How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work threatened by mold and staleness. Without chemical preservatives, your "clean label" bread is fighting a losing battle against time and humidity from the moment it leaves the oven.

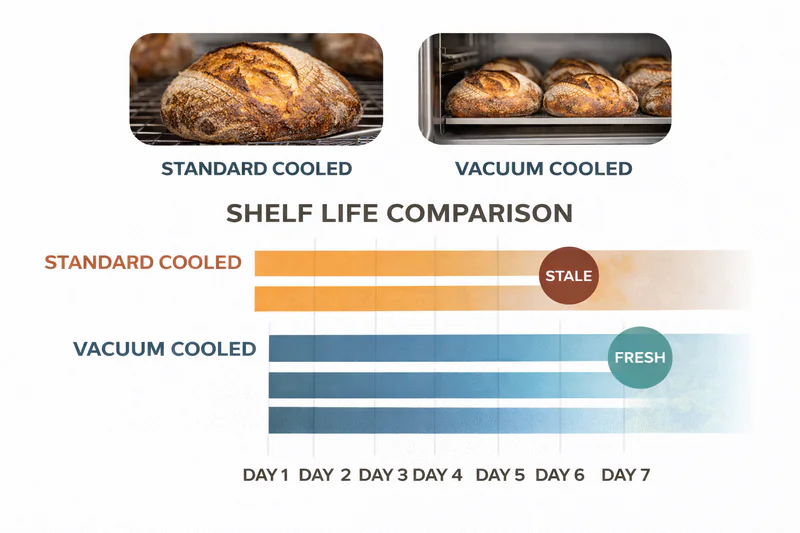

Vacuum cooling is the ultimate hygiene solution for organic operations. By rapidly dropping the core temperature from 100°C to 28°C in a sealed chamber, our machines eliminate the "danger zone" where bacteria thrive, extending your shelf life naturally while locking in the moisture that keeps the crumb fresh.

I remember speaking with a client named Carlos, who runs a large packing center and bakery operation. He was frustrated. His organic loaves were excellent, but they couldn’t survive the logistics chain to reach supermarkets without losing quality. He refused to add preservatives, but the traditional cooling rooms were just too slow, leading to mold issues during the rainy season. He needed a solution that respected his organic ingredients while providing industrial efficiency. That is when we introduced him to our AVCF series. If you are facing similar challenges, let’s dive deeper into how this technology specifically solves the problems unique to organic baking.

Can You Beat Mold and Bacteria Without Chemicals?

You are committed to a strict "no-additive" policy, but you struggle with a short distribution window that limits your sales. You need a physical way to sanitize your cooling process, ensuring that your bread is safe and stable before it is sliced and packaged.

Vacuum cooling acts as a physical sterilization phase. By reducing the cooling time from hours to just 15-20 minutes, we stop the "sweating" and condensation that fuels mold growth. This process happens in a sealed, clean environment, protecting your product from airborne spores common in open bakeries.

The Physical Solution to a Biological Problem

In the world of organic baking, you cannot rely on calcium propionate or other chemical mold inhibitors. Your only defense is hygiene and moisture control1. When you cool bread using traditional racks or spiral coolers, the product sits for hours in a temperature range of 30°C to 60°C. We call this the "danger zone" because it is exactly where bacteria and mold spores are most active and reproduce the fastest.

Our vacuum coolers2 change this dynamic completely. Based on the operational logic of our machines, the cooling process is incredibly fast and precise. The bread enters the chamber at approximately 100°C (or directly from the oven). Once you press the "Start" button on the touch screen, the system engages the cooling pump and vacuum pump in a specific sequence. Within just 15 to 25 minutes depending on the density of your loaf, the core temperature drops to a safe, stable 28°C.

This speed does two critical things for organic bread:

- It Skips the Bacterial Window: The bread spends almost no time at the temperatures where mold activates. By the time the bacteria could potentially wake up, the bread is already cold and ready for packaging.

- It Eliminates Surface Condensation: In a traditional fridge or ambient room, as bread cools, moisture migrates to the crust and creates a soggy, wet surface—a perfect breeding ground for mold. In our vacuum chamber, the machine performs a "Deflation" and "Drainage" cycle automatically at the end of the process. This ensures that the moisture is flashed off or locked inside the starch structure, leaving the crust crisp and dry.

Furthermore, the environment itself is cleaner. The cooling happens inside a stainless steel chamber. Unlike an open bakery floor where yeast and mold spores float in the air, the vacuum chamber is a controlled, sealed environment. This gives you a "clean room" standard of hygiene without needing to build a clean room.

| Feature | Organic Benefit | Technical Operation |

|---|---|---|

| Rapid Cooling | Skips bacterial growth zone. | 100°C to 28°C in ~15 mins. |

| Sealed Chamber | Protects from airborne spores. | Stainless steel sealed door. |

| Moisture Lock | No soggy crusts/mold risk. | Auto-stop at target temp. |

Will Fast Cooling Ruin the Texture of Artisan Sourdough?

You worry that the aggressive nature of a vacuum pump will destroy the open crumb structure you worked so hard to achieve. You fear that rapid cooling will turn your premium product into a dry, crumbling mess or explode the crust.

We specifically addressed this with our "Vacuum delay facility." This feature automatically detects products with high water yield resistance—like dense organic doughs—and modulates the pressure drop. This ensures the structure sets firmly and uniformly without collapsing or drying out.

Respecting the Dough Structure

I often hear bakers ask, "Won’t the vacuum suck all the moisture out and leave my bread dry?" It is a valid concern, especially for organic flours which often have different protein structures and hydration levels compared to standard commercial flours. They can be more sensitive to pressure changes. If you pull the vacuum too hard, too fast, the water inside flashes into steam aggressively and can rip the gluten structure apart.

That is why our AVCF models come standard with a "Vacuum delay facility3." This is not just a simple on/off switch; it is a smart monitoring system designed for products with higher water yield resistance. The machine senses how the bread is reacting. If the moisture release meets resistance, the system slows down the pressure drop. This ensures uniform cooling of the whole product load, from the core to the crust.

Here is how we give you control:

- Target Temperature: You can customize the "finish cooled temperature" to exactly what your product needs. For slicing, you might set it to 30°C. If you are freezing the bread immediately, you can set it lower.

- Real-Time Monitoring4: The touch screen operator control allows you to monitor the vacuum level, product temperature, and time elapsed in real-time. You are not flying blind.

- Automatic Stabilization: Once the target temperature is reached, the compressor and fans stop, but the system holds the state until the next cycle starts. This prevents the bread from re-absorbing heat or moisture.

By using this technology, you are actually improving the texture. The rapid cooling "sets" the starch structure faster, which helps maintain that chewiness and volume that artisan bread is known for. You get a crust that stays crispy and a crumb that stays moist, extending the "fresh-baked" feel by several days.

Is High-Tech Machinery Sustainable and Safe for My Team?

You built your brand on sustainability, so you hesitate to add energy-hungry heavy machinery to your process. You also need to ensure that any new equipment is safe for your staff to operate in a busy, fast-paced bakery environment.

Our vacuum coolers are designed with energy efficiency and worker safety as top priorities. They feature an intelligent "Start sequence" to minimize power surges and a "Power Save" mode that shuts down the system when idle. Plus, multiple emergency safeguards protect your team.

Efficiency Meets Ecology and Safety

In the organic sector, "green" isn’t just a label; it’s a business philosophy. We understand that wasting electricity hurts your bottom line and contradicts your brand values. When designing our coolers, we integrated specific power-saving logic to ensure the machine is as efficient as possible.

Energy Efficiency5:

The machine utilizes a "Start sequence" that delays motor engagement. Instead of turning everything on at once and causing a massive spike in electricity usage, the components start in order: cooling pump, vacuum pump, then compressor. This minimizes the full load of electrical power drawn. Furthermore, if the cooler is idle between batches—perhaps while you are loading the next oven—the machine will automatically shut down to save electricity usage. It wakes up instantly when you press the "cycle start button" for the next load. We also use high-efficiency evaporators and air-cooled condensers to keep the energy consumption low relative to the cooling power.

Worker Safety6:

We know that in a busy factory, safety is paramount. Our machines are CE-marked, meeting strict European safety directives. We have installed "Emergency Stop" buttons in two locations: one on the main control cabinet and one inside the chamber itself. If a worker were to accidentally be inside (which should never happen, but we plan for the worst), they can stop the machine instantly.

Additionally, the system has built-in diagnostics. It checks if the cooling water flows smoothly, if the pressure is stable, and if the oil levels are correct. If any abnormal noise occurs or if there is a leakage, the guidelines are clear: stop and examine. We provide detailed maintenance checklists—like checking connection pipes and valves for oil stains—to ensure the machine runs safely for years. This reliability protects your investment and your people.

| Eco/Safety Feature | Function | Benefit |

|---|---|---|

| Auto-Shutdown7 | Turns off when idle. | No wasted standby power. |

| Soft Start | Staggered motor start. | Reduces peak power demand. |

| Dual E-Stops | Buttons inside & outside. | Maximum worker protection. |

| Self-Diagnostics8 | Monitors pressure/oil. | Prevents major breakdowns. |

Conclusion

For organic bakeries, vacuum cooling is the missing link between the oven and the customer. By using our "Vacuum delay facility" to protect your unique textures and rapid cooling to 28°C to ensure superior hygiene, you can deliver a preservative-free product that stays fresh days longer. It is a sustainable, safe, and smart investment for your business.

-

Discover the importance of moisture control in baking and its impact on bread freshness. ↩

-

Explore how vacuum coolers enhance baking efficiency and product quality, ensuring fresher bread. ↩

-

Explore this link to understand how a vacuum delay facility enhances bread quality and prevents moisture loss. ↩

-

Discover the benefits of real-time monitoring in baking, ensuring optimal conditions for perfect bread. ↩

-

Explore how energy efficiency can significantly reduce operational costs and enhance sustainability in your business. ↩

-

Learn about innovative safety features in machinery that protect workers and ensure compliance with safety regulations. ↩

-

Discover how auto-shutdown can prevent energy waste and enhance safety in manufacturing processes. ↩

-

Find out how self-diagnostic systems can help maintain equipment reliability and prevent costly breakdowns. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the