Are You Ruining Your Perfect Bread in the Last 10 Minutes?

You have perfected the dough, nailed the proofing, and baked it to a golden crisp. But then, you let it sit on a rack for hours, losing moisture and risking contamination.

Is your cooling process the weak link in your bakery?

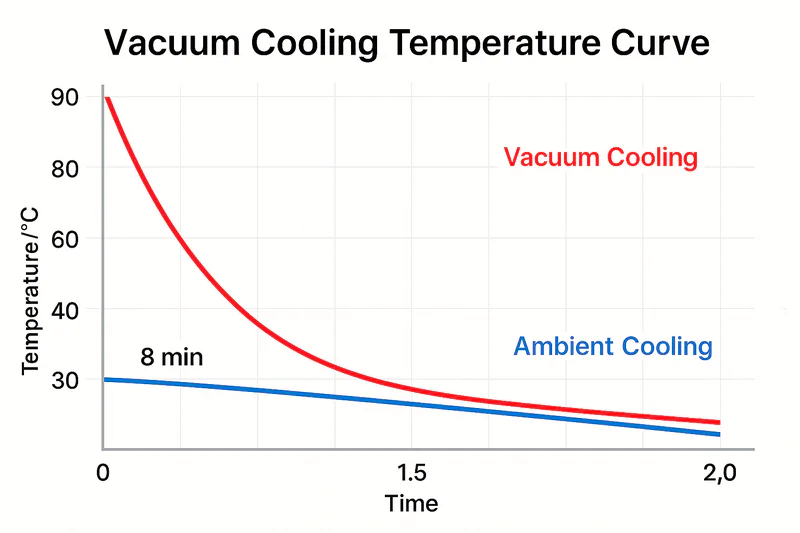

Traditional cooling is slow and unpredictable. It depends on the weather, the airflow, and luck. Vacuum cooling changes the rules. It uses physics to cool bread from the core out, dropping the temperature from 92°C to 30°C in just minutes, locking in freshness and extending shelf life.

As a manufacturer, I have seen bakers struggle with "collapsed" loaves because they didn’t understand the science. Today, I will share the exact parameters and best practices to get it right every time.

What Are the Critical Temperature Parameters for Bread?

Cooling bread isn’t just about making it cold; it is about stopping the cooking process at the exact right moment. If you stop too soon, the center is doughy. If you wait too long, the crust gets tough.

The "Magic Zone" for bread vacuum cooling starts at an initial temperature of around 92°C immediately after baking. The target finish temperature should be set to 30°C (or slightly lower for slicing). This entire cycle typically takes between 5 to 15 minutes, depending on the product density.

Setting the Right Targets

For a technical buyer like Carlos, understanding these numbers is key to optimizing the production line.

1. The Starting Point: +90°C1

You must load the bread into the vacuum cooler as soon as it leaves the oven.

- Why? At 90°C-92°C, the water inside the bread is ready to flash-evaporate. This energy drives the cooling process. If you let the bread cool to 60°C on the rack first, the vacuum cooling will be less efficient and slower.

2. The Finish Line: +30°C2

Most slicing machines work best when the bread is firm and cool.

- The Sweet Spot: We recommend setting the target temperature to 30°C. This is safe for packaging and perfect for slicing.

- The Danger Zone: Do not over-cool to 5°C unless necessary. Going too low removes too much moisture, making the bread dry.

3. The Cooling Speed

Speed is money, but quality is king.

- Standard Cycle: For most baked bread, a 5 to 10-minute cycle is ideal.

- Dense Products: Heavy rye breads might take 15-20 minutes.

- Light Products: Sponges and buns can cool in under 5 minutes, but be careful of "flash cooling" which can damage the structure.

| Parameter | Recommended Value | Why it matters? |

|---|---|---|

| Inlet Temp | >90°C | Maximizes evaporation energy for fast cooling. |

| Target Temp | 30°C | Ideal for slicing and preventing mold growth. |

| Cycle Time | 5 – 15 mins | Balances speed with moisture retention. |

How Does the "Vacuum Delay" Prevent Product Damage?

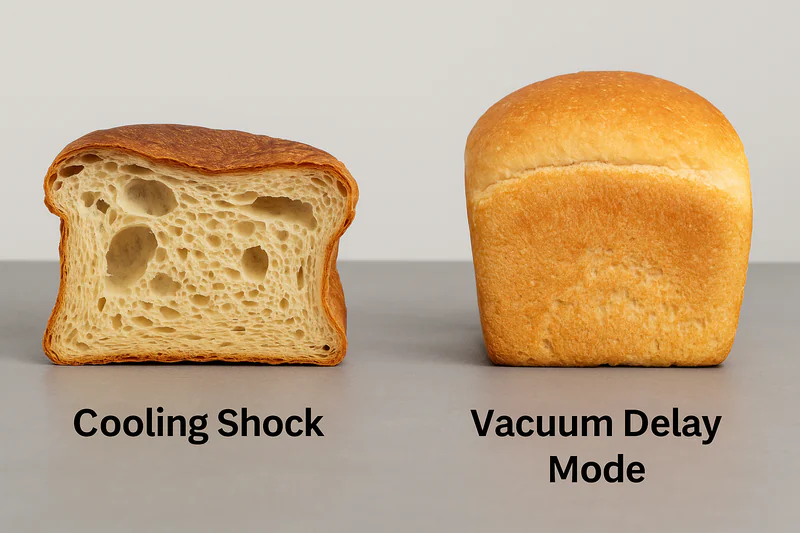

Have you ever put a loaf in a vacuum cooler and watched it explode or collapse? This happens when the pressure drops too fast while the crumb is still too soft.

It is heartbreaking to see a perfect batch ruined in seconds. But there is a simple fix.

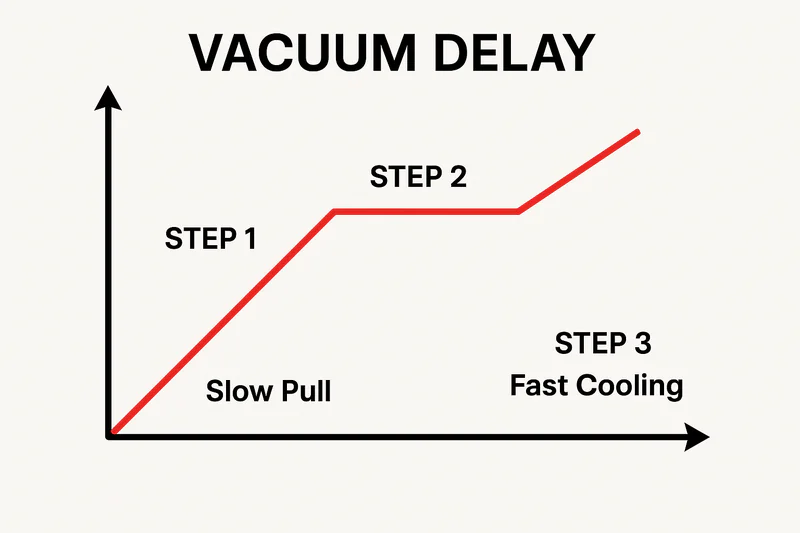

The "Vacuum Delay Facility" is a specialized function that controls the rate of pressure drop. Instead of pulling a hard vacuum instantly, the system reduces pressure in steps or pauses at specific points. This allows the bread’s internal structure to stabilize before the deep cooling begins.

Mastering the Pressure

For a QA manager like Sophia, this feature is the difference between a premium product and waste.

The Risk: Flash Expansion

When water turns to steam under vacuum, it expands 1,600 times in volume. If the bread’s gluten structure hasn’t set, this rapid expansion tears the crumb apart.

The Solution: The Delay Function

Our machines come equipped with a Vacuum Delay Facility3 specifically for products with "higher water yield resistance" like sponge cakes or high-hydration ciabatta.

- How it works:

- Initial Pull: The pump starts slowly to remove the air from the chamber.

- The Pause: The system holds the vacuum level at a "simmering point" (e.g., 500 mbar). This lets the heat redistribute without boiling the water violently.

- Final Pull: Once the structure is stable, the machine goes to full power to finish the cooling.

This ensures uniform cooling of the whole product load4 without the risk of deformation.

What Are the Operational Best Practices for Longevity?

A vacuum cooler is a Ferrari, not a tractor. It needs to be treated with respect. Ignoring simple maintenance will lead to expensive downtime.

To keep your machine running at peak performance, follow the "Clean and Dry" rule. Run the vacuum pump for 20-40 minutes after the shift to remove moisture from the oil. Check the oil levels monthly, and keep the chamber clean to meet hygiene standards.

Daily & Weekly Rituals

For an owner like Norman, proper maintenance means protecting the ROI.

1. The "Self-Cleaning" Mode

Moisture is the enemy of vacuum pump oil.

- The Problem: During cooling, water vapor enters the pump. If it stays there, it turns into water and ruins the oil’s lubrication properties.

- The Best Practice: After the last cycle of the day, use the system’s automated Zero Load Protection5. This runs the pump for 20-40 minutes to evaporate any trapped moisture. Do not skip this!

2. Oil Management

The heart of the machine is the Leybold or Busch pump.

- Check: Look at the oil sight glass every week. If the oil looks milky, it has water in it. Change it immediately.

- Change: Even with good care, change the vacuum pump oil every 6 months to 1 year depending on usage.

3. Hygiene and Environment

- Chamber Cleaning: Wipe down the stainless steel chamber daily. Our machines are designed with hygiene in mind, often meeting CE and HACCP standards for easy cleaning.

- Power Down: If the machine won’t be used for a long time (like off-season), cut the main power and cover the refrigeration unit to protect it from dust and dampness.

Conclusion

Vacuum cooling is a game-changer for bakeries, but only if you use it correctly. By controlling the temperature targets, utilizing the Vacuum Delay for delicate items, and following a strict maintenance schedule, you can turn your cooling rack bottleneck into a profit center.

Don’t just cool your bread; optimize it.

-

Understanding the significance of starting at +90°C can enhance your bread cooling process, ensuring optimal quality and efficiency. ↩

-

Exploring why 30°C is crucial for bread cooling can help you maintain quality and prevent spoilage, ensuring better product outcomes. ↩

-

Explore this link to understand how the Vacuum Delay Facility enhances baking quality and prevents product deformation. ↩

-

Discover the significance of uniform cooling in baking processes to ensure product integrity and quality. ↩

-

Understanding Zero Load Protection is crucial for maintaining your vacuum pump’s efficiency and longevity. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy