Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy as they cool on the rack. You struggle with the delicate balance of retaining moisture without creating a dense, wet crumb that customers reject.

The secret to cooling specialty breads without collapse lies in the "Vacuum delay facility" found in our AVCF systems. This feature automatically adjusts the pressure drop for products with high water yield resistance, ensuring the bread structure stabilizes before it cools completely.

I have spent years talking to bakers who specialize in "difficult" doughs—from high-hydration sourdoughs to fragile gluten-free mixes. The story is always the same: you master the mix, you master the bake, but you lose the quality during the cooling phase. Traditional cooling allows starch retrogradation to happen slowly, often resulting in that dreaded gummy texture. Recently, when designing systems for clients in Vietnam and Poland, we focused specifically on this issue. The solution isn’t just "fast cooling"; it is "smart cooling." Let’s look at why the specific engineering of modern vacuum coolers is the game-changer for specialty baking.

Why Do Specialty Breads Collapse During Standard Cooling?

You fear that using a powerful vacuum machine will literally explode your fragile gluten-free loaves. You worry that the rapid pressure drop will tear apart the delicate starch network that replaces gluten, leaving you with crumbs instead of slices.

We solved the "explosion" risk by integrating a "Vacuum delay facility" as standard equipment. This allows the system to pause or slow the pressure drop automatically, specifically catering to products with high water yield resistance to ensure the whole load cools uniformly without structural damage.

The Science of the "Vacuum Delay"

When we quote systems for clients handling sensitive products—like our recent project for Steamed Rice in Poland or Bread in Vietnam—we don’t just sell a freezer; we sell a pressure management system. Specialty breads, especially gluten-free1 ones, hold water differently than wheat breads. If you drop the pressure too fast, the water flashes to steam violently, ripping the bread apart because there is no gluten network to hold it together.

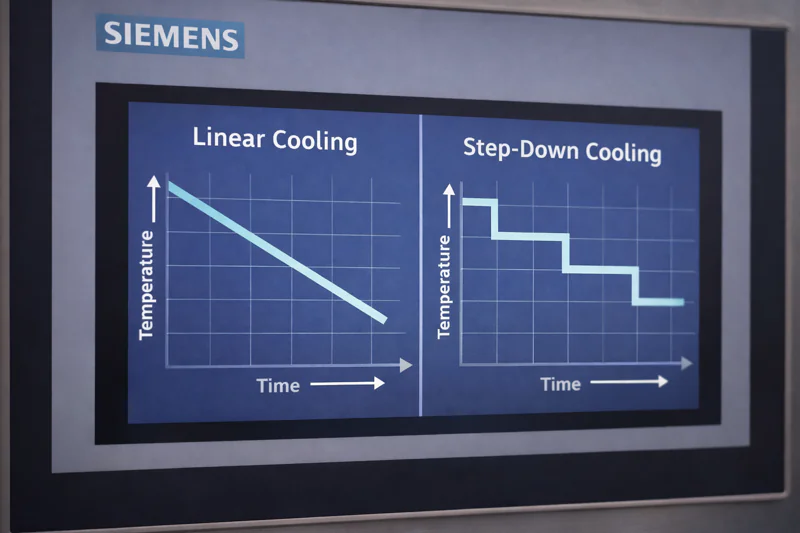

To prevent this, our machines include a specialized "Vacuum delay facility2." This is not a manual toggle you have to guess at; it operates based on the physics of the product. The logic is designed for products with higher water yield resistance. This means the machine senses the resistance of the moisture leaving the product and adjusts the vacuum pump’s intensity accordingly. By stepping down the pressure gently, we allow the starch structure to set and harden before the aggressive cooling takes over. This ensures uniform cooling of the whole product load, preventing the center from collapsing while the crust stays intact. It changes the cooling process from a physical shock to a controlled environment, preserving the volume you achieved in the oven.

| Feature | Standard Cooling | Allcold Vacuum Delay | Benefit for GF Bread |

|---|---|---|---|

| Speed | Slow (Hours) | Fast (~10-25 mins) | Stops starch retrogradation instantly. |

| Pressure | Atmospheric | Controlled/Stepped | Prevents structure collapse and cracking. |

| Uniformity | Outside-In | Uniform Whole Load | No soggy centers or wet bottoms. |

| Control | None | Automatic Delay | Adaptable to different flour blends. |

Can You Lock in Freshness Without "Sweating"?

You are tired of packaging your bread only to find condensation inside the bag the next day. You know that waiting for the bread to reach room temperature takes hours of valuable floor space and exposes your product to mold spores in the air.

Our systems take bread from a core temperature of 100°C down to a finish temperature of 28°C in roughly 10 minutes. This rapid transition prevents the "danger zone" where bacteria grow, allowing you to slice and pack immediately without condensation risks.

Precision Temperature Management3

In the specialty bread market, shelf life4 is everything. Gluten-free products often stale faster or mold quicker due to higher moisture content. The traditional method of leaving racks in a hallway is inconsistent. On a hot day, it takes too long; on a cold day, the crust cracks.

In our technical specifications for recent projects, the bread goes in at a temperature of 100°C, directly from the oven. The target is a finished cooled temperature of around 28°C to 30°C. Achieving this massive drop in a cooling cycle time of around 10 to 15 minutes does something magical for the crumb. It halts the movement of water. By stopping the evaporation process precisely at the slicing temperature, we keep the necessary moisture inside the starch lattice, keeping the bread soft, but we remove the excess free water that causes mold. You can even set specific targets; while the machine allows limits between +2°C and -8°C, for bakery products we typically aim for that sweet spot of 25°C to 30°C. This precision is impossible with fans or air conditioning, and it is the key to extending shelf life without preservatives.

| Parameter | Specification | Why it matters for Specialty Bread |

|---|---|---|

| Start Temp | 100°C | Directly from oven to cooler, saving space. |

| End Temp | 28°C – 30°C | Perfect slicing temperature immediately. |

| Cycle Time | ~10 Mins | Maximizes production throughput significantly. |

| Target Setting | Adjustable | Customize for different hydration levels. |

Is This Technology Too Fragile for a Hot Bakery?

You operate in a high-heat environment, perhaps with ovens running 24/7, and you worry that sensitive cooling equipment will overheat. You cannot afford to have a machine trip its safety breakers every time the ambient temperature rises.

We build our coolers for extreme conditions. Designed for a maximum ambient temperature of +52°C, our units use high-efficiency air-cooled condensers and top-tier Bitzer compressors to ensure consistent performance even in the hottest kitchens.

Built for the Bakery Environment

Bakeries are hot. It sounds obvious, but many machinery suppliers forget this. A machine tested in a cool lab will fail in a bakery where the ambient temperature hits 40°C. When we designed the AVCF-600 series and the AVCF-150 units, we explicitly engineered them for a maximum ambient temperature of up to +52°C.

This reliability comes from the components we choose. We don’t use generic parts that might fail under stress. We use Bitzer Compressors5 from Germany and Leybold Vacuum Pumps6. These are the workhorses of the industry. Furthermore, to handle the dust and flour in the air, we emphasize maintenance in our design. Our manual explicitly outlines steps for overall hygiene maintenance and ensures the air-cooled condenser is supplied to minimize KW rating while maintaining efficiency. We also include Phase Protection by Carlo Gavazzi to guard against the dirty power supplies or voltage fluctuations often found in industrial zones. This means your specialty bread production doesn’t stop just because it’s a hot summer day; the machine keeps running.

| Component | Brand/Spec | Origin/Detail | Reliability Factor |

|---|---|---|---|

| Compressor | Bitzer | Germany | Handles high load and heat effortlessly. |

| Ambient Limit | +52°C | – | Won’t overheat in summer production peaks. |

| Vacuum Pump | Leybold | Germany | Consistent pressure draw every cycle. |

| Protection | Carlo Gavazzi | Switzerland | Protects electronics from power spikes. |

Is It Complicated to Operate for Daily Staff?

You worry that introducing "aerospace technology" to your bakery will confuse your staff. You don’t want to be the only person who knows how to run the machine, tethering you to the factory floor forever.

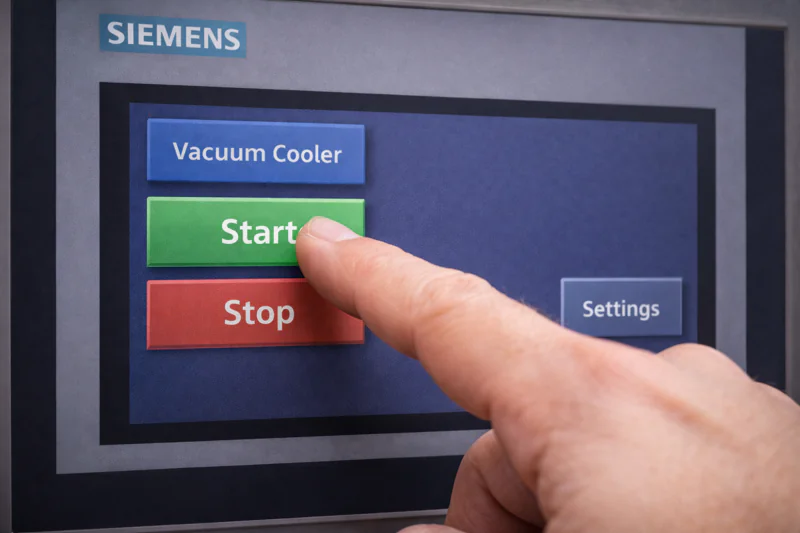

We prioritized simplicity with a Siemens Touch Screen interface. Operators can simply close the door and press "Start" for an automatic cycle. The screen displays vacuum levels, temperature, and time elapsed clearly, making it as easy to use as a microwave.

Smart Automation for Consistent Results

Consistency is the hardest part of scaling specialty bread production. If one shift operator cools the bread for 15 minutes and another for 20, your product quality changes. We solved this by digitizing the process. Our units feature a user-friendly touch screen operator control powered by Siemens.

This isn’t just a display; it’s a command center that simplifies complex physics. The facility allows simple operation of the vacuum cooler where data like vacuum level, product temperature, and time elapsed are displayed throughout the cycle. For daily use, your staff can use the "Auto screen": simply close the door and press the "Start" button. The machine runs, stops, deflates, and drains automatically when the target temperature is reached. There is no guesswork involved. If a problem arises, the system even provides a troubleshooting assist system. This "Plug & Play7" approach ensures that even temporary staff can produce perfect, gummy-free gluten-free bread every single shift without needing an engineering degree.

| Control Feature | Function | Benefit for Staff |

|---|---|---|

| Interface | Siemens Touch Screen8 | Intuitive, visual control reduces errors. |

| Auto Mode | One-touch Start | No manual adjustments needed per batch. |

| Info Display | Temp/Time/Vacuum | Real-time monitoring for quality assurance. |

| Safety | Auto-Shutdown | Saves power when idle and ensures safety. |

Conclusion

Vacuum cooling is no longer just for standard wheat rolls; it is a necessity for specialty baking. By utilizing the "Vacuum delay facility" to protect fragile structures and high-performance Bitzer compressors to withstand heat, Allcold systems ensure your gluten-free bread cools from 100°C to 28°C perfectly every time, eliminating the gummy texture that kills sales.

-

Exploring the challenges of gluten-free processing can provide insights into effective techniques and innovations in food technology. ↩

-

Understanding the Vacuum delay facility can enhance your knowledge of pressure management in sensitive food products. ↩

-

Explore this link to understand how precision temperature management can enhance the quality and shelf life of specialty bread. ↩

-

Learn about the importance of shelf life in gluten-free bread and how it impacts freshness and quality. ↩

-

Explore how Bitzer Compressors enhance reliability and efficiency in bakery environments, ensuring optimal performance even in high temperatures. ↩

-

Discover the advantages of Leybold Vacuum Pumps, known for their consistent performance and reliability in demanding industrial settings. ↩

-

Learn about the advantages of Plug & Play systems in simplifying technology integration and user accessibility. ↩

-

Explore how Siemens Touch Screens enhance automation efficiency and user experience in various industries. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the