How Do Different Temperature Settings Impact Your Produce's Freshness?

Losing money on produce that spoils too quickly? The cause is often simple: incorrect temperature. Getting it right is the single most important step you can take for your business.

Temperature directly controls the rate of respiration and microbial growth. Optimal cold temperatures slow these processes to preserve quality, but temperatures that are too low cause chilling injury, while those that are too high accelerate decay.

But it’s more than just "making things cold." The difference between profit and loss can be just a few degrees. Let’s explore exactly how finding the perfect temperature—and avoiding the wrong ones—can transform the quality and longevity of your products.

What is the "Optimal" Temperature and Why Does it Matter So Much?

Are you treating all your vegetables the same? Setting one temperature for everything is a common mistake that can actually shorten the shelf life of many of your most valuable items.

The optimal temperature is the specific cold temperature that slows a product’s respiration and decay the most without causing damage. Each type of produce has its own unique optimal range for maximum freshness and shelf life.

Think of fresh produce as still being alive. It continues to "breathe," a process called respiration, where it uses its own stored sugars for energy. This process generates heat and uses up the very things that make it taste good and feel firm. Our goal with cooling is to slow this breathing down as much as possible. As a general rule, for every 10°C (18°F) rise in temperature, the rate of deterioration doubles. This is why getting produce out of the field heat is so critical for farmers like Carlos. Finding that "sweet spot" temperature puts the produce into a state of suspended animation, preserving its quality for days or even weeks longer. This is the foundation of a successful cold chain.

Finding the Sweet Spot: Respiration and Quality

The optimal temperature is a fine balance. For a robust vegetable like broccoli, this might be very close to freezing, around 0°C (32°F). But for a sensitive item like a tomato, that same temperature would be a disaster. Slowing respiration does more than just extend life; it preserves nutritional value, color, flavor, and texture. For a buyer like Norman, whose clients demand top quality, receiving produce that has been held at its optimal temperature means it looks better, tastes better, and lasts longer on the shelf. This directly translates to higher sales and less waste for his customers.

| Product Example | Optimal Storage Temp (°C) | Optimal Storage Temp (°F) | Key Benefit of Optimal Temperature |

|---|---|---|---|

| Lettuce/Greens | 0°C | 32°F | Slows respiration dramatically, preventing wilting. |

| Broccoli | 0°C | 32°F | Prevents yellowing and preserves Vitamin C content. |

| Cucumber | 7°C – 10°C | 45°F – 50°F | Avoids chilling injury while still slowing decay. |

| Tomato (Ripe) | 10°C – 13°C | 50°F – 55°F | Preserves flavor and texture without causing cold damage. |

What Happens When Produce Gets Too Cold (But Not Frozen)?

Ever stored cucumbers in a walk-in cooler only to find them pitted and watery a few days later? That’s chilling injury, a hidden profit-killer caused by temperatures that are too low.

Chilling injury is physiological damage in certain produce, especially tropical types, when stored at low, non-freezing temperatures. It causes pitting, discoloration, and rapid decay once the product returns to warmer temperatures.

This is one of the most misunderstood aspects of produce cooling. Many people think colder is always better, but that’s not true. For many fruit-vegetables and tropical fruits, temperatures that are above freezing but still too cold cause the cell membranes to lose their integrity. The damage isn’t always visible while the product is cold, but it becomes very apparent when it’s moved to a warmer environment like a grocery store shelf. The produce can fail to ripen, develop sunken pits, or become extremely susceptible to mold. This is a major risk for buyers. Norman cannot afford to have a shipment look good on arrival, only to have his clients complain that it decayed in one day.

The Invisible Damage of "Too Cold"

Chilling injury is like a hidden time bomb. A pallet of bell peppers stored at 2°C (36°F) might look fine in the warehouse. But after a day on a truck and another on display, they might develop sheet pitting and ugly black spots near the stem. The damage was already done. This is why our allcold vacuum coolers are designed with precise controls; they can be programmed to cool a product to its safe optimal temperature, not just to a generic cold setting. It avoids costly mistakes and protects the supplier’s reputation. For anyone handling sensitive commodities, knowing the specific chilling thresholds is just as important as knowing the optimal temperature.

| Produce Type | Safe Minimum Temp (°C) | Typical Chilling Injury Temp (°C) | Common Chilling Injury Symptoms |

|---|---|---|---|

| Cucumber | 7°C | Below 7°C | Water-soaked spots, pitting, accelerated decay. |

| Tomato (Green/Ripe) | 10°C – 13°C | Below 10°C | Uneven ripening, poor flavor, surface pitting, decay. |

| Bell Pepper | 7°C | Below 7°C | Sheet pitting, calyx discoloration, high decay risk. |

| Banana | 13°C | Below 13°C | Dull, greyish-yellow peel color, failure to ripen. |

Why is Even a Few Degrees Too Warm So Damaging?

Think a few degrees above the recommended temperature won’t hurt? That small difference can cut the shelf life of your produce in half, leading to significant and unnecessary waste.

Temperatures even slightly too warm dramatically accelerate respiration, water loss, and the growth of decay-causing microorganisms like bacteria and mold. This leads to rapid softening, discoloration, and spoilage, reducing saleable life.

This is the more obvious enemy of freshness, but its impact is often underestimated. Remember the rule: every 10°C increase can double or triple the rate of deterioration. So, storing lettuce at 5°C (41°F) instead of its optimal 0°C (32°F) can slash its shelf life by 50% or more. The produce is literally burning through its energy reserves faster. Furthermore, these warmer temperatures are an open invitation for bacteria and mold to grow. For a central kitchen manager like Sophia, who must adhere to strict HACCP food safety plans, preventing microbial growth is a top priority. Storing produce at the correct, colder temperature is a critical control point that directly impacts food safety as well as quality.

The Cascade of Decay at Warmer Temperatures

The problems compound when things are too warm. Not only does respiration speed up, but the produce also loses water faster, leading to shriveling and weight loss. On top of that, many fruits and vegetables produce ethylene gas as they ripen, which acts as a signal for more ripening and aging. Warmer temperatures increase ethylene production, creating a vicious cycle of accelerated decay that can spread through an entire batch. For large-scale operations like Carlos’s packing center, a malfunctioning cooler that runs a few degrees too warm for a day can translate into thousands of dollars in lost product. It highlights the need for reliable equipment and precise temperature monitoring.

| Problem | Cause at Warmer Temperatures | Consequence for Produce |

|---|---|---|

| Accelerated Respiration | Metabolic processes speed up exponentially. | Rapid use of sugars, heat generation, loss of flavor. |

| Microbial Growth | Ideal breeding ground for bacteria, yeasts, and molds. | Visible decay, rot, off-odors, food safety risks. |

| Increased Water Loss | Higher transpiration rates from the produce surface. | Wilting, shriveling, loss of saleable weight. |

| Ethylene Production | Hormonal ripening/aging process is accelerated. | Premature softening, yellowing, and aging. |

Why is Rapid Cooling the Final Piece of the Puzzle?

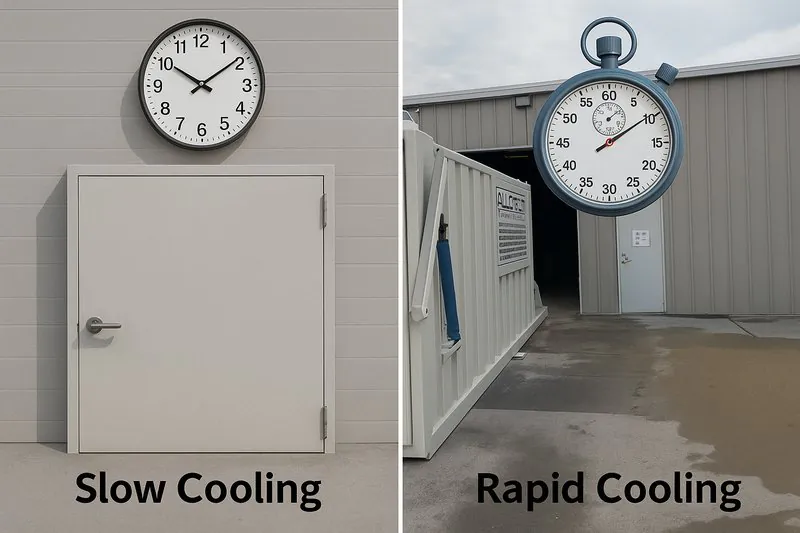

You know the right temperature, but how you get there is just as important. Slow cooling means your produce is still warm and degrading, losing valuable shelf life with every passing hour.

Rapid cooling technologies like vacuum cooling are critical because they halt field heat and respiration almost instantly. This maximizes the time the produce spends at its optimal temperature, drastically extending its freshness and quality.

It’s a race against time from the moment produce is harvested. A traditional cold room cools produce slowly, from the outside in. A pallet of lettuce might take 12-24 hours to cool to its core, and during that entire period, it’s respiring at a high rate. A vacuum cooler, however, can cool that same pallet down to 2°C (36°F) in just 20-30 minutes. It works by lowering the pressure, causing water on the lettuce leaves to evaporate and carry the heat away. This process is incredibly fast and cools the entire product uniformly. This speed is a game-changer, adding days of valuable shelf life that would otherwise be lost.

The True Value of Speed and Uniformity

The benefit of speed is simple: more shelf life to sell. By quickly stopping the "decay clock," you give everyone in the supply chain—from the farm to the store—more time. But uniformity is just as important. Slow cooling can lead to "hot spots" in the middle of a pallet, where produce stays warm for hours longer than the produce on the outside. These hot spots are where decay starts. Vacuum cooling cools every single leaf, head of broccoli, or mushroom at the same time, ensuring there are no spots left behind. This uniformity leads to a more consistent, reliable, and high-quality final product, which is exactly what professional buyers like Norman, Carlos, and Sophia demand from their suppliers.

| Cooling Method | Speed | Uniformity | Shelf Life Impact |

|---|---|---|---|

| Slow (Cold Room) | Very Slow (12-24 hours) | Poor (cools outside-in, hot spots) | Reduced; significant freshness lost during cooling time. |

| Rapid (Vacuum Cooler) | Extremely Fast (20-30 minutes) | Excellent (uniform cooling throughout) | Maximized; decay is halted almost instantly. |

Conclusion

Mastering temperature by using rapid cooling to reach the optimal level, while avoiding chilling injury and warmth, is the key to unlocking maximum freshness, shelf life, and profit for your produce.

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But