How Do You Get Perfect Cooling Results Every Time?

You invested in a vacuum cooler for its power and speed. But one day your lettuce is perfect, and the next it’s slightly frozen at the edges. This inconsistency is frustrating and costly.

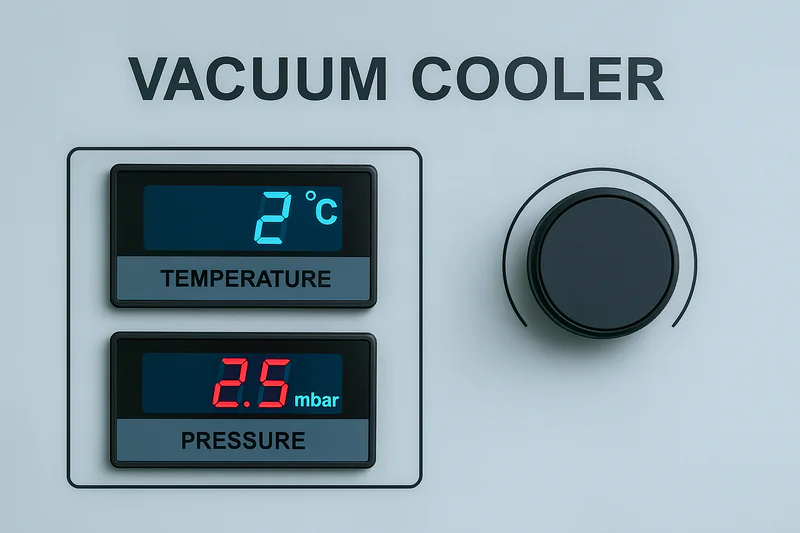

Perfect results come from matching the cooling parameters—specifically the final pressure and cycle time—to each vegetable’s unique structure. It is a science, not guesswork. Mastering these settings is the key to consistency.

Your vacuum cooler is a powerful, precise tool. But like any advanced tool, using it to its full potential requires moving beyond the "start button" and understanding the specific settings that deliver optimal results. Let’s break down the best practices for the most common types of vegetables.

Why Can’t You Use One Setting for All Vegetables?

It’s tempting to find one "good enough" setting and use it for everything. But this approach will either damage delicate produce or fail to properly cool dense items, leading to waste and lost profits.

Because every vegetable has a different physical structure. A leafy green has a huge surface area and releases moisture easily, while a dense broccoli head holds heat deep inside. A single setting cannot be optimal for both.

The core principle of vacuum cooling is making water evaporate at low temperatures. How easily this happens depends entirely on the vegetable itself. Think about two key factors: surface area and density. A porous vegetable like spinach has a massive surface area relative to its weight. This means moisture is readily available everywhere, and it cools incredibly fast. You need a gentle cycle to avoid damaging it. Conversely, a dense vegetable like a cauliflower head has a low surface area and a lot of mass deep inside. The heat is trapped in the core. To cool it effectively, you need to pull a stronger vacuum (lower pressure) for a longer time to force that internal heat out. Using a "lettuce setting" on broccoli would leave its core warm, leading to rapid decay. Using a "broccoli setting" on lettuce would likely freeze and destroy it.

The Science of Structure

Matching the machine’s parameters to the plant’s biology is the secret to perfect pre-cooling.

| Vegetable Type | Key Characteristic | Cooling Requirement1 |

|---|---|---|

| Leafy & Porous | High surface area, loose structure. | Gentle vacuum (higher pressure), shorter cycle. |

| Dense & Solid | Low surface area, tight core. | Stronger vacuum (lower pressure), longer cycle. |

| High Water Content2 | Releases moisture easily. | Standard cycle, focus on final temperature. |

| Low Water Content | Releases moisture slowly. | Often unsuitable or requires special techniques. |

What Are the Ideal Settings for Leafy Greens?

Leafy greens like lettuce and spinach are the classic candidates for vacuum cooling, but they are also the most fragile. Get the settings wrong, and you can instantly lose an entire pallet to freezer burn.

For most leafy greens, the target final pressure is around 6.1 millibars (mbar). This allows water to boil just above freezing (0.01°C), ensuring rapid cooling without damaging the delicate leaves. Pre-wetting often improves efficiency.

The 6.1 mbar pressure point is magic for leafy greens. It corresponds to the "triple point" of water, where it can exist as a solid, liquid, and gas simultaneously. By setting your machine’s final pressure limit just above this point, you ensure the fastest possible cooling right down to 1-2°C without the risk of freezing. For even better results, especially with spinach or cut greens, a light pre-wetting with clean water before cooling can be very effective. This provides extra "sacrificial" water for evaporation, which means the product loses less of its own moisture, resulting in a heavier, crisper final product. As someone like Sophia from a central kitchen knows, maintaining weight and texture in greens is critical for portion control and quality. This technique guarantees both.

Quick Reference: Leafy Green Parameters

| Vegetable | Target Temp. | Final Pressure | Key Tip |

|---|---|---|---|

| Iceberg Lettuce3 | 1-2°C | ~6.5 mbar | Cores cool well; ensure pallets are packed evenly. |

| Romaine Lettuce4 | 1-2°C | ~6.5 mbar | Pre-wetting helps maintain crispness. |

| Spinach | 2-3°C | ~7.0 mbar | Use a gentler cycle. Always pre-wet if possible. |

| Baby Greens Mix | 2-3°C | ~7.0 mbar | Shorter cycle time is critical to prevent damage. |

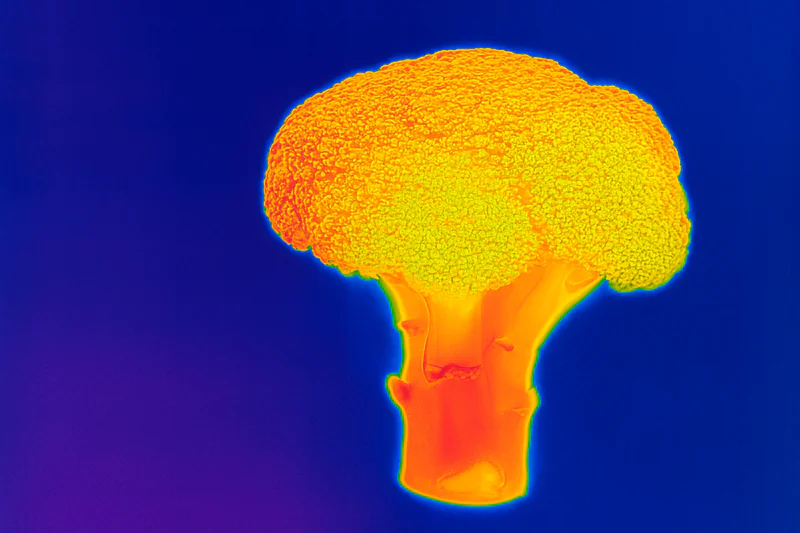

How Should You Adjust for Dense Vegetables Like Broccoli?

You’ve mastered leafy greens, but now you have a harvest of broccoli. You use the same settings, but the stems are still warm an hour later. What did you do wrong?

You must use a lower final pressure—typically 4.6 to 5.5 mbar—and a longer cycle time. This stronger vacuum is needed to pull the stubborn field heat from the very core of the dense stalks and florets.

With dense vegetables, the challenge is getting the heat out from the inside. The outer florets will cool quickly, but the thick, dense stalk acts like an insulator. To overcome this, we need to lower the boiling point of water even further. By aiming for a final pressure around 4.6 mbar, we are forcing the moisture deep inside the stalk to evaporate and carry heat away. This process takes more time and energy than with lettuce. You might extend the vacuum pump-down time by a few minutes to ensure the vacuum fully penetrates the entire pallet load. Some advanced machines, like ours at allcold, have specific pre-programmed cycles for broccoli or cauliflower that automatically manage this longer, deeper pull. This is crucial for farmers like Carlos, who supply supermarkets that will check the core temperature of the product upon arrival.

Quick Reference: Dense Vegetable Parameters

| Vegetable | Target Temp. | Final Pressure5 | Key Tip[^26] |

|---|---|---|---|

| Broccoli | 1-2°C | ~5.0 mbar | Ensure a longer cycle; pack boxes loosely. |

| Cauliflower | 1-2°C | ~5.0 mbar | Trim excess leaves for better vacuum flow. |

| Sweet Corn | 2-3°C | ~4.6 mbar | Cools very effectively; preserves sugars. |

| Cabbage | 1-2°C | ~6.0 mbar | Less dense than broccoli, but needs good penetration. |

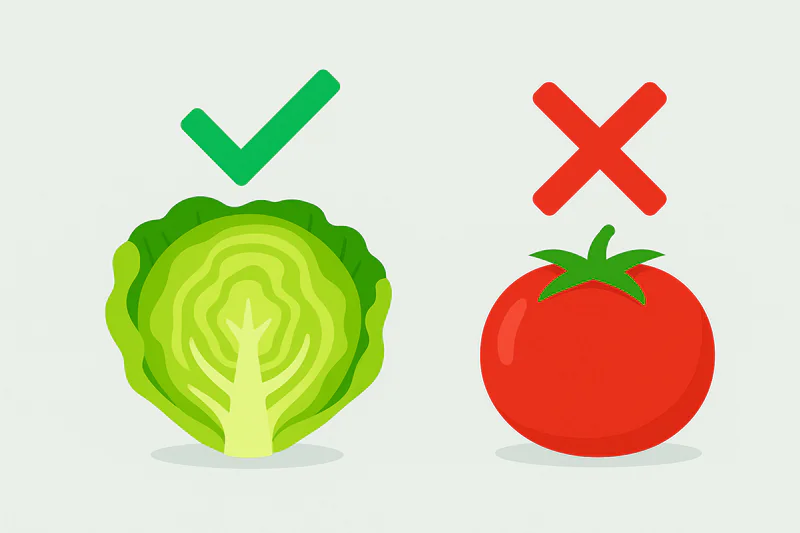

Which Vegetables Need Special Care or Should Be Avoided?

Emboldened by your success, you might want to try vacuum cooling everything. This can be a costly mistake. Some products are perfect for it, while others are completely unsuitable.

Delicate items like mushrooms require gentle cycles. Crucially, vegetables with thick, waxy skins that prevent moisture evaporation—like tomatoes, peppers, and cucumbers—cannot be vacuum cooled effectively and must be avoided.

Knowing what not to do is just as important as knowing what to do. Vacuum cooling relies on evaporation from the surface. If a vegetable has a natural, waterproof skin, the process simply won’t work. A tomato has a thick, waxy peel; lowering the pressure will do almost nothing because no water can escape to carry the heat away. You will waste energy and time with zero results. On the other hand, some products are suitable but very delicate. Mushrooms, for example, cool beautifully but can be bruised by a cycle that is too aggressive. For them, a "soft" vacuum ramp-down is essential to prevent physical damage. Always consult with your equipment provider (like me at allcold!) if you are unsure. Running a small test batch is a cheap way to avoid a very expensive mistake.

The "Go / No-Go" List

| Vegetable | Suitable for Vacuum Cooling6? | Reason |

|---|---|---|

| Lettuce | YES (Ideal) | High surface area, perfect for evaporation. |

| Broccoli | YES (Ideal) | Porous florets allow for deep cooling. |

| Mushrooms | YES (With Care) | Cools well but requires a gentle, controlled cycle. |

| Tomatoes | NO | Waxy skin prevents moisture evaporation. |

| Bell Peppers | NO | Impermeable skin traps heat inside. |

| Cucumbers | NO | Waxy skin and dense structure are unsuitable. |

Conclusion

Mastering these cooling parameters transforms your vacuum cooler from a simple machine into a precision tool. This guarantees optimal quality, maximizes shelf life, and secures higher profits for every batch you ship.

-

Understanding cooling requirements is crucial for maintaining freshness and quality in vegetables. ↩

-

Exploring the impact of water content can help optimize storage techniques for better vegetable preservation. ↩

-

Explore this link to learn optimal storage methods that keep Iceberg Lettuce fresh and crisp. ↩

-

Discover the science behind pre-wetting and how it enhances the crispness of Romaine Lettuce. ↩

-

Understanding the ideal final pressure can enhance your vacuum sealing process, ensuring better preservation of your vegetables. ↩

-

Understanding vacuum cooling can enhance your knowledge of efficient cooling methods for vegetables. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not