Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you wait for it to cool down? Every minute your product sits there, you are losing moisture, freshness, and potential profit.

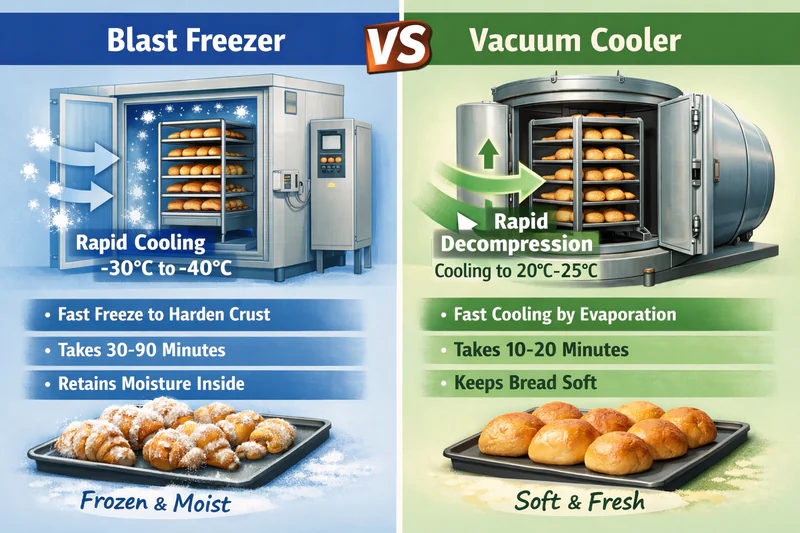

The choice depends on your end goal. If you need to freeze products for long-term storage, a blast freezer is necessary. However, if you want to cool fresh bread rapidly for immediate slicing and packaging while improving quality, a vacuum cooler is the superior, more efficient option.

Many of my clients, from large industrial factories to artisanal bakeries, get confused by these two technologies. They sound similar because they both lower temperatures, but they work in completely different ways. Let me walk you through the differences so you can make the best decision for your business.

How Do Speed and Efficiency Differ Between the Two?

Time is money in the bakery business. If your packing team is standing around waiting for bread to reach the right slicing temperature, you are burning cash on labor costs.

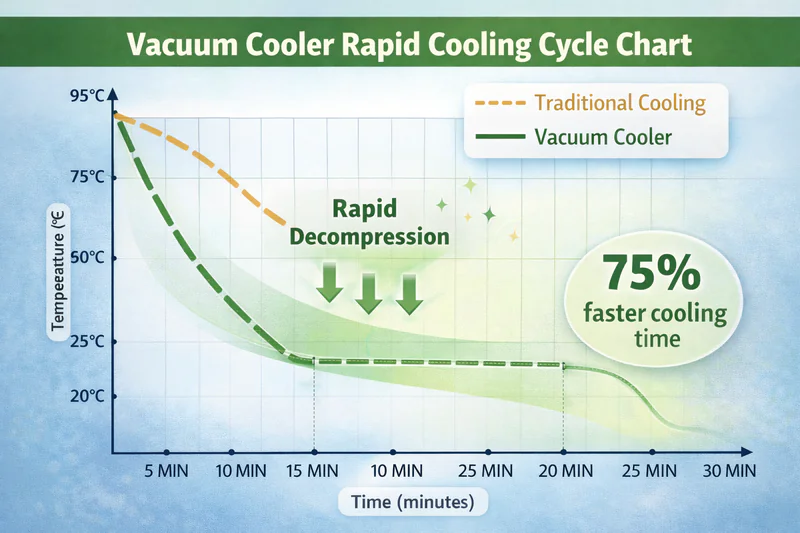

Vacuum coolers are incredibly fast, cooling bread from 100°C to 30°C in just 3 to 10 minutes. Blast freezers rely on blowing cold air, which is a much slower process, typically taking 90 minutes to 2 hours to achieve the same result for the core temperature.

The Physics of Speed

To understand why there is such a huge time gap, we have to look at how these machines remove heat. This is not just about a "stronger fan"; it is about physics.

Blast Freezers (The Outside-In Approach)1:

A blast freezer works by convection. It uses powerful fans to blow freezing cold air (often -30°C or lower) over the surface of your hot bread.

- The heat must travel from the center of the loaf to the crust.

- Then, the air must carry that heat away.

- Bread is like a sponge; it is an insulator. Heat does not like to move through it.

- This is why the crust gets freezing cold while the center stays warm for a long time. It is a slow fight against nature.

Vacuum Coolers (The Inside-Out Approach)2:

At my factory, Allcold, we design machines that use evaporation. We place the trolley of hot bread into a sealed chamber. We don’t blow air; we remove air.

- As the pressure drops, the boiling point of water drops.

- The moisture inside the bread starts to boil at a low temperature.

- This phase change (turning water into vapor) sucks a massive amount of heat out of the bread instantly.

- It happens everywhere at once—in the core and on the crust simultaneously.

I recently worked with a client in Vietnam who was using fans to cool his bread. He was waiting two hours before he could slice it. When we installed our AVCF-150 model, he was cooling 150kg of bread in just 10 minutes. That is not just an improvement; that is a revolution in his production schedule.

| Feature | Blast Freezer | Vacuum Cooler |

|---|---|---|

| Cooling Method | Cold Air Convection | Flash Evaporation |

| Typical Time (Bread) | 90 – 120 Minutes | 3 – 10 Minutes |

| Core Temperature | Slow to drop | Drops instantly |

| Energy Impact | Continuous running | Short cycles |

How Does Each Method Affect Product Quality and Shelf Life?

Have you ever bought a loaf of bread that looked great but felt dry and crumbly the next day? Or perhaps you have dealt with mold issues during the humid summer months?

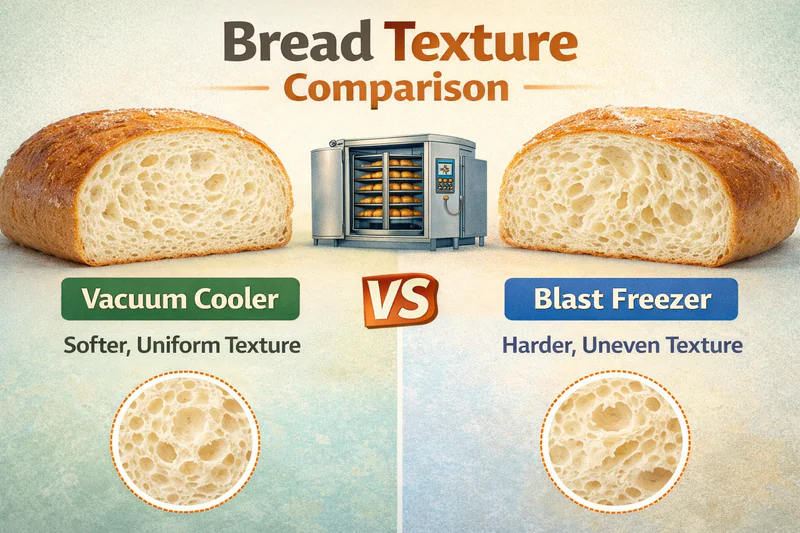

Vacuum cooling locks in moisture by gelatinizing starches and extending shelf life significantly. Blast freezers can sometimes dry out the crust or cause ice crystals to form if the product isn’t wrapped, damaging the texture of fresh baked goods.

The Battle for Freshness

Quality is usually the main concern for buyers like Norman in the US, who needs to supply supermarkets with consistent products.

The Moisture Problem in Blast Freezers:

When you put hot bread in a blast freezer, the dry, cold air strips moisture from the crust. This can lead to a hard, dry shell. However, the heat inside is still pushing moisture out. When you finally take the bread out and bag it, that residual heat trapped in the core releases moisture.

- Result: Condensation forms inside the plastic bag.

- Consequence: Soggy crusts and mold growth within days.

The Vacuum Advantage3:

In our vacuum coolers, we control the moisture loss perfectly. We even have a "Vacuum Delay" facility in our machines to handle products with different water contents.

- Uniformity: The cooling is uniform. There is no hot core and cold crust. The whole loaf is 30°C.

- Structure: The rapid drop in pressure helps "set" the structure of the bread. This gives you better volume and a nicer crumb texture.

- Shelf Life: Bacteria love the temperature range between 60°C and 30°C. A blast freezer keeps your bread in this "danger zone" for a long time. A vacuum cooler skips over this zone in seconds. This results in a much lower initial bacteria count, giving you days of extra shelf life without adding more preservatives.

I recall Carlos from Mexico asking me about this. He supplies large retail chains. His biggest headache was returns due to mold. By switching to vacuum cooling, he eliminated condensation in the bag, and his returns dropped to almost zero.

Which System Is More Energy Efficient?

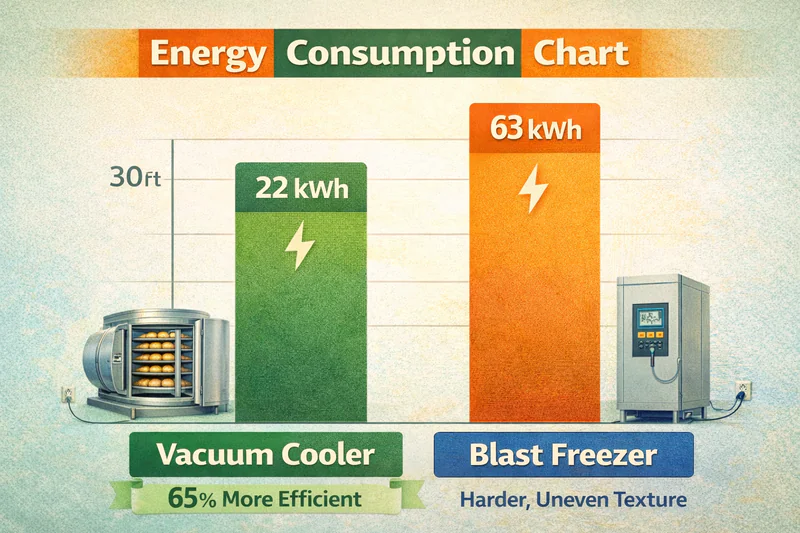

Energy bills are one of the biggest overheads in any bakery. You might think a high-tech vacuum machine uses more power, but the reality is often the opposite.

Blast freezers must run compressors and fans continuously for hours to remove heat. Vacuum coolers only consume peak power for a few minutes per cycle and automatically shut down when not in use, leading to massive energy savings.

Calculating the Real Cost of Cooling

Let’s look at the operational costs. I often show my customers the breakdown of electricity usage because it surprises them.

Blast Freezer Consumption4:

A blast freezer is a marathon runner. To cool a batch of bread, the large compressors and heavy-duty fans must run at full capacity for 1.5 to 2 hours. Even when the bread is removed, the room must be kept cold, so the system is always drawing power. It fights against the ambient heat of your bakery, which might be 30°C or 40°C.

Vacuum Cooler Consumption5:

A vacuum cooler is a sprinter.

- Standby: When you are loading the trolley, the machine is off.

- The Cycle: You press start on the touch screen. The vacuum pump and refrigeration unit kick in. They run hard, but only for roughly 10 minutes.

- The Stop: Once the bread hits 30°C, the cycle ends. Our machines have a "Start sequence/power save" feature. If the machine isn’t operated for a period, it automatically shuts down to save electricity.

For a standard 150kg batch:

- Blast Freezer: Might run a 15kW motor for 90 minutes.

- Vacuum Cooler: Runs a similar motor load, but only for 10 minutes.

The math is simple. You are paying for the time the machine is working. With vacuum cooling, that time is drastically reduced. Over a year, this difference can amount to thousands of dollars in savings, which goes straight to your bottom line.

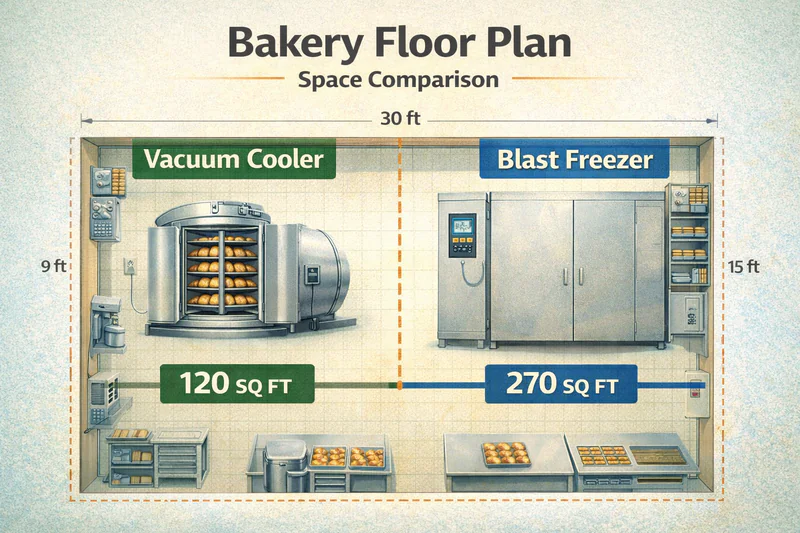

What About Space and Installation Requirements?

Is your bakery floor crowded? Do you have room to build a large insulated room, or do you need a compact solution that can fit into a tight corner?

Blast freezers require large insulated rooms and significant floor space for airflow. Vacuum coolers are compact, skid-mounted units that take up very little room and are often "plug and play," making them easier to install in existing production lines.

Footprint and Facility Impact

Space is a premium asset. If you are renting a factory in a city like Singapore or New York, every square meter costs you money.

The Blast Freezer Footprint6:

To build an effective blast freezing tunnel or room, you need:

- Insulated panels (walls and ceiling).

- Space for the evaporator units.

- Space for air to circulate around the trolleys (you cannot pack them too tight, or the air won’t flow).

- A dedicated floor with drainage.

This is a construction project. It disrupts your business, takes weeks to build, and once it is there, you cannot move it easily.

The Vacuum Cooler Footprint7:

Our machines, like the AVCF-150, are designed to be compact. The internal chamber fits two trolleys, but the external dimensions are tight (approx. 2.5m x 1.8m).

- Skid-Mounted: The whole unit sits on a steel base. If you move factories next year, you can put the vacuum cooler on a truck and take it with you.

- Installation: It is mostly "plug and play." You need a power supply (380V/3Phase) and a stable concrete floor. That’s it.

- Hygiene: Our chambers are made of stainless steel. There are no hidden corners or evaporator fins inside the food zone where mold can hide. You can hose down the inside of the chamber in minutes. Compare that to trying to clean the fans inside a blast freezer tower—it is a nightmare.

For a growing business, the flexibility of a vacuum cooler allows you to scale up without needing to acquire a new building. You can simply add another unit next to the first one.

When Should You Actually Choose a Blast Freezer?

I am a vacuum cooler manufacturer, but I will be honest with you. Vacuum cooling is not the answer for everything. There are specific times when a blast freezer is the right tool.

If your business model relies on selling frozen dough, frozen cakes, or products that need to be stored for months, you need a blast freezer. Vacuum coolers cool products down, but they are not designed to freeze them solid.

Understanding Your Business Model

The decision ultimately comes down to what you are selling.

The Case for Blast Freezer8s:

If you are a factory that produces raw dough balls or par-baked bread that needs to be shipped frozen to supermarkets, you must have a blast freezer.

- Freezing: Vacuum coolers can take bread down to about 0°C or slightly below, but they are not efficient at freezing a product solid to -18°C. The physics of evaporation slows down too much at those temperatures.

- High Fat/Sugar: Some very dense cakes or products with extremely high sugar/fat content might not react as well to the vacuum pressure.

The Case for Vacuum Coolers9:

If you are selling fresh bread, cooked foods, buns, sponge cakes, or ready-to-eat meals, vacuum cooling is the winner.

- Speed: You beat the competition to market.

- Quality: Your product tastes fresher for longer.

- Logistics: You can bake, cool, slice, and ship in the same morning.

The Hybrid Approach:

Some of my smartest clients use both. They use the vacuum cooler to drop the temperature from 100°C to 30°C in 5 minutes. Then, they move the product to a blast freezer to finish the freezing process.

Why do this? Because removing that first massive chunk of heat (100°C to 30°C) is the most energy-intensive part for a blast freezer. By letting the vacuum cooler handle the "heavy lifting," they reduce the load on their freezer, save electricity, and improve the texture of the bread before it freezes.

| Goal | Best Technology | Why? |

|---|---|---|

| Slice & Pack Fresh | Vacuum Cooler | Speed & Moisture Retention |

| Long-term Storage | Blast Freezer | Deep Freezing Capability |

| Reduce Bacteria | Vacuum Cooler | Skips "Danger Zone" fast |

| Frozen Dough | Blast Freezer | Need solid ice structure |

Conclusion

If you sell frozen goods, buy a freezer. But if you sell fresh bread and want to cut cooling time from hours to minutes, save energy, and improve shelf life, a vacuum cooler is the smartest investment you can make.

-

Learn about Blast Freezers and their unique cooling methods that preserve food quality while saving time in production. ↩

-

Explore the advantages of Vacuum Coolers to understand how they revolutionize food cooling processes, enhancing efficiency and quality. ↩

-

Explore how vacuum cooling can enhance bread quality and shelf life, reducing returns due to mold. ↩

-

Understanding the costs associated with blast freezers can help you optimize your energy usage and save money. ↩

-

Exploring vacuum cooler efficiency can reveal significant savings and operational benefits for your business. ↩

-

Learn about the critical role of blast freezers in preserving food quality and the challenges they present. ↩

-

Explore this link to understand how vacuum coolers can enhance efficiency and hygiene in food processing. ↩

-

Explore the advantages of blast freezers for food preservation and quality, crucial for businesses in the food industry. ↩

-

Learn how vacuum coolers enhance food freshness and speed up production, vital for competitive food businesses. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the