stages) |

| Pump Speed | Constant High Speed | Variable Speed, with Pauses |

| Cycle Time | 3-8 Minutes | 8-15 Minutes |

| Primary Risk | None | Total Structural Collapse |

| HMI Recipe Name | "Baguette" or "Rye" | "Muffin," "Sponge," "Cheesecake" |

I once worked with a client in Singapore who was a central kitchen supplier (much like Sophia). Their cheesecakes kept cracking on top during cooling. We implemented a 3-stage vacuum delay profile, which held the pressure steady just as the surface began to cool. This allowed the top to set evenly, completely eliminating the cracking problem and saving them thousands in wasted product.

How Do You Protect the Delicate Layers in a Croissant?

You spend two days laminating your croissant dough, creating hundreds of paper-thin layers of butter and dough. But during cooling, the butter melts and leaks out, leaving you with a greasy, dense pastry instead of a light, flaky one.

Vacuum cooling is the best way to preserve lamination. Its incredible speed chills the product so fast that the butter solidifies inside the layers before it has a chance to melt and pool. This locks in the flaky texture you worked so hard to create.

Winning the Race Against Butter’s Melting Point

For a true artisan, the quality of a croissant is measured in its layers. The challenge is that when the croissant comes out of the oven, the dough is over 95°C, but the butter layers are molten.

The Traditional Cooling Problem

On a cooling rack, the croissant cools from the outside in.

- Heat Retention: The internal layers stay hot for a long time.

- Butter Migration7: The liquid butter fat gets absorbed by the surrounding dough layers.

- The Result: The layers fuse together. You lose the delicate separation. The final product is heavy and greasy, and the "honeycomb" interior structure is lost. The bottom of the croissant is often visibly oily.

The Vacuum Cooling8 Solution

Vacuum cooling works from the inside out by removing heat via evaporation.

- The Race: We are in a race against time to bring the internal temperature of the croissant from ~95°C down below the solidification point of butter (around 28-30°C).

- Incredible Speed: With a powerful vacuum system, this happens in about 90 to 120 seconds.

- The "Snap Freeze" Effect: The butter goes from a liquid to a solid almost instantly, trapping it in its designated layer. The steam created during cooling helps to further separate the dough layers, enhancing the flakiness.

The process for laminated dough is a hybrid—it needs to be fast but not so violent that it damages the delicate shape.

| Feature | Air Cooling | Vacuum Cooling |

|---|---|---|

| Cooling Time9 | 30-45 minutes | 3-5 minutes |

| State of Butter | Stays liquid for >15 mins | Solidifies in <2 mins |

| Layer Integrity | Layers merge, become greasy | Layers remain separate and distinct |

| Final Texture | Chewy, dense, oily bottom | Light, airy, flaky, clean bottom |

| Vacuum Profile | N/A | "Fast-Ramp" (Fast, but not as aggressive as bread) |

This is also critical for filled pastries like Danishes. By cooling the fruit or cream cheese filling at the same rapid rate as the pastry, we prevent the filling’s moisture from making the bottom of the Danish soggy. It keeps everything perfectly contained.

Can You Keep Soft Breads Moist Without Making Them Gummy?

For enriched breads like brioche, shokupan (milk bread), or burger buns, the goal is a soft, moist, and fluffy crumb. The fear is that vacuum cooling, which removes moisture, will dry them out. Or worse, if done incorrectly, make them dense.

Yes, you can maintain perfect moisture. We program the vacuum cooler to a less aggressive final pressure. This corresponds to a slightly higher final product temperature (e.g., 30°C instead of 22°C), intentionally leaving more residual moisture in the crumb for maximum softness.

Mastering Equilibrium Pressure for Softness

This is where the true precision of the Allcold system comes into play. It all comes down to the physics of the Pressure-Temperature Relationship of water.

The final temperature of your product is directly determined by the final pressure inside the vacuum chamber.

- Deep Vacuum (e.g., 20 mbar): Corresponds to a lower boiling point, resulting in a cooler, drier product (perfect for crusty bread).

- Shallow Vacuum (e.g., 40 mbar): Corresponds to a higher boiling point, resulting in a warmer, moister product (perfect for soft bread).

The "Moisture-Lock" Recipe

For a brioche or a batch of soft dinner rolls, we are not aiming for a crispy crust. We want a soft crust and a pillowy interior.

- Cooling Curve: We use a moderately fast, linear curve. It is faster than cake cooling but gentler than bread cooling.

- Target Pressure: Instead of programming the cycle to end at 25 mbar, we tell the Siemens controller to stop the pump when the chamber reaches 40 mbar.

- Equilibrium: At 40 mbar, water boils at approximately 29°C. This means that once the entire loaf has reached 29°C, the cooling process naturally stops.

- Result: We have successfully removed enough energy to make the bread stable for slicing and packaging, but we have intentionally left a higher percentage of moisture locked inside the crumb compared to a sourdough loaf.

Here is a simple guide to our recipe-driven approach:

| Product Goal | Target Temp | Target Pressure | Resulting Moisture Loss |

|---|---|---|---|

| Ultra-Crispy Crust (Baguette) | 18°C | 20 mbar | ~4-5% |

| Standard Crisp Crust (Sourdough) | 22°C | 25 mbar | ~3-4% |

| Soft & Moist Crumb (Brioche) | 29°C | 40 mbar | ~2-3% |

| Delicate Structure (Cake) | 25°C | 30 mbar (with steps) | ~2% |

By controlling this single parameter—the final pressure—we give the baker complete control over the final moisture content and texture of their product. It transforms the machine from a simple cooler into a versatile texture-management tool.

Conclusion

A vacuum cooler is not a "one-size-fits-all" appliance. It is a highly adaptable system. With the right programming and an understanding of your products, you can use a single machine to achieve a crispier crust on bread, prevent the collapse of cakes, preserve the layers in croissants, and maintain the moisture in soft buns.

Your bakery produces a diverse range of art. Your cooling equipment should be smart enough to treat each piece accordingly.

-

Understanding the Aggressive Cooling Curve can enhance your knowledge of vacuum cooling techniques for better product quality. ↩ ↩

-

Explore how Linear Pressure Drop impacts the efficiency of vacuum cooling processes and product quality. ↩

-

Learn about Rapid Evaporation and its crucial role in achieving optimal cooling for baked goods. ↩

-

Explore the Soft Air protocol to understand how it enhances pastry quality and consistency. ↩

-

Learn about Vacuum Delay and its role in preventing structural collapse in delicate cakes. ↩

-

Discover how Variable Frequency Drives optimize cooling processes for better pastry outcomes. ↩

-

Learn about butter migration and its impact on pastry quality, ensuring your baked goods maintain their ideal texture. ↩

-

Explore this link to understand how vacuum cooling revolutionizes pastry making by preserving texture and flavor. ↩

-

Discover the significance of cooling time in baking and how it influences the final product’s texture and taste. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy