Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it is too hot to slice. You wait for hours, losing precious freshness, while your customers are waiting for that perfect sandwich. This bottleneck kills your efficiency and risks your food safety every single day.

A vacuum cooler is the ultimate solution for hotel and restaurant bakeries facing this problem. It is not a freezer, but a machine that cools hot food from 100°C to roughly 30°C in just minutes. This technology locks in moisture, extends shelf life, and ensures you can slice and serve immediately.

Many chefs and bakery owners think that traditional cooling racks are enough. However, in a high-volume hotel or a busy restaurant, time is money. I have talked to many clients like you who struggle with space and time. You might be wondering if this technology is too big or too complex for your kitchen. The truth is, choosing the right machine changes everything. Let’s look at how you can select the perfect model for your specific needs.

How Much Space Do You Really Have in Your Kitchen?

Space is often the biggest headache for central kitchens in Singapore or busy hotels in New York. You cannot afford to waste square meters on bulky equipment that blocks your workflow.

Compact design is the most important factor for restaurants. You need a machine that fits through standard doors and integrates into your existing layout. We design "plug and play" models specifically for these tight spaces.

When I speak with clients like Sophia, a central kitchen manager, her first question is always about dimensions. In a hotel or restaurant environment, you rarely have the luxury of a massive industrial floor. You need a machine that is powerful but small. This is where the design of the integrated unit becomes critical.

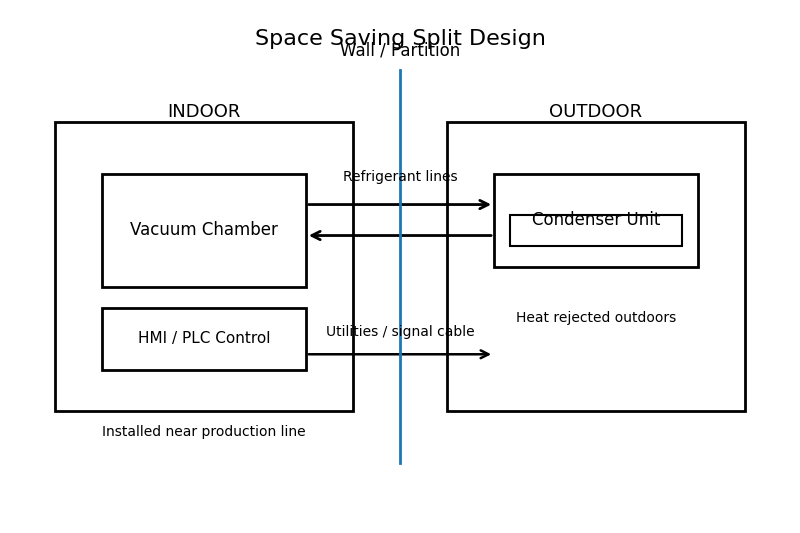

In the past, vacuum coolers were split systems. You had the chamber inside and the noisy condenser outside. While this is good for huge factories, it is a nightmare for a hotel basement kitchen. Today, we focus on skid-mounted designs. This means the vacuum chamber, the pump, and the refrigeration unit are all built into one single frame.

You must measure your elevators and door widths before you buy. I always tell my clients to send me their floor plan. A machine that cools 150kg of bread per cycle can still be compact. For example, our standard indoor unit is designed to be around 1600mm by 1450mm. This size is manageable for most commercial kitchens.

If you have a very small kitchen, you must prioritize a machine with a sliding door rather than a hinged door. Hinged doors require extra swing space. Sliding doors move vertically or horizontally within the machine’s frame, saving you that precious meter of space where your staff needs to walk.

Comparison of Unit Designs

| Feature | Integrated (Skid-Mounted)1 | Split System2 |

|---|---|---|

| Footprint | Small, all components in one box | Large, requires outdoor installation |

| Installation | Plug & Play (Easy) | Complex piping required |

| Noise Level | Higher (inside kitchen) | Lower (condenser is outside) |

| Suitability | Hotels, Restaurants, In-store Bakeries | Large Industrial Factories |

| Mobility | Can be moved with a forklift | Permanent fixture |

Can You Afford to Wait Hours for Bread to Cool Down?

Waiting for bread to cool naturally takes hours, and during that time, bacteria can grow. If you serve hundreds of customers at a breakfast buffet, you simply do not have this time.

Vacuum cooling slashes this time dramatically. Instead of waiting two hours, you can cool a trolley of baguettes or steamed rice in less than 10 to 20 minutes. This speed is the main reason my clients invest in this technology.

Let’s talk about the physics of time and temperature. In a traditional bakery, a loaf of bread comes out at 92°C. It sits on a rack. It takes at least 90 minutes to reach a slicing temperature of 30°C. During summer, or in a hot kitchen in Mexico, it might take even longer.

For a business owner like Carlos, who runs a large operation, this delay is a financial loss. You cannot package warm bread because condensation will ruin the crust. You cannot slice warm bread because it will tear and look terrible.

With a vacuum cooler, we change the boiling point of water. By lowering the pressure inside the chamber, the water inside the bread "boils" and evaporates at a much lower temperature. This process takes the heat away instantly.

Based on our testing with steamed rice and baked bread, here is what you can expect:

- Bread: From 100°C to 30°C in about 10 minutes.

- Rice/Cooked Food: From 90°C to 10°C in about 15-20 minutes.

This speed means you can bake later in the morning. Your staff does not have to arrive at 3 AM to ensure the bread is cool by breakfast. You can bake at 6 AM, cool at 6:30 AM, and serve fresh, crispy bread at 7 AM. This freshness is a huge selling point for your hotel guests.

Operational Time Savings

| Process Step | Traditional Cooling | Vacuum Cooling3 |

|---|---|---|

| Baking End Time | 05:00 AM | 06:30 AM |

| Cooling Start | 05:05 AM | 06:35 AM |

| Cooling Duration4 | 120 Minutes | 10 Minutes |

| Ready to Slice | 07:05 AM | 06:45 AM |

| Result | Bread is 2 hours old | Bread is 15 minutes old |

Does the Machine Meet Strict Hygiene and Safety Standards?

Food safety is not optional; it is the law. In hotels and chain restaurants, a single case of food poisoning can destroy your brand reputation forever.

Vacuum coolers are safer than traditional cooling. They rapidly pass through the "danger zone" (40°C–60°C) where bacteria multiply fastest. You need a machine built with high-quality stainless steel and hygienic components.

My client Sophia in Singapore manages a central kitchen for a fast-food chain. Her top priority is HACCP compliance. She deals with cooked food and rice, which are very sensitive to bacteria like Bacillus cereus.

When you choose a vacuum cooler, you must look at the internal construction. The chamber must be made of food-grade stainless steel (usually SUS304). It should not have sharp corners where food particles can hide. We design our machines with smooth surfaces that are easy to wash down.

Furthermore, the cooling process itself is a hygiene benefit. In traditional cooling, food sits in the "danger zone" temperatures for a long time. Bacteria love warm, moist environments. Vacuum cooling pulls the food temperature down so fast that bacteria do not have time to grow.

Another critical feature is the filter system. As the air is sucked out, flour dust or food particles can enter the pumps. You need a machine with a good filtration system to keep the mechanics clean and the chamber sanitary. We recommend a general hygiene maintenance check every two seasons, but daily cleaning of the chamber is essential.

Hygiene Checklist for Buyers

| Component | Requirement | Why it matters? |

|---|---|---|

| Chamber Material | Stainless Steel 3045 | Prevents rust and is easy to sanitize. |

| Corners | Rounded / Smooth | Avoids dirt accumulation. |

| Condenser | Stainless or coated | Prevents corrosion from food steam. |

| Pump Filter | Accessible | Protects the pump and ensures clean air flow. |

| Door Seal | Food grade silicone6 | Ensures a tight seal and prevents contamination. |

Will It Ruin the Texture of My Product?

Many bakers worry that vacuum cooling will dry out their bread or make the crust tough. They fear that sucking out the air will collapse the structure of their delicate pastries.

Actually, vacuum cooling improves texture. It creates a crispier crust and a more uniform crumb. The key is using a machine with a "vacuum delay" or "step-by-step" function to control the process gently.

This is the most common misconception I hear. People think vacuum cooling is violent. It can be, if you use a cheap machine with no controls. However, a professional vacuum cooler for bakeries has a specific feature called Vacuum Delay or Pulse Cooling.

Here is my insight: Different foods have different water contents. Steamed rice is very wet; a baguette is drier. If you pull the vacuum too fast on a delicate cake, it might expand too quickly and break.

Our machines use a Siemens touch screen to control the curve. You can set the machine to pause at certain pressure levels. This allows the internal structure of the bread to stabilize. The result is actually better than traditional cooling.

- Volume: The bread keeps its volume better because the structure sets instantly.

- Crust: The rapid evaporation of surface moisture creates a shatteringly crisp crust that stays crispy longer.

- Shelf Life: Because there is less free moisture left in the crumb to cause mold, the shelf life extends by days.

You are not just buying a cooler; you are buying a quality enhancer. For products like "Baked Bread," we typically aim for a finish temperature of 30°C. We ensure the program fits your specific dough recipe.

Texture Impact Analysis

| Aspect | Traditional Cooling | Vacuum Cooling7 |

|---|---|---|

| Crust | Often becomes soft due to humidity | Remains very crispy |

| Crumb Structure8 | Can collapse if moved while warm | Sets immediately, very stable |

| Moisture | Uneven distribution | Even distribution throughout |

| Volume | Shrinks as it cools slowly | Retains oven spring volume |

| Mold Risk | High (moisture lingers on surface) | Low (surface is dry) |

How Do I Ensure I Get Good After-Sales Support?

Buying a machine from overseas, especially from China, can be scary. You worry about what happens if a part breaks or if the software glitches during a busy dinner service.

You must choose a supplier who uses top global brands for components. If your compressor is a generic brand, you are in trouble. If it is Bitzer or Emerson, you can find parts locally in America or Europe.

I always tell buyers like Norman: "Look inside the box." The steel frame is made in our factory, but the heart of the machine—the pumps and compressors—should be famous brands.

At Allcold, we use Bitzer (Germany) or Emerson (USA) for compressors. We use Leybold or Busch (Germany) for vacuum pumps. We use Schneider (France) for electrical parts. Why do we do this? Because if a relay burns out in Mexico, Carlos can drive to a local supply store and buy a Schneider replacement in one hour. He does not have to wait two weeks for me to ship a part from China.

Also, look for remote troubleshooting. Modern machines have smart systems. If your machine stops, my engineering team can look at the data codes. We can often tell you exactly which sensor is loose or which setting is wrong without ever stepping foot in your kitchen.

We provide a 1-year warranty, but the goal is to build a machine that lasts 10 years. The best way to ensure this is by combining Chinese manufacturing efficiency with European component reliability. This gives you the competitive price Norman wants, with the reliability Sophia demands.

Key Components to Check

| Component System | Recommended Brands | Benefit |

|---|---|---|

| Compressor | Bitzer, Emerson, Frascold | Global warranty, easy to find parts. |

| Vacuum Pump | Busch, Leybold | High reliability, long service life. |

| PLC / Touch Screen | Siemens | User-friendly, stable software. |

| Electricals | Schneider | Safety, prevents fires or shorts. |

| Refrigeration Parts | Danfoss | Precise control of cooling flow. |

Conclusion

Choosing the right vacuum cooler for your hotel or restaurant is about balancing speed, space, and quality. You need a compact machine that fits your kitchen, cools your specific food safely, and uses reliable parts. Do not just look at the price tag; look at the components and the hygiene features. If you make the right choice, you will not just save time; you will serve better food.

-

Explore this link to understand the advantages of Integrated (Skid-Mounted) systems for efficient space utilization. ↩

-

Discover the benefits of Split System HVAC, especially for large industrial applications, by visiting this resource. ↩

-

Explore the advantages of Vacuum Cooling to understand how it significantly reduces cooling time and enhances product quality. ↩

-

Learn about the impact of Cooling Duration on food quality and safety to optimize your food processing methods. ↩

-

Explore the advantages of Stainless Steel 304 for hygiene and durability in food equipment. ↩

-

Learn why food grade silicone is essential for preventing contamination in food storage. ↩

-

Explore the advantages of Vacuum Cooling to enhance your baking techniques and achieve better texture. ↩

-

Understanding Crumb Structure is key to improving your bread quality; discover expert insights on this topic. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the