How Can You Cool Vegetables Faster to Maximize Freshness and Profit?

Losing money from spoiled vegetables before they even reach the market? Traditional cooling is often too slow, letting precious quality and profits degrade.

Rapid vegetable cooling, especially advanced methods like vacuum cooling, quickly removes field heat. This dramatically slows decay, extends shelf life, and preserves nutritional value, directly boosting your market returns and customer satisfaction.

Now that you see why fast cooling is such a big deal, let’s dive a bit deeper. It’s more than just chilling your produce; it’s about protecting your investment and reputation. We’ll look at why this speed is so critical and what options you have.

Why is Rapid Vegetable Cooling So Crucial Anyway?

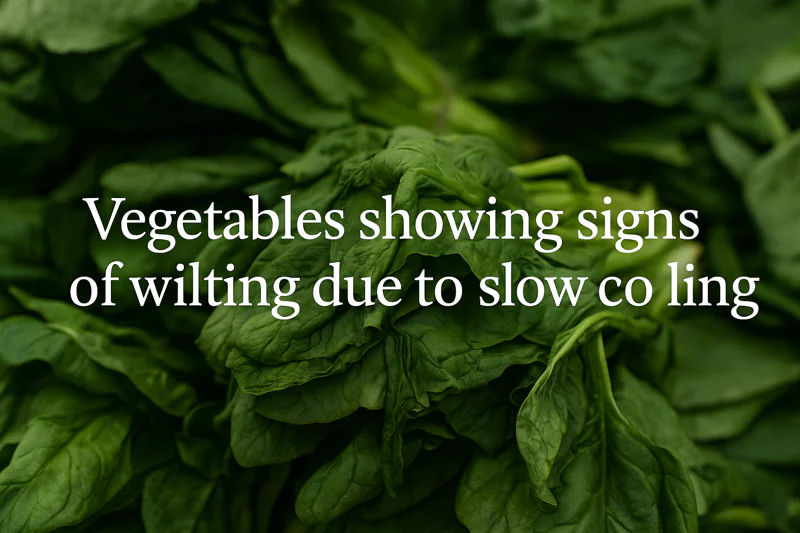

Seeing your freshly harvested vegetables wilt or lose their crispness before they reach customers? This is a common frustration, and this loss directly eats into your hard-earned profits. Learn why immediate, effective cooling is your first line of defense.

Rapid cooling is crucial because it quickly halts detrimental biological processes like enzyme activity and microbial growth. This action preserves the vegetable’s freshness, texture, color, and vital nutrients, directly impacting its market value and consumer appeal.

Let’s break this down further. Vegetables, once harvested, are still living, breathing organisms. They continue to respire, consuming their stored sugars and releasing heat and moisture. If this field heat isn’t removed quickly, several negative things happen. I remember a farmer I worked with in [Country Name Placeholder, e.g., Spain] who was losing almost 20% of his lettuce crop during transport in warmer months. The issue was traced back to slow pre-cooling. Once he implemented a faster system, his losses dropped dramatically.

The Biology of Spoilage After Harvest

After picking, vegetables enter a race against time.

- Respiration: They "breathe," using up stored energy (sugars) and producing heat. Faster cooling slows this down.

- Moisture Loss: Vegetables can lose water to the atmosphere, leading to wilting and weight loss. Rapid cooling reduces this.

- Enzymatic Activity: Enzymes continue to work, which can lead to changes in texture, color, and flavor. Chilling slows these enzymes.

- Microbial Growth: Bacteria and fungi thrive at warmer temperatures. Quick cooling inhibits their growth.

Economic Impacts of Slow Cooling

The consequences of slow cooling are not just biological; they hit your wallet hard.

- Reduced Shelf Life: Faster spoilage means less time to sell.

- Lower Quality: Wilted, discolored, or off-flavor produce fetches lower prices or gets rejected. Customers like Norman, who are very quality-conscious, will notice.

- Increased Waste: More produce gets thrown away, which is lost revenue. This is a huge pain point for farmers like Carlos, who aims to minimize post-harvest losses.

Here’s a simple table showing the impact:

| Impact Area | Consequence of Slow Cooling | Benefit of Rapid Cooling |

|---|---|---|

| Respiration Rate | High, burns sugars rapidly | Significantly Reduced |

| Moisture Loss | Wilting, shriveling, weight loss | Minimized |

| Microbial Growth | Accelerated decay, mold, rot | Inhibited, delayed |

| Shelf Life | Shortened, rapid quality decline | Extended considerably |

| Market Value | Reduced, potential rejection | Maintained, premium possible |

| Nutritional Value | Faster degradation of vitamins | Better retention |

So, you see, getting that field heat out fast is a fundamental step.

What Are the Traditional Vegetable Cooling Methods and Their Limitations?

Still relying on just a cold room or fans to cool your vegetables? While these methods have been around for a while, they might be costing you more than you realize in terms of time, quality, and ultimately, money.

Traditional methods like room cooling or forced-air cooling are often slow and can result in uneven temperature reduction throughout the produce. This inconsistency can lead to variable quality, shorter shelf life, and increased spoilage for many types of vegetables.

For years, many in the industry, including some of my early clients, relied on these common methods. They are seemingly simple, but their drawbacks become very clear, especially with delicate, high-respiration produce or large volumes. Carlos, one of my customers in Mexico, used to struggle with his old cold rooms; he’d say, "Mila, the lettuce on the outside of the pallet is cool, but the center is still warm! It’s just too slow." This is a common story.

Room Cooling: The Simplest, But Often Slowest

This involves placing produce in a refrigerated room.

- How it works: Cold air in the room gradually absorbs heat from the produce.

- Limitations: Very slow, especially for densely packed produce. Air circulation can be poor, leading to "hot spots." It can take many hours, even days, for the core temperature to drop.

Forced-Air Cooling: An Improvement, But Still Has Issues

Here, fans are used to pull or push cold air through stacks of produce.

- How it works: Increases contact between cold air and the produce surface.

- Limitations: Faster than room cooling, but still can be slow for core cooling. Can cause dehydration or "windburn" on some vegetables if humidity isn’t controlled. Energy consumption can be high for the cooling duration.

Hydrocooling: Fast for Some, But Not All

This method uses chilled water to cool produce.

- How it works: Produce is immersed in or sprayed with cold water.

- Limitations: Effective and fast for some robust vegetables (like carrots or celery). However, it’s not suitable for many delicate leafy greens or vegetables prone to water absorption or water-borne diseases. Requires water management and sanitation.

Let’s compare them:

| Method | Typical Cooling Time | Evenness of Cooling | Risk of Dehydration | Suitable For Examples | Key Limitations |

|---|---|---|---|---|---|

| Room Cooling | 12-72+ hours | Poor | Low | Hardy root vegetables | Very slow, uneven, high spoilage risk |

| Forced-Air | 4-10 hours | Moderate to Good | Moderate to High | Berries, broccoli, tomatoes | Can be slow for dense loads, dehydration risk |

| Hydrocooling | 5-30 minutes | Good | None (adds moisture) | Asparagus, sweet corn, carrots | Not for leafy greens, water management, pathogen risk |

These methods have their place, but for achieving truly rapid and uniform cooling, especially for high-value or delicate crops, we often need something more advanced.

How Does Vacuum Cooling Revolutionize Vegetable Pre-Cooling?

Frustrated with slow cooling times, uneven results, and product loss using older methods? There’s a highly effective, modern technology that offers a breakthrough solution for many types of vegetables, especially leafy ones.

Vacuum cooling revolutionizes pre-cooling by rapidly evaporating a small amount of moisture directly from the vegetables’ surface under low pressure. This process cools produce incredibly quickly and uniformly, often from field temperature to optimal storage temperature in under 30 minutes.

This technology is a core part of what we offer at allcold, and I’ve seen firsthand the difference it makes for businesses. When I explain the science to farmers or wholesalers, they’re often amazed. Imagine water boiling at room temperature – that’s essentially what happens, but it’s a controlled process that cools instead of cooks.

The Science Behind Vacuum Cooling

It’s all about physics.

- Lowering Pressure: The vegetables are placed in a sealed chamber, and air is pumped out, creating a vacuum.

- Reduced Boiling Point: As the pressure drops, the boiling point of water also drops.

- Evaporative Cooling: The water on and within the vegetables starts to "boil" (evaporate) at these low temperatures. This evaporation process requires energy (latent heat of vaporization), which is drawn from the vegetables themselves, thus cooling them down rapidly. For every 1% of moisture evaporated, the product temperature drops by about 6°C (11°F). This usually means only 1-3% moisture loss for significant cooling.

Unmatched Speed and Uniformity

This is where vacuum cooling truly shines.

- Speed: Cooling cycles are typically 15-30 minutes. This is a game-changer compared to hours or days with traditional methods. Carlos was able to process his lettuce much faster, meeting tight delivery schedules for supermarket chains.

- Uniformity: Because the cooling happens from within (as water evaporates from all surfaces and even slightly below the surface), the entire product, from core to skin, cools down evenly. No more hot spots.

Benefits Beyond Just Cooling

The advantages extend further:

- Extended Shelf Life: Rapid, uniform cooling drastically slows respiration and microbial growth, leading to a significant increase in shelf life.

- Preserved Quality: Minimizes moisture loss (beyond the controlled evaporation), maintains crispness, color, and nutritional value.

- Increased Efficiency: Less handling, faster turnaround, and reduced spoilage contribute to overall operational efficiency. Some of our models can even be customized to fit directly into packing lines.

Here’s a quick comparison:

| Feature | Vacuum Cooling | Traditional Methods (General Average) |

|---|---|---|

| Cooling Time | 15-30 minutes | Hours, often 4-24+ |

| Uniformity | Excellent (core and surface cool evenly) | Often Poor to Moderate |

| Moisture Loss | Controlled, minimal (1-3% for cooling) | Can be higher and uncontrolled (forced air) |

| Energy Efficiency | High per pound cooled quickly | Can be less efficient for long durations |

| Shelf Life Impact | Significant extension (days, even weeks) | Moderate extension |

| Suitable Produce | Leafy greens, broccoli, mushrooms, sweet corn | Varies widely by method and produce |

When clients see the results – the crispness of their lettuce, the extended life of their broccoli – they understand why vacuum cooling is an investment, not an expense.

What Key Factors Should You Consider When Choosing a Vegetable Cooling System?

Ready to upgrade your vegetable cooling but feeling overwhelmed by the options? Choosing the right system is a critical decision that will impact your product quality, operational efficiency, and bottom line for years to come.

Key factors include the specific types and volumes of vegetables you handle, your desired cooling speed, available space, energy efficiency targets, and your budget. Equally important are supplier reliability, after-sales service, and the potential for customization.

I always advise my clients, whether they are a large-scale farmer like Carlos or a meticulous buyer like Norman, to think through their specific needs carefully. It’s not just about buying a machine; it’s about finding the right solution. One time, a potential client was focused solely on the upfront cost of a vacuum cooler, but when we analyzed their spoilage rates and the market premium they could get for consistently high-quality produce, the ROI on a slightly more expensive, but better-suited, custom machine became obvious.

Understanding Your Produce and Operational Needs

- Type of Vegetable: Different vegetables have different cooling requirements. Leafy greens (lettuce, spinach) are ideal for vacuum cooling. Denser products might need specific considerations or alternative methods.

- Throughput Volume: How much produce do you need to cool per hour or per day? This determines the required capacity of the cooling system.

- Desired Cooling Speed: How quickly do you need to reach the target temperature to maintain quality and meet shipping schedules?

- Existing Infrastructure: Consider available space, power supply, and how the new system will integrate with your current packing line or workflow. Sophia, managing a central kitchen, needs compact systems that integrate smoothly.

Evaluating Equipment Specifications

- Cooling Performance: Look at cycle times, temperature uniformity, and energy consumption (kW per ton of produce cooled).

- Build Quality and Materials: Durability is key, especially for equipment that will be used intensively. For food products, materials must be food-grade and easy to clean to meet hygiene standards like HACCP, which is crucial for clients like Sophia.

- Ease of Operation and Maintenance: Is the system user-friendly? How much maintenance is required, and is it easy to perform?

Choosing the Right Supplier

This is as important as the machine itself.

- Experience and Expertise: Does the supplier understand your specific industry and product needs? We at allcold have worked with diverse clients globally.

- Customization: Can the supplier tailor the equipment to your specific requirements? This is one of our key strengths.

- After-Sales Service and Support: What kind of warranty, technical support, and spare parts availability do they offer? Good after-sales service is critical to minimize downtime, a major pain point for many. Norman always emphasizes this.

- Reputation and References: Check reviews, ask for case studies or references.

Here’s a checklist to guide your decision:

| Consideration Factor | Key Question(s) for Your Business | Why It Matters for Optimal Results |

|---|---|---|

| Produce Profile | What specific vegetables? What are their vulnerabilities? | Determines suitability of cooling technology |

| Volume & Throughput | Pallets per hour? Tons per day? Peak season needs? | Dictates machine size, capacity, and investment |

| Cooling Speed & Target | From X°C to Y°C in how many minutes/hours? | Impacts shelf life, quality, and operational flow |

| Energy Efficiency | What are the projected operational costs (kWh/cycle)? | Affects long-term profitability |

| Space & Integration | Footprint? Fit with existing layout? Automation? | Practical implementation and workflow efficiency |

| Budget & ROI | Initial cost vs. long-term savings and revenue gains? | Financial feasibility and value justification |

| Supplier Credibility | Proven track record? Good after-sales? Customization? | Ensures reliability, support, and tailored solutions |

Taking the time to evaluate these factors will help you invest wisely.

Conclusion

Ultimately, rapid vegetable cooling, especially with advanced methods like vacuum cooling, is essential for maintaining peak quality, extending shelf life, and maximizing your profits. Choose your system wisely.

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not