Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it across an ocean. As the container doors close, you’re left to hope that the quality you packed is the quality that arrives three weeks later.

This uncertainty is a massive business risk. A single container rejected at a foreign port due to spoilage or failed inspection can wipe out your profits for the entire season. It’s a high-stakes gamble that damages not just your finances, but your reputation with international buyers.

No, you don’t have to gamble. Vacuum cooling is the essential pre-shipping technology that transforms exporting from a game of chance into a reliable science. It ensures your vegetables meet the stringent quality and phytosanitary standards of international markets by locking in freshness for long-haul transit.

For years, I’ve worked with exporters who have built their entire international business on a foundation of reliability. That reliability doesn’t start at the port; it starts in the packing house, in the 30 minutes a pallet of produce spends inside a vacuum cooler. Let’s break down how this one step removes the biggest risks in the export chain.

How Do You "Pause" the Spoilage Clock for a 3-Week Journey?

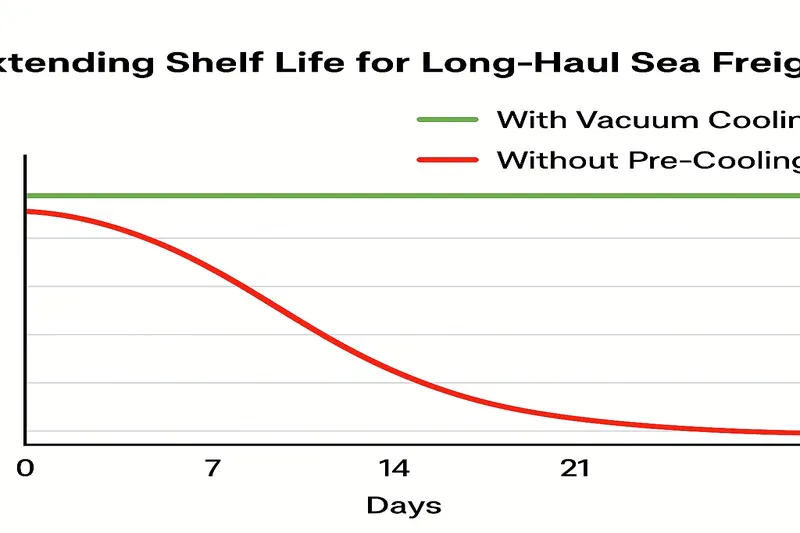

The moment a vegetable is harvested, it begins to die. It respires (breathes), consuming its own sugars and moisture to stay alive. The heat from the field acts like a fast-forward button on this process, accelerating decay with every passing hour. A 21-day sea voyage is an eternity for a living, breathing product.

You’re fighting a biological clock that is ticking at high speed. A standard refrigerated container can slow this clock down, but it can’t rewind it. If the produce goes into the container warm, the damage has already begun, and it will continue throughout the journey.

Vacuum cooling acts as a powerful "hibernation" switch for vegetables. By instantly dropping the core temperature, it dramatically reduces the respiration rate to a near-dormant level. This effectively "pauses" the aging process, preserving the vegetable’s moisture, nutrients, and cellular integrity for weeks, not days.

The Biology of Long-Haul Transit

An ambitious producer like Carlos in Mexico wants to sell his romaine lettuce to buyers in Europe. This is a 15 to 20-day journey. For him, understanding the science of senescence1 (aging in plants) is the key to his business model.

Winning the Respiration Race

Think of a head of lettuce like a marathon runner. At a warm field temperature of 30°C (86°F), it’s sprinting, burning through its stored energy and water reserves at an incredible rate. It will exhaust itself and wilt in a day or two. A refrigerated container set to 2°C (36°F) tells the runner to slow to a jog. It helps, but a lot of energy was already wasted in the initial sprint. A vacuum cooler2 brings the lettuce from 30°C to 2°C in under 30 minutes. This is like instantly teleporting the runner from the starting line to a state of complete rest. The energy reserves are saved. The water is retained. The marathon journey can now be completed with ease. This dramatic reduction in respiration is the single most important factor in achieving a 21+ day shelf life for perishable goods.

Preserving Marketable Weight and Quality

During respiration, the vegetable loses moisture and solid matter (sugars), which translates directly to a loss of sellable weight. Over a long journey, this can be a significant financial loss. More importantly, this moisture loss results in a loss of turgor3, the crisp texture that defines quality for leafy greens. Vacuum cooling, while removing a small amount of water (1.5-2.5%) as part of the cooling process, ultimately preserves far more water over the long term by nearly stopping the respiration process4. This means Carlos’s lettuce arrives in Rotterdam not only looking green but weighing more and having the crisp texture that the buyer, Norman, expects.

| Temperature | Respiration Rate (Relative) | Shelf Life Potential | Export Viability (21 days) |

|---|---|---|---|

| 30°C (86°F) | 100% (Sprint) | 1-2 Days | Impossible |

| 10°C (50°F) | 30% (Jog) | 5-7 Days | Very Unlikely |

| 2°C (36°F) (Slow Cooled) | 10% (Walk) | 7-10 Days | Risky, inconsistent |

| 2°C (36°F) (Vacuum Cooled) | <5% (Hibernation) | 21+ Days | Reliable and Safe |

Can Vacuum Cooling Help Pass Strict Phytosanitary Inspections?

Your container has arrived at the destination port after weeks at sea. Now it faces its final, most stressful test: the phytosanitary inspection. Officials are looking for any sign of disease, pests, or decay. The rules are black and white, and there is no room for error.

The discovery of even a small amount of mold (Botrytis) or bacterial soft rot can cause the entire container to be flagged. This leads to costly delays, mandatory fumigation treatments (which can damage your product), or, in the worst-case scenario, the complete rejection and destruction of your shipment.

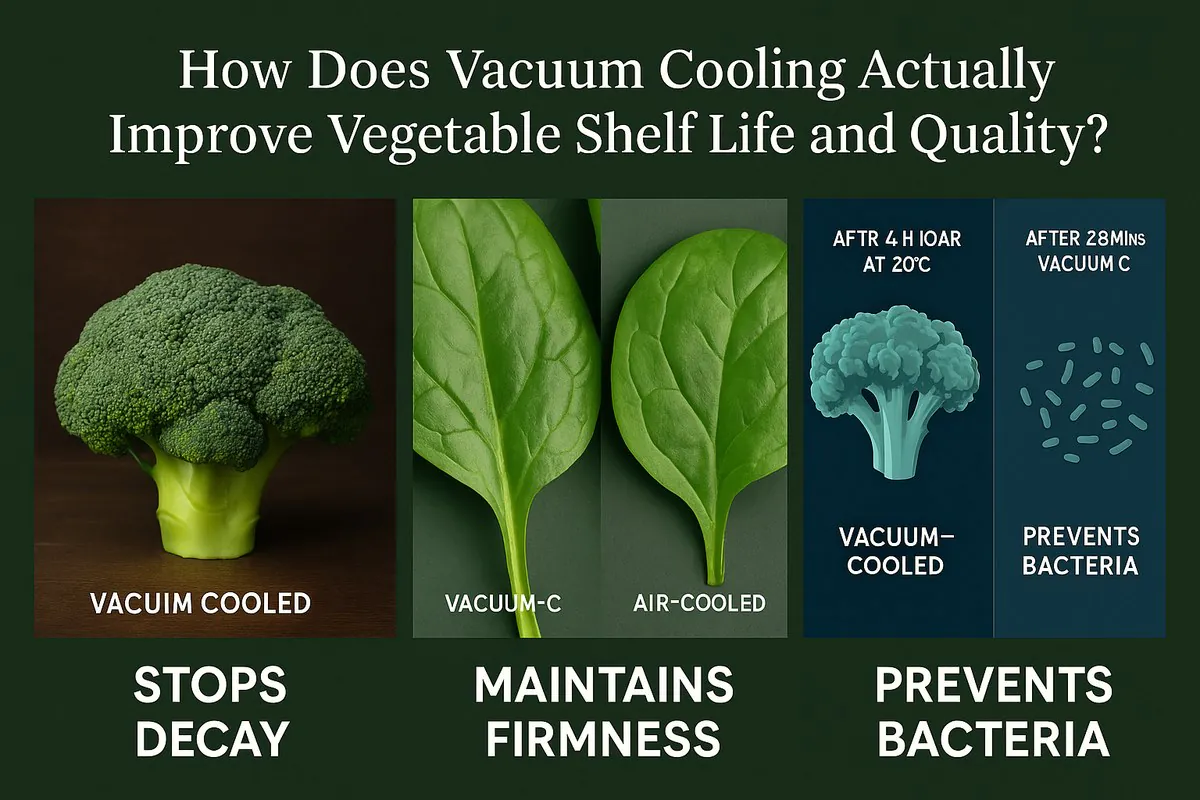

Absolutely. Vacuum cooling is a powerful phytosanitary tool. By rapidly cooling produce, it creates an environment where spoilage microorganisms cannot multiply. This prevents the development of mold and rot during transit, ensuring the product arrives clean, healthy, and able to pass the toughest quarantine inspections.

Proactive Disease and Pest Management

A procurement manager like Sophia, who may be responsible for sourcing ingredients for a global food chain, is obsessed with compliance and food safety. Her suppliers must have processes that mitigate these risks.

A Non-Chemical Hurdle for Microbes

Spoilage organisms like mold and bacteria are present on all fresh produce. They are dormant in the field but are waiting for the right conditions to grow: warmth, moisture, and time. A long sea voyage provides the time. The humidity inside a pallet provides the moisture. The residual field heat provides the warmth. This is a perfect storm for spoilage. Vacuum cooling proactively removes the "warmth" variable from the equation with incredible speed. It pulls the produce through the microbial "danger zone" (4-40°C or 40-100°F) in minutes, giving these organisms no chance to activate. The result is a shipment that arrives with a dramatically lower microbial load than one that was cooled slowly. This isn’t a treatment; it’s a preventative measure that aligns perfectly with the principles of Integrated Pest Management (IPM)5 and HACCP food safety plans6.

Reducing the Risk of Pests

While vacuum cooling does not kill insects directly, it contributes to a lower pest risk profile. Many quarantine pests are attracted to decaying organic matter. A clean, crisp, healthy product is far less appealing to scavengers. Furthermore, the process of loading and unloading a vacuum chamber provides an additional inspection point in a clean, controlled environment before the pallet is loaded into the sea container. By ensuring the product is in a state of suspended animation, you are minimizing the biological activity that can attract unwanted attention from both microorganisms and insects during its long journey. This proactive cleanliness is something port inspectors notice and value.

Why Is Uniform Cooling the Secret to a Perfect Export Container?

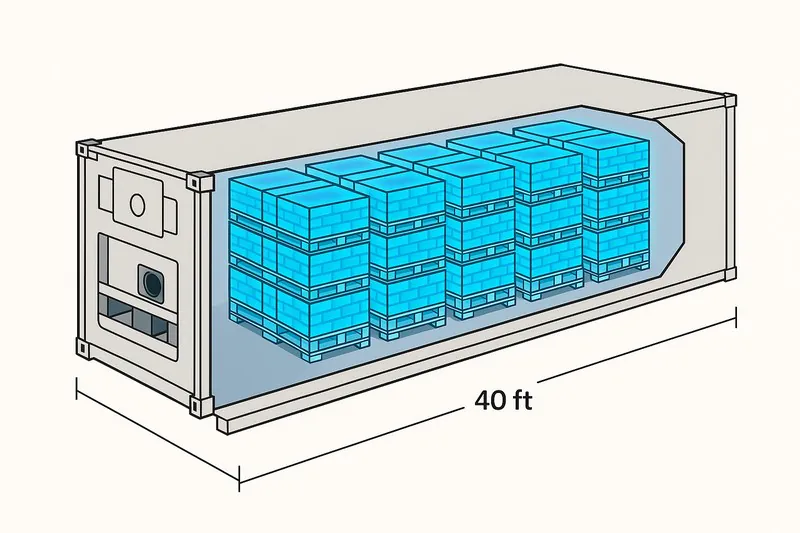

You’ve loaded 20 pallets into a 40-foot container. But are they all the same? If you used a conventional cold room, the answer is almost certainly "no." The pallets on the outside might be cold, but the ones in the middle, deep within the container, are likely warmer.

This inconsistency is a hidden threat. A single warm pallet can begin to decay, releasing ethylene gas and heat, which can trigger a chain reaction of spoilage in the surrounding pallets. When the buyer opens the doors, they find a disaster: a few good pallets at the front and a mess of spoiled produce at the back.

Uniformity is everything in exporting, and vacuum cooling is the only technology that guarantees it. The vacuum is applied to the entire chamber at once, ensuring every single leaf on every pallet cools at the exact same rate. This eliminates the "hot core" problem and creates a truly homogenous, stable load.

Engineering Predictability for Global Trade

An international buyer like Norman in the US is purchasing produce from Carlos’s facility in Mexico. Norman’s entire business model depends on predictability. He needs to know that the 20th pallet he unloads is identical in quality to the first.

The Physics of True Pre-Cooling

A refrigerated sea container is designed to maintain temperature, not to cool a load. Its airflow is designed to circulate around the periphery of the stacked pallets. It cannot effectively penetrate to the core of the container. If you load pallets that are at different starting temperatures, they will stay at different temperatures for much of the journey. Vacuum cooling solves this at the source. Because the pressure drop is instantaneous and uniform throughout the sealed chamber, it doesn’t matter if a pallet is in the corner or the center. The cooling physics act on every head of lettuce simultaneously. This means that when you load the container, you are loading 20 identical thermal blocks, all at a stable 2°C. The container’s reefer unit can now easily do its job of maintaining that temperature, rather than fighting a losing battle against hidden hot spots.

The Data-Driven Guarantee

Modern vacuum coolers provide a data log7 for every cycle. This log shows the starting temperature, the final temperature, and the time it took to get there. Carlos can print this report and attach it to the shipping documents (the Bill of Lading). This is an incredibly powerful tool. He is not just telling Norman the produce is cold; he is providing a data-backed certificate that proves it. This elevates the transaction from a simple sale to a professional, transparent partnership. It gives the buyer immense confidence and reduces disputes. It is the ultimate proof that the product was prepared to the highest possible standard before the container doors were sealed.

Conclusion

Exporting vegetables is not about hoping for the best; it’s about engineering the best possible outcome. Vacuum cooling is the foundational engineering step that takes the gamble out of global logistics. It guarantees the quality, safety, and consistency your international partners demand, ensuring your brand is synonymous with excellence, no matter how many oceans your product has to cross.

-

Understanding senescence is crucial for improving the shelf life and quality of perishable goods. ↩

-

Learn how vacuum cooling technology can significantly enhance the freshness and marketability of produce during transport. ↩

-

Explore the role of turgor in maintaining the quality and texture of leafy greens, essential for consumer satisfaction. ↩

-

Discover how respiration affects the longevity and quality of vegetables, vital for successful long-haul transport. ↩

-

Understanding IPM is crucial for effective pest control strategies in food safety and compliance. ↩

-

Exploring HACCP plans can enhance your knowledge of food safety standards and compliance. ↩

-

Learn how data logs can elevate shipping practices by providing verifiable proof of product conditions. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But

How Does Vacuum Cooling Actually Improve Vegetable Shelf Life and Quality?

You’ve done the hard work. Your harvest is in, and the vegetables look perfect—crisp, vibrant, and full of life. But