Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

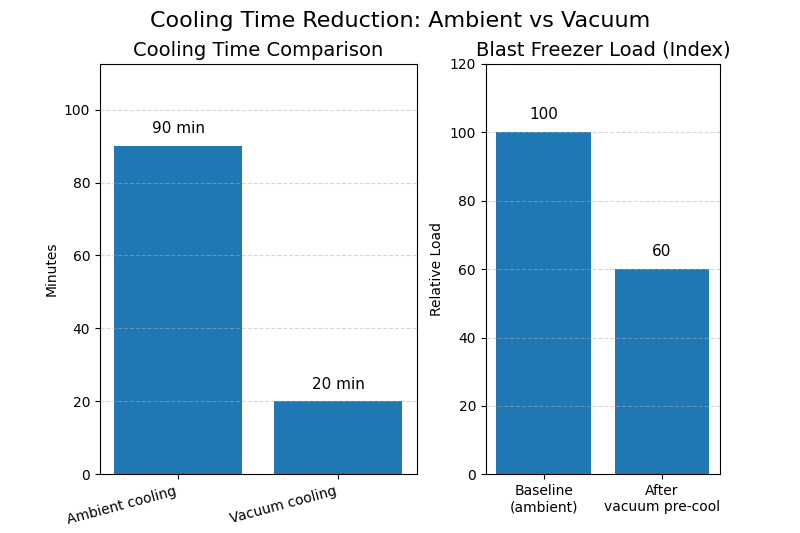

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form because your dough needs hours to cool down naturally before it is safe to freeze, and you know there must be a faster, cleaner way to manage your throughput.

Vacuum cooling is the ultimate pre-cooling solution for frozen dough lines. By rapidly dropping core temperatures from 100°C to your target in minutes, you reduce the thermal load on your freezers and lock in the dough structure instantly using our specialized "Vacuum delay facility."

I remember sitting down with Sophia, a Central Kitchen Manager who was struggling with a common dilemma. Her ovens were efficient, and her blast freezers were powerful, but the "middle step"—cooling—was a disaster. The dough sat on racks for hours, exposed to the air, forming a dry skin that ruined the final crust. She tried putting the dough into the freezer sooner, but the excess heat caused ice crystals to form, destroying the gluten structure. She needed a bridge between the heat of the oven and the cold of the freezer. That is when we introduced the concept of vacuum pre-cooling. If you are running a high-volume line, you likely face the same bottleneck. Let’s dive deeper into how this technology specifically optimizes frozen dough production.

Can You Slash Cooling Time to Boost Freezer Efficiency?

You are tired of seeing your production floor cluttered with cooling racks that take up valuable space. You know that time is money, and every minute your product sits in ambient air is a minute it is not being packaged and sold.

Our vacuum coolers shrink the cooling cycle from hours to mere minutes, utilizing the principle of rapid water evaporation at low pressure. This massive reduction in time allows you to move products directly from the oven to the freezer, creating a continuous flow that maximizes your factory’s output.

The Physics of Efficiency and Energy Savings

The "Danger Zone" and Thermal Load

In a traditional bakery setup, cooling is a passive process. You rely on the air in the room to slowly absorb heat from the bread or dough. This is inefficient for two reasons. First, it takes a long time. Second, it puts a massive strain on your blast freezers if you rush the process. If you load dough that is still 40°C or 50°C into a freezer, the freezer must work aggressively to remove that "sensible heat" before it can even begin the freezing process. This causes temperature fluctuations that can damage other products sharing the same space.

Vacuum cooling1 changes the physics entirely. The machine works by the rapid evaporation of water from the product under very low atmospheric pressures inside a vacuum chamber. Energy, in the form of heat, is required to change water from a liquid to a vapor state. By lowering the pressure, we force this boiling point down. The heat used for this evaporation comes directly from the product itself. This means the cooling happens from the inside out, not the outside in. This ensures that the core of your dough is just as cool as the crust, eliminating the "hot center" problem that plagues traditional freezing methods.

Smart Energy Management2

You might worry that adding a new machine will spike your electricity usage. However, we have designed our systems with intelligent energy management logic to counteract this.

Firstly, we use a staggered "Start sequence" for the components. When you begin a cycle, the machine does not turn on every motor at once. It creates a sequence: cooling pump first, then the vacuum pump, and so on. This prevents a massive surge in electrical current that could trip your breakers or increase your peak demand charges.

Secondly, we have integrated a "power save" logic into the PLC system. If your production line has a gap—say, you are waiting for the next trolley to come out of the oven—the machine detects this idle state. It will automatically shut down to save electricity usage. It is not wasting power humming in the background. As soon as your operator is ready and presses the start button, it wakes up instantly. This makes the vacuum cooler an "on-demand" tool rather than a constant energy drain, ultimately saving your blast freezer from doing the heavy lifting of cooling.

| Feature | Function | Benefit |

|---|---|---|

| Rapid Evaporation3 | Lowers boiling point of water. | Uniform core cooling in minutes. |

| Start Sequence | Staggers motor activation. | Prevents power surges/peak costs. |

| Power Save Mode4 | Auto-shutdown when idle. | Minimizes operational costs. |

Will Rapid Cooling Collapse Your Dough Structure?

You worry that the aggressive nature of a vacuum pump will "suck the life" out of your dough, causing it to collapse or dry out. You have likely heard horror stories of other cooling methods ruining the texture of artisan products.

We specifically addressed this risk with our "Vacuum delay facility." This feature allows the machine to detect products with high water yield resistance and automatically adjust the pressure drop speed, ensuring your dough structure remains intact and porous.

Protecting the Gluten Network

The Risk of "Flashing"

Dough is a delicate matrix of gluten and starch. It is not a solid block like a carrot or a piece of meat. It relies on air pockets for its structure. If you drop the pressure too fast, the moisture inside flashes into steam explosively. For some robust products, this is fine. But for high-quality dough intended for frozen distribution, this can tear the gluten network. If the steam escapes too violently, the dough can implode or shrink, leading to a collapsed, dense final product that your customers will reject.

Our Technical Solution: The Vacuum Delay

To solve this, our machines come equipped with a specific "Vacuum delay facility5." This is a critical feature for bakers. The system is smart enough to handle "product with higher water yield resistance." Instead of a linear, aggressive pull, the machine modulates the vacuum pump. It slows down the pressure drop at critical moments (flash points) to allow the moisture to release gently. This preserves the volume and the "sponge" texture of the dough. It essentially "sets" the structure of the dough before it freezes, ensuring that when it is baked later, it rises perfectly.

Precision Temperature Targets6

Furthermore, you are not limited to a single "cold" setting. You can control the "Temp SV (setting value)" precisely.

For frozen dough, you often don’t want to freeze it completely in the vacuum cooler; you just want to get it cold enough to enter the blast freezer safely. Our machines allow you to set a target, and the system supports a "Low limit -8°C." This capability allows you to achieve a "crust freeze" or a deep chill of around 0°C to 5°C, which is ideal for handing off to the blast freezer.

Throughout the cycle, your operator can monitor the vacuum level, product temperature, and time elapsed on the touch screen. If you see the temperature dropping too fast or too slow, you can adjust. This gives you scientific repeatability. Every batch comes out at the exact same temperature, ensuring your freezing times are consistent, which is key to standardizing your final product quality.

| Parameter | Standard Cooling | Vacuum Cooling (Smart) |

|---|---|---|

| Core Temperature | Uneven (Hot center). | Uniform throughout. |

| Moisture Loss | Uncontrolled (Dry skin). | Controlled evaporation7 (~2-3%). |

| Structure | Risk of collapse in freezer. | Set and stabilized before freezing. |

Is the Equipment Complicated to Operate and Maintain?

You want to modernize your factory, but you cannot afford to hire specialized engineers just to run a cooling machine. You need equipment that is robust enough for 24/7 operations but simple enough for your current floor staff to manage.

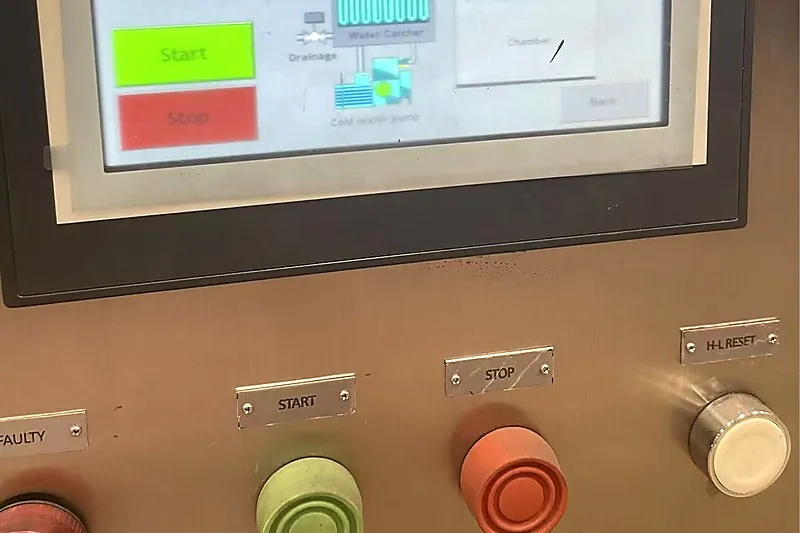

Our systems are designed for "Plug & play" simplicity. We use a user-friendly Siemens touch screen that allows operators to run a full cycle with a single button press, while the system automatically handles complex tasks like deflation and drainage.

Simplified Industrial Operation

User-Centric Controls

We know that in a busy bakery, complexity leads to errors. That is why we utilize high-quality Siemens touch screens8 as the interface. The operation is broken down into simple modes so that anyone on your floor can use it.

In "Auto screen" mode, the workflow is effortless:

- "Close the door first."

- Press "Start."

The machine takes over. It manages the cooling pump, the vacuum pump, and monitors the probe. Once the target temperature is reached, the machine doesn’t just stop; it performs a "Deflation" cycle to equalize pressure and handles "Drainage automatically." This automatic drainage is crucial because it removes the water condensed during the cooling process, keeping the chamber clean and reducing the risk of bacterial growth.

Built-in Diagnostics and Safety

We also empower your maintenance team without requiring them to be refrigeration experts. The system includes an "Alarm Screen9." If a fault occurs—say, a motor overload or a sensor issue—you can find detailed information there to help you solve the problem.

We also include "Input/Output (PLC Terminals)10" indicators. These lights show exactly which parts are active or inactive, which helps the factory with troubleshooting.

For example, if the compressor does not start, the guide suggests checking if there is a power cut or low pressure. If the vacuum degree is not low enough, it prompts you to check if the chamber door is closed well.

Safety is also built-in. We use Schneider components for the Emergency Stop and Safety Relay11. If there is ever an issue, the machine shuts down safely to protect both the operator and the equipment.

| Component | Brand/Type | Advantage |

|---|---|---|

| Touch Screen | Siemens. | Intuitive, multi-language support. |

| Compressor | Bitzer. | Industry standard for reliability. |

| Vacuum Pump | Leybold / Nash. | High performance, durable. |

| Electricals | Schneider. | Global availability for spares. |

How Difficult Is the Installation and Commissioning Process?

You dread the idea of a long, disruptive installation process that shuts down your production line for weeks. You need a solution that arrives ready to work so you can start seeing a return on your investment immediately.

We deliver our vacuum coolers as "Whole skid type" systems, meaning they are plug-in ready and well-piped. Installation is as simple as placing the machine on a flat concrete floor, connecting the power and water, and running the pre-tested system.

Seamless Integration into Your Factory

Pre-Tested Reliability

One of the biggest fears with industrial machinery is "Dead on Arrival." We eliminate this. Before any machine leaves our factory, it undergoes a rigorous testing process. We perform a "72 hours trouble-free trial operation." This ensures that every valve, every seal, and every line of code is working perfectly. When the machine arrives at your facility, it has already proven itself under load conditions.

Simple Site Requirements

We have simplified the installation requirements to the absolute basics so your local team can handle it.

- Prepare concrete floor: You just need a level surface capable of supporting the machine’s weight (e.g., 6000kg for the larger AVC-600 model).

- Place machine: Forklift or crane it into position.

- Connections: You connect the copper pipes for the refrigeration (if split) or water lines, and the air pipe connections for the pneumatic door.

- Power: Connect the Main power (Live, Earth, Null wires).

Support and Warranty

We stand behind this ease of installation with a solid warranty. All our systems enjoy a "12 MONTHS guarantee ever since installation date." If anything goes wrong, we provide "7*24 hours phone assistance." We also provide a detailed "Maintenance Checklist" to help you keep the machine running. This includes simple weekly tasks like checking the oil pump oil filling and looking for any loose connections. Because the system is a plug-in ready unit based on the "Whole Skid type," you don’t need to weld pipes or wire complex control panels on-site. You simply plug it in, and you are ready to cool.

| Step | Requirement | Responsibility |

|---|---|---|

| Site Prep | Level concrete floor. | Customer (Norman/You). |

| Placement | Forklift/Crane offloading. | Customer. |

| Trial Run | 72-hour pre-shipment test. | Allcold Factory. |

| After-Sales | 24/7 Phone Support & Spares. | Allcold Support Team. |

Conclusion

Vacuum cooling is the missing link in a modern frozen dough production line. By utilizing our "Vacuum delay facility" to protect your dough’s structure, cutting cooling times to minutes, and relying on a "plug-in ready" system that saves energy, you can solve your production bottlenecks immediately.

-

Explore how vacuum cooling revolutionizes food preservation by enhancing efficiency and reducing energy costs. ↩

-

Learn how smart energy management can optimize operations and reduce electricity costs in your business. ↩

-

Discover the science behind rapid evaporation and its impact on uniform cooling in food production. ↩

-

Find out how power save mode can significantly lower operational costs and improve energy efficiency. ↩

-

Explore this link to understand how vacuum delay technology enhances dough quality and prevents collapse during freezing. ↩

-

Learn about the importance of precision temperature in baking and how it ensures consistent product quality. ↩

-

Find out how controlled evaporation techniques improve food quality and texture, especially in baking. ↩

-

Explore how Siemens touch screens enhance user experience and operational efficiency in industrial settings. ↩

-

Learn about the importance of Alarm Screens in diagnosing issues quickly and effectively, ensuring smooth operations. ↩

-

Find out how PLC Terminals aid in real-time monitoring and troubleshooting, enhancing operational reliability. ↩

-

Discover how Emergency Stop and Safety Relay systems protect operators and equipment in case of emergencies. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the