Could a Vacuum Cooler Save an Organic Farm? A Case Study.

You pour your heart into organic farming, but the clock starts ticking the moment you harvest. The fear that your beautiful, chemical-free produce will spoil before it reaches the customer is a constant source of stress.

Yes, it can, by transforming your biggest liability—spoilage—into your greatest asset. This case study demonstrates how one organic farm used vacuum cooling to slash waste, unlock premium markets, and achieve a full return on investment in just over a year.

Theory is one thing, but results are what matter. I want to walk you through the real-world story of one of my clients, a dedicated organic farmer whose situation might sound very familiar to you. Let’s call his farm "Finca Orgánica del Sol."

What Problem Was ‘Finca Orgánica del Sol’ Trying to Solve?

Finca Orgánica was producing beautiful organic lettuce and leafy greens. But they were hitting a wall, unable to grow because their product simply couldn’t survive the journey to better-paying markets.

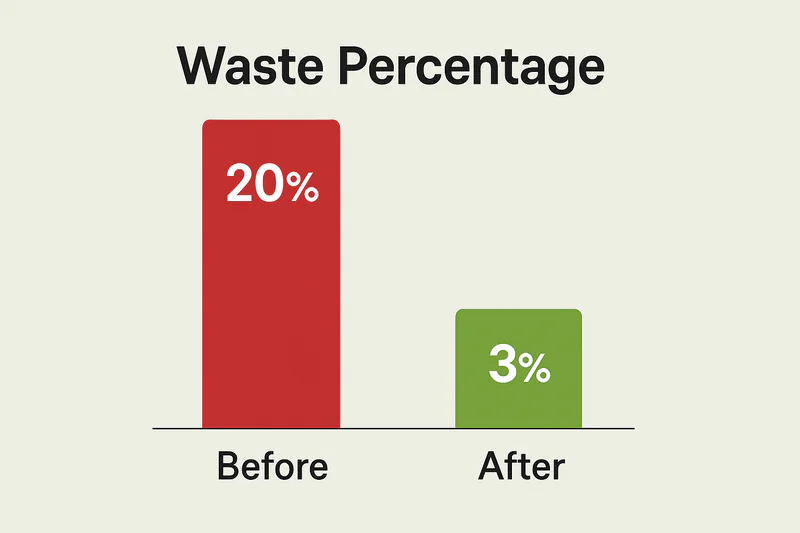

The core problem was a 20% spoilage rate. This financial drain prevented them from investing in growth and made large retail buyers reject them due to inconsistent quality and shortened shelf life.

I remember my first conversation with Carlos, the owner. He was passionate and knowledgeable about organic cultivation. His farm was located in Mexico, and his dream was to supply major supermarket chains in the region. The problem was physics. His greens were harvested in 30°C heat. By the time they were packed and sent to a traditional cold room, hours had passed. The delicate leaves were already respiring heavily, losing moisture and crispness. His buyers were reporting that the shelf life was too short. He was losing one out of every five crates he harvested, a direct and painful financial loss. This wasn’t just about lost product; it was about lost opportunity. He was stuck selling to local markets that accepted the lower quality but also paid a much lower price.

The Growth Ceiling

The farm was trapped. They couldn’t reduce their waste, so they couldn’t afford to expand. And because their quality was inconsistent, they couldn’t attract the premium customers who would help them grow.

| Challenge | Impact on the Farm | Consequence |

|---|---|---|

| High Field Heat | Accelerated respiration and wilting. | Product looked old upon arrival. |

| Slow Cooling | Allowed microbial growth to begin. | Shortened shelf life by 3-4 days. |

| Inconsistent Quality1 | Some pallets were better than others. | Major retailers refused to partner. |

| Financial Drain2 | 20% of all harvested greens were lost. | No capital for reinvestment. |

How Did Vacuum Cooling Immediately Cut Product Waste?

Carlos knew he had to tackle field heat, but he was skeptical. How could one machine, a chemical-free process, make such a dramatic difference to a biological problem like spoilage?

By changing the cooling time from 12 hours to 25 minutes. The vacuum cooler pulled heat from the very core of the lettuce instantly, halting the decay process. His post-harvest waste dropped from 20% to less than 3% in the first week.

The change in his packing house was immediate and dramatic. Before, his team would harvest and then rush the pallets to a crowded cold room, where they would sit for half a day or more, slowly losing life. After we installed the allcold vacuum cooler, the workflow was transformed into a smooth, continuous process. Pallets came from the packing line and went directly into the cooler. Less than 30 minutes later, they emerged with a core temperature of 2°C, perfectly crisp and vibrant. The "race against time" was over because they could now remove the damaging field heat faster than the plants could wilt. This wasn’t a small improvement. He went from losing a full pallet for every four he shipped to losing almost nothing. The visual quality was so striking that even his packing house workers were amazed.

The Operational "Before and After"

The impact was clear not just on the balance sheet, but on the daily stress levels of the entire operation.

| Metric | Before Vacuum Cooler | After Vacuum Cooler |

|---|---|---|

| Time to Cool3 | 12-18 Hours | 25 Minutes |

| Spoilage Rate4 | ~20% | <3% |

| Product Consistency | Variable, often wilted. | Uniformly crisp, vibrant, and cold. |

| Workflow | Rushed, stressful, high-pressure. | Calm, predictable, continuous flow. |

Did This Unlock New, More Profitable Markets?

Reducing waste was a huge win, but Carlos’s original dream was bigger. He wanted to break into the premium retail market. Could this new level of quality actually open those doors?

Yes, completely. The extended shelf life and guaranteed quality gave him the credentials to approach two national supermarket chains. He secured contracts that paid a 15% price premium over his previous local buyers.

This was the real business transformation. With vacuum-cooled produce, Carlos could now guarantee a 14-day shelf life. This was the key that unlocked the door to major distribution centers located hundreds of miles away. He prepared sample shipments for the quality managers of two large supermarket chains who had previously turned him down. This time, the response was different. The buyers were impressed by the "just-harvested" look and the cold, documented chain of custody. They ran their own shelf-life tests and confirmed his claims. Within three months, he signed contracts with both of them. He was no longer just a local farmer; he was a certified supplier to a premium market. This elevated his farm’s brand and, most importantly, its revenue.

From Local Supplier to Strategic Partner

The investment changed how buyers perceived his entire operation, turning him from a commodity provider into a trusted partner.

| Business Metric | Before Vacuum Cooler | After Vacuum Cooler |

|---|---|---|

| Market Reach5 | Local (within 100 miles) | National (up to 1,000 miles) |

| Customer Type | Small wholesalers, local markets. | Major supermarket chains. |

| Price Point | Standard market rate. | +15% Premium Price6 |

| Brand Reputation | Just another local farm. | Professional, reliable, premium supplier. |

What Was the Final Financial Impact and ROI?

This all sounds great, but a vacuum cooler is a significant capital investment. For a farm that was struggling, the numbers have to make sense. Did the benefits truly outweigh the cost?

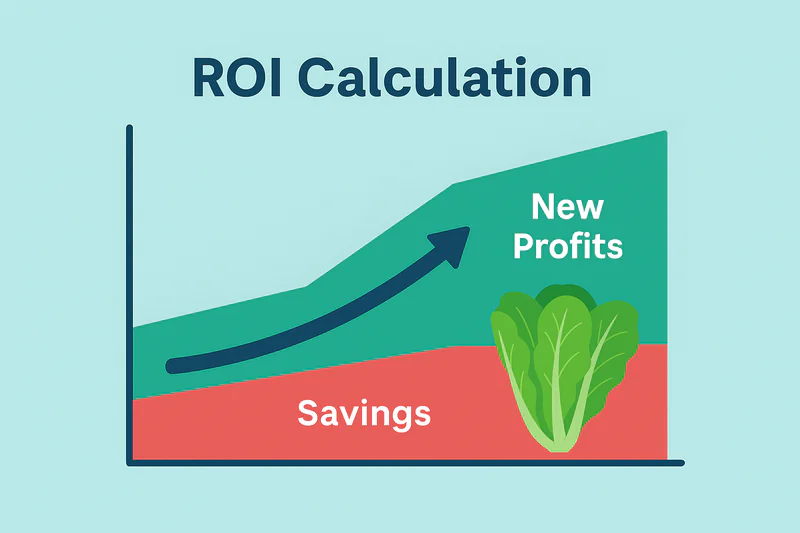

The investment paid for itself in 14 months. The combined savings from eliminated waste and the new revenue from premium contracts created a powerful and rapid return on investment (ROI).

Let’s break down the final calculation for Carlos. We analyzed his numbers after the first full year of operation. The results were clear. First, we calculated the savings from waste reduction. By saving 17% of his crop that was previously lost, he added over $40,000 in revenue from produce he grew but couldn’t sell before. Second, we looked at the new revenue. His new supermarket contracts, with their 15% price premium and higher volume, generated an additional $65,000 in profit compared to the previous year. The total positive financial impact was over $100,000 in the first year alone. When we set that against the cost of the allcold machine, the payback period was just over one harvest season. For Carlos, the machine wasn’t an expense; it was the most profitable investment his farm had ever made.

The Simple Math of Success

Here is a simplified look at the financial turnaround for Finca Orgánica del Sol.

| Financial Item | Value | Impact on Business |

|---|---|---|

| Savings from Waste7 | +$42,500/year (17% of a $250k crop value) | Recaptured lost revenue. |

| New Premium Revenue8 | +$65,000/year (Higher volume & 15% premium) | Created new, high-margin profit streams. |

| Total Annual Gain | $107,500 | Transformed farm’s overall profitability. |

| Return on Investment | ~14 Months | Rapid payback, long-term financial stability. |

Conclusion

Carlos’s story at Finca Orgánica del Sol proves it. For organic growers, vacuum cooling is a direct investment in quality and profitability, turning the challenge of perishability into a powerful competitive advantage.

-

Understanding the impact of inconsistent quality can help farmers improve their practices and attract premium customers. ↩

-

Exploring solutions for financial drain can provide valuable insights for farmers looking to reinvest and grow their operations. ↩

-

Exploring this can reveal how cooling times influence food safety and quality, crucial for any food business. ↩

-

Understanding spoilage rates can help improve food production efficiency and reduce waste. ↩

-

Exploring strategies to expand market reach can significantly boost your business growth and customer base. ↩

-

Understanding premium pricing can help you enhance your brand’s reputation and attract more customers. ↩

-

Explore how savings from waste can significantly boost agricultural profitability and sustainability. ↩

-

Learn about innovative strategies to create premium revenue streams that enhance farm profitability. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not