How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if this essential machine is silently eating into your profits, leaving you feeling powerless against rising energy costs.

You can significantly cut your vacuum cooler’s energy use by focusing on three key areas: running fully optimized loads, setting precise cooling temperatures, and maintaining a clean, well-ventilated system. These operational habits have a direct and immediate impact on your power consumption.

I remember a conversation with a new farm owner in Europe who had just installed one of our two-pallet machines. He called me after his first month, concerned about the energy bill. When I asked about his process, he told me he was so focused on getting orders out quickly that he was often running the machine with just one pallet inside. I explained that a vacuum pump uses a similar amount of energy to evacuate the air from the chamber whether it’s empty or full. By simply waiting to run full, two-pallet loads, he was able to cut his energy cost per pallet of lettuce nearly in half. It was a simple change in workflow that saved him thousands of euros a year. This guide is filled with those kinds of practical, proven tips to help you get the most out of every kilowatt.

Does how you load the chamber really affect energy use?

When you’re under pressure to move product, it’s tempting to cool whatever is ready, even if it’s just a single pallet. You might think that a smaller load means a shorter, cheaper cycle, but you suspect it might not be that simple.

Yes, it has a massive impact. Running consistently full loads is the single most effective way to improve your energy efficiency. The energy required to create the vacuum is largely fixed, so cooling two pallets at once is far cheaper per pallet than cooling one.

The Economics of Empty Space

Think of your vacuum chamber like a delivery truck. The fuel cost to drive the truck across town is almost the same whether it has one box inside or is filled to the ceiling. It makes no financial sense to send out a half-empty truck. Your vacuum cooler operates on a very similar principle. The vacuum pump is one of the biggest energy consumers in the system. Its job is to remove all the air from the steel chamber. It takes a specific amount of energy to bring that large volume of air down to the 4.6 millibars of pressure where water starts to boil. That energy cost is paid on every single cycle, regardless of how much product is inside.

Therefore, the key metric you should focus on is not the energy cost per cycle, but the energy cost per pallet1 or per kilogram of product. When you run a full load, you are spreading that big, fixed "air removal" energy cost across the maximum amount of product. When you run a half load, you pay that same big energy cost but only get half the product cooled. This instantly doubles your energy cost per pallet. For a business owner like Carlos, who manages a large-scale operation, optimizing this single factor across hundreds of cycles a year translates into a huge operational saving. Furthermore, consider the stacking pattern. Product should be loaded to allow for even airflow. Tightly packed boxes or blocked vents can create pockets of warm air, forcing the system to run longer to cool the entire load, which wastes even more energy. A well-planned, full load is the foundation of an energy-efficient cooling operation2.

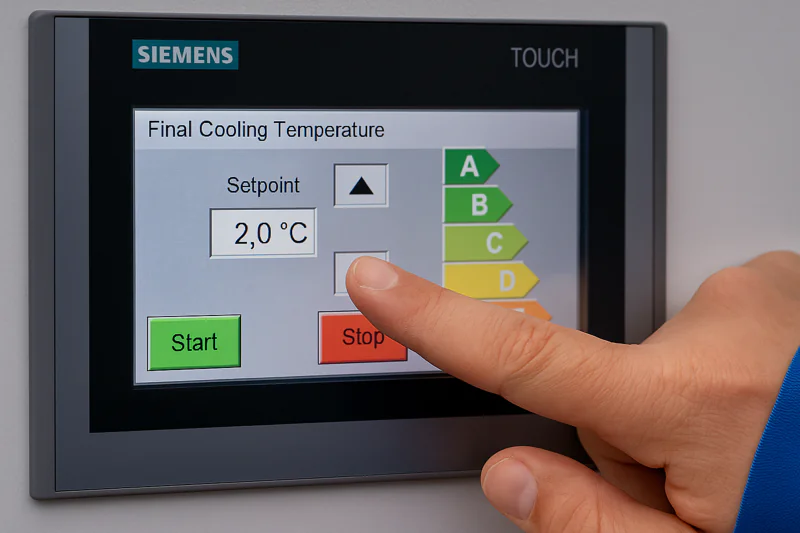

Are your cooling setpoints wasting electricity?

To ensure maximum shelf life and food safety, you set your cooler’s target temperature to the lowest possible setting, maybe 1°C or 2°C. But you have a nagging feeling that this "better safe than sorry" approach might be costing you a lot on your energy bill.

Absolutely. Cooling from 3°C to 2°C uses significantly more energy than cooling from 25°C to 24°C. Setting your endpoint to the precise temperature your product requires, and not a single degree lower, is a critical energy-saving practice.

The Law of Diminishing Returns3

The refrigeration system in your cooler works by moving heat from your product to the outside air. As the product gets colder, it becomes harder and harder for the system to extract the remaining heat. This is a fundamental principle of thermodynamics. Think of it like trying to squeeze water from a damp towel. The first squeeze gets a lot of water out easily. But the last few drops require a huge amount of effort. Your refrigeration system experiences the same thing. The energy needed to drop the temperature that last one or two degrees is disproportionately high.

For many types of produce, like some varieties of lettuce or greens, cooling to 3°C provides the exact same shelf-life benefit as cooling to 2°C. That extra degree of cooling, however, could increase the refrigeration cycle time by 10-15%, using more electricity with zero added benefit to your product quality. This is where you need to know your product. For a procurement manager like Sophia, who deals with cooked foods that must meet strict HACCP rules, a precise endpoint is non-negotiable. But for many types of fresh produce, there is some flexibility. I encourage my clients to conduct their own tests. Cool one batch to your usual 2°C and another to 3°C. Tag them, store them, and compare their quality and shelf life over the next few days. You may find that the higher setpoint is perfectly adequate, and you can adopt it as your new standard, saving energy on every single cycle from that day forward. Accurate temperature sensors are vital here. Our machines use high-precision sensors to ensure that when you set it to 3°C, you get exactly 3°C, giving you the confidence to optimize without risking quality.

How does regular maintenance impact your power bill?

You know maintenance is important for preventing breakdowns, but you’re busy, and it’s easy to postpone. You might not realize that a poorly maintained machine isn’t just a reliability risk; it’s actively costing you more money to run every single day.

Regular maintenance is one of the most direct ways to control energy costs. Two key areas, a clean condenser and an airtight door seal, can influence your machine’s power consumption by as much as 30-40%.

The Hidden Costs of Neglect

A vacuum cooler is a finely tuned system with two main energy-consuming parts: the vacuum pump and the refrigeration compressor. Neglecting maintenance forces both of these parts to work much harder and for much longer, which sends your electricity bill soaring.

First, let’s look at the condenser. As we’ve discussed before, its job is to release all the heat captured from your product into the atmosphere. When its delicate fins get clogged with dust, dirt, and debris, it’s like forcing an athlete to run a marathon while wearing a thick winter coat. The condenser can’t breathe. The heat gets trapped, causing the pressure in the refrigeration system to skyrocket. This forces the compressor to work dramatically harder, drawing significantly more amperage to do the same amount of cooling. Keeping your condenser coils clean is not just about reliability; a clean condenser4 can use up to 30% less energy than a dirty one. Second is the door seal5. A tiny, invisible leak from a dirty or worn-out gasket is a constant enemy. It forces the vacuum pump to run continuously just to fight the air that’s leaking back into the chamber, dramatically extending the time it takes to reach the target pressure. That means the pump motor is running for longer, using more electricity on every single cycle. For a buyer like Norman, who is sensitive to long-term operational costs, understanding this connection between simple maintenance6 and energy bills is a key part of making a smart purchase.

| Maintenance Task | Energy-Wasting Problem it Prevents | Estimated Energy Saving |

|---|---|---|

| Weekly Condenser Cleaning | High refrigerant pressure forces the compressor to work harder. | 15-30% on refrigeration costs. |

| Daily Door Seal Inspection | Air leaks extend vacuum pump run time. | 5-10% on vacuum pump costs. |

| Monthly Oil Level Check | Poor lubrication causes higher friction and motor strain. | 2-5% on motor efficiency. |

| Annual Sensor Calibration | Inaccurate sensors can lead to over-cooling and wasted energy. | 5-15% by ensuring precise setpoints. |

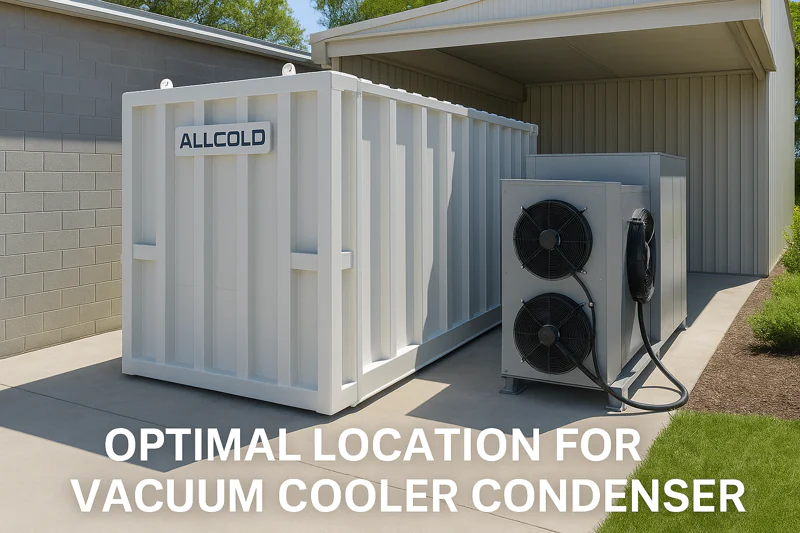

Could your cooler’s location be inflating your energy costs?

When you installed your vacuum cooler, the main concern was likely about fitting it into your workflow and connecting it to power. You probably didn’t consider that the specific spot where the machine sits could have a major impact on its daily energy consumption.

Definitely. The ambient environment, especially around the condenser unit, plays a huge role in your machine’s efficiency. A well-ventilated, cooler location can significantly reduce the energy needed for the refrigeration cycle.

Giving Your Machine Room to Breathe

The job of the condenser is to transfer heat from the hot refrigerant gas to the surrounding air. This heat transfer is most efficient when there is a large temperature difference between the refrigerant and the air. If you place your condenser in a hot, stagnant corner of your facility, you are making its job incredibly difficult. The surrounding air is already warm, so the temperature difference is smaller. This forces the entire refrigeration system to run at higher pressures and for longer durations to shed the same amount of heat, which consumes a lot more electricity.

When planning an installation, always consider the condenser’s environment. The ideal location is outdoors, on a shaded side of the building (like the north side in the northern hemisphere), where it has access to an unlimited supply of cool, ambient air. If the unit must be located indoors, proper ventilation is not optional—it’s essential. The room must have good airflow, ideally with an exhaust fan to constantly remove the hot air that the condenser generates and draw in cooler replacement air. You must also ensure there are several feet of clear space around the condenser unit on all sides. Never allow pallets, boxes, or other equipment to be stacked next to it, as this will block airflow and create a pocket of hot air that the machine will just keep recycling. Making this right is a one-time decision during installation that pays dividends in energy savings for the entire lifespan of the machine.

Conclusion

Energy efficiency isn’t about one big secret; it’s the result of smart habits. By running full loads, fine-tuning your setpoints, maintaining your equipment, and ensuring good ventilation, you can take control of your energy costs and boost your profitability.

-

Understanding energy cost per pallet can help businesses optimize their cooling operations and reduce energy expenses. ↩

-

Exploring strategies for energy-efficient cooling can lead to significant savings and improved operational efficiency. ↩

-

Understanding this principle can help you optimize energy use in refrigeration systems, enhancing efficiency and reducing costs. ↩

-

Understanding condenser maintenance can significantly reduce energy costs and improve system efficiency. ↩

-

Learn how a proper door seal can prevent energy loss and enhance the performance of your vacuum system. ↩

-

Regular maintenance is key to ensuring efficiency and longevity, ultimately saving you money on energy bills. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not