How Can You Keep Organic Vegetables Fresh Without Chemicals?

You put incredible effort into growing beautiful organic produce, free from synthetics. But then, after the harvest, you watch helplessly as it wilts and loses its value faster than conventional vegetables.

You preserve organic freshness with vacuum cooling, a purely physical process. It rapidly removes field heat—the main cause of decay—using water’s natural properties, extending shelf life dramatically without adding any chemicals or altering the product’s organic integrity.

The entire value of your organic certification is in that promise of purity. The challenge is making that purity last from your farm to the consumer’s kitchen. You need a preservation method that is as clean as your farming methods. Let’s explore why vacuum cooling is the organic farmer’s best friend.

Why Do Organic Vegetables Spoil So Fast?

It’s a frustrating reality for organic growers. You produce a superior product, yet its shelf life seems shorter, making every hour after harvest critical and stressful.

Organic vegetables spoil faster because they are alive and breathing. This respiration, combined with natural microbial activity, is accelerated by "field heat." Without chemical inhibitors, this natural process of decay happens very quickly.

Think of a freshly harvested vegetable like a runner who has just finished a race. It’s hot, it’s breathing hard, and it’s using up its stored energy. This "breathing" is called respiration. The sun’s heat stored in the vegetable—the field heat—is like fuel for this process. It makes the vegetable burn through its own sugars and moisture, causing it to wilt, lose nutrients, and become weak. Because you don’t use chemical fungicides, naturally occurring bacteria and mold have a perfect, warm environment to grow. This is especially true for high-value organic crops like leafy greens, broccoli, and mushrooms, which have a high surface area and water content. The problem isn’t your growing method; it’s the natural biology of the plant working against you after harvest. The only organic-compliant way to slow this down is to remove the heat, fast.

The Race Against Field Heat

Slowing respiration is the key to extending shelf life1. Getting the core temperature2 down from 30°C to 2°C as quickly as possible is the single most important factor in preserving the quality you worked so hard to create.

| Factor | Warm Produce (Immediately After Harvest) | Properly Pre-Cooled Produce |

|---|---|---|

| Respiration Rate | High (burning energy and moisture). | Very Low (energy and moisture preserved). |

| Microbial Growth | Fast (ideal warm, moist conditions). | Slowed dramatically. |

| Visual Quality | Rapid wilting, loss of color and crispness. | "Just-harvested" look is locked in. |

| Result for Organics | Short shelf life1, high risk of spoilage. | Extended shelf life1, premium quality. |

How Does Vacuum Cooling Work Without Using Chemicals?

The term "vacuum" might sound industrial, but you’re rightfully concerned about maintaining your organic certification. You need to know that any process is 100% natural.

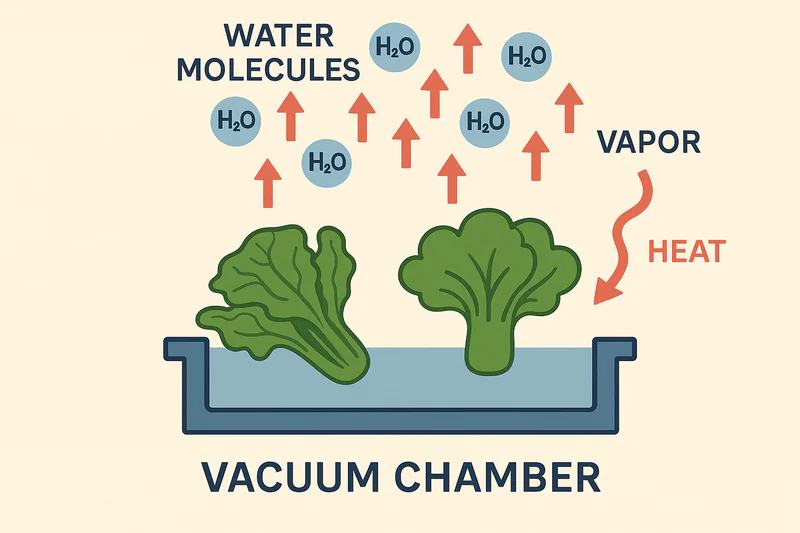

Vacuum cooling is a neat trick of physics. By lowering the air pressure inside a sealed chamber, we make water "boil" at a very low temperature. This evaporation pulls heat directly out of the vegetable itself.

It’s the same principle as feeling cold when you get out of a swimming pool on a windy day. The evaporating water on your skin is pulling heat from your body. We just do it much faster inside a controlled chamber. Nothing is added. No chemicals, no gases, no additives. The process simply removes two things: air and a tiny amount of the product’s own water (about 1-2%), which is what carries the heat away. The entire cycle takes about 25 minutes and drops the core temperature of the produce uniformly to a safe 2°C. A procurement manager like Sophia, who needs to meet strict HACCP hygiene certifications for her kitchens, would appreciate this technology. It’s a closed, clean, and fast process that introduces no contaminants. It is physically impossible for it to violate organic standards because it’s based on the natural properties of water.

A Purely Physical Process

The beauty of this method lies in what it doesn’t do. It doesn’t spray, coat, or irradiate your produce. It leverages nature to preserve nature.

| Process Step | Action | Organic Impact |

|---|---|---|

| 1. Seal the Chamber | Vegetables are loaded, and the door is sealed. | None. |

| 2. Evacuate Air | Powerful pumps remove most of the air. | None. Creates a low-pressure environment3. |

| 3. Flash Evaporation4 | Water evaporates, rapidly removing heat. | None. Purely physical change of state. |

| 4. Repressurize | Air is let back into the chamber. | None. |

| Result | Produce is cooled from core to surface. | Product remains 100% pure and organic. |

Can This Process Really Protect Your Organic Price Premium?

You grow organic produce to earn a better price. But if your beautiful lettuce looks limp and sad by the time it reaches the store shelf, that premium vanishes.

Yes, absolutely. Vacuum cooling protects your premium by preserving the visual proof of quality. It locks in the vibrant color, crisp texture, and turgidity that tells a customer, "This is fresh, this is healthy, this is worth it."

Consumers who choose organic are paying for an ideal. They expect perfection. A farmer like Carlos, who supplies large supermarket chains, knows that buyers have zero tolerance for anything less. When a customer sees your organic broccoli and it’s a deep, rich green with a firm texture, they don’t question the price. But if it’s slightly yellowed or limp, the organic label doesn’t matter; they won’t buy it. Vacuum cooling is the single best way to ensure your produce looks as good on day seven as it did on day one. This visual perfection is your price protection. It allows you to confidently ship to markets further away, widening your customer base without sacrificing the quality that justifies your premium price in the first place. You are not just selling organic food; you are selling organic confidence.

The Visual Indicators of Value

In a retail setting, people buy with their eyes. Protecting these visual cues is directly protecting your revenue.

| Visual Attribute | Without Rapid Pre-Cooling | With Vacuum Cooling |

|---|---|---|

| Color | Fades, can turn yellow or brown. | Vibrant and locked-in. |

| Texture | Becomes limp, soft, and wilted. | Stays crisp, firm, and turgid. |

| Perceived Freshness5 | Looks old, tired. | Looks "just-harvested." |

| Price Justification6 | Weak. Customer questions the value. | Strong. The quality speaks for itself. |

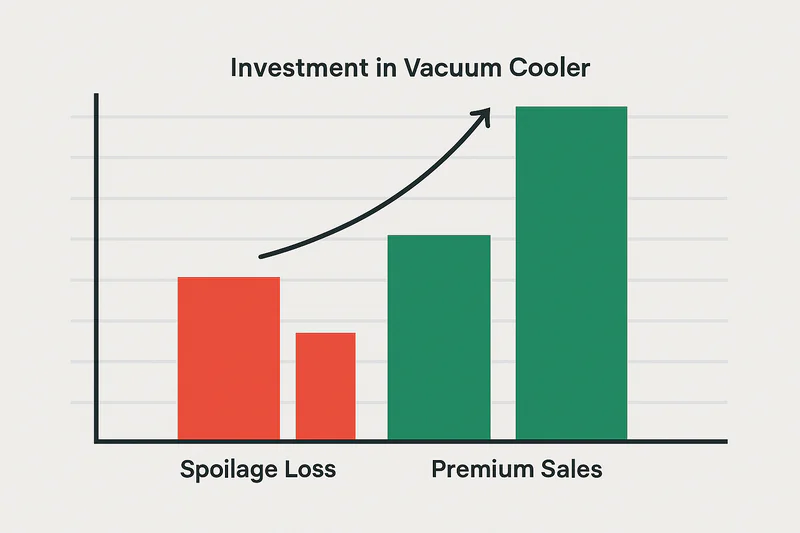

What Is the Real ROI for an Organic Grower?

As an organic farmer, every investment must be carefully considered. You need to know that a machine will not just sit there, but actively make you more money.

The ROI is clear and powerful: you make more money by selling nearly all of what you grow. You stop losing revenue to spoilage and start securing higher prices because your quality is guaranteed.

Let’s break down the return on investment into simple terms. First, there’s the money you stop losing. If you currently lose 15% of your sensitive leafy green crop to spoilage, and that crop is worth $100,000, that’s $15,000 in lost revenue. Vacuum cooling can cut that loss to under 3%, putting $12,000 back in your pocket. Second, there’s the money you secure. By delivering a visually perfect product, you guarantee you get your full premium price, preventing forced discounts on slightly older-looking stock. Third, there’s the money you gain. The extended shelf life allows you to enter new geographic markets or supply bigger clients who were previously out of reach, creating entirely new revenue streams. The investment is not a cost; it is a tool that directly addresses the three biggest financial challenges of organic farming.

The Three Pillars of Organic ROI

The financial benefits are a direct solution to the natural challenges of chemical-free agriculture.

| ROI Component | The Problem It Solves | Financial Impact |

|---|---|---|

| 1. Waste Reduction7 | Organic produce has a naturally short lifespan. | Drastically cuts revenue lost to product spoilage. |

| 2. Quality Guarantee | The organic premium is tied to perceived freshness. | Secures top-dollar pricing, prevents markdowns. |

| 3. Market Expansion8 | Short shelf life limits shipping distance and time. | Unlocks new, more distant, and often more lucrative markets. |

Conclusion

Vacuum cooling is the perfect partner for organic farming. It uses a natural, physical process to preserve your product’s integrity, protect your premium prices, and ensure your hard work pays off.

-

Exploring methods to extend shelf life can help you preserve freshness and reduce waste. ↩ ↩ ↩

-

Understanding core temperature is crucial for maintaining produce quality and extending shelf life. ↩

-

Exploring the effects of a low-pressure environment can provide insights into effective preservation methods. ↩

-

Understanding Flash Evaporation can enhance your knowledge of innovative food preservation techniques. ↩

-

Understanding perceived freshness can enhance your marketing strategies and improve customer satisfaction. ↩

-

Exploring price justification can help you optimize pricing strategies and boost sales. ↩

-

Understanding waste reduction can help you maximize profits and minimize losses in organic farming. ↩

-

Exploring market expansion strategies can lead to new opportunities and increased revenue for organic producers. ↩

Mila

You May Also Like

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

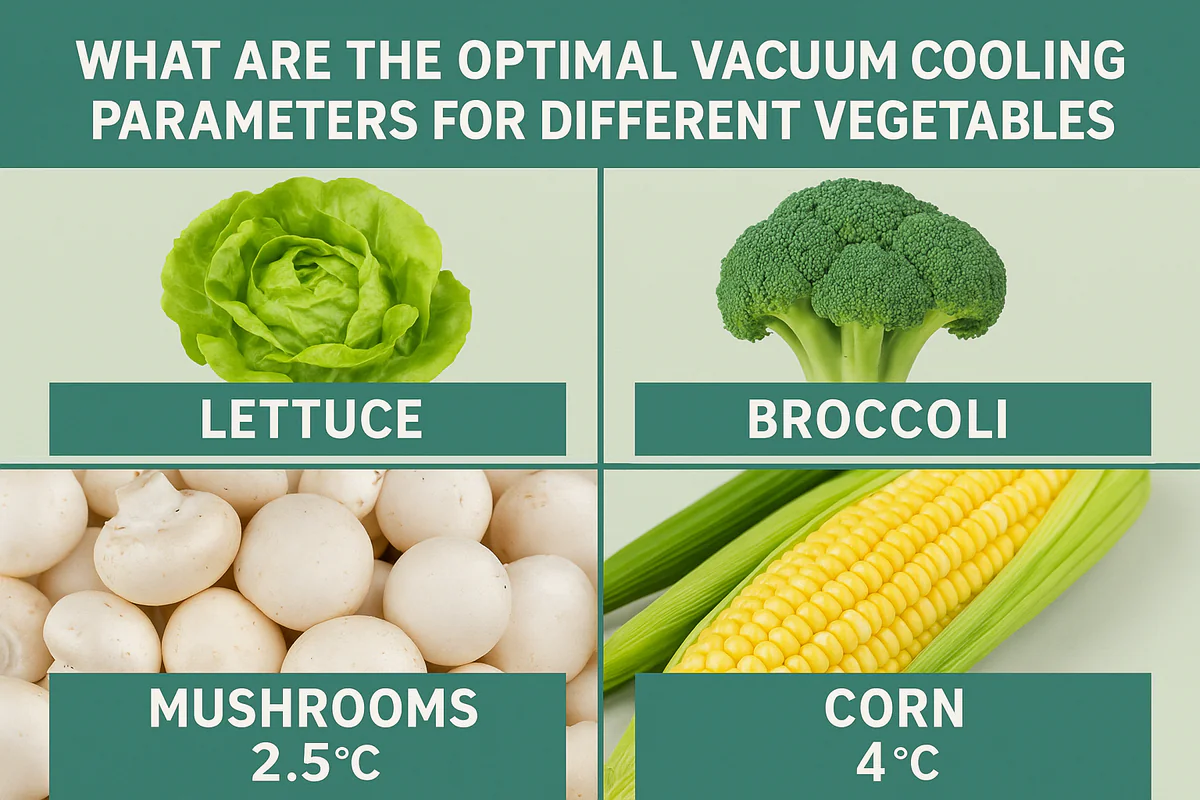

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

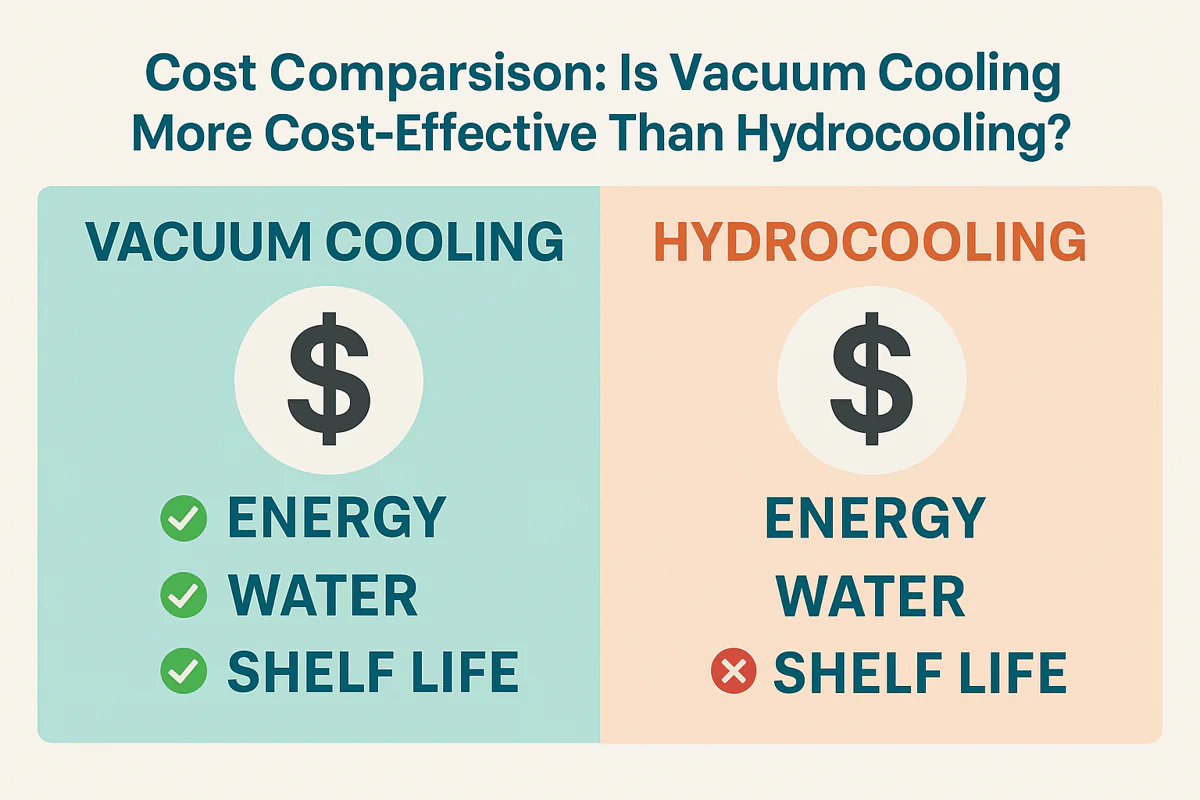

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are