How Can Vacuum Cooling Transform Your Bakery's Production Line?

Your ovens are incredibly efficient, but your bakery floor is clogged with cooling racks. This dead time kills your throughput, delaying slicing and packaging for hours and creating a massive production bottleneck.

Vacuum cooling removes this bottleneck by cooling fresh-from-the-oven bread or pastries to a perfect slicing temperature in minutes. This technology drastically increases production capacity, improves product quality, and extends shelf life by locking in moisture.

As an engineer, I see bakeries as high-speed factories. But almost every one I’ve visited has the same problem: a huge, slow, and uncontrollable cooling area that brings the entire factory to a halt. We design systems to solve this specific problem, making your entire production line faster and more profitable. Let’s explore how.

Why is Traditional Cooling the Biggest Bottleneck in Your Bakery?

You’ve invested in high-capacity mixers and ovens, but your output is limited by the hours it takes for bread to cool. Racks fill up your floor space, creating a logistical nightmare and preventing you from starting the next batch.

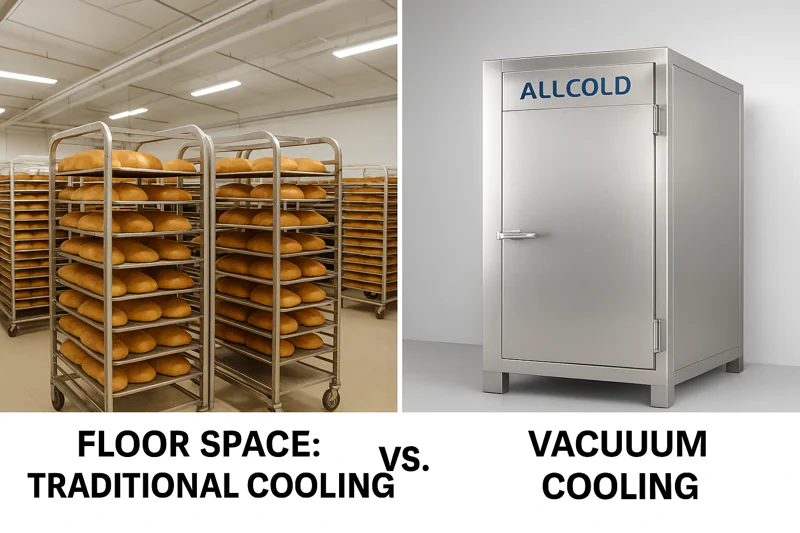

Traditional ambient cooling is a massive bottleneck because it is slow and space-intensive, taking 2-4 hours. Vacuum cooling completes the same process in just 15-25 minutes, freeing up valuable floor space and dramatically increasing your daily production capacity.

Reclaiming Your Floor Space and Production Time

For a high-volume operation like a central kitchen managed by someone like Sophia, floor space is money. Traditional cooling methods1 are the enemy of efficiency. A typical rack of bread needs to sit for several hours to cool to a temperature suitable for slicing (around 25-30°C). During this time, it occupies a huge footprint on your production floor. If you produce thousands of loaves per hour, this can mean dedicating a warehouse-sized area just to cooling. This is unusable space that holds up your entire process. Staff have to manually move these heavy, hot racks, creating safety hazards and adding labor costs.

Vacuum cooling2 fundamentally changes this equation. The process works by lowering the atmospheric pressure inside a sealed chamber. This causes water within the bread to boil at a very low temperature (around 30°C), rapidly removing heat from the core of the product. An entire cycle, from 95°C out of the oven to 30°C, takes around 15 to 25 minutes. A single vacuum cooler can handle the output of an industrial oven, replacing an entire room of cooling racks. This allows you to immediately start the next baking cycle, effectively doubling or tripling the throughput of your existing ovens without needing to expand your building. It transforms a slow, uncontrolled part of your process into a fast, repeatable, and automated step.

| Metric | Traditional Rack Cooling | ALLCOLD Vacuum Cooling |

|---|---|---|

| Cooling Time | 2-4 hours | ~20 minutes |

| Floor Space Required | Massive | Minimal, compact footprint |

| Labor | High (moving racks) | Minimal (load/unload machine) |

| Process Control | Uncontrolled, varies with ambient conditions | Fully controlled and repeatable |

Can You Really Improve Bread Quality by Cooling It Faster?

You worry that rapid cooling might harm the delicate structure of your bread. Common sense suggests that letting bread rest naturally is the best way to preserve its texture and flavor.

Yes, vacuum cooling significantly improves bread quality. It sets the crust perfectly, retains more moisture in the crumb for a softer texture, increases volume, and extends the sellable shelf life by slowing the staling process.

The Science of a Better Loaf

The quality improvements from vacuum cooling3 are not magic; they are based on food science. When a loaf of bread cools slowly, two negative things happen. First, moisture from the hot, gelatinized crumb migrates outwards, making the crust lose its initial crispness. Second, the starch structure begins a process called retrogradation (staling), where it recrystallizes and pushes water out, leading to a dry, crumbly texture.

Vacuum cooling interrupts this. By rapidly lowering the temperature from the core outwards, it "locks" the moisture into the crumb structure before it has a chance to migrate. The flash evaporation stabilizes the bread’s internal structure very quickly, preventing the loaf from collapsing as it cools, which often results in a better, more consistent volume. The result is a product with a longer-lasting crispy crust and a noticeably moister, softer crumb. This improved moisture retention is the key to a longer shelf life. The bread simply stays fresh longer because the staling process has been significantly inhibited from the moment it leaves the chamber. We even developed a "vacuum delay facility" which can be used on products to ensure perfectly uniform cooling, even on denser baked goods.

| Quality Attribute | Traditional Cooling | Vacuum Cooling |

|---|---|---|

| Crust Texture | Becomes soft quickly | Crispy for longer |

| Crumb Moisture | Drier, moisture loss | Higher moisture retention4, softer |

| Product Volume | Can shrink or collapse | Stable, often increased volume |

| Shelf Life (Staling) | Begins immediately | Significantly delayed |

How Do You Ensure Hygiene and Food Safety?

Your bakery operates under strict HACCP rules. The idea of introducing a new, complex piece of industrial equipment raises concerns about cleaning, sanitation, and potential contamination.

We design our bakery coolers with hygiene as a top priority. They feature easy-to-clean stainless steel interiors and can be equipped with oil-free vacuum pumps, eliminating any risk of contamination and ensuring compliance with the highest food safety standards.

An Architecture Built for Food Safety

When dealing with ready-to-eat products like bread, hygiene is non-negotiable. A professional buyer like Norman or a quality manager like Sophia will scrutinize every detail of the equipment. We build our systems to exceed their expectations. The chamber itself is constructed from high-grade stainless steel5 with a smooth, polished interior finish, making it very easy to clean and sanitize. Overall hygiene maintenance and cleaning of the chamber are part of our standard recommended procedures.

A critical consideration for bakeries is the vacuum pump technology. Many standard vacuum pumps are "oil-sealed," meaning they use oil within the pumping mechanism. While they are reliable, there is a small but unacceptable risk of oil mist contaminating the food product. For this reason, we strongly recommend and design bakery systems with premium, oil-free dry screw vacuum pumps6. These pumps, from world-class brands like Leybold in Germany, use no oil or water in the vacuum chamber, guaranteeing zero risk of contamination. While standard maintenance like checking compressor oil is still required, eliminating oil from the vacuum process itself is the key. This commitment to using high-quality, hygienic components like Siemens touch screens and Schneider contactors ensures the machine is not only safe but also incredibly reliable.

How Does This Integrate with Slicing and Packaging?

Your slicing machines are sensitive and require bread to be at a perfect, consistent temperature. Any variation causes tearing and slows down the packaging line, forcing you to maintain a large buffer area.

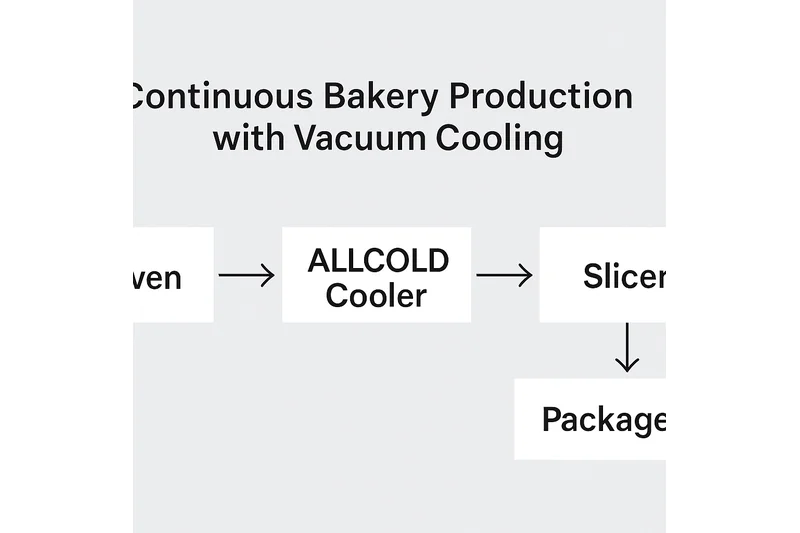

Vacuum cooling delivers bread at a precise, uniform temperature, ready for immediate slicing and packaging. This eliminates the need for a cooling buffer area and allows you to create a truly continuous production line from oven to truck.

vacuum cooling7 is its ability to create a seamless, continuous production line8. In a traditional bakery, the space between the ovens and the packaging machines is a chaotic buffer zone filled with racks in various states of cooling. It’s an inefficient, stop-and-go process. Slicing bread that is even slightly warm results in torn crusts, gummy crumbs, and damaged slicer blades.

vacuum cooling7 is its ability to create a seamless, continuous production line8. In a traditional bakery, the space between the ovens and the packaging machines is a chaotic buffer zone filled with racks in various states of cooling. It’s an inefficient, stop-and-go process. Slicing bread that is even slightly warm results in torn crusts, gummy crumbs, and damaged slicer blades.

By implementing a vacuum cooler, you create a perfect link between baking and packaging. Racks of bread are taken directly from the oven to the cooler. The cycle is started with a simple touch screen interface, and 20 minutes later, the bread emerges at a perfect, uniform 25°C from crust to core. It can be moved directly to the slicer. There is no guesswork and no waiting. This predictable output allows you to perfectly synchronize your entire factory. The speed of your slicer and packaging machines can be matched to the output of your ovens because the cooling step is no longer a variable. Our systems are delivered "plug-in ready" and undergo 72 hours of trouble-free trial operation at our factory, so you can be confident they will perform reliably from day one.

Conclusion

Vacuum cooling for bakeries is a transformative technology. It eliminates bottlenecks, increases throughput, saves space, improves bread quality, and enhances food safety, delivering a rapid return on investment for any modern bakery.

-

Learn how traditional cooling methods can hinder your bakery’s efficiency and discover alternatives. ↩

-

Explore the advantages of vacuum cooling to enhance efficiency and reduce space in your baking operations. ↩

-

Explore how vacuum cooling enhances bread quality, ensuring a crispy crust and moist crumb for longer-lasting freshness. ↩

-

Learn about the importance of moisture retention in bread, which contributes to texture and shelf life. ↩

-

Learn why high-grade stainless steel is essential for food processing equipment, ensuring durability and easy sanitation. ↩

-

Discover how oil-free dry screw vacuum pumps enhance food safety by eliminating contamination risks, ensuring high hygiene standards. ↩

-

Explore this link to understand how vacuum cooling enhances efficiency and product quality in bakeries. ↩

-

Discover the advantages of a continuous production line and how it streamlines bakery processes for better productivity. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy