Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan loaves, and switching production lines wastes hours, leaving you wondering if you need separate machines for every single product type.

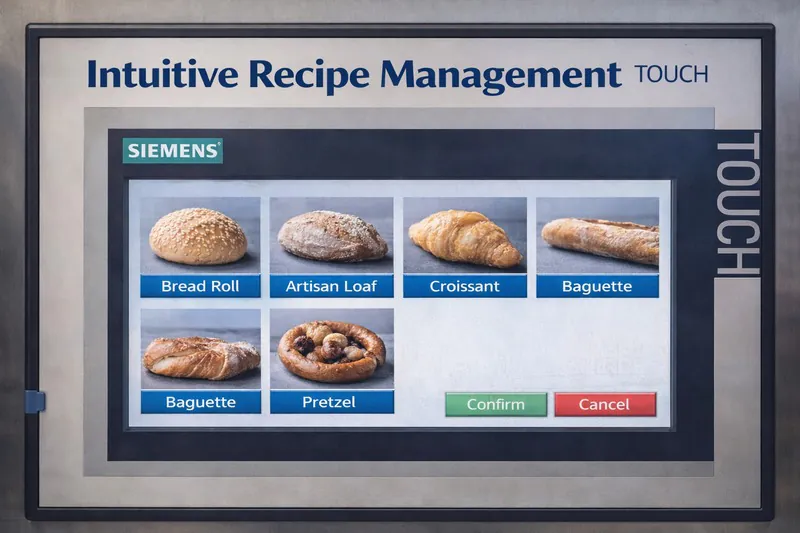

Our vacuum coolers utilize programmable Siemens touch screen controls to adapt to any product instantly. Whether you need a gentle "Vacuum delay" for high-hydration artisan bread or a rapid chill for standard rolls, one machine manages your entire SKUs with specific recipes.

I recently spoke with Sophia, a procurement manager for a central kitchen in Singapore. Her facility is a logistical nightmare. In the morning, they bake crusty baguettes that need to retain a specific moisture content. By afternoon, they are processing cooked foods and frozen dough that require rapid, deep chilling. Her old system was a bottleneck. She had to physically move racks between different rooms with different ambient temperatures. It was slow. It was inconsistent. And frankly, it was costing her money. She asked me, "Mila, can one machine really understand the difference between a sponge cake and a sourdough loaf?" The answer lies in the adaptability of modern vacuum technology. If you are running a facility that produces more than one type of product, you cannot afford a "one-speed-fits-all" solution. You need a partner that understands the nuance of dough. Let’s dive deeper into how customizable vacuum profiles allow you to consolidate your cooling into one efficient step.

Is Switching Between Different Dough Types Too Complex?

Your operators struggle to manually adjust valves and timers every time you change the product line. You fear that a setting designed for rugged sandwich bread will destroy the delicate structure of your high-end croissants, leading to collapsed products and financial waste.

With our Siemens touch screen interface, you don’t need to be an engineer to switch products. You can utilize the "Vacuum delay facility" to automatically detect and adjust for products with higher water yield resistance, ensuring uniform cooling for everything from dense rye to light sponges.

The Science of "Vacuum Delay" for Diverse Textures

Understanding Water Yield Resistance

In a multi-product bakery, the biggest challenge is that different doughs release moisture differently. A high-hydration artisan loaf holds water tightly in its gluten network. A standard bun might release it easily. If you apply a strong vacuum too quickly to a delicate product, you risk "flashing" the water into steam so violently that it tears the structure. We call this "flashing." It is the enemy of quality.

We solved this with the "Vacuum delay facility1" logic embedded in our systems. This feature is not just a timer. It is a smart control method. It is designed specifically for products with higher water yield resistance. By slowing down the pressure drop at critical moments, we allow the internal pressure to equalize gently. This ensures uniform cooling of the whole product load, regardless of how dense or delicate the item is.

Simplified Recipe Control

In a busy factory, simplicity is safety. You do not want your floor staff guessing parameters. Our systems utilize a Touch screen operator control2 powered by Siemens components. This interface allows you to monitor the vacuum level, product temperature, and time elapsed in real-time.

More importantly, the system is designed for "Automatic mode3." Your operator simply selects the correct program. Whether the cycle time needs to be fast for standard bread or extended for denser foods, the machine adapts automatically. You can protect these settings with an Operator level password4. This prevents unauthorized changes. This means you, as the manager, can set the specific cooling curve for "Product A" and "Product B." Your operator just hits "Start." This eliminates human error. It ensures that your baguette stays crispy and your sponge cake stays fluffy, back to back, on the same machine.

| Product Type | Challenge | Solution Feature | Benefit |

|---|---|---|---|

| Artisan Bread | High water retention; risk of bursting. | Vacuum Delay Facility | Preserves open crumb structure. |

| Standard Rolls | Needs speed; high volume. | Automatic Cooling Cycle | Fast throughput (approx. 10 mins). |

| Mixed Loads | Varied density on one trolley. | Uniform Cooling Logic | Consistent quality across the batch. |

Can You Manage Both Fresh Delivery and Frozen Storage Lines?

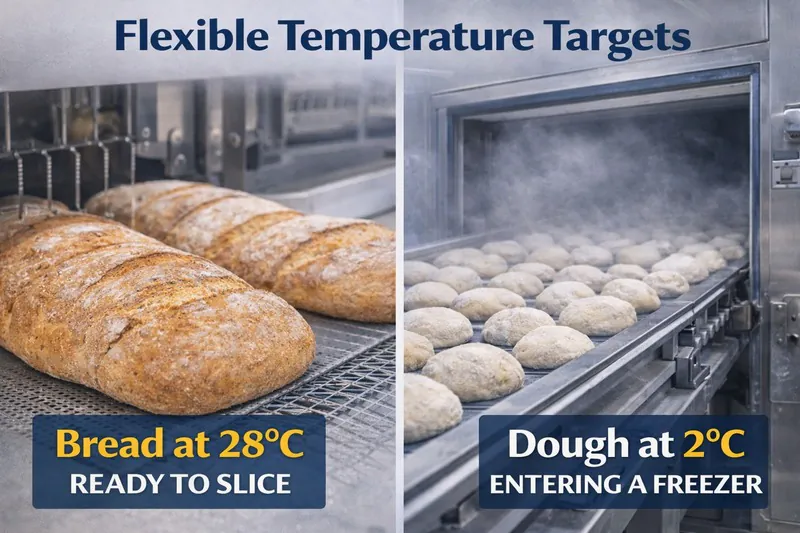

You run a hybrid facility: some bread goes to supermarkets fresh for slicing, while other dough goes to the freezer for long-term storage. Managing two different temperature targets creates logistical chaos and often overworks your blast freezers.

Our system gives you absolute control over the final core temperature. You can set a finish temperature of 28°C for slicing or drive it down to a "Low limit of -8°C" for frozen dough preparation, all within the same unit.

From Slicing to Freezing: Precision Control

Targeting the Slicing Temperature5

For fresh bread, the goal is to cool it down just enough to slice it without gumming up the blades. Typically, bread comes out of the oven at a core temperature near 100°C. For immediate packaging or slicing, you need to bring this down rapidly. Our standard specifications allow you to hit a "Temp SV (setting value)" precisely. This allows you to achieve a "Goldilocks" zone—cool enough to slice (around 30°C), but warm enough to retain freshness. This process is incredibly fast. It prevents the staling window that occurs during slow, ambient cooling.

Deep Chilling for Frozen Dough6

However, if your facility also produces frozen dough or par-baked goods, 30°C is too hot. Putting warm product into a blast freezer creates ice crystals. These crystals damage the gluten structure. They ruin the quality of the final bake.

Our machines are versatile enough to handle this. The system settings allow for a much wider range. The control system supports a low limit of -8°C. This allows you to perform a "pre-freeze" or deep chill.

For example, you can target a finish temperature of +3°C or even lower. By bringing the core temperature down to near-freezing in the vacuum chamber, you significantly reduce the thermal load on your blast freezer. The refrigeration units are robust enough to handle this load. We verify that the suction and discharge pressures are stable to handle these loads. This flexibility means one parking spot on your floor handles both your fresh daily deliveries and your long-term frozen stock. You save energy on your blast freezer. You improve the texture of your frozen goods. It is a win-win for hybrid production lines.

Is Your Staff Training Keeping Up with High Turnover?

Bakery floors often see high staff turnover. You worry that new, inexperienced workers might mishandle complex machinery, leading to safety accidents or broken equipment that halts your entire production schedule.

We design for safety and simplicity. From visual "Entanglement Hazard" pictograms to automated door safety checks, our machines are built to guide even temporary staff safely through the process, minimizing training time and maximizing safety.

Safety Features for a Busy Floor

Visual Communication

In a multi-product facility, chaos is common. Workers are moving fast. We believe the machine should communicate clearly. That is why we utilize clear pictograms on the machine body. For example, if a label is damaged or illegible due to wastage, it must be replaced immediately. We use standard symbols for "Entanglement Hazard" to warn against touching moving parts, and "Extreme Temperature" warnings for hot pipes. These are not just stickers. They are essential tools for a multilingual or temporary workforce. A new worker does not need to read a complex manual to know where the danger zones are.

Automated Safety Protocols

Beyond labels, the machine actively protects the user. The system includes strict protocols before a cycle can start. For instance, the chamber door must be closed properly. If the door gap is not adjusted correctly, or if the door is not sealed, the vacuum pump simply will not start. The troubleshooting guide explicitly states that if the "Compressor not start," one of the first checks is the safety interlocks.

Furthermore, we emphasize the rule: "Keep nobody in the vacuum chamber when the machine is in use." This sounds obvious, but in a large industrial cooler, safety protocols are vital. Our system ensures that the vacuum cannot be pulled if safety conditions aren’t met. This gives you peace of mind. You know that even on your busiest days, with your newest staff, the machine will not operate unless it is safe to do so.

How Do You Prevent Downtime When Every Minute Counts?

In a high-volume bakery, a machine breakdown is a disaster. You cannot afford to wait days for a technician while pallets of hot bread go stale. You need a system that is easy to maintain and quick to troubleshoot.

Our vacuum coolers are designed with transparent maintenance needs. From checking the oil levels in the vacuum pump to cleaning the air condenser, we provide a clear "Regular Maintenance" checklist that your internal team can follow to keep production running smooth.

Proactive Maintenance vs. Reactive Panic

The Daily Checklist

Reliability is not magic. It is discipline. We make that discipline easy. For a multi-product facility running continuously, we recommend a simple Maintenance Checklist7. This includes checking the oil level of the vacuum pump regularly. If the oil is low, the vacuum degree won’t be low enough, and your cooling times will extend.

We also emphasize the cleaning of the air condenser8. In a bakery, flour dust is everywhere. It clogs condenser fins. If the condenser is blocked, the cooling water or air cannot flow smoothly. This leads to high pressure alarms and stops the machine. Our manual advises regular cleaning to ensure the "suction/discharge pressure is stable." A clean machine is a running machine.

Troubleshooting Made Simple

When things do go wrong, you need answers fast. Our systems come with a clear Troubleshooting guide.

For example, if you see "No reduction of goods temperature," the guide points you to three things: Is the vacuum degree low enough? Is the temperature probe broken? Is the refrigeration unit failing?

If the "Compressor not start," it prompts you to check for power cuts or low pressure. This logic allows your on-site maintenance team to fix 90% of issues without waiting for an external engineer. We also advise checking for "frosting on the expansion valve." This visual cue helps diagnose refrigerant issues instantly. By empowering your team with this knowledge, we turn potential days of downtime into minutes of quick fixes.

| Issue | Potential Cause | Quick Fix |

|---|---|---|

| High Temp Results | Vacuum degree not low enough. | Check pump oil; Check door seal. |

| Compressor Stalls | High pressure / Dirty condenser. | Clean the air condenser fins. |

| System Won’t Start | Door not closed well. | Adjust door gap/sensor. |

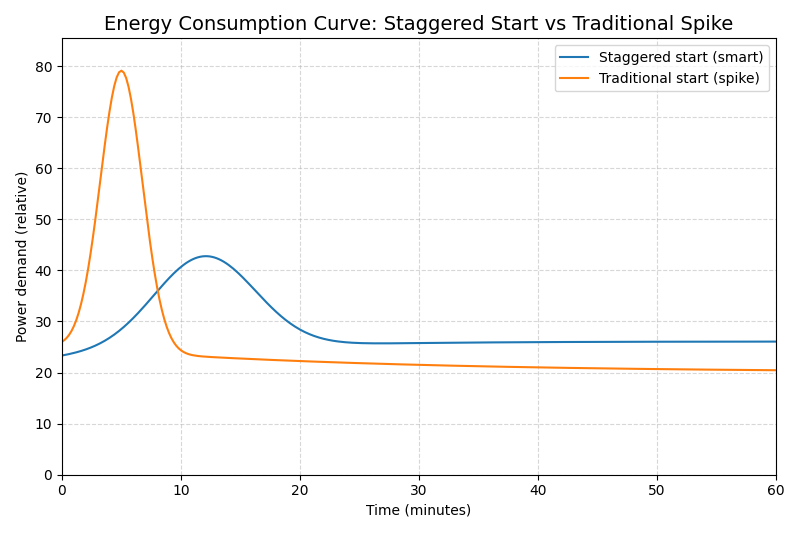

Will Variable Batch Sizes Spike Your Energy Costs?

Some days you run full pallets to meet holiday demand; other days, you are just running a few test trolleys. You fear running a large industrial machine for small batches will destroy your profit margins through peak electricity bills.

We integrated a smart "power save" logic that automatically shuts down the machine during gaps in production. Combined with a staggered "start sequence," this ensures you only pay for the cooling you actually use, regardless of batch frequency.

Intelligent Power for Inconsistent Production

The "Plug & Play" Efficiency

In a multi-product facility, production isn’t always continuous. You might have a gap of 20 minutes while switching from baking muffins to baking loaves. Traditional cooling tunnels run their fans constantly. They waste money heating up the room.

Our vacuum coolers feature a "Start sequence/power save9" mode. When the vacuum cooler has not been operated for a period of time, the machine will automatically shut down to save electricity usage. It goes into a sleep mode. It consumes negligible power.

When your next trolley is ready, you simply press the "Start" button on the touch screen. It wakes up immediately. This feature alone can save significantly on your monthly utility bill if your production flow has gaps.

Preventing Peak Demand Charges

Furthermore, we use high-quality components like Bitzer compressors10 and vacuum pumps, managed by a smart start-up logic.

Instead of turning on all these powerful motors at once—which causes massive electrical spikes—the system uses a "Start sequence." It staggers the activation of the motors. It runs the cooling pump, then the vacuum pump, and finally the compressor in an orderly fashion. This minimizes the full load of electrical power drawn upon startup.

We also utilize "High efficiency evaporator and air cooled condenser" designs. This ensures that for every kilowatt of power you pay for, you get maximum cooling capacity. We advise checking that the refrigerant levels are sufficient (High pressure at 4MPa, Low at 0.8MPa) to maintain this efficiency. This ratio is crucial for keeping your operational costs low, even when your production schedule is unpredictable.

Conclusion

A multi-product bakery needs a cooling system that adapts, not one that restricts. By leveraging our "Vacuum delay facility" for texture control, utilizing flexible temperature targets down to -8°C, and relying on smart "power save" features, you can run a diverse, high-quality production line with a single, efficient machine.

-

Explore how the Vacuum delay facility enhances baking quality by managing moisture release effectively. ↩

-

Learn how a Touch screen operator control streamlines processes and reduces human error in baking. ↩

-

Discover the advantages of Automatic mode for efficiency and consistency in baking operations. ↩

-

Find out how an Operator level password secures settings and enhances operational safety in bakeries. ↩

-

Understanding the ideal slicing temperature can enhance your bread quality and slicing efficiency. ↩

-

Exploring deep chilling techniques can improve your frozen dough’s texture and overall baking results. ↩

-

Explore this link to understand how a Maintenance Checklist can enhance operational efficiency and prevent costly downtimes. ↩

-

Learn why regular cleaning of the air condenser is crucial for maintaining optimal performance and preventing equipment failures. ↩

-

Explore how the Start sequence/power save mode can drastically reduce energy costs in production facilities. ↩

-

Learn about the advantages of Bitzer compressors and how they enhance efficiency in industrial cooling applications. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the