What's Really Inside Your Vacuum Cooler that Makes it Work?

Ever wondered what makes a vacuum cooler tick, transforming warm produce into perfectly chilled goods in minutes? It’s not magic, but a symphony of crucial components working together seamlessly.

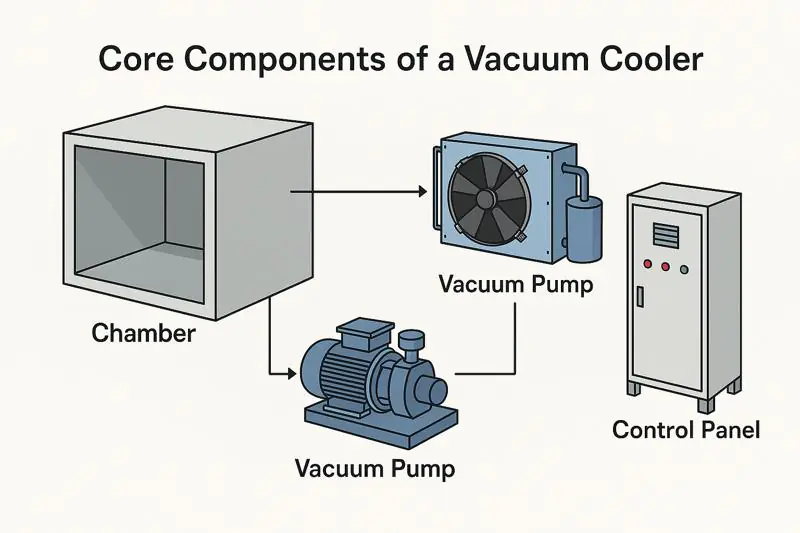

The heart of any vacuum cooler lies in its vacuum pump, refrigeration system (including the condenser), vacuum chamber, and control system. The quality and synergy of these core components directly determine the cooler’s efficiency, reliability, and the final quality of your cooled products.

Understanding these parts helps you appreciate the technology and make informed decisions when investing in such vital equipment for your business. Let’s open up the "black box" and explore what each key player does.

How Does the Vacuum Pump Drive the Entire Cooling Process?

Is your current system struggling to reach the target vacuum quickly, slowing down your entire operation? The vacuum pump is the powerhouse, and its performance is absolutely critical for productivity.

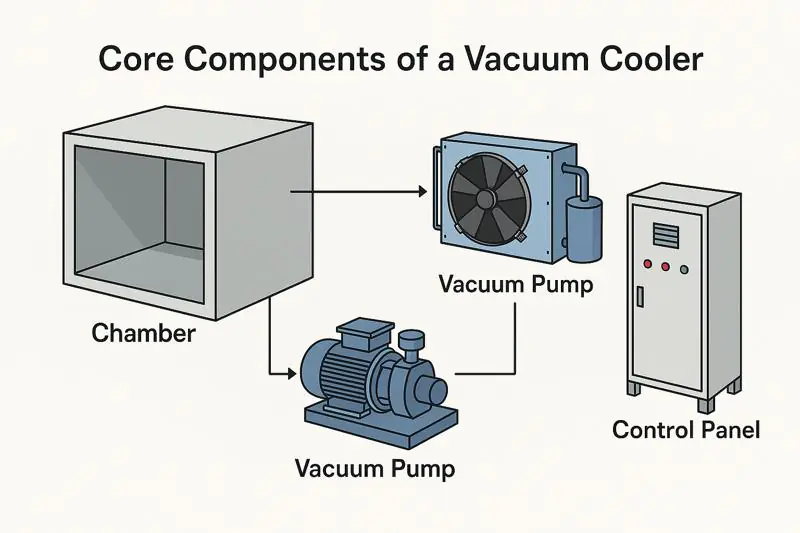

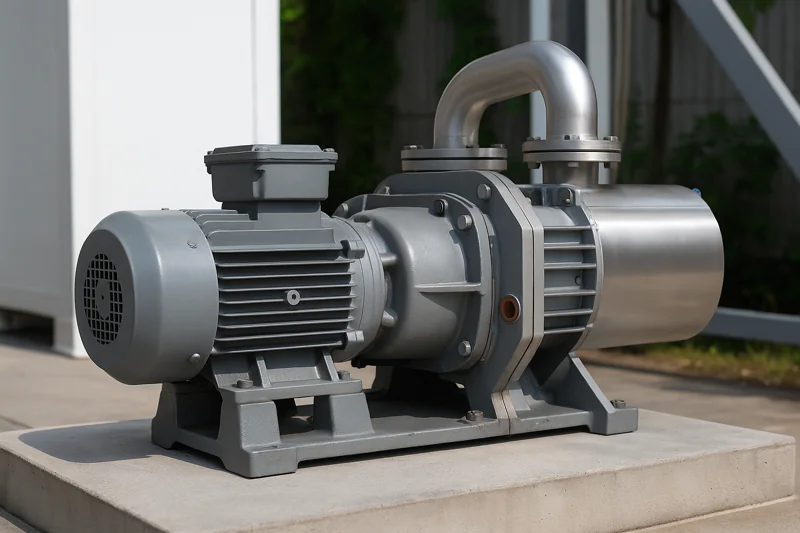

The vacuum pump is the engine of the vacuum cooler. It rapidly removes air from the sealed chamber to create the low-pressure environment needed for water to boil at a low temperature, driving evaporative cooling.

When I talk to clients like Carlos, who runs a large-scale farm and needs equipment that can keep up with high throughput, the vacuum pump’s capacity and reliability are always key discussion points. If the pump is undersized or inefficient, the entire cooling cycle slows down. Its job is to evacuate air from the chamber, which lowers the atmospheric pressure inside. This pressure drop lowers the boiling point of water to just 5-7°C. The evaporation of this water is what pulls heat from the produce. For food applications, oil-sealed rotary vane pumps are very common due to their robustness and ability to achieve the deep vacuums we need for effective cooling. At allcold, we select pumps that are not just powerful, but also dependable for the long haul, because downtime in high season is simply not an option for our customers.

Key Performance Metrics for a Vacuum Pump

Choosing the right pump is about matching its specifications to the job. For a buyer like Norman, who is very sensitive to quality, understanding these metrics helps in evaluating different machines. It’s not just about brand names; it’s about measurable performance. A pump with a high capacity (pumping speed) will evacuate the chamber faster, leading to shorter cycle times. The ultimate vacuum level determines the lowest possible temperature for cooling. Finally, reliability is everything. A cheaper pump that requires frequent maintenance is a poor investment in the long run. We focus on a balance of all three to ensure our machines perform efficiently and reliably for years.

| Performance Metric | Importance for Vacuum Cooling | What to Look For in a Quality Machine |

|---|---|---|

| Pumping Speed (m³/hr)1 | Determines how quickly the chamber reaches its target vacuum level. | A higher number means faster cycle times and greater throughput. |

| Ultimate Vacuum (mbar)2 | The lowest pressure the pump can achieve. | A lower pressure allows water to boil at a lower temperature. |

| Reliability / Build3 | Dictates pump longevity and maintenance needs. | Robust construction, proven brand, good service history. |

| Power Consumption (kW) | Affects your long-term operational costs. | An efficient motor that doesn’t compromise on pumping speed. |

Why is the Condenser Vital for Efficiency and Pump Protection?

Noticing your vacuum pump working harder than it should, or is your cooling not as effective as it once was? The condenser and its refrigeration system play a silent but crucial role.

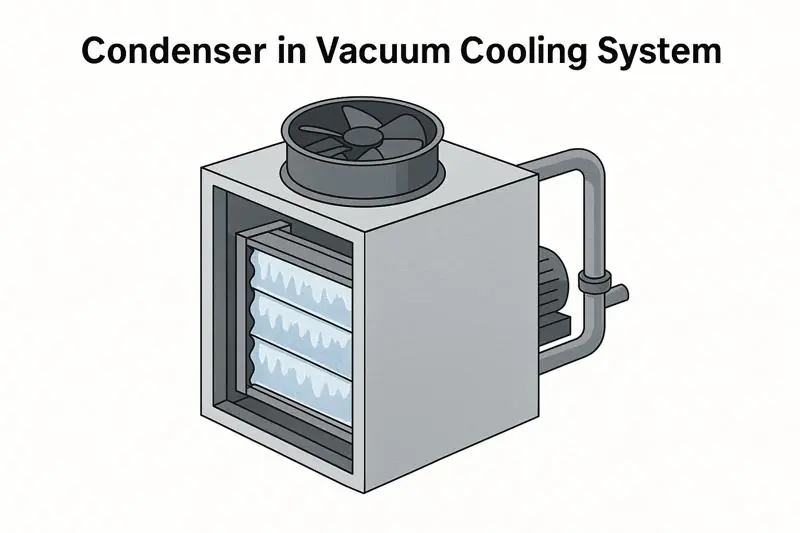

The condenser is essential for trapping the massive amounts of water vapor released from the product. This protects the vacuum pump from being overwhelmed and dramatically improves the overall system efficiency by removing latent heat.

A high-efficiency condenser directly contributes to a machine’s long-term performance. Without it, all the water vapor from the produce would go straight into the vacuum pump. This can mix with the pump’s oil, reducing its effectiveness and leading to costly repairs. The condenser works by having extremely cold surfaces, created by the refrigeration system. When the warm, moist vapor from the produce hits these cold coils, it instantly turns back into ice, trapping it. This process removes a huge amount of vapor and heat, which makes it much easier for the vacuum pump to do its main job: removing air. This synergy between the refrigeration system and the vacuum pump is something we engineer very carefully at allcold.

Understanding Condenser and Refrigeration Synergy

The refrigeration system is what makes the condenser cold, and its power is critical. I always explain to clients that the refrigeration capacity4 must be matched to the amount of product you want to cool. If you have a large chamber but an undersized refrigeration system, the condenser won’t be able to trap all the vapor. This results in longer cooling cycles and puts more strain on the vacuum pump5. It’s a false economy to save money on the refrigeration unit. A powerful refrigeration system ensures the condenser coils get very cold, very fast, leading to efficient vapor trapping. This means the vacuum pump can achieve its target pressure quicker, shortening the entire cycle. It’s this balance that creates a truly high-performance machine.

| Condenser Performance | Impact on Vacuum Pump | Impact on Cooling Cycle Time | Impact on Energy Efficiency |

|---|---|---|---|

| High (Sized Correctly) | Lower workload, protected from vapor, longer life. | Shorter | High efficiency, lower energy use per cycle. |

| Low (Undersized) | High vapor load, risk of oil contamination, shorter life. | Longer | Low efficiency, pump works harder, higher energy use. |

What Makes the Vacuum Chamber Important for Performance and Hygiene?

Experiencing vacuum leaks or struggling with cleaning your cooling equipment? The vacuum chamber is more than just a box; its design and construction are fundamental to safety, hygiene, and performance.

The vacuum chamber must be robustly constructed to withstand immense atmospheric pressure, perfectly sealed to prevent leaks, and made from food-grade stainless steel for ultimate hygiene and durability, a critical factor for food safety.

For clients like Sophia, who manages a central kitchen under strict HACCP rules, the material and cleanability of the vacuum chamber are non-negotiable. When a deep vacuum is pulled, the outside air exerts a massive force—around 10 tons per square meter—on the chamber walls. Our chambers are engineered with reinforced stainless steel to handle this pressure safely, day in and day out. Furthermore, any tiny leak in a weld or door seal can prevent the system from reaching the necessary vacuum, making cooling impossible. That’s why we use high-quality, resilient seals and meticulous welding techniques. This focus on construction ensures our machines are not only effective but also safe and easy to maintain for food-grade operations.

Material and Construction: A Buyer’s Checklist

The choice of material is one of the most important decisions in the construction of a vacuum chamber. While some manufacturers might use painted mild steel to cut costs, it is simply not suitable for a modern food environment. Paint can chip, and the steel underneath can rust, creating a serious hygiene risk. This is why we exclusively use food-grade stainless steel6 for our chambers at allcold. It is corrosion-resistant, incredibly durable, and has a smooth surface that is easy to clean and sanitize. This prevents the buildup of bacteria and ensures the equipment can meet international food safety standards. When you are inspecting a machine, always check the quality of the welds and the resilience of the door seal. These small details tell you a lot about the overall build quality.

| Feature | Standard Quality (e.g., Mild Steel) | High Quality (e.g., allcold’s SUS304) | Why It Matters for You |

|---|---|---|---|

| Chamber Material | Painted Mild Steel | Food-Grade Stainless Steel (SUS304) | Hygiene, rust prevention, durability, HACCP compliance7. |

| Welding | Basic, sometimes porous | Smooth, non-porous, ground flush where needed | Prevents leaks, eliminates bacteria traps, ensures strength. |

| Door Seal | Standard rubber | High-resilience, food-grade silicone or specialized rubber | Ensures a perfect vacuum seal8 over thousands of cycles. |

| Internal Finish | Standard industrial finish | Smooth, often with rounded corners | Fast and effective cleaning, better food safety. |

How Does the Control System Ensure Consistent and User-Friendly Operation?

Are your cooling cycles inconsistent, or is your equipment overly complicated for your staff? A sophisticated yet user-friendly control system acts as the brain of the entire vacuum cooler.

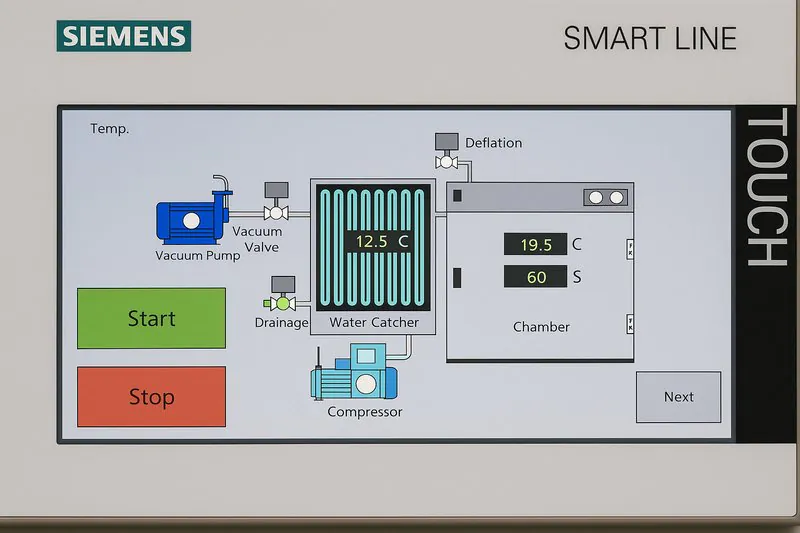

The control system, typically a PLC, precisely manages the vacuum pump and refrigeration system. It uses sensors to monitor pressure and temperature, ensuring consistent, efficient cooling cycles through a simple interface.

All my customers, regardless of their technical background, value equipment that is easy to operate and delivers the same result every time. This is the job of the control system. It automates the entire process, from starting the pump to monitoring the pressure drop and stopping the cycle when the target temperature is reached. We use Programmable Logic Controllers (PLCs) in our allcold machines, which are industrial-grade computers known for their reliability. This is paired with an intuitive Human Machine Interface (HMI), often a touchscreen, that allows operators to simply select a pre-set program for their specific product—like lettuce or mushrooms—and press start. It takes the guesswork out of the process and ensures consistent quality.

The Brains of the Operation: PLC Control Features

A good control system does more than just start and stop the machine; it optimizes the entire process. For example, our systems use precise sensors to monitor both the vacuum pressure in the chamber and the actual core temperature of the product with a probe. The PLC uses this real-time data to adjust the cycle, ensuring the product is cooled perfectly without being over-cooled, which could waste energy or damage the product. Features like programmable recipes are incredibly valuable. A client can save the exact settings for different vegetables or batch sizes. This means an operator can switch from cooling broccoli to spinach with the touch of a button, guaranteeing the optimal parameters are used every time. It enhances efficiency, reduces the chance for human error, and gives managers like Sophia the process control she needs.

| Control System Feature | Description | Direct Benefit to the User |

|---|---|---|

| PLC (Programmable Logic Controller) | An industrial computer for automating and controlling the process. | High reliability, repeatable cycles, consistent product quality. |

| HMI (Human Machine Interface) | A user-friendly touchscreen or panel for operation. | Easy to operate, reduces training time, minimizes operator error. |

| Programmable Recipes | Ability to save and recall settings for different products. | Fast changeovers, optimized cooling for every product type. |

| Accurate Sensors | Probes that measure vacuum pressure and product temperature. | Guarantees product is cooled to the correct specification. |

Conclusion

The vacuum pump, condenser, chamber, and control system are the critical pillars of any vacuum cooler. High-quality, well-matched components are essential for optimal performance, reliability, and delivering perfectly cooled products day after day.

-

Understanding pumping speed is crucial for optimizing cycle times and throughput in vacuum applications. Explore this link to learn more. ↩

-

The ultimate vacuum level is key to achieving efficient cooling. Discover its impact on your operations by checking this resource. ↩

-

Reliability ensures longevity and reduces maintenance costs. Learn why it’s vital for your investment in vacuum technology. ↩

-

Understanding refrigeration capacity is crucial for optimizing cooling systems and ensuring efficiency in operations. ↩

-

Exploring how vacuum pumps function can enhance your knowledge of refrigeration systems and their efficiency. ↩

-

Explore the advantages of using food-grade stainless steel for hygiene and durability in food environments. ↩

-

Understanding HACCP compliance is crucial for ensuring food safety standards are met in your construction projects. ↩

-

Learn about the importance of vacuum seals in preserving food quality and safety, essential for any food-related construction. ↩

Mila

You May Also Like

Is Your Cooling Process Holding Back Your Ready-Meal Business?

Your kitchen produces delicious, complex ready-meals, but the slow cooling process introduces food safety risks and production delays. This critical

How Can Vacuum Cooling Revolutionize Meat and Poultry Processing?

You’ve cooked a thousand kilograms of chicken perfectly, but now it sits for hours, slowly passing through the temperature danger

What Are the Preservation Techniques for Ready-to-Eat Foods?

As consumers increasingly prefer ready-to-eat (RTE) foods, extending their shelf life effectively becomes a critical challenge. Currently, the most effective