How Can Vacuum Cooling Revolutionize Meat and Poultry Processing?

You’ve cooked a thousand kilograms of chicken perfectly, but now it sits for hours, slowly passing through the temperature danger zone. This bottleneck not only kills your efficiency but also creates a serious food safety risk.

Vacuum cooling revolutionizes meat processing by cooling large batches of cooked products from 90°C to below 5°C in minutes, not hours. This rapid process drastically inhibits bacterial growth, ensures food safety, improves yield by retaining moisture, and streamlines production.

I’ve walked through dozens of food processing plants. The cooking operations are often state-of-the-art, but the cooling process that follows is frequently a major liability. It’s slow, uncontrolled, and risky. This is the hidden flaw that holds back so many otherwise modern facilities. Let’s break down how we can solve this problem and what it means for your business.

How Does Vacuum Cooling Drastically Improve Food Safety?

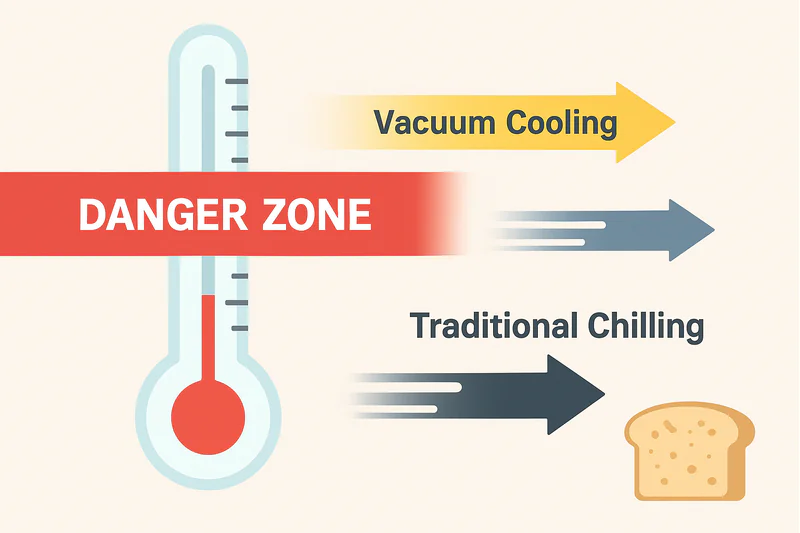

Every minute your cooked meat spends between 60°C and 5°C is a gamble. Harmful bacteria can multiply rapidly in this "danger zone," creating a huge risk for your products and your brand’s reputation.

Vacuum cooling dramatically improves food safety by moving products through the temperature danger zone in 20-30 minutes. This is too fast for bacteria to multiply, effectively acting as a critical control point to ensure a safer final product.

Winning the Race Against Bacteria

For any meat processor, food safety is the number one priority. A single recall can be catastrophic. The biggest enemy after cooking is the "temperature danger zone1," typically defined as 5°C to 60°C (41°F to 140°F). In this range, pathogens like Listeria, Salmonella, and E. coli can double their population in as little as 20 minutes. A traditional blast chiller, while effective, can take 4 to 8 hours to cool the core of a large batch of cooked meat. During all these hours, the product is lingering in the perfect breeding ground for these dangerous microbes.

This is a major concern for any procurement manager like Sophia, who must ensure her facility meets strict HACCP standards2. Vacuum cooling addresses this risk head-on. By using the principle of evaporative cooling under a deep vacuum, the technology extracts heat from the entire mass of the product simultaneously. The product’s temperature plummets through the danger zone in under 30 minutes. This speed is not just about efficiency; it’s a powerful food safety tool. By minimizing the time available for bacterial proliferation, you are drastically reducing the risk of a foodborne illness outbreak. It transforms cooling from a point of high risk into a validated, repeatable, and highly effective Critical Control Point (CCP) in your HACCP plan.

| Cooling Method | Time in Danger Zone (60°C to 5°C) | Bacterial Growth Risk |

|---|---|---|

| Traditional Blast Chiller | 4 – 8 hours | High |

| Airing Out / Room Cooling | 8+ hours | Extremely High |

| ALLCOLD Vacuum Cooling | < 30 minutes | Very Low / Negligible |

Why is Vacuum Cooling So Much Faster Than Traditional Chilling?

Your cook kettles and ovens can produce tons of cooked meat per hour, but your blast chillers can’t keep up. This creates a severe bottleneck, forcing your entire operation to slow down and wait.

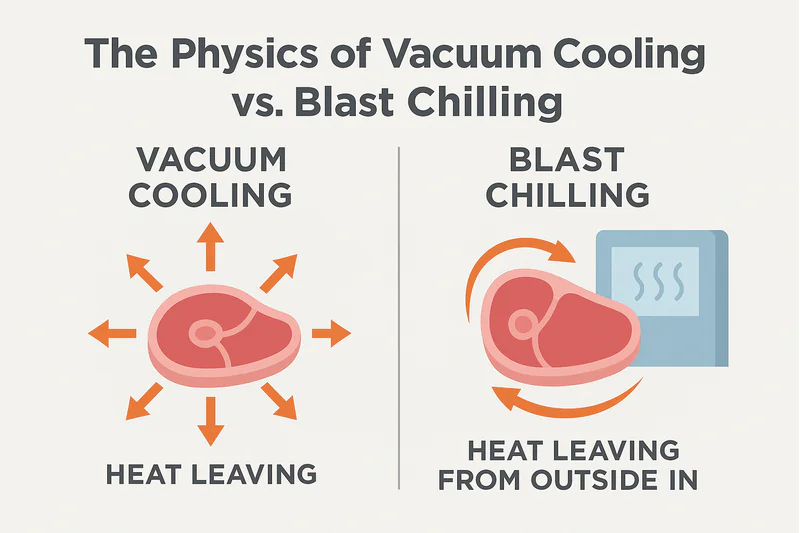

Vacuum cooling is faster because it removes heat from the entire product mass at once using physics, not just cooling the surface. By lowering pressure, we make water boil at a low temperature, causing rapid evaporative cooling from the inside out.

The Power of Uniform Cooling

A hands-on owner like Carlos values speed and efficiency. He knows that downtime and bottlenecks are lost profit. The problem with traditional methods like blast chillers or ice water baths is that they rely on conduction and convection. They apply cold to the outside of the product and wait for that cold to slowly penetrate to the core. This is an incredibly slow process for large masses of meat, like a 500 kg trolley of cooked turkey breast or a dense meat slurry. The outside freezes while the inside stays dangerously warm for hours.

Vacuum cooling3 works on a completely different principle. When we place the hot, cooked meat into our stainless steel chamber and pull a vacuum, we are lowering the atmospheric pressure. This reduces the boiling point of water. At a deep vacuum, water boils at just 5°C (41°F). The moisture within the meat itself, and on its surface, begins to flash evaporate, or "boil" without high heat. This phase change from liquid to gas requires a tremendous amount of energy, and it draws this energy in the form of heat directly from the meat. Because this happens everywhere at once—on the surface and deep within the core—the entire batch cools down with incredible speed and uniformity. There are no hot spots. The center of the batch cools almost as quickly as the outside, solving the biggest challenge of large-scale meat cooling.

| Feature | Blast Chiller | ALLCOLD Vacuum Cooler |

|---|---|---|

| Cooling Principle | Conduction (surface-in) | Evaporation (uniform) |

| Cooling Time (500kg batch)4 | 4-8 hours | 20-30 minutes |

| Bottleneck Potential | High | Low (Matches cooker speed) |

| Temperature Uniformity | Poor (hot core) | Excellent (no hot spots) |

Can Rapid Cooling Actually Improve Meat Product Quality and Yield?

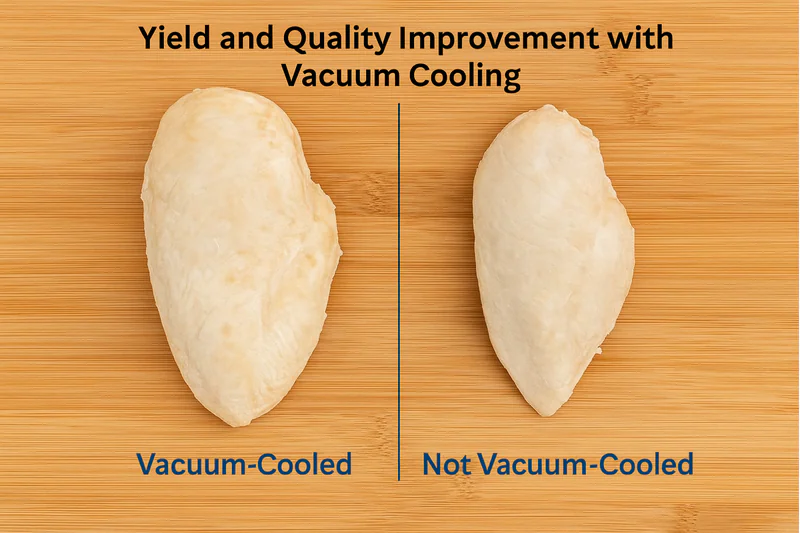

It seems counterintuitive. You might think that such a fast process, one that involves water boiling off, would dry out the meat, reduce its weight, and hurt the final product quality.

Yes, vacuum cooling significantly improves both quality and yield. By cooling rapidly, it locks in moisture that would otherwise be lost during slow chilling, resulting in a juicier product and a weight yield increase of 3-5%.

Locking In Profit and Flavor

For a professional buyer like Norman, final product quality5 and yield are everything. "Yield" is the final sellable weight of the product compared to its initial cooked weight. Every percentage point of yield lost is direct profit down the drain. When cooked meat cools slowly in a blast chiller for hours, it continuously "weeps" or purges moisture. This can result in a weight loss of 3% to 8%, depending on the product. The meat becomes drier and less tender.

Vacuum cooling6 flips this on its head. While it’s true that the process works by evaporating a small amount of water (about 1-2% of the product’s weight), the speed of the process prevents the much larger moisture loss associated with slow chilling. The rapid drop in temperature effectively "locks" the remaining moisture inside the muscle fibers. The result? A net gain in final yield of up to 5% compared to conventional methods. For a plant processing thousands of kilograms a day, this translates into a massive increase in revenue and a very rapid return on investment. Furthermore, this retained moisture leads to a demonstrably better product: it is juicier, more tender, and has a better mouthfeel. It also allows for easier slicing with less product breakage.

| Metric | Slow Blast Chilling | Rapid Vacuum Cooling |

|---|---|---|

| Typical Moisture Loss | 3% – 8% | 1% – 2% (from evaporation) |

| Net Yield Impact | Significant Loss | Net Gain of 3-5% |

| Final Product Texture | Drier, tougher | Juicier, more tender |

| Slicing Performance | More prone to breaking | Cleaner, more stable slices |

How Does a Vacuum Cooler Fit into a Modern Meat Processing Line?

You operate a complex, continuous line with cookers, tumblers, slicers, and packaging machines. You can’t afford to install a white elephant that disrupts your workflow and creates new problems.

A vacuum cooler integrates perfectly into a meat processing line, typically placed immediately after the oven or cook kettle. It functions as a high-speed bridge, connecting your cooking and post-cooling processes like slicing or packaging without delay.

- Cooking: Your meat is cooked in an oven, smoker, or steam kettle.

- Loading: The hot product is loaded into standard stainless steel trolleys or bins.

- Vacuum Cooling: The trolleys are rolled directly into the ALLCOLD vacuum chamber. The operator selects the pre-programmed recipe on the Siemens touch screen8 and presses start.

- Unloading: After a 20-30 minute automated cycle, the product is fully cooled to the core.

- Further Processing: The trolleys are rolled out and sent immediately to the next stage—be it marinating, tumbling, slicing, or packaging.

There is no waiting. There is no buffer zone. It becomes a reliable, repeatable step that synchronizes the speed of your cooking with the speed of your packaging. We customize the size of the chamber to match your batch output, whether you use one, two, or even six trolleys per batch from your cooker. The system arrives pre-tested and "plug-in ready," ensuring it fits seamlessly into the operational logic and physical space of your plant, making it a powerful upgrade for any forward-thinking manager like Carlos or Sophia.

Conclusion

For meat and poultry processors, vacuum cooling is a game-changing technology. It delivers unparalleled speed, critical food safety control, and significant yield improvement, revolutionizing your production from the cooker to the final package.

-

Understanding the temperature danger zone is crucial for food safety, helping to prevent bacterial growth and foodborne illnesses. ↩

-

Exploring HACCP standards will provide insights into effective food safety management and compliance for meat processors. ↩

-

Explore the advantages of vacuum cooling, which offers rapid and uniform cooling, crucial for maintaining food safety and quality. ↩

-

Understanding cooling time is vital for food safety; this resource will help you grasp its importance in preventing bacterial growth. ↩

-

Understanding final product quality is crucial for maximizing profits and ensuring customer satisfaction in the food industry. ↩

-

Exploring vacuum cooling can reveal innovative techniques that enhance meat quality and profitability, making it a game-changer in food processing. ↩

-

Explore this link to understand the benefits and workings of vacuum cooling systems, enhancing your operational efficiency. ↩

-

Discover how Siemens touch screens can streamline operations and improve user experience in industrial settings. ↩

Mila

You May Also Like

Is Your Cooling Process Holding Back Your Ready-Meal Business?

Your kitchen produces delicious, complex ready-meals, but the slow cooling process introduces food safety risks and production delays. This critical

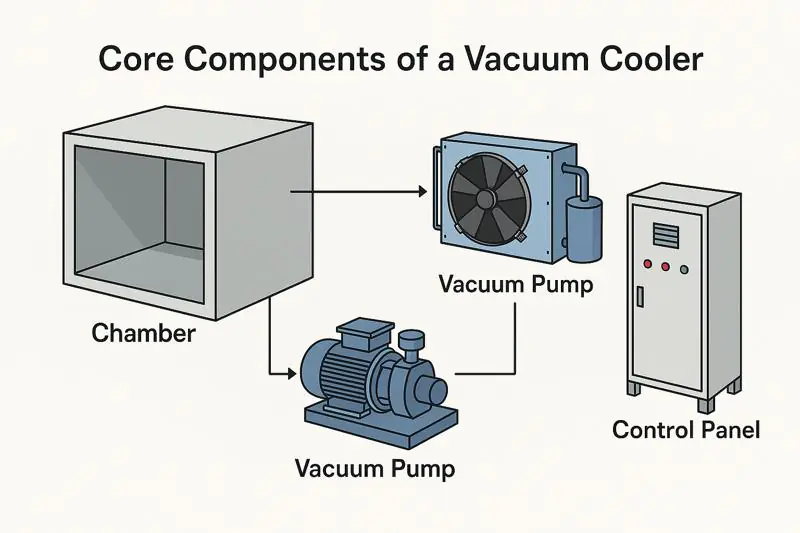

What's Really Inside Your Vacuum Cooler that Makes it Work?

Ever wondered what makes a vacuum cooler tick, transforming warm produce into perfectly chilled goods in minutes? It’s not magic,

What Are the Preservation Techniques for Ready-to-Eat Foods?

As consumers increasingly prefer ready-to-eat (RTE) foods, extending their shelf life effectively becomes a critical challenge. Currently, the most effective