Can Vacuum Cooling Really Double the Shelf Life of Your Baked Goods Without Chemicals?

You watch your profits rot away with every returned loaf of bread. You are fighting a constant battle against mold, forcing you to use expensive preservatives that your health-conscious customers hate.

Vacuum cooling extends shelf life by flash-cooling baked goods through the bacterial "danger zone" (60°C to 20°C) in minutes rather than hours. This prevents mold spores from germinating, eliminates the condensation that ruins packaging, and allows for sterile, filtered air to contact your food.

I have walked into countless bakeries, from large industrial factories in the USA to artisanal centers in Europe, and heard the same complaint: "Mila, we bake the best bread, but it goes bad too fast." Traditionally, the solution has been to pump the dough full of preservatives like Calcium Propionate or to spray the crust with ethanol. But the market has changed. Customers want "Clean Labels." They do not want to eat chemistry; they want to eat bread.

At Allcold, we treat shelf life not as a chemical problem, but as a physics problem. Spoilage is caused by biology (bacteria/mold) and environment (moisture/temperature). Vacuum cooling controls the environment so perfectly that biology doesn’t stand a chance. It allows you to expand your delivery radius because your bread survives the journey. In this guide, I will explain exactly how our technology stops the clock on spoilage.

How Does Rapid Cooling Stop Bacteria Before They Even Start?

You leave your bread on racks to cool naturally, unknowingly creating the perfect sauna for bacteria to multiply. By the time you package it, the microbial load is already dangerously high.

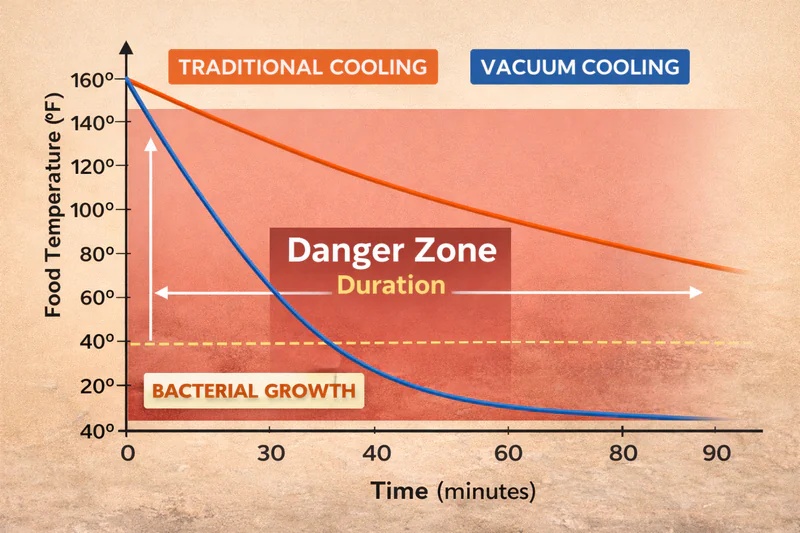

Bacteria reproduce fastest in the "Danger Zone" between 60°C and 20°C. Vacuum cooling forces bread through this temperature range in under 5 minutes, effectively "starving" bacteria of the time they need to grow, resulting in a nearly sterile product upon exit.

The Race Against Biology

To understand shelf life, you have to think like a microbe.

Mold spores and bacteria, such as Bacillus cereus1 (which causes the dreaded "rope" spoilage in bread), are everywhere. They are in the flour, in the air, and on your workers’ clothes. However, they need specific conditions to "wake up" and start multiplying. They need moisture, and they need warmth. Specifically, they love the temperature range of 35°C to 45°C.

The Traditional Cooling Trap:

In a standard bakery, like the ones my client Norman used to run in America, bread sits on a spiral conveyor or a rack for 90 to 120 minutes.

- The Problem: The core of the bread stays warm for a long time. It might spend 45 minutes sitting exactly at 40°C.

- The Biological Result: This is an incubation period. One bacterium becomes two, two become four, and four become sixteen. By the time the bread reaches room temperature, it is already teeming with microscopic life. You cannot see it yet, but the clock is ticking. You have lost 2 or 3 days of shelf life before you even put the bread in a bag.

The Vacuum Cooling2 Solution:

When we put that same cart of bread into an Allcold vacuum chamber, we change the physics.

- The Process: We lower the pressure. Water boils at a lower temperature. The heat energy inside the bread is used to turn moisture into steam.

- The Speed: We drop the temperature from 95°C (out of the oven) to 25°C (slicing temp) in roughly 3 to 6 minutes.

- The Impact: The bread spends perhaps seconds in the optimal bacterial growth range3, not minutes. The bacteria do not have time to multiply. We essentially "freeze" the biological state of the bread right out of the oven.

The "Rope" Spoilage Factor:

"Rope" is a bacterial infection that turns the crumb sticky and smells like rotting fruit. It is killed by baking, but the spores survive. If the cooling is slow, the spores hatch.

Because vacuum cooling dries the crumb slightly and cools it instantly, "Rope" spores never get the warm, wet environment they need to hatch. I have clients who completely eliminated Rope issues just by switching to vacuum cooling, without changing their flour source.

Comparative Analysis of Bacterial Growth Potential:

| Cooling Method | Time in "Danger Zone" (20°C-60°C) | Bacterial Multiplication Factor | Risk of "Rope" | Starting Hygiene Level at Packaging |

|---|---|---|---|---|

| Natural Air Cooling | 60 – 90 Minutes | High (Exponential) | High in summer | Compromised |

| Blast Freezing | 20 – 40 Minutes | Medium | Low | Good |

| Vacuum Cooling2 | 2 – 4 Minutes | Near Zero | Negligible | Excellent (Sterile) |

Why Is Condensation the Number One Enemy of Freshness?

You pack your bread thinking it is cool enough, but residual heat gets trapped in the bag. The next morning, you see water droplets inside the plastic—a guaranteed recipe for mold growth within 48 hours.

Vacuum cooling eliminates the risk of packaging condensation by ensuring the entire loaf, including the core, is uniformly cooled to the target temperature. This allows you to bag immediately without creating the trapped moisture that feeds mold.

Managing Water Activity (Aw)4

My client Sophia, who manages a central kitchen in Singapore, faced a nightmare scenario. Singapore is hot and humid. Her team would wait 2 hours for the bread to cool. They would touch the crust; it felt cold. They bagged it.

By the time the delivery truck reached the 7-Eleven stores, the bags were foggy. Why?

Because the core was still 35°C. Heat moves from hot to cold. The heat from the core moved to the crust, then warmed the air in the bag. The moisture condensed on the cool plastic.

Water + Plastic + Bread = Mold Farm.

The Core Temperature Guarantee5:

Vacuum cooling6 is the only technology that cools from the inside out.

In a refrigerator (blast chiller), the cold attacks the crust first. The center is the last to cool.

In a vacuum cooler, the pressure drop affects the entire chamber equally. The water boils in the absolute center of the loaf at the exact same moment it boils on the crust.

When my machine says the temperature is 25°C, it means the core is 25°C.

- The Benefit: You can transfer the bread from the vacuum chamber directly to the wrapping machine. There is no "waiting period." There is no guess work.

- The Result: The bag stays dry. The crust stays dry. Mold spores cannot germinate without liquid water.

The "Slicing" Hygiene Trap:

This is a detail many people miss.

If you slice bread when it is warm (e.g., 30°C-35°C), the crumb is sticky.

- Gumming: The starch gums up the slicer blades.

- Crumbs: It creates rough, torn crumbs.

- Infection: Those sticky crumbs get stuck in the blades. They mold. Then, the blades transfer that mold to every single loaf you slice afterwards.

Vacuum-cooled bread has a firmer, set structure. It slices cleanly. The blades stay clean. This mechanical difference significantly reduces cross-contamination in the slicing area.

Water Activity (Aw)4:

Shelf life is dictated by "Water Activity" (the amount of free water available for bacteria).

Vacuum cooling6 removes "Flash Steam." This lowers the water activity on the surface of the crust slightly, creating a protective barrier, while keeping the bound moisture inside the crumb for softness. It optimizes the Aw balance: too low to support mold on the outside, high enough to taste fresh on the inside.

| Feature | Traditional Cooling Issues | Vacuum Cooling Advantage | Impact on Shelf Life |

|---|---|---|---|

| Core Temperature | often 10°C hotter than crust | Same as crust | Prevents "sweating" in bag. |

| Crust Humidity | High (absorbs room moisture) | Low (flash dried) | Inhospitable to mold. |

| Slicing Quality | Tearing, sticky crumb | Clean cut, firm crumb | Reduced cross-contamination. |

| Bagging Speed | Must wait ( bottleneck) | Immediate | Air-tight seal sooner. |

Can You Really Remove Preservatives and Maintain a "Clean Label"?

Your marketing team wants to sell "All Natural" products, but your production team says it is impossible without chemicals. You are stuck between customer demand and the reality of logistics.

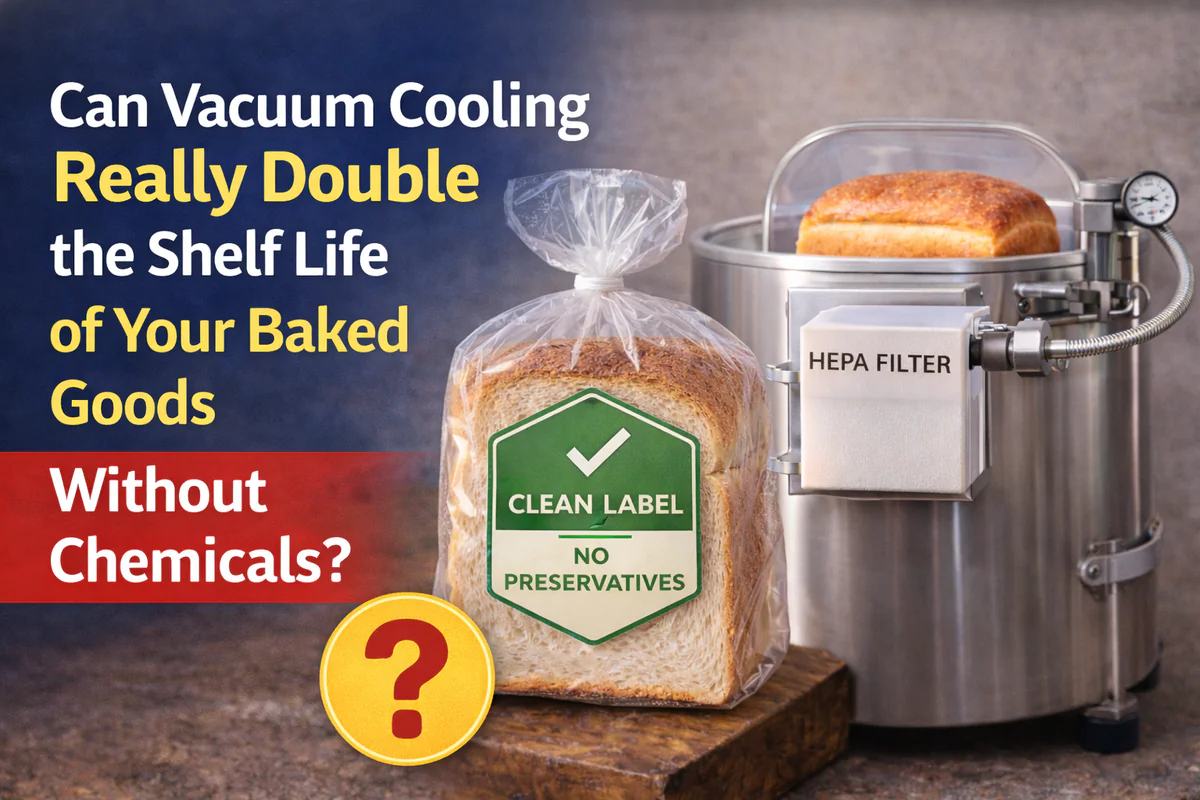

Vacuum cooling allows you to reduce or eliminate preservatives like calcium propionate because the process occurs in a sealed, HEPA-filtered environment. By preventing the initial contamination of mold spores from factory air, you start with a sterile product that naturally lasts longer.

The Clean Room Effect

This is where the ROI (Return on Investment) becomes huge for factory owners like Carlos in Mexico.

Carlos was spending thousands of dollars a month on chemical preservatives to survive the hot distribution chain. He also wanted to enter the premium organic market but couldn’t because of the chemicals.

The "Chimney Effect" of Natural Cooling:

Think about a loaf of bread cooling on a rack. As it cools, the air inside the bubbles shrinks. This creates a vacuum inside the bread. The bread literally sucks air in from the room.

What is in your factory air?

- Yeast spores from the mixing area.

- Flour dust.

- Dust from the warehouse floor.

- Exhaust from forklifts.

Your cooling bread acts like an air filter for your factory. It inhales all these contaminants. This is why bread molds even if you bake it perfectly.

The Sterile Vacuum Cycle:

Now, look at the Allcold process.

- Sterilization: The bread enters the chamber at 95°C. This temperature is lethal to most surface bacteria.

- Isolation: The door seals. The bread is cut off from the factory environment.

- Evaporation: We pump the air out. Any remaining airborne bacteria are sucked out of the chamber.

- Aeration (The Critical Step): When the cycle is done, we must let air back in to open the door. We do not just open a valve. We pull the air through a Medical-Grade HEPA Filter7 (and optionally a UV-C light sterilization tunnel).

- The Result: The air that rushes back into the bread structure is 99.99% sterile.

- The Outcome: You are sending a "sterile" loaf to the packaging room. If your packaging room is clean, you have effectively created a clean-room product without building a clean-room factory.

Case Study: The 3-Day Gain

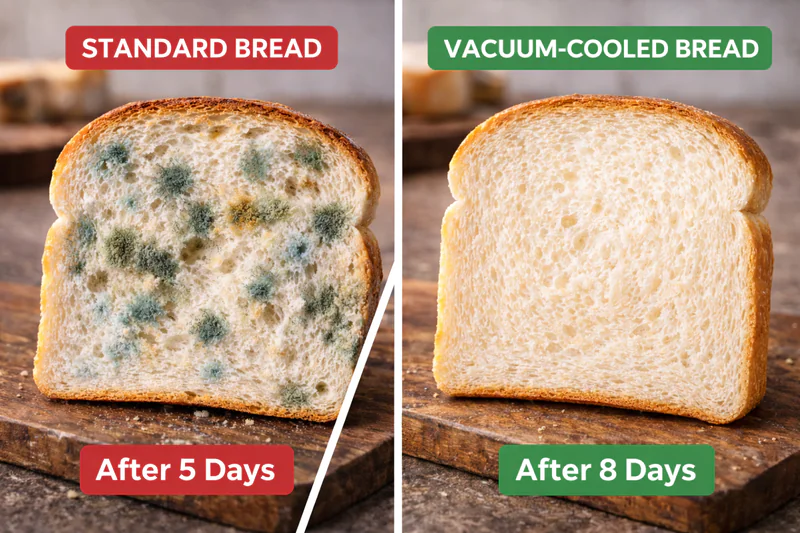

We conducted a test with a client producing muffins.

- Batch A (Fan Cooled): Mold appeared on Day 5.

- Batch B (Vacuum Cooled, No HEPA): Mold appeared on Day 7.

- Batch C (Vacuum Cooled + HEPA): Mold appeared on Day 10.

- Batch D (Vacuum + HEPA + No Preservatives): Mold appeared on Day 8.

- Conclusion: With vacuum cooling and HEPA filtration, they removed the preservatives and still gained 3 days of shelf life compared to their original chemical-laden process.

Marketing the "Clean Label8":

In Europe and North America, "Clean Label8" commands a higher price. Customers will pay 20% more for bread that contains only "Flour, Water, Salt, Yeast."

Vacuum cooling is the enabling technology that allows you to remove the "E-numbers" and chemicals from your ingredient list while keeping the logistics manager happy.

| Component | Standard Factory Air | Allcold HEPA Intake | Benefit |

|---|---|---|---|

| Particulate Size | Large dust & flour | < 0.3 Microns | No physical contaminants. |

| Microbial Load | High (Yeast/Mold) | 99.9% Removed | No biological seeds. |

| Chemical Fumes | Present (Cleaning/Forklifts) | Filtered (Activated Carbon opt.) | No off-flavors. |

| Consistency | Changes with weather | Always controlled | Predictable results. |

Conclusion

Extending shelf life is not about adding more chemistry; it is about removing the biology. By using vacuum cooling to skip the bacterial danger zone, prevent packaging condensation, and filter the air that touches your food, you can naturally double your shelf life. This allows you to reduce waste, expand your market reach, and give your customers the clean, fresh product they demand.

-

Explore this link to understand how Bacillus cereus affects food safety and spoilage, crucial for bakers. ↩

-

Learn about vacuum cooling’s benefits in food preservation, a game-changer for extending shelf life. ↩ ↩

-

Understanding the bacterial growth range is essential for food safety and quality management. ↩

-

Understanding Water Activity is crucial for optimizing shelf life and preventing spoilage. ↩ ↩

-

Discover how the Core Temperature Guarantee ensures consistent quality in baked goods. ↩

-

Explore how vacuum cooling technology can revolutionize food preservation and quality. ↩ ↩

-

Learn about Medical-Grade HEPA Filters and how they ensure air purity in food production, enhancing product safety. ↩

-

Explore the Clean Label trend to understand how consumers are shifting towards healthier, chemical-free products. ↩ ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy