How Do You Use Vacuum Cooling to Truly Maximize Vegetable Shelf Life?

You’ve invested in a vacuum cooler, but are you getting every possible hour of freshness? The machine is powerful, but it’s only one part of a larger process for achieving incredible shelf life.

To truly maximize shelf life with vacuum cooling, you must combine its rapid cooling power with best practices: starting with high-quality produce, optimizing the cooling cycle, and maintaining a strict, unbroken cold chain afterward.

Getting this right means going beyond just pressing "start." By mastering the entire process, from the field to the truck, you can unlock the full potential of your investment and deliver produce that stays fresher for days longer than your competition.

Why Does Shelf Life Begin Before the Cooler?

Think the best cooler can fix poor-quality vegetables? Even our advanced technology can’t turn back the clock on damage that has already been done in the field.

The maximum potential shelf life is determined at the moment of harvest. Starting with healthy, undamaged produce, harvested at the right time, is the essential first step. A vacuum cooler preserves this potential; it cannot create it.

This is a truth every professional buyer like Norman understands: "garbage in, garbage out." Bruises, cuts, and scrapes on vegetables are open wounds where bacteria and mold can enter. Produce that is harvested too late in the day is warmer and has already lost significant moisture. As a farmer or packer, your first job is to handle the produce gently. Train your harvest crews to cut cleanly and handle the product like they would handle eggs. Cooling poor-quality produce is a waste of time, energy, and money, because it’s destined to fail early no matter how well you cool it. Starting with a great product is the foundation of everything that follows.

Setting the Stage for Success

For a large-scale operation like Carlos’s farm, implementing best practices at harvest is a game-changer. This means harvesting in the cool of the early morning when the vegetable’s internal temperature is lowest and its water content is highest. It also means moving the harvested produce out of the sun and to the precooling station as quickly as possible. Every minute spent in the hot sun is a minute of shelf life lost forever. Trimming away any damaged or diseased outer leaves is also critical. This not only improves the appearance but also removes potential sources of contamination. By delivering a clean, healthy, and undamaged product to the vacuum cooler, you give the machine the best possible material to work with, setting the stage for a truly long shelf life.

| Best Practice | Why It’s Important | Poor Practice | Consequence of Poor Practice |

|---|---|---|---|

| Gentle Handling1 | Prevents bruises and cuts, which invite decay. | Rough throwing or dropping | Damaged product, rapid spoilage. |

| Morning Harvest2 | Lower field heat, less energy needed to cool. | Harvesting in midday heat | Product is already stressed and warm. |

| Minimize Field Time | Reduces exposure to sun and heat. | Leaving bins in the sun | Significant loss of moisture and life. |

| Trim Damaged Parts3 | Removes sources of mold and bacteria. | Packing "as is" | Contamination can spread in the box. |

How Do You Perfect the Vacuum Cooling Cycle Itself?

You have great produce, and it’s ready for cooling. Is it as simple as loading the chamber and pressing go? To get professional results, you need to tailor the cycle to the product.

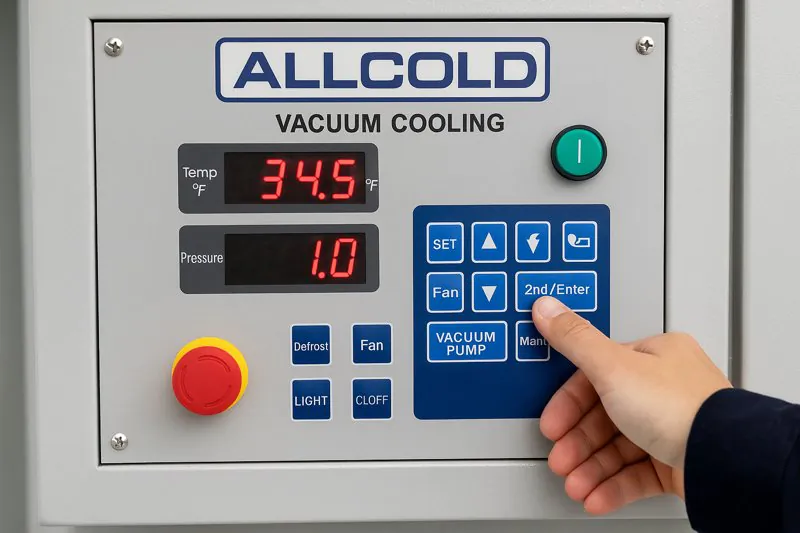

Perfecting the cycle means setting the correct final temperature and pressure based on the specific vegetable. Different products have different densities and water content, requiring customized settings for optimal speed and preservation.

A vacuum cooler is a precision instrument. While the basic principle is the same for all products, the ideal parameters are not. For example, leafy greens like lettuce have a huge surface area and release moisture easily, so they cool incredibly fast. Denser products like broccoli or mushrooms might require a slightly longer cycle or a different final pressure setting to reach their core temperature. The goal is to reach the target temperature—for example, 2°C (36°F)—as efficiently as possible without over-cooling or causing any stress to the product. As I work with clients, I help them develop "recipes" for each of their main products. This ensures consistent, perfect results every single time, which is essential for managers like Sophia who require process control for their HACCP plans.

Customizing for Product Type

Our allcold vacuum coolers are designed with this flexibility in mind. You can control the final pressure4, which directly relates to the final temperature of the product. For very delicate items or produce with lower water content, we sometimes recommend using the pre-wetting or "hydrovac" function5. A light mist of clean water is sprayed on the product before the cycle starts. This provides some sacrificial water for evaporation, ensuring the product’s own moisture is perfectly preserved while still benefiting from rapid cooling6. Knowing these small adjustments can make a big difference in the final quality. It’s the difference between being an operator and being an expert.

| Vegetable Type | Target Temp (°C) | Key Consideration | Best Practice Tip |

|---|---|---|---|

| Leafy Greens | 1°C – 2°C | High surface area, cools very fast. | Use standard cycle; ensure no over-packing in crates. |

| Broccoli/Cauliflower | 1°C – 2°C | Denser heads, may take slightly longer. | Pack loosely to allow vapor to escape from between florets. |

| Mushrooms | 2°C – 3°C | Delicate and can lose too much water if not careful. | Consider using the pre-wetting/hydrovac feature if available. |

| Sweet Corn | 1°C – 2°C | Husks can slow down cooling. | Pack in vented crates; ensure air can move freely. |

What’s the Most Critical Step After Vacuum Cooling?

Your vegetables are now perfectly chilled to 2°C in just 25 minutes. The job is done, right? Not yet. You can undo all that great work in the next 30 minutes if you’re not careful.

The most critical step after vacuum cooling is immediately moving the produce into an unbroken cold chain. The benefits of rapid cooling are lost if the product is allowed to warm up on a loading dock or in a non-refrigerated truck.

Think of that perfectly chilled lettuce as a block of ice. If you take it out of the freezer and leave it on the counter, it starts to melt immediately. It’s the same with your produce. Exposing it to warm ambient temperatures causes condensation to form ("sweating") and allows the respiration rate to speed right back up. This is a huge risk. For a buyer like Norman, temperature fluctuations during transit are a major pain point. He knows that a pallet that arrives warm has already lost a significant portion of its shelf life. The ideal workflow is seamless: from the vacuum cooler directly into a refrigerated staging area, and from there directly into a pre-chilled refrigerated truck. There should be no delays.

Protecting Your Investment

The cold chain7 is a chain; it’s only as strong as its weakest link. A 30-minute wait on a 30°C (86°F) loading dock can raise the product temperature several degrees, re-activating the aging process and potentially costing you days of shelf life. This is why we advise our clients to think about their entire facility layout. The vacuum cooler should be located as close as possible to the cold storage or shipping bay. Using dock seals to create an enclosed space between the building and the truck can also make a huge difference. Using temperature data loggers8 inside shipments is another best practice9. It provides proof that the cold chain was maintained, protecting you and giving your clients like Carlos and Norman complete confidence in your professionalism.

| Cold Chain Stage | Best Practice | Broken Chain Example | Consequence of Failure |

|---|---|---|---|

| Post-Cooling | Immediate transfer to cold storage (<3°C). | Pallets left on the floor for an hour. | Produce warms up, condensation forms, decay starts. |

| Staging Area | Staged in a refrigerated loading dock. | Staged in a non-refrigerated, open warehouse. | More temperature gain, significant loss of shelf life. |

| Loading | Loaded into a pre-chilled reefer truck. | Loaded into a warm truck that then cools down. | The truck’s unit works overtime, produce warms further. |

| Transit | Maintained at a constant, optimal temperature. | Temperature fluctuations during the journey. | Chilling injury or accelerated ripening can occur. |

Can Your Packaging and Stacking Undermine Your Cooling Efforts?

You’ve done everything else perfectly. But there’s one final step that can sabotage your success: how you pack and stack your vegetables.

Yes, improper packaging and stacking can ruin your efforts. Packaging must allow water vapor to escape during cooling, and stacking must not block airflow. Dense, unvented packaging will completely negate the benefits of vacuum cooling.

Vacuum cooling works by removing water vapor. If that vapor is trapped inside a sealed plastic bag or a wax-lined box, it has nowhere to go. The cooling process will fail. It’s essential to use packaging that is designed for precooling. This means using crates with vents on the sides and bottom, or using perforated plastic liners that allow vapor to escape. The way you stack pallets is also crucial. If crates are stacked so tightly that the vents are blocked, the produce in the middle of the pallet won’t cool properly. This creates the same "hot spot" problem we see in traditional cooling, defeating the purpose of using a vacuum cooler in the first place.

Smart Choices for Packaging and Loading

This is a detail-oriented step that managers like Sophia would focus on. The right packaging not only aids in cooling but also helps maintain quality during transit. After cooling, produce continues to respire and release small amounts of heat and gas. Vented packaging allows this heat to dissipate within the refrigerated truck, preventing localized warming. For a product like broccoli, which has a high respiration rate, this is especially important. When we consult with new clients, we always review their current packaging and palletizing methods. Often, a simple switch from a solid box to a vented crate can dramatically improve their cooling efficiency and the final quality of their product. It’s a simple change that makes a huge impact on the final result.

| Aspect | Best Practice | Problematic Practice | Why It Matters |

|---|---|---|---|

| Crates/Boxes | Use vented or slotted plastic/cardboard crates. | Use sealed, wax-lined, or unvented boxes. | Allows vapor to escape for uniform and rapid cooling. |

| Liners/Bags | Use perforated plastic liners. | Use solid, non-perforated bags. | Trapped moisture prevents cooling and promotes mold. |

| Stacking | Align vents; leave small air gaps. | Stacking in a way that blocks all vents. | Ensures even cooling throughout the entire pallet. |

| Pallet Load | Do not over-pack crates; respect weight limits. | Crates are bulging and packed too tightly. | Crushed product gets damaged and blocks airflow. |

Conclusion

A vacuum cooler is an incredibly powerful tool. But to unlock maximum shelf life, you must combine it with best practices in harvesting, cycle optimization, cold chain management, and packaging. It’s this total system that delivers truly exceptional results.

-

Understanding the significance of gentle handling can help improve your harvesting techniques and reduce spoilage. ↩

-

Exploring this resource will provide insights into optimal harvesting times and their impact on produce quality. ↩

-

This link will explain how proper trimming can enhance the quality and longevity of your harvested produce. ↩

-

Learn about the relationship between final pressure and temperature in vacuum cooling to optimize your cooling processes. ↩

-

Explore this link to understand how the hydrovac function enhances moisture preservation during cooling, crucial for delicate produce. ↩

-

Discover the advantages of rapid cooling in food preservation, ensuring quality and freshness for your products. ↩

-

Understanding the cold chain is crucial for maintaining product quality and safety in logistics. Explore this resource to learn more. ↩

-

Temperature data loggers are essential for ensuring compliance and quality in cold chain logistics. Discover their benefits and applications here. ↩

-

Learning about best practices can help you optimize your cold chain operations and prevent costly losses. Check out this informative resource. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But