What Is the Best Maintenance Schedule for a Bakery Vacuum Cooling Machine?

You dread the day your production line stops because of a broken pump. Unexpected downtime costs you thousands in wasted dough, missed deliveries, and frustrated customers.

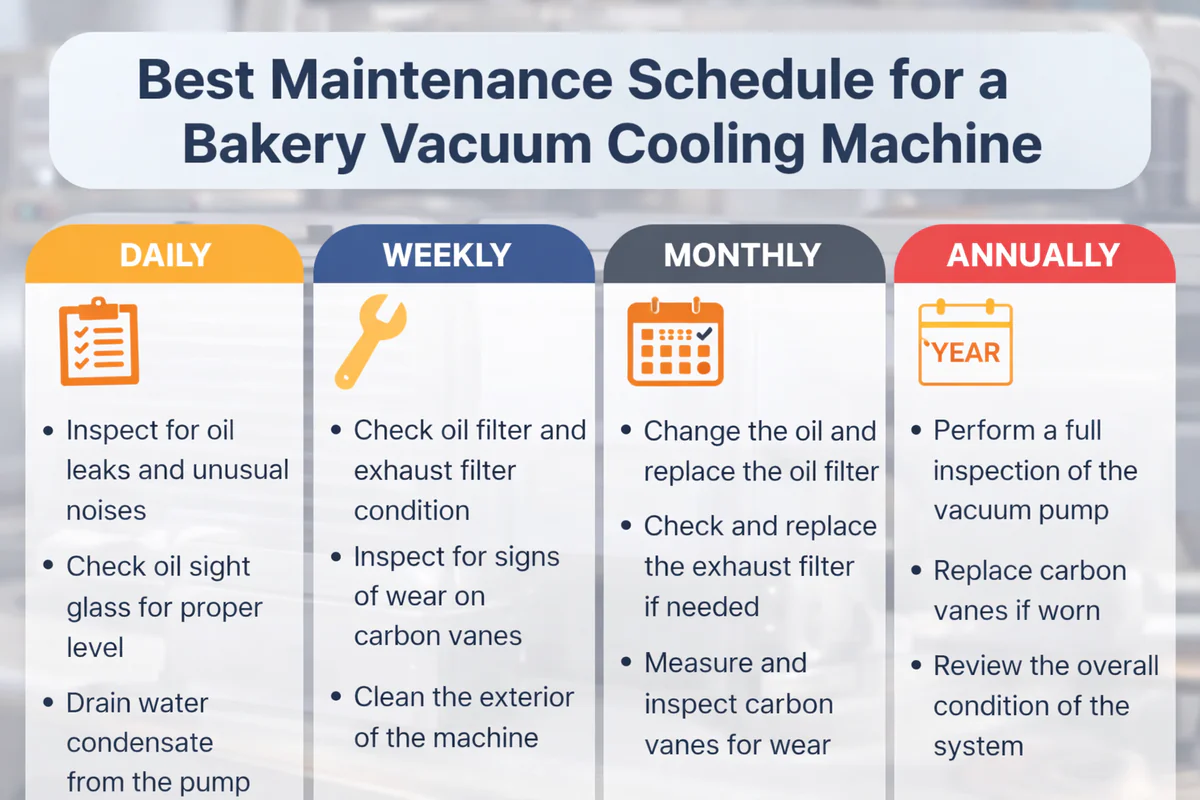

A robust maintenance schedule consists of daily hygiene checks by operators, weekly oil inspections, monthly filter replacements, and an annual professional service. Sticking to this routine prevents 90% of emergency breakdowns and extends the machine’s lifespan by over five years.

At Allcold, I often tell my clients that a vacuum cooler is like a high-performance car. If you drive it every day but never change the oil, the engine will eventually seize. It is not a question of "if," but "when." I have seen factories in Europe run the same machine for 10 years without a single major repair because they followed the schedule. I have also seen factories in humid climates neglect their machines, leading to a total system failure in 18 months.

Maintenance is not just about fixing things when they break; it is about "Preventative Care." It is about catching a small 10-cent problem before it becomes a $5,000 problem. Below, I have outlined the exact schedule I recommend to my customers, from the daily tasks your bakers can do, to the yearly tasks that require a certified technician.

What Maintenance Tasks Must Be Performed Every Single Week?

You think maintenance is only for engineers and requires heavy tools. Ignoring small daily changes, like a dirty door seal or a drop in oil level, leads to massive failures later.

Operators must check oil levels, wipe door seals, and run the self-cleaning cycle daily. Weekly, they should inspect air filters to prevent overheating and visually check the condition of the core temperature probe.

The Frontline Defense

The operators who run the machine every day are your first line of defense. They do not need to be mechanics, but they need to be observant. I always train the shift leaders to look for three specific things: Hygiene, Oil, and Air.

1. The Oil Check (The Lifeblood):

The vacuum pump is the heart of the machine. It relies on oil to seal the vacuum and lubricate the moving vanes.

- The Daily Ritual: Every morning, before the first cycle, the operator must look at the "Sight Glass" on the pump.

- Level: The oil should be in the middle of the glass. If it is low, add more. Running a pump with low oil will cause it to overheat and seize.

- Color: This is critical. Fresh oil is golden, like honey or vegetable oil.

- Milky/White: This means water has mixed with the oil (emulsification). This happens if the "Warm Up" cycle was skipped. If you see this, you must run the pump with the ballast valve open to evaporate the water.

- Black: The oil is burned or full of carbon. It needs changing immediately.

2. The Door Seal (The Vacuum Integrity):

The door gasket is made of silicone. It is soft and flexible.

In a bakery, you have crumbs, sesame seeds, and flour everywhere.

- The Problem: If a hard crust or a seed sits on the seal when the door closes, it creates a tiny leak. The pump has to work twice as hard to overcome this leak. This causes the pump to run hot.

- The Fix: Simply wipe the gasket with a damp cloth at the start and end of every shift. I remember visiting Carlos in Mexico; his machine was alarming "Overload." We found a layer of dried dough on the seal. We wiped it off, and the machine ran perfectly.

3. The Core Probe1 (The Sensor):

The probe goes into the bread 20 or 30 times a day.

- Physical Damage: Check the cable. Is it cut? Is the needle bent?

- Connection: Ensure the plug is tight in the socket. A loose probe gives erratic temperature readings, causing the machine to stop too early or run too long.

4. Weekly Air Filter Cleaning:

The electrical cabinet and the motors have cooling fans. These fans suck in air. In a bakery, the air is full of flour dust.

- The Risk: If the filters get clogged with flour, the Variable Frequency Drive (VFD) cannot cool down. It will overheat and shut off.

- The Task: Once a week, pull out the filter mats and blow them out with compressed air. It takes 2 minutes but saves expensive electronics.

| Frequency | Component | Action | Reason |

|---|---|---|---|

| Daily | Vacuum Pump2 | Check Oil Level & Color | Prevent seizure and corrosion. |

| Daily | Door Gasket | Wipe with damp cloth | Ensure vacuum tightness. |

| Daily | Chamber | Run "Self-Clean" Cycle | Remove mold/bacteria risks. |

| Weekly | Core Probe | Inspect cable and tip | Ensure accurate sensing. |

| Weekly | Cooling Fans | Blow out dust filters | Prevent electrical overheating. |

How Critical Are Monthly and Quarterly Inspections?

You might skip the monthly check because the machine "sounds fine" and you are busy. This complacency allows invisible wear and tear to destroy internal components like exhaust filters and electrical connections.

Quarterly maintenance focuses on the vacuum pump’s internal health, specifically replacing the exhaust filters (oil mist separators), tightening electrical connections, and cleaning the water cooling system to ensure maximum efficiency.

The Technician’s Review

While daily checks are for the operator, monthly and quarterly checks require someone with a bit more technical knowledge, like your facility maintenance manager. This is where we look inside the machine.

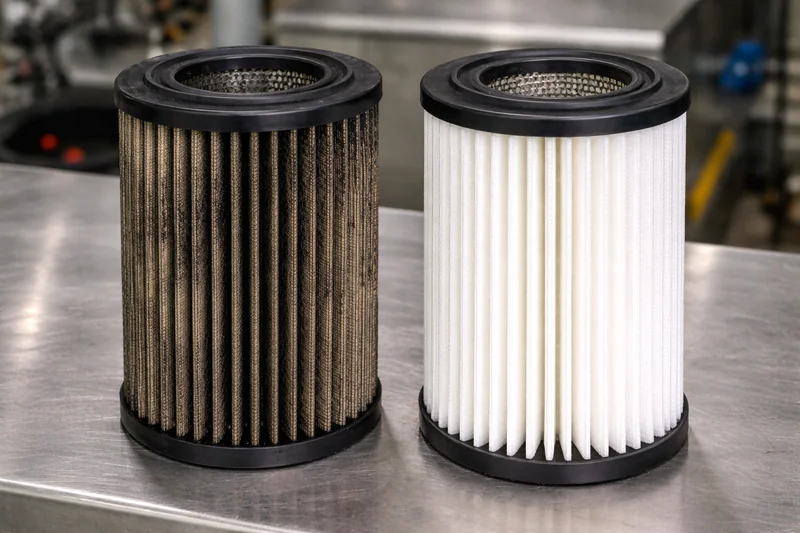

1. Exhaust Filters (Oil Mist Separators)3:

These are the "Kidneys" of the pump. They trap the oil mist so it doesn’t blow out into your factory.

- The Symptom: If these filters get clogged, the air cannot get out of the pump. This creates "Back Pressure."

- The Result: The motor has to push harder. The amperage goes up. The pump gets very hot. Eventually, the motor protection trips.

- The Rule: We recommend changing these filters every 2000 hours, or roughly every 3 to 6 months depending on usage. If you see smoke (oil mist) coming out of the exhaust pipe, the filters are failed and need immediate replacement.

2. Electrical Connections (The "Hot Spot" Check)4:

Vacuum coolers vibrate. They have heavy motors starting and stopping.

- The Risk: Vibration loosens screws in the electrical terminal block. A loose connection creates resistance. Resistance creates heat. Heat melts the wire and can cause a fire or destroy a contactor.

- The Task: Turn off the main power (Lockout/Tagout). Open the electrical cabinet. Use a screwdriver to check the tightness of all power terminals. If you have a thermal camera, scan the panel while it is running to find "hot spots." This is something Norman’s team in the US does religiously, and they have zero electrical failures.

3. The Water Cooling System:

Most of our industrial units use water to cool the pumps and the condenser.

- The Enemy: Algae, scale (calcium), and mud.

- The Check: Inspect the Y-Strainer (water filter) on the inlet pipe. If it is full of dirt, water flow decreases. Low water flow means the vacuum pump overheats.

- Cooling Tower: If you use a cooling tower, check the water quality. If the water is too acidic, it will corrode the heat exchanger inside the vacuum machine. You might need to add water treatment chemicals.

4. Vacuum Oil Change (The Mini-Service)5:

Depending on how many hours you run (e.g., if you run 24/7), you might need to change the oil every 3 months.

- Why? Bread contains organic acids and moisture. These contaminants lower the lubrication quality of the oil. Regular oil changes are the cheapest way to buy "insurance" for your pump.

| Component | Frequency | Action | Consequences of Neglect |

|---|---|---|---|

| Exhaust Filters | 3-6 Months | Replace | High amps, motor overheat, smoke. |

| Electrical Panel | 3 Months | Tighten terminals | Burnt wires, fire risk, VFD failure. |

| Water Strainer | 1 Month | Clean mesh | Low water flow, pump overheat alarm. |

| Drive Belts | 3 Months | Check tension | Slipping belts, loss of performance. |

| Vacuum Oil | 500-1000 Hrs | Drain and Refill | Pump wear, rust inside pump. |

What Happens During the Annual Major Service?

You delay the big service to save money, thinking the machine will last forever. Eventually, the pump vanes shatter inside the cylinder, costing you ten times the price of a standard service kit.

The annual service involves a full oil change, replacing exhaust filters, inspecting and measuring pump vanes, and calibrating all sensors to return the machine to factory specifications.

The Factory Reset

Once a year, or every 3000 to 4000 hours, you need a "Major Service."

At Allcold, we can send an engineer to do this, or we can guide your local technician. This is a deep dive into the machine’s health.

1. Pump Vane Inspection6:

Rotary vane pumps use composite or carbon vanes that slide in and out. They rub against the cylinder wall to create the vacuum.

- Wear and Tear: They naturally wear down, getting shorter over time.

- The Danger Zone: If they get too short, they can pop out of the slot and shatter. If a vane shatters at 1000 RPM, it destroys the cylinder block. The pump is totaled.

- The Task: Open the pump. Remove the vanes. Measure their width with a caliper. If they are below the manufacturer’s minimum width (e.g., <35mm), replace the whole set. Do not gamble with this.

2. Sensor Calibration:

Food safety is non-negotiable.

- Temperature Probe: Does 30°C on the screen actually mean 30°C in the bread?

- The Test: Place the probe in a cup of ice water (0°C) and boiling water (100°C). Check the reading. If it is off by more than 1 degree, calibrate the offset in the PLC settings.

- Vacuum Sensor: Check if the sensor reads "Atmosphere" correctly. If the sensor drifts, the machine might think it is under vacuum when it is not, causing door safety issues.

3. Valve Overhaul7:

The machine has large pneumatic butterfly valves.

- Seals: The rubber seats inside the valves can dry out or crack.

- Action: Inspect the main vacuum valve and the aeration valve. If they leak, the machine takes longer to cool because air is leaking in. Replace the rubber seats if necessary.

4. Software Updates:

Just like your phone, industrial machines sometimes need updates.

We gather data from all our clients. If we find a better way to control the VFD for energy saving, we release a software patch. The annual service is the perfect time to upload the new program to the PLC.

| Service Task | Why it is Major | Expected Outcome |

|---|---|---|

| Vane Replacement | Prevents catastrophic failure | Pump runs like new. |

| Full Seal Kit | Replaces all O-rings/Gaskets | Zero vacuum leaks. |

| Sensor Calibration | Ensures HACCP compliance | Accurate data for food safety. |

| System Flush | Cleans water jacket | Optimal cooling efficiency. |

| Safety Test | Checks E-Stop/Door Locks | Protects your staff. |

Which Spare Parts Should You Keep in Stock?

You wait until a part breaks to order a replacement. Shipping delays from China or Europe can shut your factory down for weeks, forcing you to revert to slow, traditional cooling methods.

You should always stock a "First Aid Kit" containing vacuum pump oil, exhaust filters, a door gasket, and a spare temperature probe to resolve issues immediately without waiting for shipping.

The Inventory Strategy

I often deal with frantic calls from clients who say, "Mila, the machine stopped! Send parts now!"

If you are in Europe, DHL takes 3 days. If you are in South America, customs can take 2 weeks. Can your bakery survive 2 weeks without the vacuum cooler?

I advise every client to buy a "Spare Parts Package" with the machine. It is a small investment compared to the cost of downtime.

1. The "Must-Haves" (Consumables):

These are things you will use. It is not a waste of money; you will consume them eventually.

- Vacuum Pump Oil: Keep at least one 20L drum on site.

- Exhaust Filters: Keep one full set (usually 3 or 4 filters per pump).

- Door Gasket: These can be torn by a careless trolley driver. Keep one spare.

2. The "Smart-Haves" (Wear Parts):

- Core Temperature Probe: These are fragile. If an operator drops it or shuts the door on the cable, it breaks. Without a probe, you cannot run automatic cycles. Keep two spares.

- Solenoid Valves: Small pilot valves control the big pneumatic valves. They are cheap ($20-$50), but if one coil burns out, the machine stops.

3. The "Insurance" (Critical Components):

For high-volume factories like Sophia’s central kitchen, we recommend stocking heavier parts.

- Contactor/Relay: The main contactor switches on and off hundreds of times a day. It will wear out.

- Water Flow Switch: If this fails, the machine thinks there is no water and won’t start.

Cost-Benefit Analysis:

Spending $1,000 on spare parts seems like a lot.

But if your factory produces $5,000 of bread per hour, that $1,000 is nothing.

I recommend creating a "Critical Spare Parts List." Check this inventory every time you do the monthly maintenance. If you use a filter, order a new one immediately. Do not wait until the shelf is empty.

| Priority | Part Name | Quantity to Stock | Why? |

|---|---|---|---|

| High | Vacuum Pump Oil | 20 Liters | Required for daily top-ups. |

| High | Exhaust Filters | 1 Set | Clogs cause immediate shutdown. |

| High | Core Temp Probe | 2 Units | Most common accidental breakage. |

| Medium | Door Gasket | 1 Unit | Critical for vacuum seal. |

| Medium | Solenoid Coil | 2 Units | Cheap fix for control failures. |

| Low | VFD Fan | 1 Unit | Long lead time to replace. |

Conclusion

Maintenance is not an expense; it is an investment in your profitability. By implementing a disciplined schedule of daily checks, monthly inspections, and strategic spare parts inventory, you ensure your Allcold vacuum cooler operates flawlessly, delivering fresh, perfectly cooled bread year after year.

-

Learning about core probe issues can help you avoid costly machine downtimes and improve product quality. ↩

-

Understanding the role of vacuum pumps can enhance your operational efficiency and maintenance practices. ↩

-

Explore this link to learn essential maintenance tips for exhaust filters, ensuring optimal pump performance and longevity. ↩

-

Discover effective methods for checking electrical connections to prevent failures and enhance safety in your operations. ↩

-

Learn why timely vacuum oil changes are crucial for pump health and how they can save you money in the long run. ↩

-

Understanding pump vane inspection is crucial for maintaining vacuum efficiency and preventing costly failures. ↩

-

A valve overhaul can significantly improve machine performance and prevent air leaks, enhancing cooling efficiency. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy