Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling is often the bottleneck in commercial bakeries, leading to lost profits and stale products.

The main difference lies in speed and quality. Vacuum cooling cools baked goods in minutes, locking in moisture and extending shelf life, while spiral cooling takes hours and can dry out products. For high-volume bakeries needing efficiency and freshness, vacuum cooling is the superior choice.

Choosing the right cooling method is not just about temperature; it is about transforming your entire production flow. Let’s look at how these two technologies compare and why making the switch could be the best investment for your bakery this year.

How Does Speed Impact Your Production Schedule?

Does your packing team have to wait hours for bread to be cool enough to slice? This downtime is costing you money every single day.

Vacuum cooling reduces cooling time from hours to just 3-10 minutes by lowering the boiling point of water inside the bread. Spiral coolers rely on air circulation, which naturally takes much longer.

The Efficiency Gap

When we talk about speed, we are not just talking about saving a few minutes. We are talking about a fundamental shift in how your bakery operates.

In a traditional setup with spiral cooling1, your bread comes out of the oven and enters a long conveyor system. It travels slowly, exposed to ambient air or chilled air. This process depends heavily on the difference between the bread’s core temperature and the air temperature. As the bread cools, that difference gets smaller, and the cooling slows down.

Vacuum cooling2 works completely differently. It doesn’t rely on air. Instead, we place the trolley inside a sealed stainless steel chamber. The machine lowers the pressure. This forces the moisture inside the bread to "boil" at a lower temperature. This phase change absorbs a massive amount of heat instantly.

Here is a breakdown of the time difference:

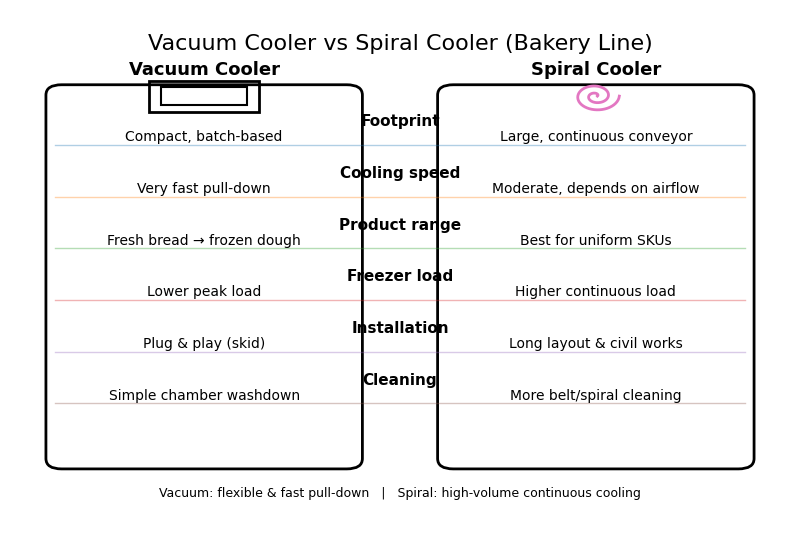

| Feature | Spiral Cooling | Vacuum Cooling |

|---|---|---|

| Cooling Principle | Convection (Air transfer) | Evaporation (Pressure drop) |

| Typical Time | 60 – 120 Minutes | 3 – 10 Minutes |

| Space Required | Large footprint | Compact footprint |

| Weather Impact | High (Humid days slow it down) | None (Closed system) |

For a factory manager like Sophia in Singapore, who deals with tight delivery schedules for cooked food and bread, waiting two hours is not an option. Vacuum cooling allows her to pack and ship almost immediately after baking.

Does Cooling Method Affect Shelf Life and Quality?

Have you ever noticed your bread getting moldy too quickly or losing its crustiness after packaging? The culprit might be the way you are cooling it.

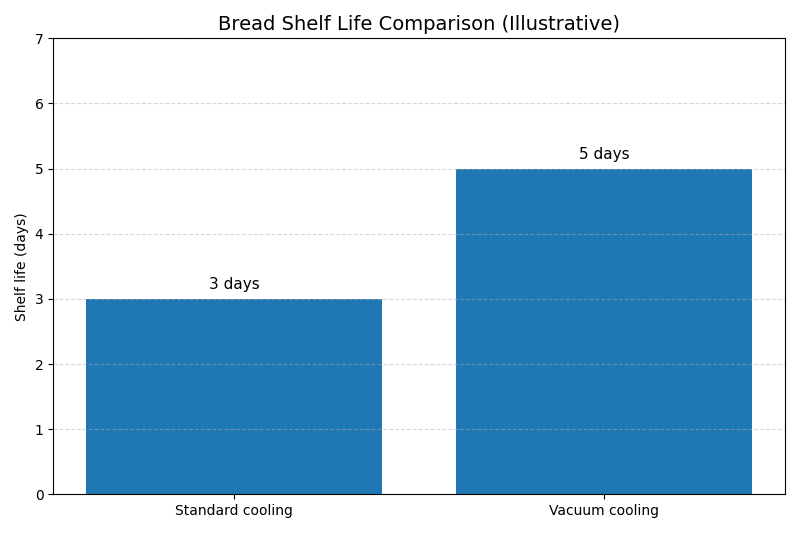

Vacuum cooling gelatinizes starches evenly and stops the "staling" process instantly, extending shelf life significantly. Spiral cooling often leaves residual heat, leading to condensation inside the bag and mold growth.

The Science of Freshness

Quality is where the battle is truly won. If you are selling to supermarkets or sensitive buyers like Norman in the US, shelf life is everything.

With Spiral Cooling, the bread cools from the outside in. The crust cools first, but the center remains hot for a long time. This temperature difference causes moisture to migrate from the center to the crust, making the crust soggy. Furthermore, between 60°C and 30°C is the "danger zone" where bacteria grow fastest. Spiral coolers keep bread in this zone for a long time.

Vacuum Cooling3 solves this physics problem. It cools the product evenly from the core to the surface.

- Crispier Crust4: The moisture evaporates outward, keeping the crust dry and crispy.

- Longer Shelf Life: By passing through the bacterial danger zone in seconds rather than minutes, you drastically reduce the initial bacteria count.

- Better Structure: The rapid cooling stabilizes the sponge structure of the bread, giving it more volume.

I once visited a client in Mexico, Carlos. He was losing money because his large batches of rolls were molding before they reached the store shelves. After switching to our vacuum system, he not only doubled his shelf life but also reduced the preservatives in his recipe.

Is Vacuum Cooling Too Expensive Compared to Spiral Systems?

You might be thinking, "Vacuum technology sounds high-tech, so it must be out of my budget." But have you calculated the cost of space and energy?

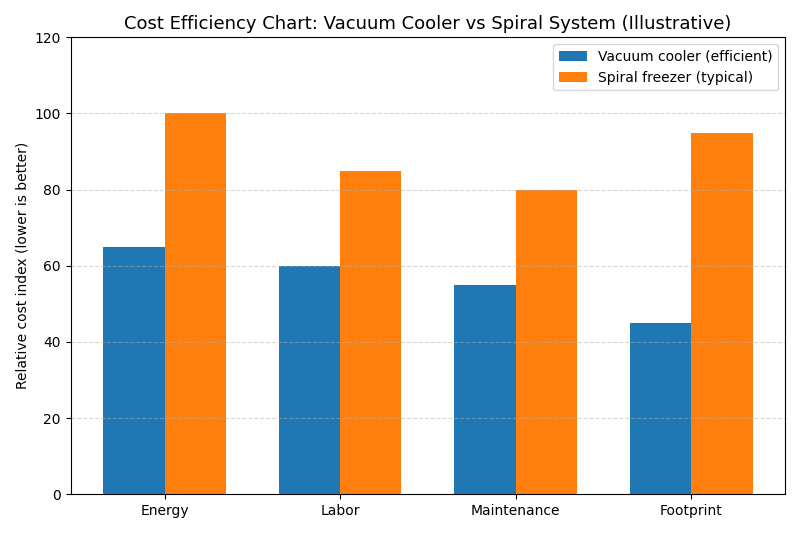

While the initial investment for vacuum coolers can be higher, they consume far less energy because they run for shorter periods. Spiral coolers require huge continuous energy to run fans and belts.

Analyzing the Total Cost of Ownership

It is easy to look at the sticker price and get scared. However, smart buyers look at ROI (Return on Investment5).

Spiral Cooling Costs:

- Space: These systems are massive. They take up valuable floor space that could be used for more ovens or packaging lines.

- Maintenance: They have hundreds of moving parts—belts, motors, bearings. Cleaning a spiral tower to meet HACCP standards is a nightmare and takes hours of labor.

- Energy: The fans must run constantly, often fighting against the ambient heat of the bakery.

Vacuum Cooling Costs:

- Space: A vacuum cooler is a compact box. It takes up 10% of the space of a spiral conveyor.

- Maintenance: As mentioned in our manual, maintenance is straightforward: check oil levels, inspect seals, and clean the chamber. There are no complex belts to scrub.

- Energy: The machine only consumes peak power during the few minutes of the cycle.

For a business growing quickly, saving space means you don’t have to rent a new factory. Saving energy increases your margin on every loaf of bread sold.

| Cost Factor | Spiral Cooling | Vacuum Cooling |

|---|---|---|

| Floor Space | High Cost (Huge footprint) | Low Cost (Compact) |

| Sanitation Labor | High (Hard to clean belts) | Low (Stainless chamber) |

| Energy Usage6 | Continuous High Load | Intermittent Load |

| Product Waste | Moderate (Slicing issues) | Low (Better structure) |

Conclusion

Spiral cooling is the traditional path, but vacuum cooling is the future of profitability. It saves space, cuts energy bills, and delivers a fresher product that your customers will love.

-

Understanding spiral cooling can help you appreciate its limitations compared to more efficient methods like vacuum cooling. ↩

-

Exploring vacuum cooling will reveal its advantages, making it a game-changer for bakeries aiming for efficiency. ↩

-

Explore how Vacuum Cooling can enhance food quality and shelf life, ensuring fresher products for consumers. ↩

-

Learn why a Crispy Crust is essential for bread quality and how it affects consumer satisfaction. ↩

-

Understanding ROI is crucial for making informed purchasing decisions and maximizing profitability. ↩

-

Exploring energy usage can reveal significant savings opportunities and enhance operational efficiency. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the