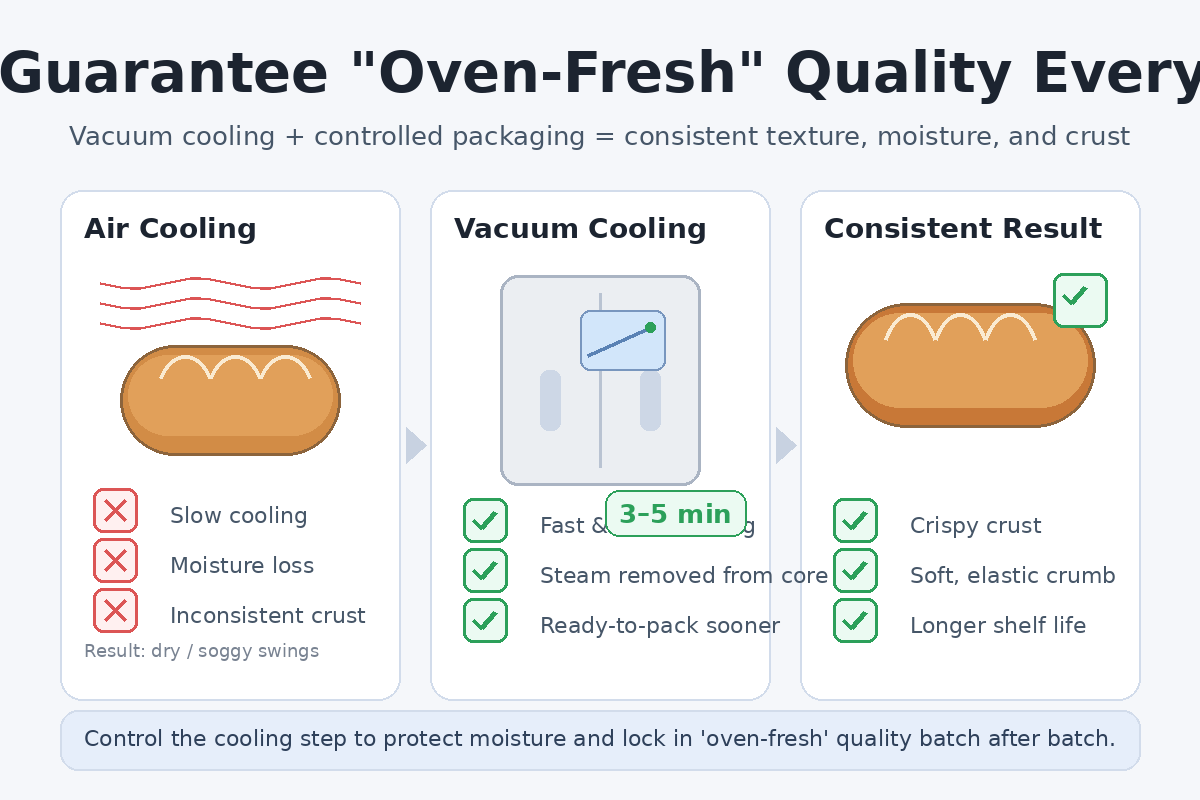

How Can You Guarantee "Oven-Fresh" Quality Every Single Time?

You perfect every dough mix, yet unpredictable ambient cooling ruins your crust consistency. Stop letting humidity and temperature shifts dictate your final product’s quality. You need a solution that standardizes this critical final step.

Vacuum cooling standardizes your process, replacing unpredictable ambient air with precise temperature control. Our systems ensure consistent results through robust components and a comprehensive 12-month warranty, guaranteeing your product cools exactly as planned every cycle.

We often treat cooling as a passive activity—something that just "happens" after the hard work of baking is done. But at Allcold, I believe cooling is an active ingredient in your quality recipe. Whether you are producing delicate pastries or hearty loaves, the challenge is the same: consistency. If your cooling equipment fails or fluctuates, your quality score drops immediately. By switching to vacuum cooling, you are not just speeding up production; you are installing a "quality firewall." Let’s dive into how this technology gives you total command over your product’s final outcome.

Is Your Equipment Reliable Enough to Trust with Your Best Product?

A breakdown during peak hours creates a backlog that ruins dough texture. You worry that complex vacuum machinery is too fragile for your daily demands, putting your reputation at risk.

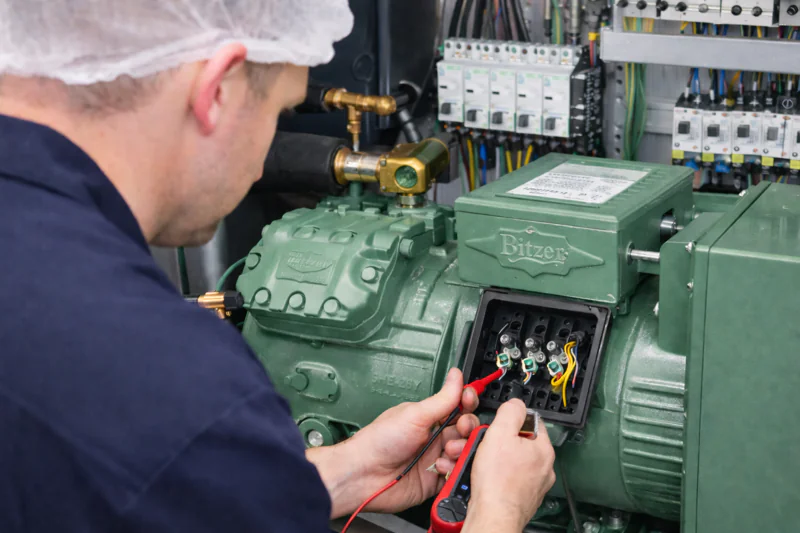

We eliminate mechanical risks by using top-tier components like Bitzer compressors and Siemens screens. Every system is delivered plug-in ready, backed by a solid 12-month warranty from the Bill of Lading date.

The Engineering Behind Consistency

Quality control relies entirely on consistency, and you cannot have consistency if your machine is a variable. When we build our machines, we don’t just assemble parts; we engineer reliability using brands you already trust. I have seen too many buyers struggle with generic machines that fail after six months because the core components cannot handle the stress of daily vacuum cycles. That is why we integrate a Siemens PLC1 for the control system and Bitzer compressors2—the gold standard in refrigeration. These aren’t just parts; they are your assurance of stability.

To further secure your investment, we explicitly state that all Allcold systems enjoy a 12-month guarantee ever since installation date. This warranty is your safety net, ensuring the risk is on us, not you. Furthermore, we deliver machines "plug-in ready and well piped." This minimizes the chaos of installation variables. You don’t need to hire external engineers to figure out complex piping; you just need to connect power and start cooling. Before any machine leaves our factory, it undergoes a rigorous 72-hour trouble-free trial operation to catch any potential issues before they reach your floor.

| Component / Feature | Specification/Brand | Impact on Quality Control |

|---|---|---|

| Warranty | 12 Months (from installation) | Guarantees long-term financial and operational security. |

| Compressor | Bitzer | Ensures reliable power for consistent cooling cycles. |

| PLC System | Siemens (Germany) | Provides precise control over vacuum parameters. |

| Installation | Plug-in Ready | Reduces setup errors that could lead to vacuum leaks. |

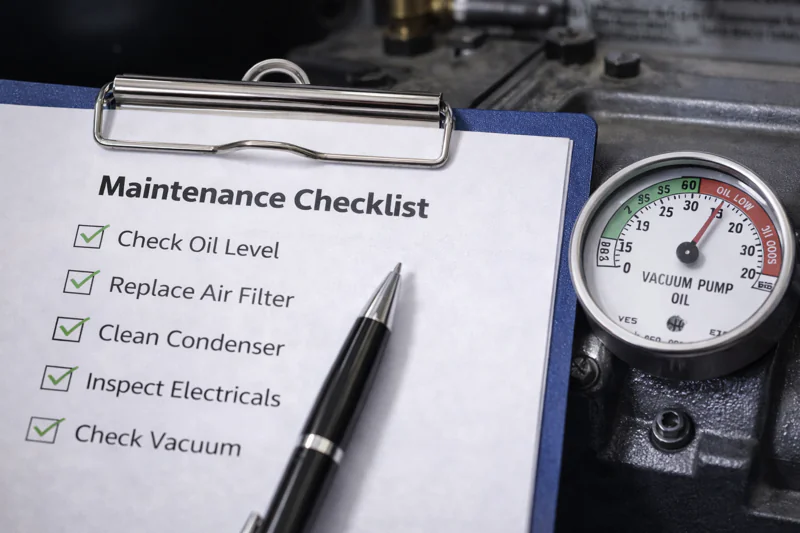

Does Your Maintenance Routine Impact Your Food Safety?

Neglected machinery doesn’t just stop working; it becomes a hygiene hazard. You fear contaminated oil or rust will compromise your strict HACCP food safety standards, leading to costly recalls.

Our maintenance protocols are designed for hygiene and efficiency. We mandate specific oil level checks before every use and automatic water-scraping cycles to prevent oil emulsification, ensuring your vacuum pump remains clean and powerful.

Hygiene as a Performance Metric

In the food industry, a dirty machine is a broken machine. I always tell my clients: "Treat your vacuum pump3 like your car engine." The manual provides a very specific maintenance checklist that is crucial for maintaining quality. One of the biggest threats to vacuum cooling quality is moisture. Bread releases massive amounts of steam. If that steam condenses in your vacuum pump oil, the oil emulsifies (turns milky) and loses its ability to seal.

To combat this, we have engineered a "water scraping" function. In automatic mode, the vacuum pumps keep running for 20 minutes after the cycle to scrape water from the oil. If operating manually, we suggest running them for roughly 30 to 40 minutes under zero load after work is finished. If you skip this, moisture destroys the pump internals. A damaged pump pulls a weaker vacuum, which extends the cooling time and ruins your bread’s texture. We also require a daily check of the oil amount for both the vacuum pump and the compressor. The oil level must be strictly maintained between 1/3 and 2/3 of the observation window to prevent overheating and ensure sanitary operation.

| Maintenance Task | Frequency | Consequence of Neglect |

|---|---|---|

| Check Oil Amount | Each Use | Overheating or seizure of the pump, stopping production. |

| Water Scraping Run | 20 Minutes (Auto) | Prevents oil emulsification4 (milky oil). |

| Manual Dry Run | 30-40 Minutes (Post-work) | Removes residual moisture to protect pump seals. |

| Oil Inspection | Monthly | Detects contamination early to prevent vacuum loss. |

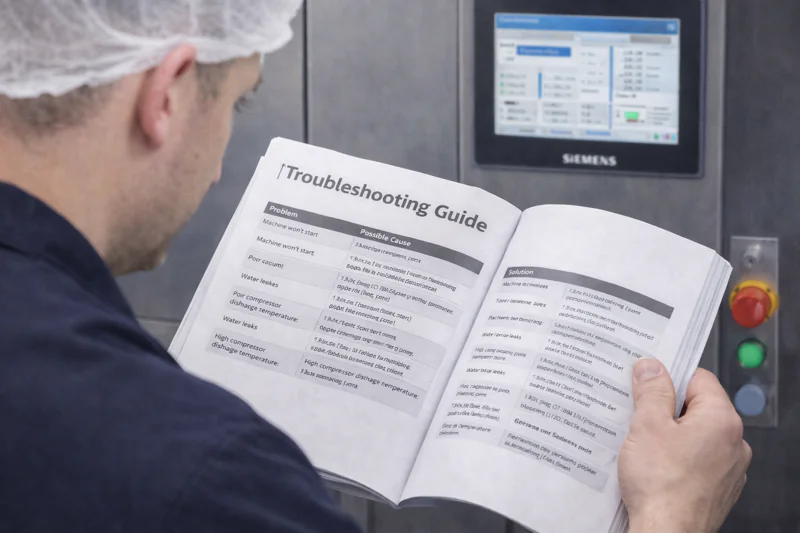

How Quickly Can You Solve Production Issues?

When a machine stops, panic sets in as your product spoils. You dread waiting days for a technician while your production line stands completely still, losing money every minute.

We empower your team to fix issues instantly with a detailed troubleshooting guide. Common problems like "No temperature reduction" or "Compressor not start" have clear, immediate elimination methods listed directly in your manual.

Empowering Your Team to Fix It

The reality of manufacturing is that things go wrong. Sensors drift, power fluctuates, and seals wear out. The difference between a minor hiccup and a major disaster is how fast you can fix it. We don’t want you to be dependent on us for every little thing. That is why we provide a "Self-Healing5" capability through our documentation.

Let’s look at a common panic scenario: You load the bread, start the cycle, but there is "No reduction of goods temperature." Instead of calling a hotline and waiting on hold, your operator can look at the manual. It asks: "Is the chamber door not closed well?" It seems simple, but often a slight misalignment in the door gap prevents the vacuum seal. The manual instructs you to "adjust door gap6" immediately. Problem solved in 5 minutes. If the issue is complex, we promise to offer further troubleshooting solutions within 24 hours after receiving your written description and pictures. We also use clear "DANGER" and "WARNING" symbols in our guides to ensure your staff stays safe while performing these quick checks. We are your backup, but we give you the tools to be your own first responder.

| Symptom | Potential Cause | Immediate Action |

|---|---|---|

| No Temp Reduction | Door gap leak | Adjust door hinges/gap to ensure airtight seal. |

| No Temp Reduction | Temp controller broken | Fix or replace to restore feedback loop. |

| Compressor Fail | Low Pressure | Check refrigerant pressure gauges. |

| Compressor Fail | Power Cut | Verify main power supply to the cabinet. |

Conclusion

Quality control is about eliminating variables. By adopting Allcold vacuum cooling, you replace the unpredictability of ambient cooling with a system that is plug-in ready and engineered for reliability. You gain a partner in maintenance with clear checklists that protect your machine’s hygiene, and you secure your production line with a solid 12-month warranty. This is how you stop hoping for good quality and start guaranteeing it.

-

Explore how Siemens PLCs enhance control systems, ensuring reliability and precision in engineering. ↩

-

Learn why Bitzer compressors are trusted for their reliability and performance in refrigeration systems. ↩

-

Understanding vacuum pump maintenance is crucial for food quality and safety, ensuring optimal performance and longevity. ↩

-

Exploring oil emulsification will help you grasp its impact on machinery efficiency and product quality in food processing. ↩

-

Explore this link to understand how Self-Healing can empower your team to troubleshoot effectively and enhance operational efficiency. ↩

-

Learn the best practices for adjusting door gaps to prevent issues and ensure optimal performance in your manufacturing processes. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy