Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer heat begins its assault. You’re in a desperate race against time, knowing that a portion of your hard work will wilt and spoil before it ever reaches a paying customer.

This isn’t just frustrating; it’s a direct hit to your income. Every crate of produce you lose is money vanishing into thin air. It feels like you’re stuck, unable to expand your sales beyond the immediate local market because your product’s freshness just doesn’t last.

Yes, they absolutely can. The affordability of a vacuum cooler for a small farm isn’t in a low price tag, but in its rapid return on investment. Modern, compact models are specifically designed for smaller operations, and they pay for themselves by eliminating spoilage, opening new markets, and enabling premium pricing.

I’ve spoken with many small farm owners who initially believed this technology was only for the giant agricultural corporations. They saw it as a luxury they could never afford. But the reality is that a vacuum cooler is one of the most powerful strategic tools a small farm can invest in to level the playing field. Let’s run the numbers and see how it works.

What is the Real Cost of Not Owning a Vacuum Cooler?

When you look at the price of a machine, it’s easy to get sticker shock and end the conversation there. But the most successful farmers I know ask a different question: "What is it costing me not to have this?" You are already paying a "spoilage tax" every single day, and it’s likely much higher than you think.

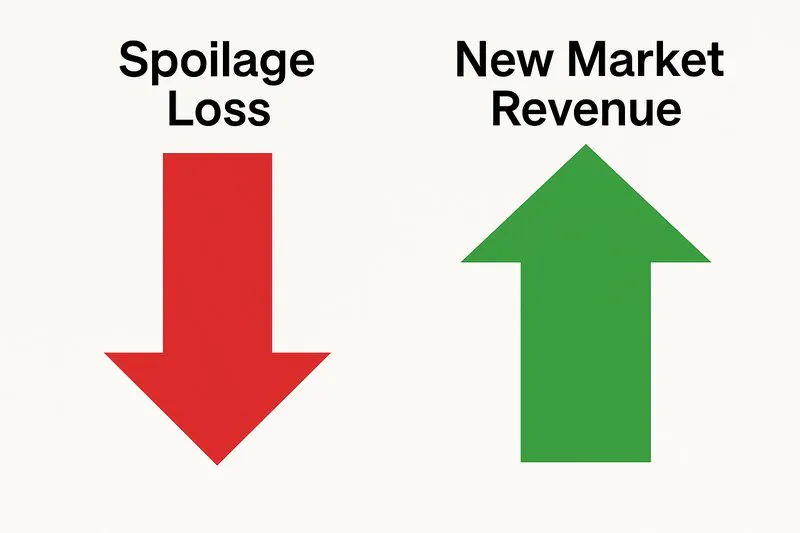

This hidden tax shows up in many ways: the produce you have to discard, the lower price you accept for less-than-perfect vegetables, and the customers you can’t sell to because they are too far away. It’s a constant drain on your potential profit.

The real cost of not owning a vacuum cooler is the perpetual loss of revenue from spoilage (often 10-25%), the inability to access more profitable distant markets, and the missed opportunity to command premium prices for superior, longer-lasting quality. This accumulated loss often surpasses the machine’s cost in just 1-2 seasons.

A Simple ROI Calculation

Let’s make this tangible. A business-savvy buyer like Norman thinks in spreadsheets, and as a small business owner, you should too. Let’s imagine you are a small farmer named Leo.

Leo has 2 acres dedicated to high-value organic lettuce.

- Yield per acre: 20,000 heads of lettuce

- Total Harvest: 40,000 heads

- Price per head: $1.50

- Total Potential Revenue: $60,000

Without a vacuum cooler1, Leo faces a conservative 15% spoilage rate2 due to heat, wilting during transport, and reduced shelf life at the farmers’ market.

- Loss Calculation: 40,000 heads * 15% = 6,000 heads lost

- Lost Revenue: 6,000 heads * $1.50/head = $9,000 lost per season.

Now, let’s say a compact, one-pallet vacuum cooler suitable for Leo’s farm costs $30,000. That seems like a lot. But by eliminating that spoilage, he immediately adds $9,000 back to his bottom line. Furthermore, because his lettuce is now demonstrably crisper and lasts 5-7 days longer, he can approach high-end grocery stores and restaurants in the next city, who are happy to pay a premium. He secures a new contract, selling 25% of his crop at a premium of $0.25 per head.

- New Premium Revenue: (40,000 heads 25%) $0.25 premium = $2,500 in new profit.

- Total Annual Gain3: $9,000 (saved loss) + $2,500 (new profit) = $11,500 per season.

| Investment & Return Component | Calculation | Financial Impact |

|---|---|---|

| Initial Investment | Machine Price | -$30,000 |

| Year 1: Spoilage Eliminated | 15% of $60,000 revenue | +$9,000 |

| Year 1: Premium Pricing | $0.25 premium on 10,000 heads | +$2,500 |

| Year 1: Net Position | -$30,000 + $11,500 | -$18,500 |

| Year 2: Total Gain | +$11,500 | -$7,000 |

| Year 3: Total Gain | +$11,500 | +$4,500 (Payback Achieved) |

In this realistic scenario, the machine fully pays for itself in under three seasons. From then on, that extra $11,500 (and more, as he grows) is pure profit, year after year. The real cost is the $9,000+ you are guaranteed to lose every year you don’t have one.

Where Would a Compact Vacuum Cooler Even Fit on My Farm?

When you hear "vacuum chamber," you might picture a massive, room-sized piece of industrial equipment that requires a dedicated concrete pad and a team of engineers to install. For a small farm with a crowded barn or a simple packing shed, that’s an impossible thought.

This mental image is one of the biggest barriers for small growers. The fear is that the infrastructure requirements are just as prohibitive as the price. You don’t have a spare warehouse, and you certainly don’t have access to heavy-duty industrial power lines.

Modern vacuum coolers for small farms are compact, self-contained units. Many models have a footprint roughly the size of two standard pallets and are designed for "plug-and-play" installation, often capable of running on the single-phase power readily available on most farms.

The New Generation of Farm-Ready Coolers

The image of the giant, complex vacuum cooler is decades out of date. At Allcold, we recognized that small farms are the backbone of the fresh food supply chain, and we’ve engineered solutions specifically for their needs. Let’s break down what "compact4" really means.

Footprint and Mobility

A typical one-pallet vacuum cooler is designed to be space-efficient. The entire system—chamber, vacuum pump, and refrigeration unit—is often built onto a single, heavy-duty steel skid. The dimensions are roughly 2.5 meters long by 1.5 meters wide (about 8 feet by 5 feet). This means if you have enough space on your packing floor to place two pallets side-by-side, you have enough space for a vacuum cooler. Because they are skid-mounted, they are not a permanent installation. You can move them with a standard forklift, allowing you to reconfigure your packing shed as your business grows.

Power and Utilities

This is a critical point for rural operations. Many small farms don’t have access to the 480-volt, 3-phase power that large industrial machines require. We and other manufacturers have developed models that run on 220/240-volt single-phase power5, which is the same type of power used for a residential clothes dryer or a well pump. This is a massive breakthrough. It means no expensive calls to the utility company to run new lines and install transformers. For cooling the refrigeration system, many compact models use simple air-cooled condensers, just like a home air conditioner, eliminating the need for complex water lines or cooling towers. This "plug-and-play" design philosophy means installation is simple: place the machine, connect the power, and you’re ready to start cooling.

Ease of Use

Just as the hardware has been simplified, so has the software. These machines aren’t run by complex industrial computers. They use simple, intuitive touchscreen controls6 (PLCs). You can select a pre-set program for "Lettuce" or "Herbs," press a single "Start" button, and the machine will run the entire cycle automatically. This means you don’t need to hire a specialized technician to operate it. You or any of your trained farmhands can become expert operators in a single afternoon.

How Does This Machine Help Me Grow My Business?

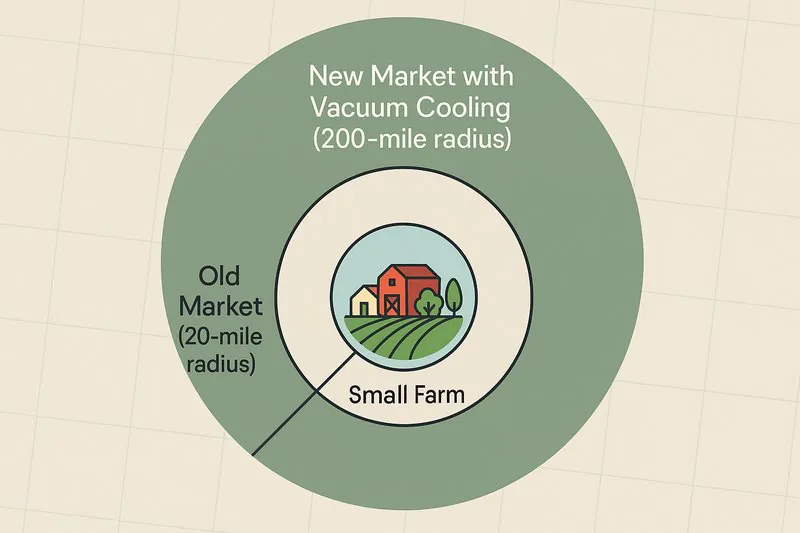

Right now, your business is defined by the short life of your product. Your sales radius is limited to how far you can drive in a few hours. You sell to customers who will use the produce immediately. This severely limits your growth potential.

This limitation keeps you in a cycle of small-scale sales, competing with dozens of other local growers for the same limited pool of customers at the farmers’ market. You’re a price-taker, not a price-maker.

A vacuum cooler fundamentally transforms your business model. It turns a highly perishable crop into a stable product with a reliable shelf life, allowing you to break out of your local market and begin competing for larger, more profitable contracts with regional distributors, grocery chains, and restaurant groups.

From Local Farmer to Regional Supplier

This isn’t just about reducing waste; it’s about unlocking entirely new streams of revenue that were previously impossible to access. This is how small farms scale up and become enduringly profitable businesses.

Accessing Wholesale and Retail Markets

A buyer for a regional grocery chain, like our friend Norman, has a checklist, and "consistent shelf life7" is at the very top. He cannot risk stocking his shelves with lettuce that will wilt in two days. When you can prove that your vacuum-cooled produce reliably lasts for 7-10 days, you are suddenly speaking his language. You can now bid on contracts to supply multiple stores in his chain. This means larger, predictable orders and a stable revenue base that isn’t dependent on the foot traffic at a single farmers’ market. You can ship your produce on a refrigerated truck to a distribution center 150 miles away, confident it will arrive in perfect condition.

Becoming a Premium Restaurant Supplier

Chefs at high-end restaurants, who a procurement manager like Sophia might supply, are obsessed with quality. They want the crispest lettuce, the most vibrant herbs, and the freshest broccoli. When you can deliver produce that has that "just-picked" texture and flavor days after harvest, you become an invaluable partner. You are no longer just a commodity supplier; you are a provider of premium ingredients8. This allows you to command a significantly higher price for your product. You can build a brand around the "hydro-cooled for superior freshness9" concept, creating a story that justifies your premium and builds a loyal following among quality-conscious chefs.

Reducing Labor and Increasing Efficiency

Think about the time your team spends sorting through harvested produce, picking out the slightly wilted heads that you can’t sell. Think about the stress of having to sell everything on Saturday before it goes bad on Sunday. A vacuum cooler10 removes this pressure. It gives you a buffer of several days. This means you can harvest more efficiently, pack with confidence, and spend more of your valuable time on sales and business development, not on damage control.

Conclusion

For a small farm, a vacuum cooler is not a cost; it’s a declaration of ambition. It’s the single most effective tool for breaking the cycle of spoilage and market limitation. It allows you to sell more of what you grow, sell it for a better price, and sell it to more people. It’s the key to growing your farm into a thriving business.

-

Explore how vacuum coolers can significantly reduce spoilage and enhance product quality for farmers. ↩

-

Understanding spoilage rates can help farmers like Leo minimize losses and maximize profits. ↩

-

Discover methods to calculate total gains from investments, crucial for making informed business decisions. ↩

-

Understanding the term ‘compact’ is crucial for small farms looking to optimize space and efficiency in their cooling solutions. ↩

-

Exploring the advantages of this power type can help small farms save on installation costs and improve operational efficiency. ↩

-

Discover how user-friendly controls can empower farm workers and streamline operations, making cooling easier and more efficient. ↩

-

Understanding consistent shelf life can help farmers meet market demands and secure contracts with retailers. ↩

-

Exploring how to supply premium ingredients can elevate a farm’s brand and profitability in the restaurant sector. ↩

-

Discovering the hydro-cooling process can help farmers market their produce effectively and attract quality-conscious buyers. ↩

-

Learning about vacuum coolers can enhance efficiency and reduce waste, leading to better business outcomes for farmers. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But

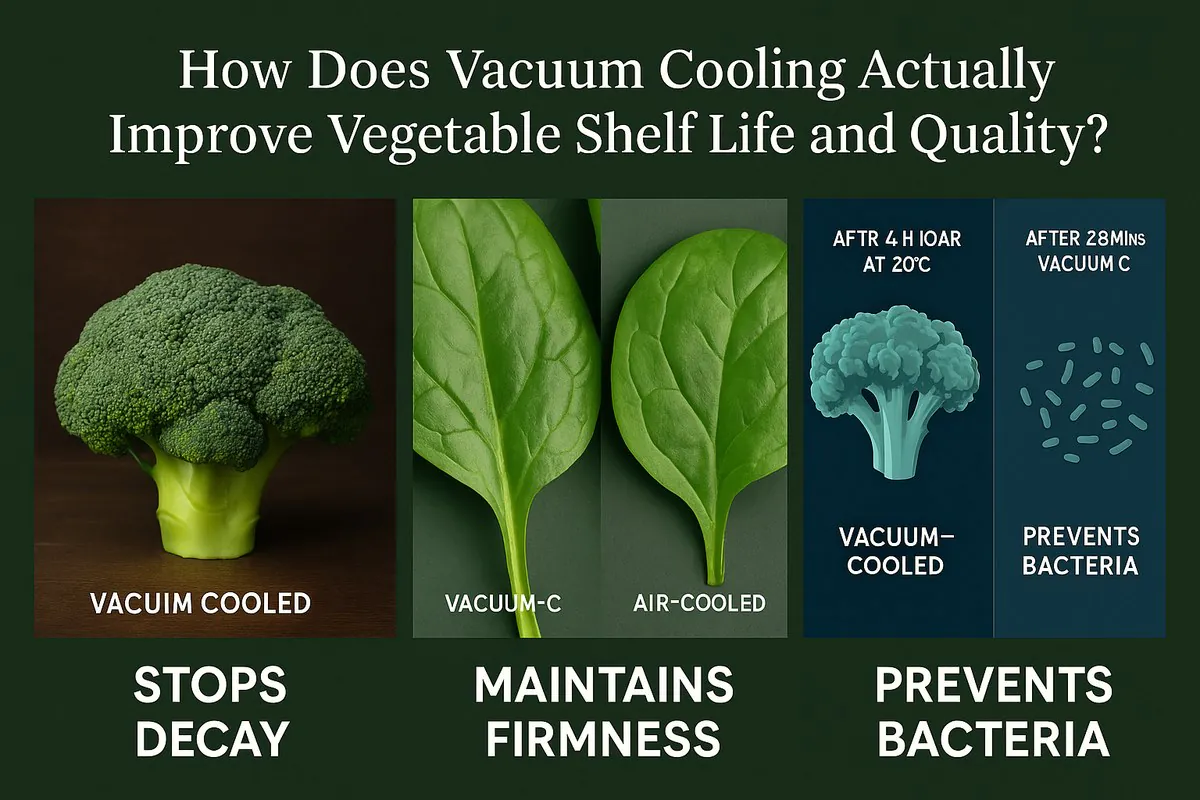

How Does Vacuum Cooling Actually Improve Vegetable Shelf Life and Quality?

You’ve done the hard work. Your harvest is in, and the vegetables look perfect—crisp, vibrant, and full of life. But