What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels wrong. You’re worried you might be damaging your most sensitive crops or not cooling the densest ones properly.

The key is to tailor your cooling cycle—specifically the final pressure setpoint and duration—to the unique physical characteristics of each vegetable. This ensures rapid, thorough cooling without causing damage, maximizing shelf life and preserving quality.

I once worked with a farm in America that was new to vacuum cooling. Norman, the owner, was brilliant with his finances but was treating all his produce the same. He was using the same aggressive cycle for his delicate baby spinach as he was for his hardy iceberg lettuce. He couldn’t understand why the spinach was coming out with dark, wilted spots. I explained that the violent boiling of water under a very low vacuum was rupturing the cells of the delicate leaves. We programmed a custom, gentler cycle with a slightly higher final pressure, and the problem vanished overnight. His spinach quality was suddenly the best in his region. This guide is designed to give you that same level of control and precision.

Why can’t you use the same settings for all vegetables?

It seems easier to find one setting that works and stick with it. You’re busy, and programming a new cycle for each product type feels like a hassle. You wonder if the small differences really matter that much to the final product quality.

Every vegetable has a unique density, water content, and surface area. These factors dramatically change how easily the vegetable releases water vapor, which is the core of the cooling process. A single setting will inevitably over-cool some and under-cool others.

It’s All About the Physics of Water

The principle of vacuum cooling is simple: by lowering the atmospheric pressure inside the chamber, we lower the boiling point of water. The water on and inside your produce begins to boil at a very low temperature (around 2-3°C), and this boiling process absorbs heat, rapidly chilling the product from the inside out. However, the speed and efficiency of this process depend entirely on how easily that water can turn into vapor and escape.

This is where the physical structure of the vegetable becomes the most important factor.

Three Key Characteristics

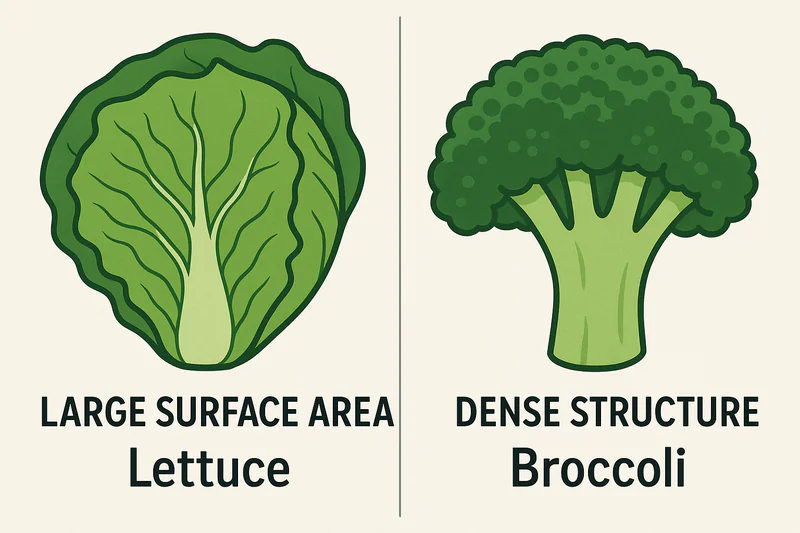

- Surface area-to-mass ratio1: A leafy vegetable like lettuce or spinach has a massive surface area compared to its weight. This allows water to evaporate quickly and easily from all surfaces, leading to extremely fast cooling. A dense product like a carrot or a potato has a very low surface area-to-mass ratio, making it a poor candidate for vacuum cooling because the water is trapped deep inside.

- Density and Structure2: A dense broccoli floret will resist the escape of water vapor much more than a loose-leaf lettuce. The vapor has to travel through a more complex and compact cell structure. This means dense products require a longer, more patient cooling cycle to allow the heat to be removed from the core.

- "Free" Water Content: The process relies on available water. Vegetables that have been freshly harvested and are well-hydrated cool much more efficiently. Some products, like sweet corn, benefit from being lightly sprayed with water before the cycle (a technique called hydro-cooling3) to ensure there is enough surface moisture to facilitate evaporation.

| Vegetable Type | Surface Area | Density | Typical Cooling Speed |

|---|---|---|---|

| Leafy Greens (Lettuce, Spinach) | Very High | Very Low | Very Fast (15-25 mins) |

| Flower Vegetables (Broccoli, Cauliflower) | Medium | Medium | Moderate (25-30 mins) |

| Fungi (Mushrooms) | High | Low but Delicate | Fast but Gentle (Approx. 20 mins) |

| Root Vegetables (Carrots, Potatoes) | Very Low | Very High | Not Suitable for Vacuum Cooling |

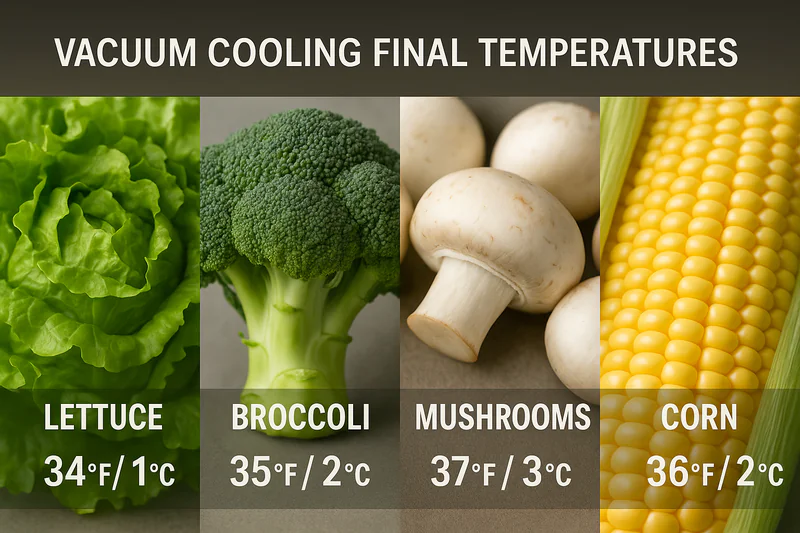

What are the best parameters for leafy greens?

Your main crop is lettuce, and speed is everything. You need to get it from the field to the cold chain as fast as possible to meet supermarket deadlines, but you can’t risk freezing the delicate outer leaves, which would make the whole pallet unsellable.

For most leafy greens like iceberg lettuce, romaine, and spinach, the target final temperature is 2-3°C. This is achieved with a final pressure setpoint of 6.1 to 7.0 mbar and a typical cycle time of 15 to 25 minutes.

The Ideal Candidates

Leafy greens are the star performers of vacuum cooling. Their high surface area and water content are perfectly suited to the technology, allowing for incredibly fast and uniform cooling that traditional methods can’t match. For a large-scale grower like Carlos in Mexico, this speed is a competitive advantage, allowing him to harvest and ship on the same day. The key is to control the process to avoid damage.

The final pressure setpoint4 is the most important parameter. Water’s boiling point is directly tied to pressure. By setting the final pressure on our Siemens touch screen, you are essentially setting the final temperature of the product. Setting it too low (e.g., 5.0 mbar) could cause the water to boil at a temperature below 0°C, leading to ice crystal formation and cell damage, which appears as dark or translucent spots on the leaves. Setting it too high (e.g., 8.0 mbar) will not cool the product sufficiently. The 6.1-7.0 mbar range is the sweet spot for achieving that crisp, fresh 2-3°C target. The cycle time5 can be adjusted based on the initial field heat of the lettuce. Lettuce harvested on a cool morning may only need 15 minutes, while lettuce harvested in the peak afternoon heat might need the full 25 minutes. Our modern machines can even use temperature probes6 to end the cycle automatically when the core of the product reaches the target, ensuring perfect results and maximum energy efficiency7 every time.

| Vegetable | Target End Temp | Final Pressure Setpoint | Average Cycle Time | Notes for Success |

|---|---|---|---|---|

| Iceberg Lettuce | 2°C | 6.5 mbar | 20-25 minutes | Very robust. Can handle a fast pressure drop. |

| Romaine Lettuce | 2-3°C | 6.5-7.0 mbar | 20-25 minutes | Similar to iceberg. Ensure good packing for airflow. |

| Baby Spinach | 3°C | 7.0 mbar | 15-20 minutes | Delicate. Use a slightly gentler cycle (slower pressure drop). |

| Kale | 3°C | 7.0 mbar | 25-30 minutes | Denser leaves require a slightly longer cycle to cool fully. |

How should you adjust parameters for broccoli and cauliflower?

You’ve tried cooling broccoli, but when you check it, the outside feels cool while the deep inner core remains warm. This temperature difference is a recipe for rapid spoilage, and you’re worried about quality claims from your customers.

For denser vegetables like broccoli and cauliflower, the key is a longer cycle time (25-35 minutes) combined with pre-wetting. Lightly spraying the product with clean water before cooling provides the necessary "free" moisture for effective evaporation.

Cooling from the Outside In

Unlike lettuce, where the cooling happens everywhere at once, dense products like broccoli present a challenge. The heat is trapped deep within the compact head and thick stems. While the small florets on the surface have a decent amount of surface area, the core has very little. The vacuum can’t magically pull heat out; it needs to evaporate water to carry the heat away. If the inner parts of the broccoli are dry, they simply won’t cool.

This is where the hydro-vac technique8 becomes essential. By adding a small amount of water (typically 1-2% of the product weight) via a spray system, you ensure a thin film of moisture covers the entire product. When the vacuum is pulled, this surface water evaporates first, providing a powerful initial cooling effect. This pre-chills the outer layers, creating a temperature gradient9 that helps draw the heat out from the core. The cycle needs to be longer to give this process time to work. We program a "dwell" time at the target pressure, holding the vacuum for several minutes to allow the heat to migrate from the core and be removed. It’s a more patient approach, but it results in a uniformly cooled product from stem to floret. For buyers like Norman, who are extremely sensitive to quality control, proving that you have this process mastered is a huge selling point.

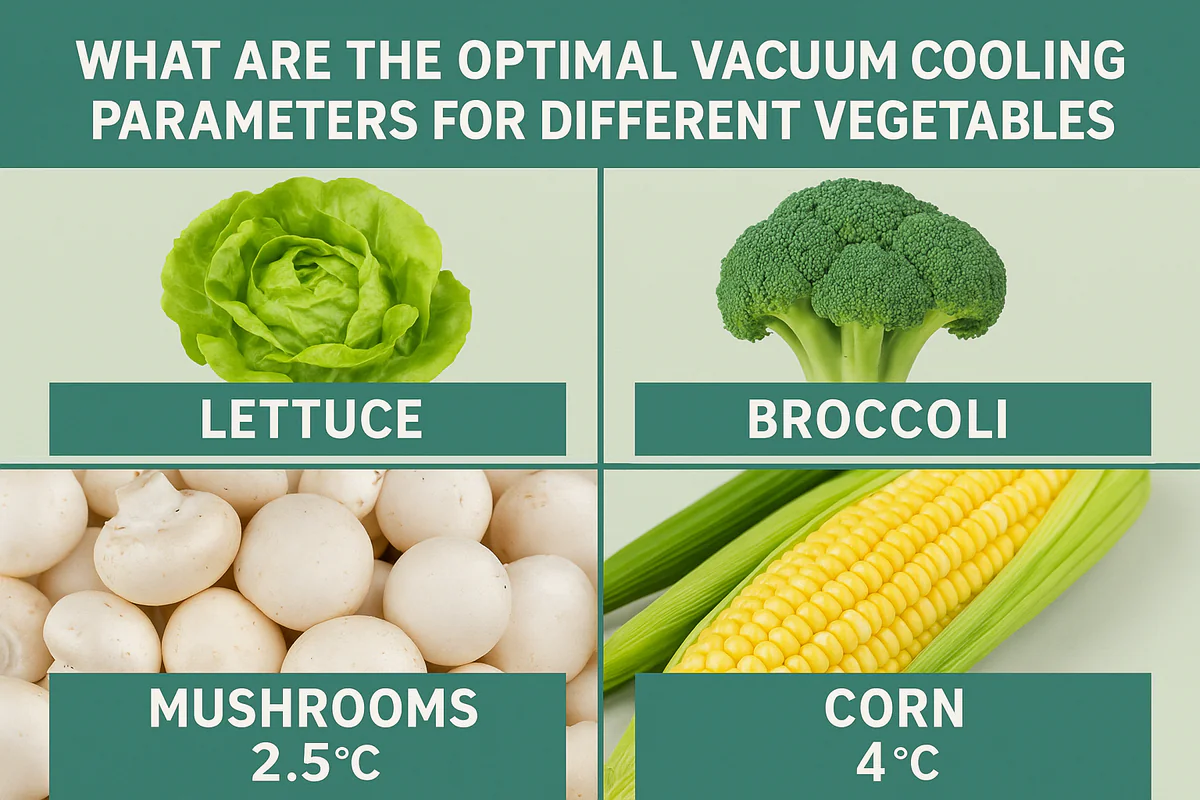

What are the special requirements for cooling mushrooms?

Mushrooms are a high-value, but extremely delicate, product. You know that rapid cooling is critical to stop them from turning brown and losing texture, but you’re afraid the powerful vacuum process will physically damage them or "suck" all the moisture out.

Mushrooms require a specialized, gentle cooling cycle. The process involves a slower rate of pressure drop and a final pressure that’s slightly higher than leafy greens, typically completed in about 20 minutes to preserve their delicate structure and moisture content.

Precision is Paramount

Cooling mushrooms is the ultimate test of a vacuum cooler’s control system. You cannot simply use a standard vegetable cycle. Their cellular structure is very delicate and can be easily ruptured by a sudden, aggressive drop in pressure, causing bruising and discoloration. Furthermore, their high water content makes them prone to excessive moisture loss if the vacuum is held too low for too long.

To address this, we use a feature on our machines called "ramp control." Instead of opening the vacuum valve fully and dropping the pressure as fast as possible, our Siemens PLC controls the valve to lower the pressure gradually over several minutes. This allows the water vapor to escape in a more controlled manner, preventing physical damage. We also set a slightly higher final pressure setpoint, often around 7.5 mbar, to ensure the boiling process is less vigorous. The goal is to cool them quickly to around 3-4°C to halt enzymatic browning, but to do so with the utmost care. This level of precision requires high-quality components, from the German-made Leybold vacuum pump to the sensitive pressure transmitters. It’s a perfect example of how investing in professional, high-quality equipment pays off by allowing you to perfectly handle high-value, sensitive products.

Conclusion

There is no magic number for vacuum cooling. The optimal parameters are a precise balance of pressure and time, tailored to the vegetable’s unique story—its shape, density, and structure. Mastering these settings transforms your cooler from a simple machine into a powerful tool for quality preservation.

-

Understanding this ratio is crucial for optimizing vacuum cooling processes in vegetables. ↩

-

Explore how the physical characteristics of vegetables influence their cooling efficiency. ↩

-

Discover the benefits of hydro-cooling for enhancing the efficiency of vacuum cooling. ↩

-

Understanding the final pressure setpoint is crucial for optimizing vacuum cooling processes and ensuring product quality. ↩

-

Learn about the ideal cycle times for different leafy greens to maximize freshness and minimize damage during cooling. ↩

-

Explore how temperature probes enhance the efficiency of vacuum cooling, ensuring precise temperature control for optimal freshness. ↩

-

Discover how vacuum cooling technology can lead to significant energy savings while maintaining product quality. ↩

-

Understanding the hydro-vac technique can enhance your knowledge of effective cooling methods in food processing. ↩

-

Exploring the impact of temperature gradients can provide insights into optimizing cooling processes for better product quality. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not