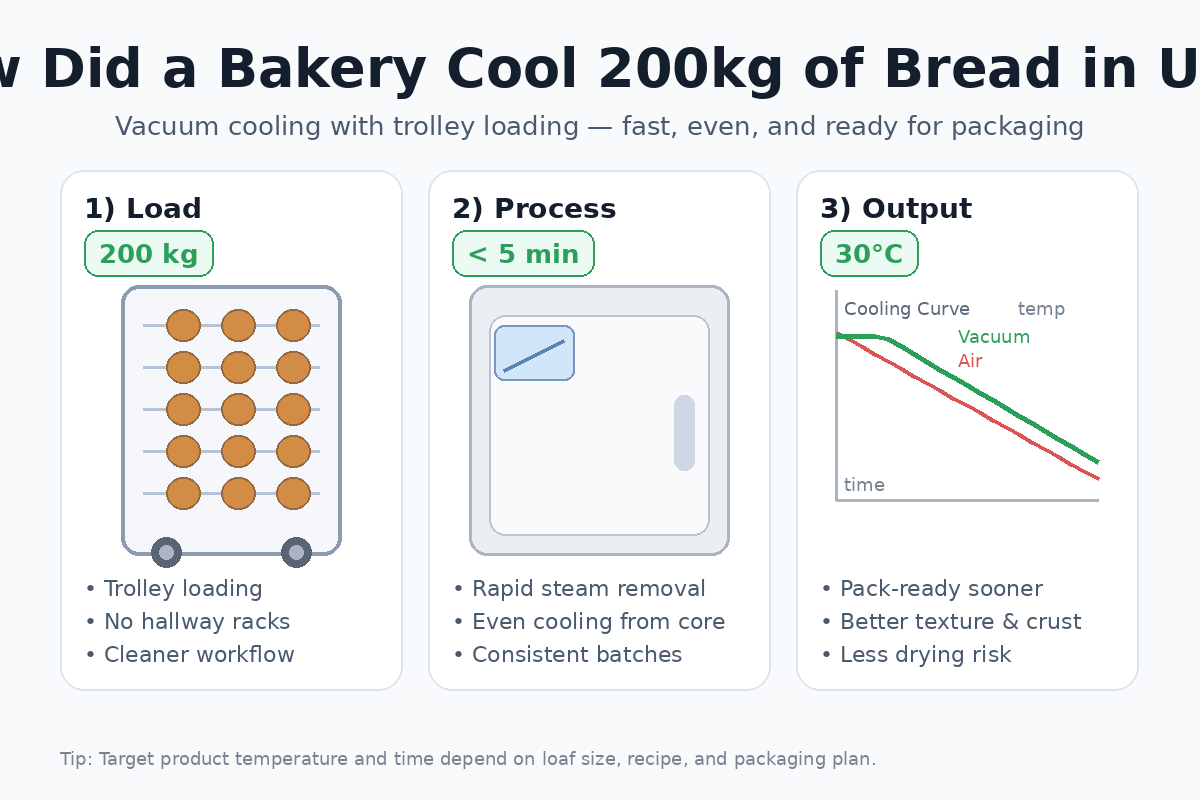

Case Study: How Did a Bakery Cool 200kg of Bread in Under 5 Minutes?

You finish baking perfect loaves, only to watch them lose moisture and crust crispiness during hours of slow ambient cooling. You are losing shelf life and money every minute your racks sit idle in the hallway.

Our recent implementation demonstrated that vacuum cooling can drop baked bread temperatures from 92°C to 30°C in less than 5 minutes. This creates a "bake-off" quality structure while significantly extending shelf life compared to traditional methods.

Many bakery owners I talk to, like Carlos from Mexico, worry that speeding up the process will ruin the product. They fear that rapid cooling might suck the moisture out of the crumb. However, the data from our recent installations proves the opposite. By controlling the pressure, we lock in the structure. Let’s look at a specific case study from our recent project in Hungary to see how we transformed their production line using high-spec engineering.

Can You Really Cool a Full Trolley Without Compromising Quality?

Scaling up production usually means sacrificing control. You worry that cooling a massive 200kg trolley at once will lead to uneven centers or soggy crusts.

In our Hungary project, the system successfully cooled a 200kg trolley of baked bread from a core temperature of 92°C down to 30°C in under 5 minutes. The result was uniform consistency from the crust to the center of every loaf.

The Science of "Flash" Stabilization

Speed is vanity, but consistency is sanity. In this specific case, the client needed to handle high volumes—specifically 200kg per trolley with dimensions of 760x610x1800mm. The challenge wasn’t just cooling it; it was cooling it fast enough to prevent starch retrogradation (staling) but gentle enough to keep the crust crispy. If you cool bread too slowly in a humid room, the crust absorbs moisture from the air and becomes chewy. If you cool it too fast without control, you might explode the structure.

The data from this implementation is clear. We achieved a cooling cycle within 5 minutes1, dropping the product from a scorching 92°C down to 30°C. This isn’t just about speed; it’s about stabilizing the product instantly. To ensure this happens every time, we implemented a specific feature called the "Vacuum delay facility2." This is crucial for products with high water content or resistance. It allows the temperature to equalize throughout the trolley before the final deep vacuum pulls the heat out. This means no matter how dense your bread is, or where it sits on the trolley, the center cools at the exact same rate as the corners. You get a product that is ready for slicing and packaging immediately, reducing the bacterial growth window to almost zero.

| Parameter | Specification (Hungary Case) | Benefit |

|---|---|---|

| Load Capacity | 200kg / Trolley | High volume throughput for industrial bakeries. |

| Start Temp | 92°C | Handle product straight from the oven. |

| End Temp | 30°C | Ready for slicing and packaging immediately. |

| Cooling Time | < 5 Minutes | Increases daily production cycles by 10x. |

Will the Machine Survive Your Bakery’s Harsh Environment?

Bakeries are hot, humid, and demanding environments. You can’t afford a machine that overheats when the room temperature rises, causing downtime during your busiest season.

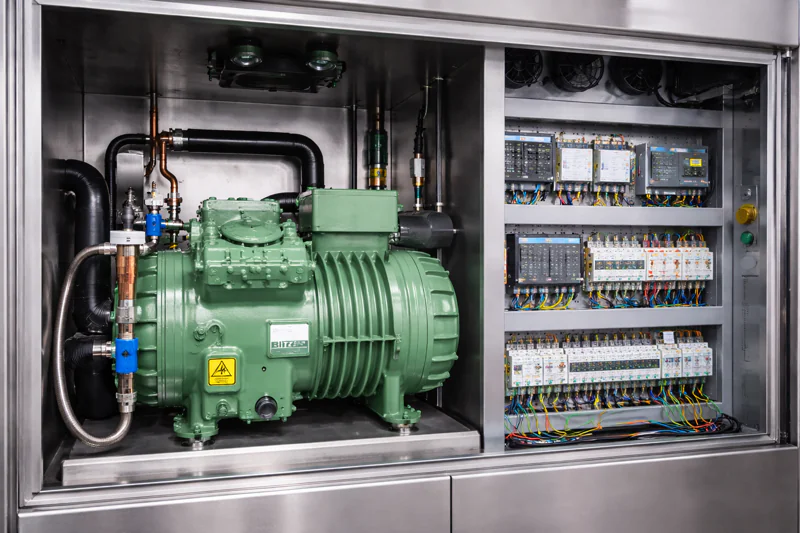

We engineer our coolers to thrive in extreme heat, designed to operate in ambient temperatures up to 52°C. We rely on top-tier components like Bitzer compressors and Siemens screens to ensure 24/7 reliability.

A "Who’s Who" of European Engineering

A case study isn’t just about the first week of operation; it’s about the first five years. Cheap machines use generic parts that fail under stress. For our clients, we refuse to compromise. In our standard build list, we utilize Bitzer compressors from Germany3 and Leybold vacuum pumps, ensuring the heart of the machine is bulletproof. But we go further than just the main engine.

We pay attention to the smallest details because that is where failures often start. For example, we use Danfoss expansion valves and solenoid valves from Denmark, and Frascold oil separators from Italy. Even the phase protection relays are sourced from Carlo Gavazzi in Switzerland. Why do we mix so many premium European brands? Because in hot climates, standard machines trip their safety switches. Our systems are designed with high-efficiency condensers capable of working in a maximum ambient temperature of +52°C4. Control is equally important. We use Siemens touch screens and Schneider electrics, so your operators have a responsive, industrial-grade interface. Plus, to save you money during downtimes, we have programmed an automatic shutdown feature that cuts power consumption when the machine is idle.

| Component | Brand / Spec | Origin | Reliability Factor |

|---|---|---|---|

| Compressor | Bitzer | Germany | Industry standard for heavy-duty cooling. |

| Valves | Danfoss | Denmark | Precise flow control preventing leaks. |

| Separators | Frascold | Italy | Ensures oil stays where it belongs. |

| Phase Relay | Carlo Gavazzi | Switzerland | Protects against voltage spikes/drops. |

| Max Ambient | +52°C | N/A | Won’t overheat during summer peaks. |

How Do You prevent "Milky Oil" from destroying your pump?

Vacuum cooling bread releases massive amounts of steam. You fear this moisture will mix with the pump oil, turning it into a useless sludge that kills your expensive equipment.

Moisture is the enemy of vacuum pumps. Our protocol requires a "water scraping" run—keeping the pump running for 40 minutes after work to evaporate residual moisture and prevent oil emulsification.

The Discipline of Daily Maintenance

The most common failure I see in case studies of failed implementations isn’t the machine’s fault; it is neglected maintenance. Bread releases liters of water as steam during the cooling process. If that steam condenses inside your vacuum pump and stays there, the oil becomes emulsified. It turns into a white, milky sludge that loses its ability to seal and lubricate. Once this happens, your vacuum pressure drops, cooling times extend, and eventually, the pump seizes.

To prevent this, we mandate a strict, yet simple routine. After the production shift is finished, the operator must keep the vacuum pumps running for 40 minutes under zero loading condition5. This generates enough heat to evaporate the water out of the oil, leaving it clean for the next day. Furthermore, we advise checking the oil level through the fluid-view spot every time the compressor stops to ensure it reaches the sign line. We also recommend an overall hygiene maintenance every two seasons6 to clear out dust from the condenser fins and check for any loose connections. This discipline transforms a machine from a consumable expense into a long-term asset that holds its value.

| Maintenance Step | Frequency | Purpose |

|---|---|---|

| Water Scraping | Daily (40 mins) | Removes water from oil to prevent sludge. |

| Oil Check | Each Stop | Ensure oil isn’t "milky" (emulsified). |

| Comp. Oil Change | Every 2 Years | Maintain compressor lubrication quality. |

| Hygiene Check | Every 2 Seasons | Prevent dust and contamination buildup. |

Conclusion

A successful implementation relies on three pillars: speed, components, and discipline. As shown in our Hungary case, we can achieve 92°C to 30°C cooling in under 5 minutes, supported by robust Bitzer, Siemens, and Danfoss components. Backed by a 12-month guarantee and clear maintenance protocols, Allcold ensures your investment delivers fresh results for years to come.

-

Explore how a rapid cooling cycle can enhance food quality and safety, ensuring freshness and reducing spoilage. ↩

-

Learn about the innovative vacuum delay facility and its role in achieving uniform cooling, crucial for maintaining product integrity. ↩

-

Explore this link to understand why Bitzer compressors are a top choice for reliability and efficiency in heavy-duty cooling systems. ↩

-

Learn about the challenges and solutions for machinery operating in extreme heat, ensuring optimal performance and longevity. ↩

-

Understanding this practice can significantly enhance your equipment’s longevity and efficiency. ↩

-

This resource will explain how regular maintenance can prevent costly breakdowns and extend equipment life. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy