How Can High-Capacity Vacuum Cooling Double Your Bread Production Speed?

You have optimized your mixing times. You have upgraded to high-speed ovens. But at the end of the line, your production halts. Your racks of hot bread sit in a massive spiral cooler or a holding room for an hour, wasting space and losing weight. This is the bottleneck that kills your efficiency.

High-capacity vacuum cooling systems reduce the cooling time of baked goods from 60 minutes to just 3-5 minutes. By lowering the atmospheric pressure inside a sealed chamber, water boils at a lower temperature, flash-cooling the product from the core outward while stabilizing the structure and extending shelf life.

In my experience working with factory upgrades, the cooling phase is often the most neglected part of the production line. You treat it as a passive storage activity. It should be an active processing step. Traditional cooling is at the mercy of ambient temperature and humidity. Vacuum cooling is controlled physics. It completely changes how you schedule your shifts, how you utilize your floor space, and ultimately, how much product you can ship out the door. Let’s break down the mechanics and see if this heavy machinery belongs in your bakery.

Why Does Lowering Pressure Cool Bread Instantly?

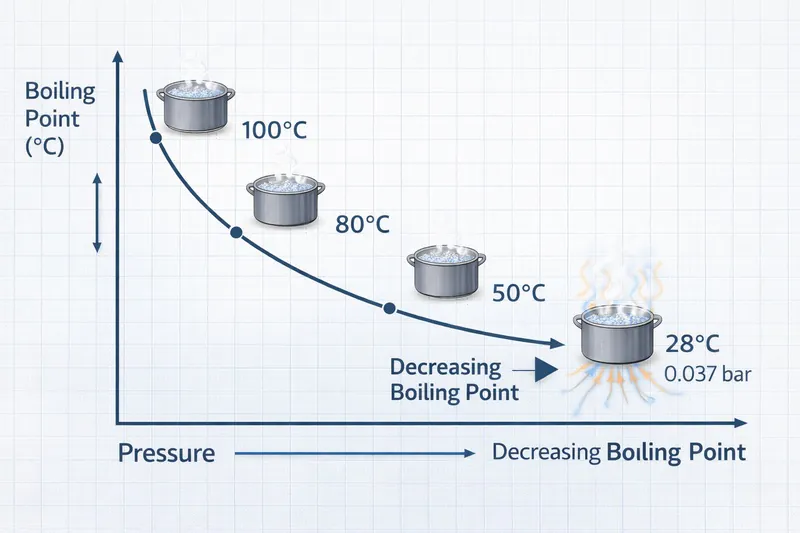

Most bakers understand heat, but few understand the relationship between pressure and boiling points. You might think "vacuum" implies sucking the air out to dry things, but it is actually about manipulating temperature thresholds.

Vacuum cooling works by reducing the pressure in the chamber, which drops the boiling point of water from 100°C down to around 30°C. This forces the moisture inside the bread to "flash evaporate," absorbing massive amounts of heat energy instantly from the center of the loaf, regardless of the bread’s size or density.

The Thermodynamics of Speed

To understand why this system is worth the investment, you have to look at the physics of "Latent Heat of Evaporation1." In a standard spiral cooler, you are blowing cold air over the crust. The heat must migrate from the hot core of the bread, through the crumb, to the crust, and then be carried away by the air. This is slow. It creates a temperature gradient—cool crust, hot center.

In a vacuum chamber, we bypass this. When we pump the air out, the pressure drops.

- The Boiling Shift: At sea level (1013 mbar), water boils at 100°C. In the vacuum chamber, we drop the pressure to around 40 mbar. At this pressure, water boils at roughly 28°C to 30°C.

- Flash Evaporation2: The moisture inside the hot bread (which is sitting at 95°C coming out of the oven) suddenly finds itself far above its boiling point. It turns to steam instantly.

- Energy Consumption: To turn water into steam requires energy (heat). The water takes this heat directly from the dough. This happens everywhere in the loaf simultaneously—core and crust.

- The Result: The temperature plummets. We are not cooling from the outside in; we are cooling the entire mass at once. You can take a 1kg loaf of sourdough from 95°C to 30°C in roughly 4 minutes. There is no other technology on earth that can do this.

| Feature | Traditional Air/Spiral Cooling | Vacuum Cooling |

|---|---|---|

| Cooling Mechanism | Convection (Air over surface) | Evaporation (Internal phase change) |

| Time (Standard Loaf) | 40 – 70 Minutes | 3 – 6 Minutes |

| Temperature Consistency | Hot Core / Cold Crust | Uniform Temp throughout |

| Weather Dependency | Sensitive to ambient humidity | Independent of environment |

Will Vacuum Cooling Dry Out or Ruin the Bread Quality?

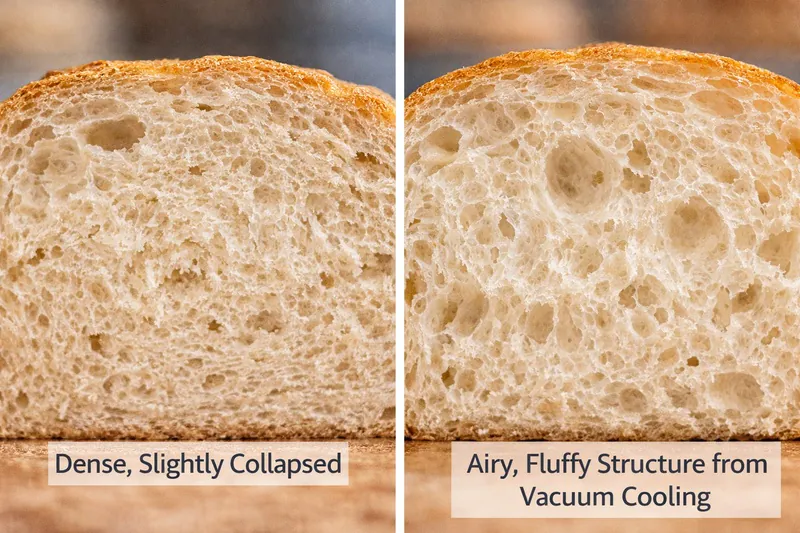

The biggest fear I hear from production managers is about moisture loss. They worry that "boiling off" the water will result in a dry, crumbling brick. The reality is quite the opposite if the parameters are set correctly.

While vacuum cooling does remove moisture, it locks in the final structure much faster than air cooling preventing the starch from retrograding slowly. The result is a crispier crust, a more voluminous crumb, and a product that stays fresh longer because it spends less time in the "danger zone" where bacteria thrive.

The Science of Starch and Structure

When you take bread out of the oven, it is not "done." The structure is still setting. In a traditional cooler, the bread is heavy. The gluten structure is soft. As it sits there for an hour, gravity works on it. It shrinks. The crust absorbs moisture from the air and gets chewy or soft.

Vacuum cooling changes this biological process:

- Instant Rigidification3: Because the cooling happens in minutes, the starch gelatinizes and sets almost instantly. The visible result is volume. Your bread keeps its oven spring. It doesn’t collapse.

- The Moisture Paradox: Yes, you lose about 3-5% more moisture in a vacuum cooler compared to a spiral cooler. However, because the cooling is so fast, you can simply add that 5% water back into your initial dough mix. The dough handles better because it is more hydrated, and the final product comes out with the perfect moisture content.

- Shelf Life Extension4: Mold and bacteria love temperatures between 30°C and 60°C. In a tunnel cooler, your bread sits in this danger zone for 40 minutes. In a vacuum cooler, it passes through this zone in seconds. Furthermore, the air entering the vacuum chamber is usually filtered (HEPA), meaning you are cooling in a sterile environment. You aren’t blowing factory dust onto your clean bread.

- Slicing Efficiency: This is a huge downstream benefit. Because the crust is crisp and the crumb is firm (but moist), you can slice the bread immediately. No more gummed-up slicer blades. No more waiting for the "slicing window." You cool, you slice, you bag.

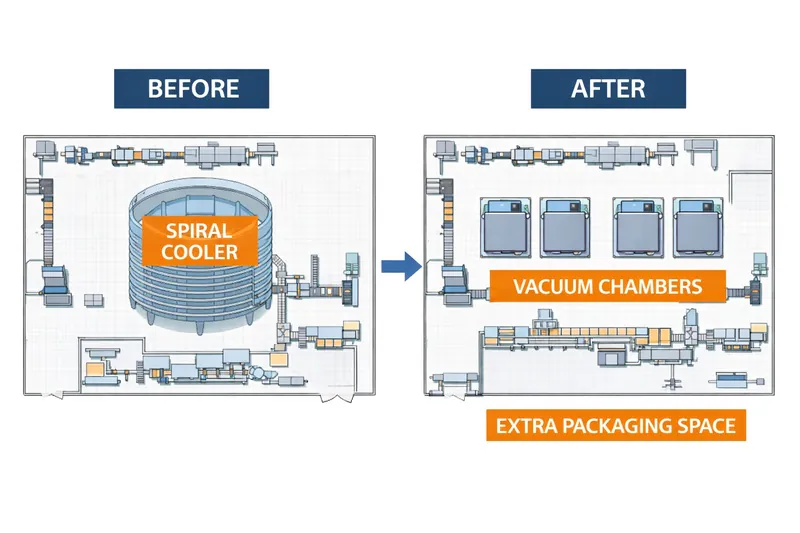

How Much Floor Space Can You Reclaim from Spiral Coolers?

Real estate is expensive. In a large industrial bakery, the cooling spiral is often the single largest piece of equipment. It dominates the warehouse. It requires high ceilings and massive climate control systems.

Vacuum cooling systems are incredibly compact, occupying only 10% to 20% of the footprint of an equivalent spiral conveyor. This allows you to reclaim valuable square footage for packaging lines, extra ovens, or storage, effectively expanding your factory without buying new land.

The Logistics of the Swap

Let’s talk about the physical reality of your factory floor. A spiral cooler designed for 2,000 loaves an hour is a monster. It involves hundreds of meters of belt, massive motors, and complex ductwork for air conditioning. It is a maintenance nightmare. If the belt snaps in the middle, your production is down for hours.

Now, look at the vacuum alternative:

- The Footprint: A vacuum chamber looks like a large industrial oven or a walk-in freezer. A system capable of handling the same 2,000 loaves might consist of two chambers, each roughly the size of a minivan. You can place them anywhere. You don’t need continuous conveyance.

- Modularity5: This is critical for risk management. If you have one giant spiral cooler and it breaks, you stop baking. If you have three vacuum chambers and one pump fails, you are still running at 66% capacity. You have redundancy.

- Energy Hygiene6: Spiral coolers fight the ambient air. In the summer, your AC works overtime to keep the cooling room down to 20°C. Vacuum coolers are closed loops. They don’t fight the warehouse temperature. You don’t need to air-condition the whole room just to cool the bread.

- Loading Logistics7: You can integrate these with automated rack systems. The oven racks slide directly into the chamber. 3 minutes later, they slide out to the packaging line. It supports a "Batch Flow" rather than a "Continuous Flow," which offers more flexibility for changing products. You can run sourdough in Chamber A and burger buns in Chamber B with completely different pressure curves. You can’t do that on a single spiral belt.

| Dimension | Spiral Cooling System | Vacuum Cooling System8 |

|---|---|---|

| Space Required | ~150 – 200 sq. meters | ~20 – 30 sq. meters |

| Ceiling Height | High (for spiral stack) | Standard Industrial |

| Cleaning Time | Hours (Belt washing) | Minutes (Wipe down box) |

| Flexibility | Low (One speed fits all) | High (Programmable recipes) |

Is the Energy Cost of Vacuum Cooling Worth the Investment?

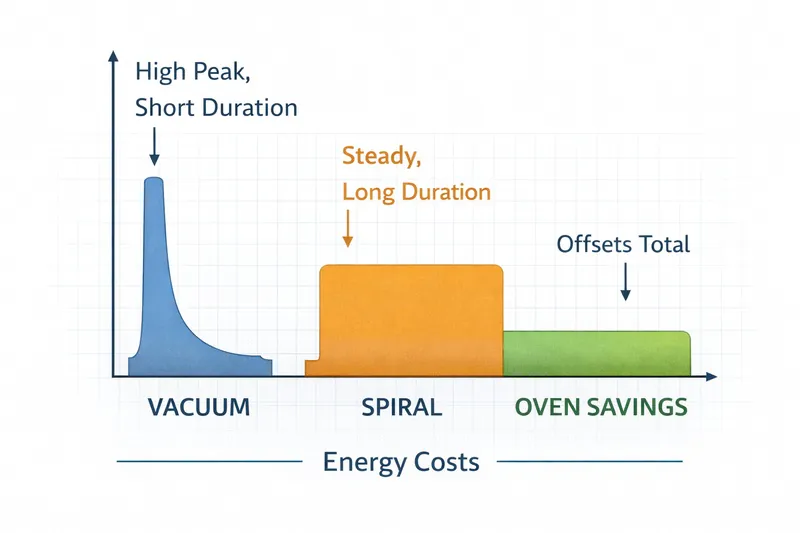

When you look at the spec sheet of a vacuum pump, the kilowatt rating scares people. "Jeremy," they say, "this pump draws huge power." It does. But you are looking at peak power, not total energy consumed per unit of product.

While the peak power draw of vacuum pumps is higher than conveyor motors, the operational duration is significantly shorter. You run high power for 3 minutes instead of medium power for 60 minutes. Furthermore, vacuum cooling allows you to reduce baking time by 10-15%, saving immense amounts of energy at the oven, which is the most expensive appliance in your building.

The Total Cost of Ownership (TCO) Calculation

You cannot calculate the ROI of vacuum cooling just by looking at the electricity bill of the cooler. You have to look at the whole line.

- The Oven Savings: This is the hidden secret. In traditional baking, you bake the bread until it is fully structured. In vacuum cooling, you can take the bread out of the oven slightly "underbaked" (or "wet baked").

- Why? Because the flash evaporation in the vacuum chamber continues the physical process of setting the crumb structure.

- If you can reduce your bake time from 40 minutes to 35 minutes, you have just increased your oven capacity by 12.5%. You are using less gas or electricity in the oven. The oven is the biggest energy consumer; saving 10% there pays for the electricity of the vacuum pump easily.

- Maintenance: Think about moving parts. A spiral cooler has thousands of bearings, links, belts, and motors. It creates dust. It needs lubrication. A vacuum cooler is a stainless steel box with a door and a pump. The pump needs oil changes and filter checks. The maintenance labor hours are drastically lower.

- Yield: Remember the moisture loss discussion? If you traditional cool, you might bake a 1000g dough to get an 850g loaf. With vacuum cooling, because you control the end point precisely, you might be able to scale that dough at 980g to get the same 850g loaf (by adding more water initially). You are selling water instead of flour. Even a 1% yield increase on an industrial scale is pure profit.

- Throughput: Being able to ship an order 1 hour after it leaves the oven instead of 4 hours means your logistics flow is leaner. You hold less inventory. You react faster to rush orders.

Conclusion

Industrial bread production is a game of margins and minutes. Vacuum cooling is not just a faster way to get cold bread; it is a strategy to reduce baking times, eliminate clean-room bottlenecks, and standardize quality. If you are tired of losing floor space to giant conveyors and losing shelf-life to slow cooling, it is time to pressurize your process.

-

Understanding this concept is crucial for grasping how vacuum cooling works and its advantages over traditional methods. ↩

-

Exploring this topic will reveal the science behind rapid cooling processes and their applications in various industries. ↩

-

Explore this link to understand how Instant Rigidification enhances bread quality and maintains its structure. ↩

-

Discover the benefits of Shelf Life Extension through vacuum cooling and how it prevents mold and bacteria. ↩

-

Explore how modular systems enhance efficiency and risk management in industrial settings. ↩

-

Learn about the importance of energy hygiene in optimizing cooling efficiency and reducing costs. ↩

-

Discover effective loading logistics strategies that improve workflow and product handling in food production. ↩

-

Understand the mechanics and advantages of vacuum cooling systems for efficient food processing. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy