How Can You Lock in "Oven-Fresh" Quality for Days?

You bake the perfect loaf. It smells amazing. The crust is crisp, and the crumb is soft. But by the time it reaches the customer, that magic is often gone. You are fighting a losing battle against time, temperature, and evaporation.

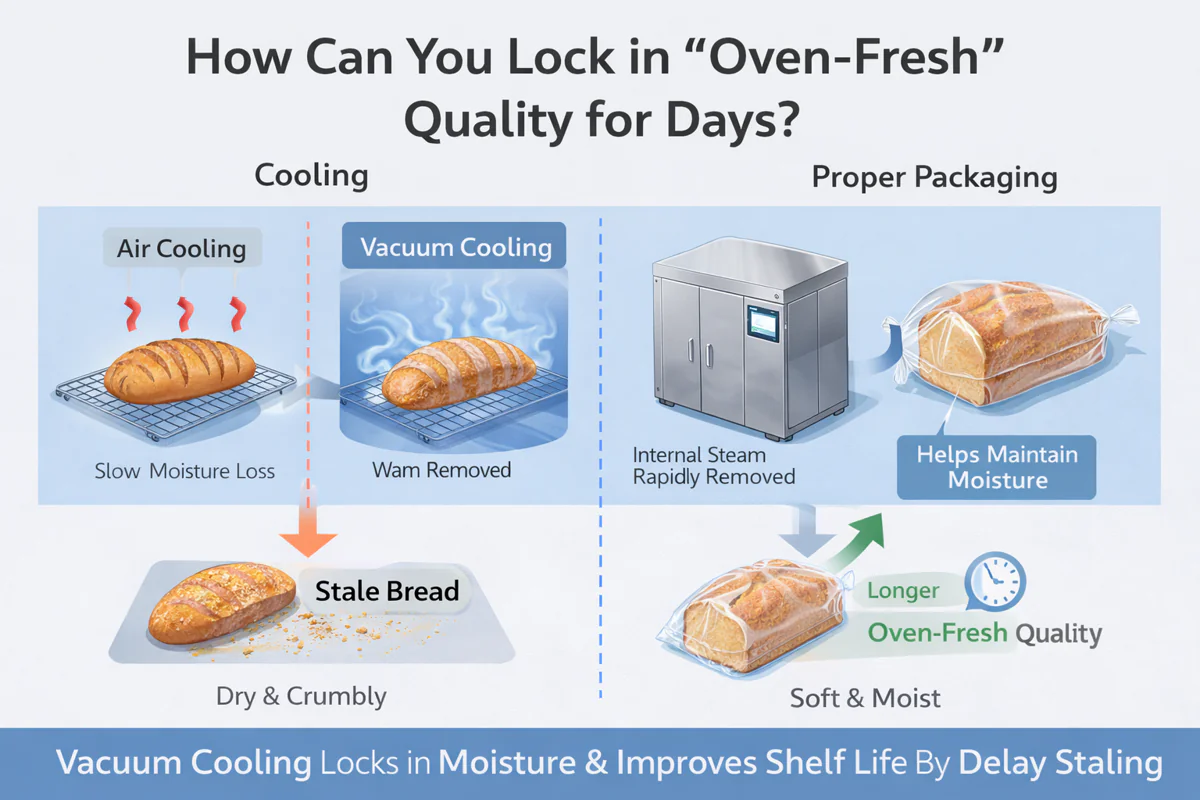

Vacuum cooling locks in freshness by reducing the internal temperature of baked goods from 92°C to 30°C in just minutes. This rapid cooling halts the starch retrogradation process immediately, preserving the aroma, texture, and moisture content that usually evaporates during slow air cooling.

We often think of "freshness" as something that happens inside the oven. But I believe freshness is actually determined by how you handle the product after it leaves the oven. If you let your bread sit in a warm room for two hours, you are allowing the structure to age prematurely. At Allcold, we see cooling as the first step of preservation, not the last step of baking. Whether you are a large wholesale bakery in America or a specialized food factory in Singapore, the challenge is the same: how do you stop the clock? Let’s look at how speed changes everything.

Is Your Cooling Process Stealing Your Product’s Shelf Life?

You might think that letting bread cool naturally on a rack is gentle and traditional. In reality, it is a slow death for freshness. The longer bread stays hot, the more it dries out and ages before it is even packaged.

Traditional cooling exposes bread to oxidation and moisture loss for up to two hours. Allcold vacuum coolers slash this time dramatically, effectively freezing the "freshness clock" the moment the bread leaves the oven.

The Biology of Speed

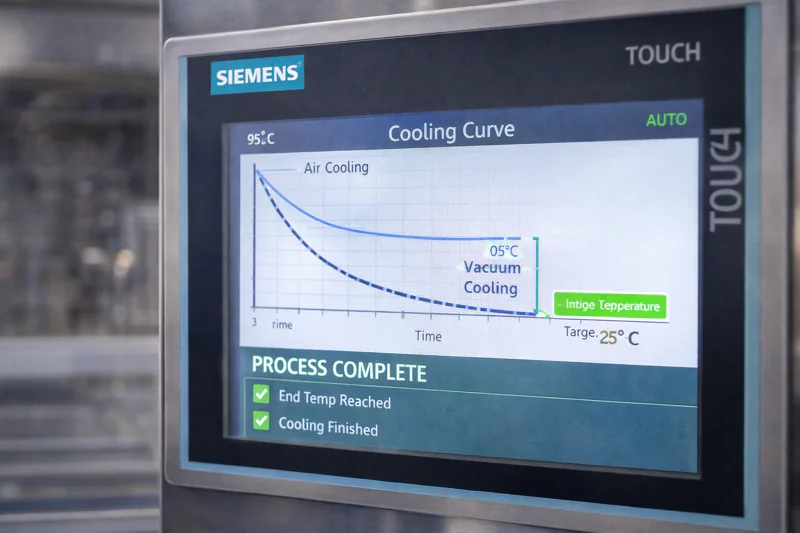

The enemy of freshness is time. With our vacuum technology1, we automate the cooling process to ensure consistency. Once the ‘Target temperature’ reaches the setting figure, the system automatically stops the compressor and condenser fans, then proceeds to deflation and drainage. This rapid sequence effectively freezes the "freshness clock" before staling can begin.

Efficiency Meets Intelligence (Energy Savings)

You might worry that such speed consumes massive amounts of power. However, our systems are designed to be intelligent regarding energy consumption2. When the vacuum cooler has not been operated for a period of time, the machine will automatically shut down to save electricity usage. It restarts instantly when you press the cycle start button on the remote control panel. This means you get the industrial speed you need to preserve freshness, but you do not pay for wasted energy during downtime or shift changes.

Can You Trust a Machine to Handle Delicate Baked Goods?

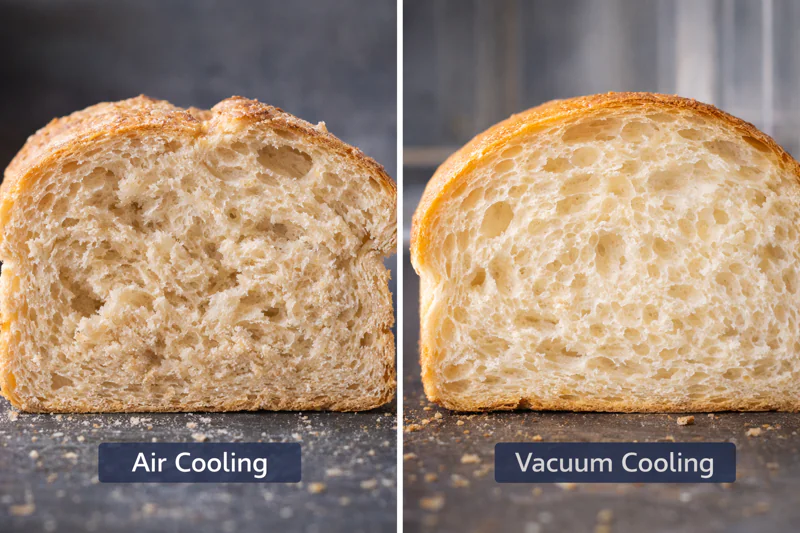

You are afraid that a powerful vacuum machine will crush your croissants, explode your sponge cake, or collapse your carefully proofed dough. It is a valid fear, but only if you use the wrong technology or outdated settings.

Precise control prevents damage. Allcold systems use advanced components like Siemens touch screens to gently manage pressure, ensuring even the most delicate structures are cooled uniformly from the inside out without collapsing .

Precise Automation for Perfect Texture

Precise control is the only way to prevent damage to delicate structures. Our machines utilize a sophisticated control system3 that removes human error. The system is built with high-quality components, including Siemens touch screens and Schneider electric parts, to ensure reliable operation . This level of automation ensures that the pressure drop is managed perfectly every time.

Hygiene and Safety Standards4

Freshness also means safety. In a busy bakery, safety cannot be compromised. Our manuals explicitly state that you must never allow children to use the machine and should avoid operating it while people are nearby. Furthermore, for the safety of your staff, you must ensure nobody is in the vacuum chamber when the machine is in use. This focus on safety and standardized operation ensures that your high-speed cooling doesn’t become a liability.

Will This Technology Work in Your Hot Bakery Environment?

Your bakery is hot. In the summer, it is unbearable. You worry that sensitive refrigeration equipment will fail when the ambient temperature climbs, ruining your production schedule and spoiling your dough.

Standard fridges struggle in heat, but Allcold vacuum coolers are built for it. Designed to operate in high ambient temperatures, our systems use robust Bitzer compressors to guarantee consistent cooling performance regardless of the weather outside.

Engineered for Extreme Heat

I have a client who runs a facility in a region where summers are brutal. He was terrified that a vacuum cooler would overheat. However, our technical specifications confirm that our machines are designed for a working condition with a maximum ambient temperature of +52°C5 . Even in other configurations, we design for at least +45°C . By using high-quality refrigerants like R448A or R404A and robust Bitzer compressors , we ensure the system maintains compression ratios even when the factory floor feels like an oven.

Is the Maintenance Too Complex for Your Staff?

You worry that adding high-tech equipment will require hiring expensive specialist engineers. You think maintaining a vacuum system is complicated, messy, and prone to costly errors that will stop production.

We simplify maintenance so your existing team can handle it. With clear checklists for oil levels and automated self-cleaning cycles, Allcold machines require minimal daily attention, ensuring long-term performance without the need for specialized external technicians.

Routine Made Simple (The 10-Second Check)

A machine that is hard to maintain is a machine that will eventually break. We have simplified the daily routine to a few seconds of visual checks. You simply need to ensure the oil level of the compressor and vacuum pump is within the normal range of 1/3 to 2/3 . We also recommend periodically checking all connection pipes and valves to see if they are firm. A practical method to find leaks is to use a sponge with soap foam—if bubbles appear, you have found a leak . These clear, visual indicators mean any staff member can perform the daily safety check.

Proactive Self-Cleaning Features

Bread releases moisture, and moisture is the enemy of vacuum pump oil. To prevent the oil from turning milky, our machine has a built-in self-cleaning protocol. After the cooling cycle reaches the target temperature, the vacuum pumps keep running for 20 minutes specifically to scrape water in the vacuum pump oil. This simple, automated step extends the life of your equipment significantly.

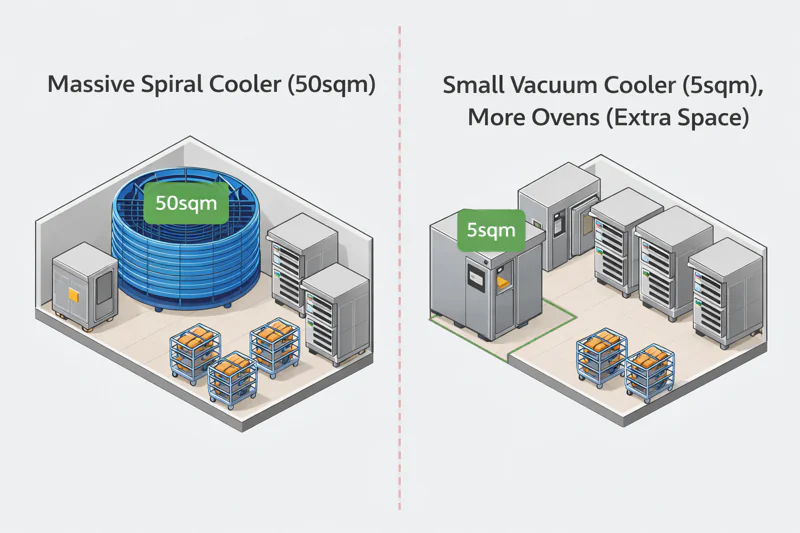

Are You Wasting Valuable Floor Space on Slow Cooling?

Real estate in a bakery is expensive. You look around your facility and see huge spiral conveyors or racks taking up hundreds of square meters, just holding bread while it cools. It feels like a waste of potential production space.

Vacuum cooling frees up your factory floor. Because the process is significantly faster than air cooling, one compact Allcold machine can replace large areas of spiral conveyors, allowing you to increase your production capacity without building a new factory.

Reclaiming Your Factory Floor

Real estate in a bakery is expensive. Traditional spiral conveyors take up massive amounts of "passive" space. In contrast, our vacuum coolers are incredibly compact. By utilizing top-tier components like Bitzer compressors and Leybold vacuum pumps , we pack immense cooling power into a small footprint. This frees up space for an additional oven or a new packaging line, directly increasing your revenue per square meter without the need for costly building expansions.

Conclusion

Freshness is not just about ingredients; it is about physics and efficiency. By switching to vacuum cooling, you reduce your cooling time, lock in moisture, and ensure your product survives even the hottest kitchen environments. You reclaim your floor space and empower your staff with easy-to-maintain equipment that includes automated safety features like auto-shutdown and self-cleaning cycles . This is how you deliver a loaf that tastes like it just came out of the oven, even days later, while running a more profitable business.

-

Explore this link to understand how vacuum technology enhances freshness and efficiency in various applications. ↩

-

Learn about innovative strategies to minimize energy consumption while maintaining performance in cooling systems. ↩

-

Understanding sophisticated control systems can enhance your knowledge of automation technology and its benefits. ↩

-

Exploring hygiene and safety standards will help you ensure a safe working environment in your bakery. ↩

-

Understanding the maximum ambient temperature can help ensure optimal performance and longevity of vacuum coolers in extreme conditions. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy