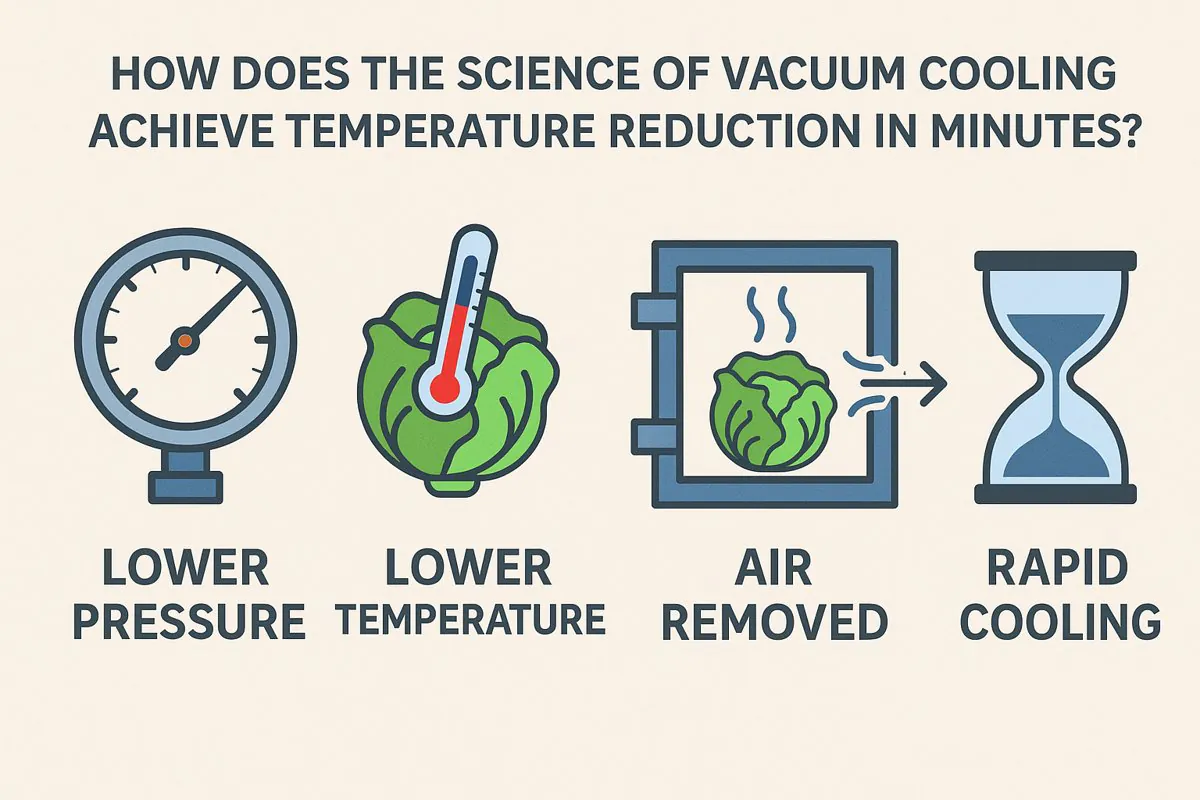

How Does the Science of Vacuum Cooling Achieve Temperature Reduction in Minutes?

You know that field heat is the enemy of fresh produce, but traditional cooling methods take hours to fight it, slowly draining the life and value from your harvest.

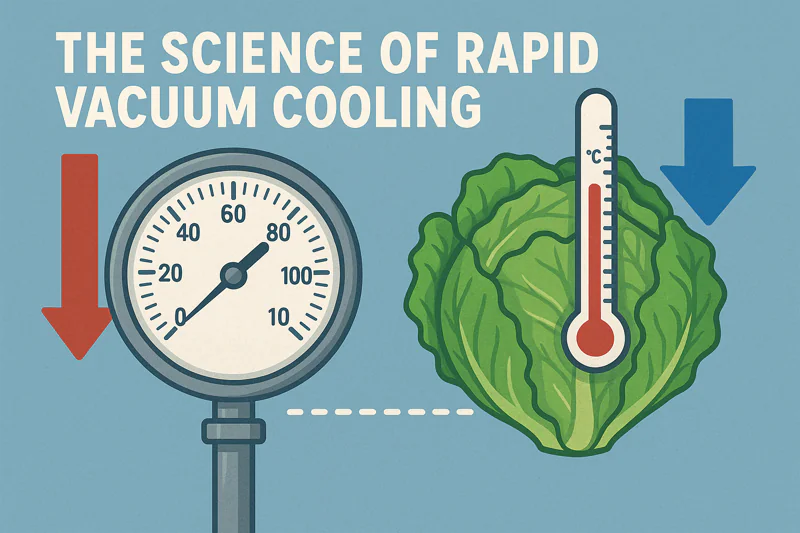

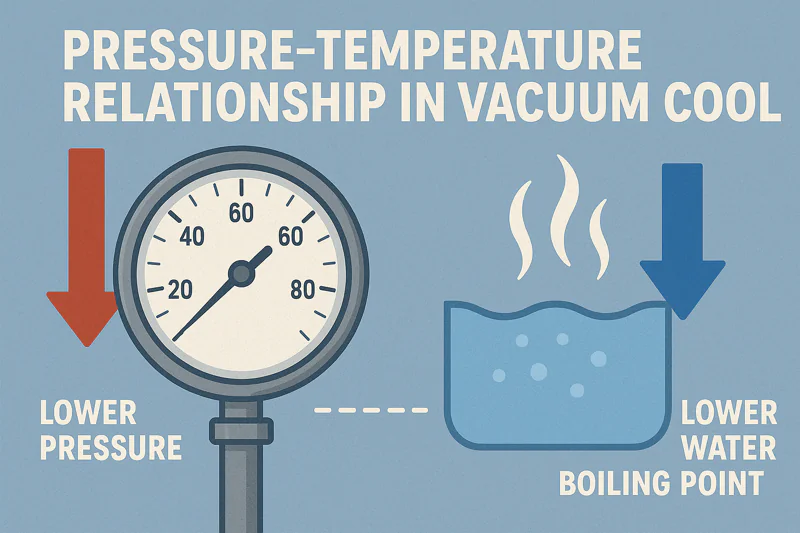

The science is based on a simple principle: lowering air pressure reduces the boiling point of water. This forces a tiny amount of moisture in the produce to evaporate, rapidly drawing heat from the core and cooling it down in just minutes.

I often get asked how it’s possible to chill an entire pallet of vegetables so fast. It’s not magic; it’s pure physics. This article will walk you through the science of how this process works so effectively to protect your hard work.

How can reducing pressure make things cold?

It seems counterintuitive. You normally associate pressure with heat, not cold. The idea that removing air can rapidly chill your vegetables seems like something from a science fiction movie.

By lowering the chamber’s atmospheric pressure, we lower the boiling point of water. The water in the vegetables boils at a very low temperature (around 3°C), and this evaporation rapidly pulls heat from the produce.

Evaporation: Nature’s Refrigerator

The core principle behind vacuum cooling is called evaporative cooling1. It’s the same reason you feel cold when you get out of a swimming pool; as the water on your skin evaporates, it draws heat from your body. A vacuum cooler2 takes this natural process and makes it incredibly powerful. Inside a sealed chamber, strong vacuum pumps remove air, which drastically reduces the atmospheric pressure. At normal sea-level pressure, water boils at 100°C. But inside the vacuum cooler, the pressure drops so low that water starts to boil at just 3°C. A tiny fraction of the water within the vegetables themselves turns into vapor. This phase change from liquid to gas requires a massive amount of energy, and it takes that energy in the form of heat directly from the produce. Because this happens everywhere at once, it cools the product from the inside out, ensuring a fast and uniform temperature drop. This is why we can cool baked bread from 92°C to 30°C in under five minutes for our clients in Hungary. It’s an extremely efficient way to transfer heat.

| Feature | Vacuum Cooling Physics | Traditional Cooling Physics |

|---|---|---|

| Energy Transfer | Phase Change (Evaporation) | Convection (Air Movement) |

| Heat Removal | From the core outwards | From the surface inwards |

| Primary Medium | Product’s own moisture | Cold air |

| Efficiency | Extremely high and rapid | Slow and gradual |

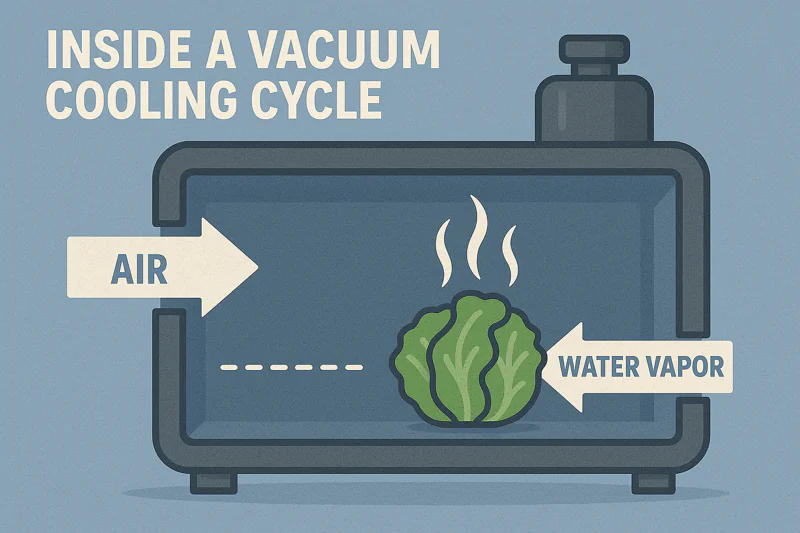

What happens inside the chamber during a typical cycle?

You press the start button, the door seals, and you hear the pumps turn on. But what is actually happening inside that steel chamber to cool your produce so quickly?

The cycle is a controlled sequence: first, the pressure drops steadily. Then, as the boiling point is reached, the temperature begins to fall rapidly. The process stops automatically when the target temperature is hit.

A Precisely Controlled Process

Every cooling cycle is a carefully managed event designed for maximum efficiency, and an operator just needs to touch the screen for control. I explain to my clients that our systems, controlled by reliable Siemens electronics3, handle everything automatically. Here’s a breakdown of a typical 25-minute cycle.

First, during Minutes 0-15, the vacuum pumps are working hard. The main goal here is to remove air from the chamber. During this phase, you see the inside pressure drop quickly on the gauge, but the product temperature doesn’t change much yet. The machine is creating the right environment for cooling.

Second, from Minutes 15-25, we reach the critical point. The pressure is now low enough for the water in the vegetables to begin evaporating. This is when the rapid cooling happens. Both the pressure and the product temperature start to fall together, quickly and uniformly.

Finally, After 25 minutes, the system reaches its goal. Once the pre-set target temperature is achieved, the refrigeration compressor and condenser fans shut off automatically to save power. The machine then allows air back into the chamber. The vacuum pumps might keep running for a short period to clear any moisture from the pump oil. Once the pressure is balanced, the door can be opened, and the perfectly cooled produce is ready.

| Cycle Stage | Time Elapsed | Chamber Pressure | Product Temperature |

|---|---|---|---|

| Pump Down | 0 – 15 minutes | Decreasing (↘) | Stable (→) |

| Evaporative Cooling4 | 15 – 25 minutes | Decreasing (↘) | Decreasing (↘) 4 |

| Cycle End | After 25 minutes | Stabilizing (→) | Reached Target (✓) |

Why is this rapid cooling process so uniform?

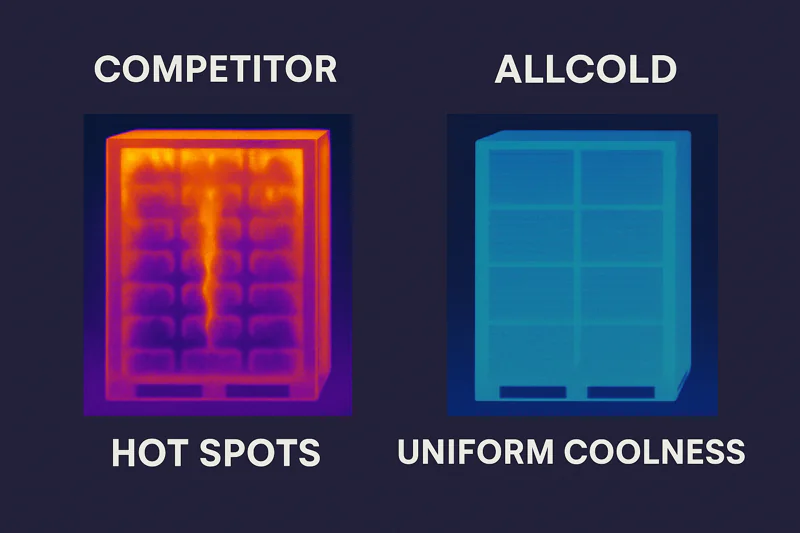

Speed is great, but consistency is what makes you money. If a pallet of lettuce is cold on the outside but warm in the middle, you still have a big problem with shelf life.

Our coolers are equipped with smart features to ensure uniformity. The system automatically adjusts the cycle for produce that releases water slowly, guaranteeing the entire load cools down evenly.

Smart Technology for a Perfect Result

This is a critical point I discuss with technically-minded clients like Carlos in Mexico. He knows that uneven cooling5 leads to unpredictable quality and can cause entire shipments to be rejected. Some vegetables, especially dense ones or those with waxy skins, have a higher resistance to giving up their water. In a basic vacuum cooler, this could lead to the outer layers cooling faster than the core. That’s why we don’t just build a powerful machine; we build a smart one. Our systems monitor the relationship between pressure drop and temperature drop. If the machine detects that the product has a higher water yield resistance, it automatically modifies the cycle parameters. It might hold the pressure at a certain level for a little longer to give the core temperature time to catch up with the surface temperature. This ensures that every single head of broccoli or lettuce on the pallet, whether it’s in a corner or in the very center, reaches the target temperature uniformly. For a large-scale supplier, this guaranteed consistency is non-negotiable. It means every box you ship has the same high quality and the same extended shelf life.

What technology ensures this science is reliable every day?

Advanced science is only useful if it’s reliable day in and day out, especially during the peak of harvest season. You need to know the machine will work every time you press start.

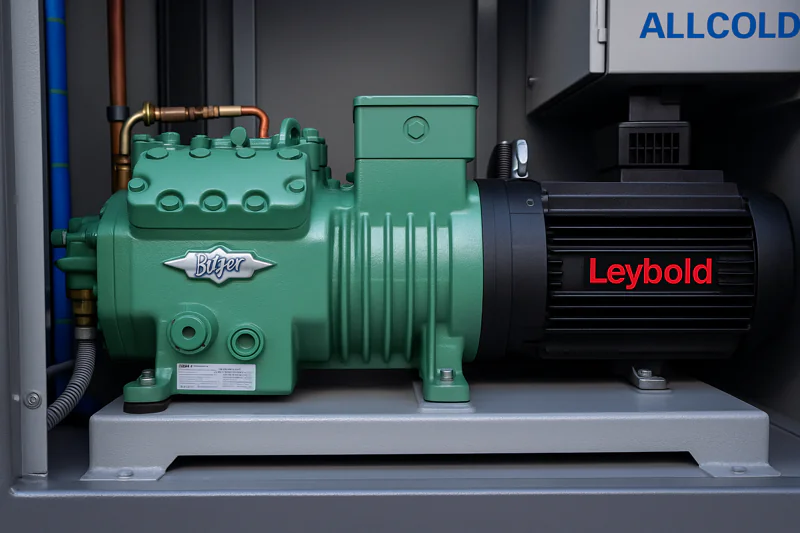

We build our systems for long-term reliability by using world-class components. Key parts like the compressor and vacuum pump come from top German brands like Bitzer and Leybold.

Engineering You Can Trust

When a professional buyer like Norman from America asks about quality control, I don’t just give him promises; I show him our parts list. The reliability of the entire vacuum cooling process depends on the quality of its core components. The heart of the refrigeration unit6 is the compressor, which we source from Bitzer in Germany. The equally critical vacuum pump is from another German leader, Leybold. The entire electrical system, from the touch screen to the safety relays, is built using components from Siemens and Schneider, two of the most trusted names in industrial electronics. Even smaller parts like expansion valves are from respected European brands like Danfoss. Why does this matter? Because these components are designed for heavy-duty, continuous operation with maximum efficiency. They ensure that the pressure drops quickly, the refrigeration is powerful, and the controls are precise, cycle after cycle. This focus on quality engineering7 means less downtime, simpler maintenance, and a machine you can depend on for years. Every machine also comes with a 12-month guarantee for your peace of mind.

| Component | Brand | Country of Origin | Role in the System |

|---|---|---|---|

| Compressor | Bitzer | Germany | Powers the refrigeration system |

| Vacuum Pump | Leybold | Germany | Removes air to lower pressure |

| Touch Screen | Siemens | Germany | Provides simple operator control |

| AC Contactor | Schneider | Germany / France | Manages electrical power safely |

Conclusion

The science of vacuum cooling uses the simple physics of evaporation under low pressure. It delivers incredibly fast, uniform temperature reduction that preserves the peak freshness and value of your harvest.

-

Understanding evaporative cooling can enhance your knowledge of energy-efficient cooling methods and their applications. ↩

-

Exploring vacuum coolers will reveal their advantages in food preservation and energy efficiency, crucial for modern cooling solutions. ↩

-

Explore how Siemens electronics enhance efficiency and reliability in cooling systems, ensuring optimal performance. ↩

-

Learn about the principles of evaporative cooling and its advantages in refrigeration processes for better energy efficiency. ↩

-

Understanding uneven cooling can help improve food quality and reduce waste in storage. ↩

-

Learn about the workings of refrigeration units to appreciate their design and functionality in various applications. ↩

-

Explore this link to understand how quality engineering enhances product reliability and efficiency in manufacturing. ↩

Mila

You May Also Like

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

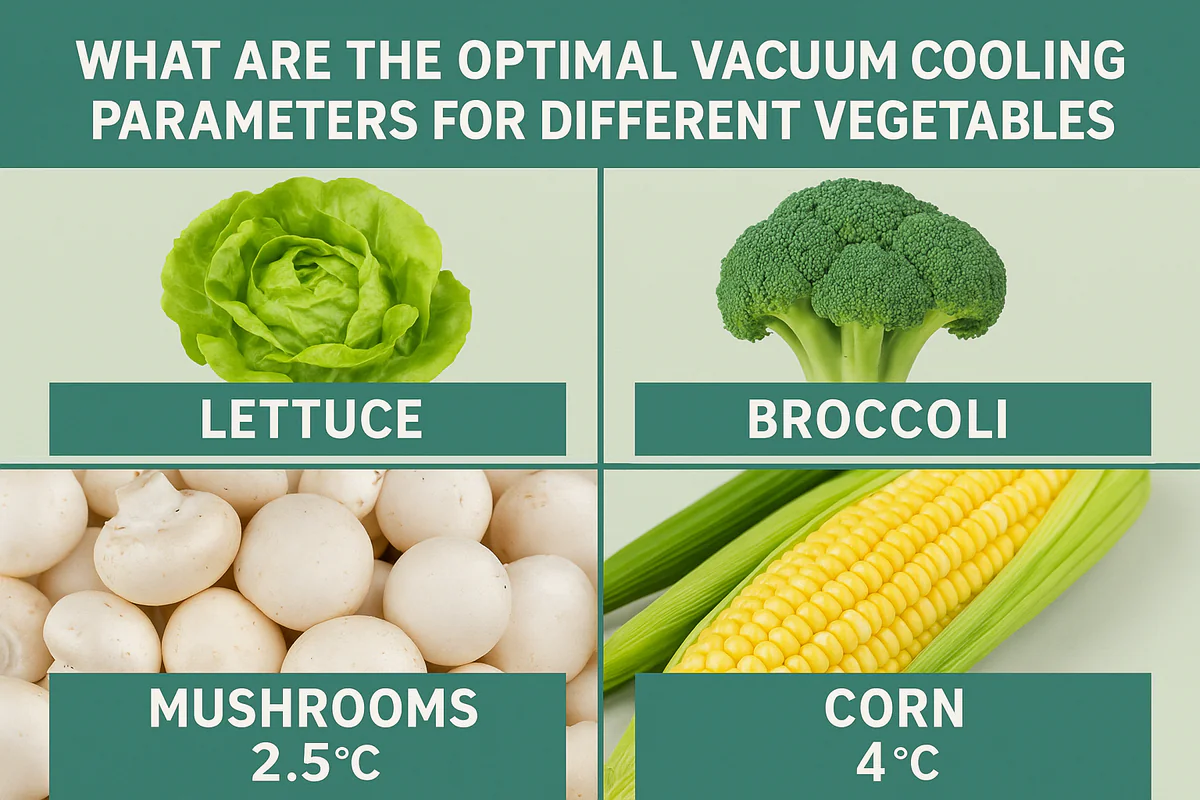

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

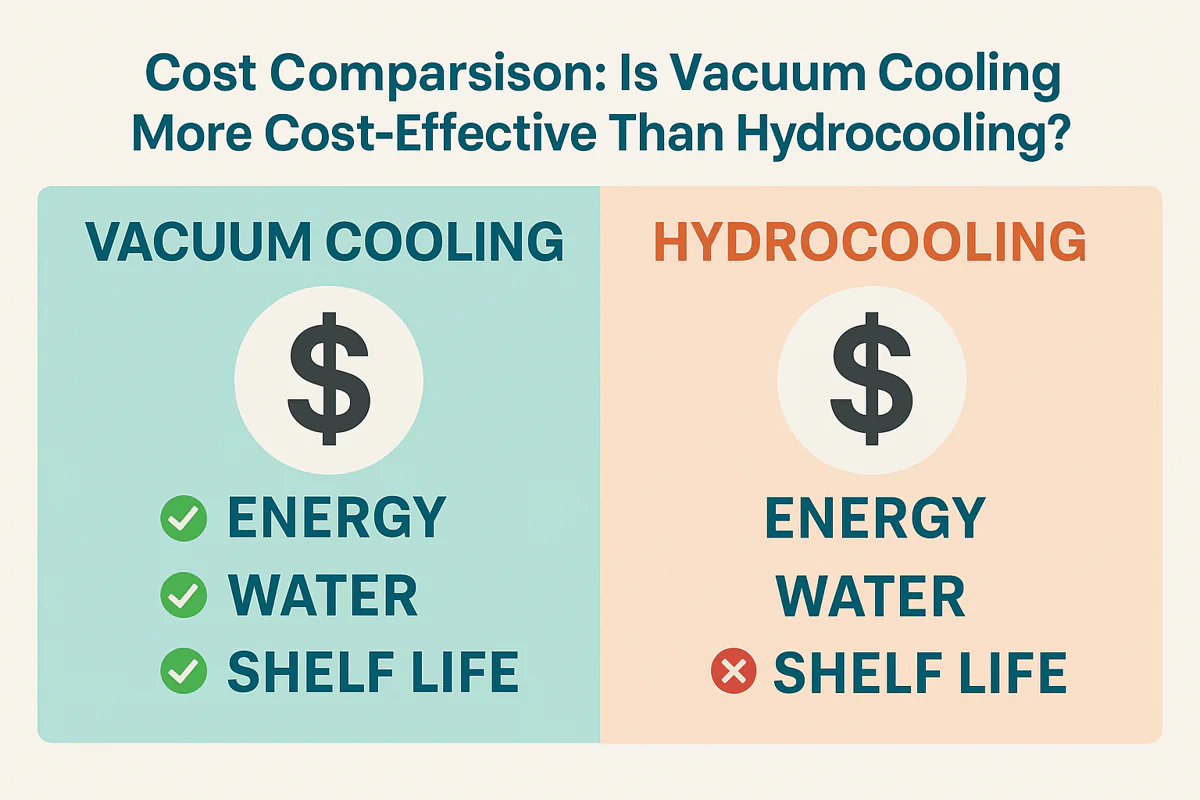

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are

What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your

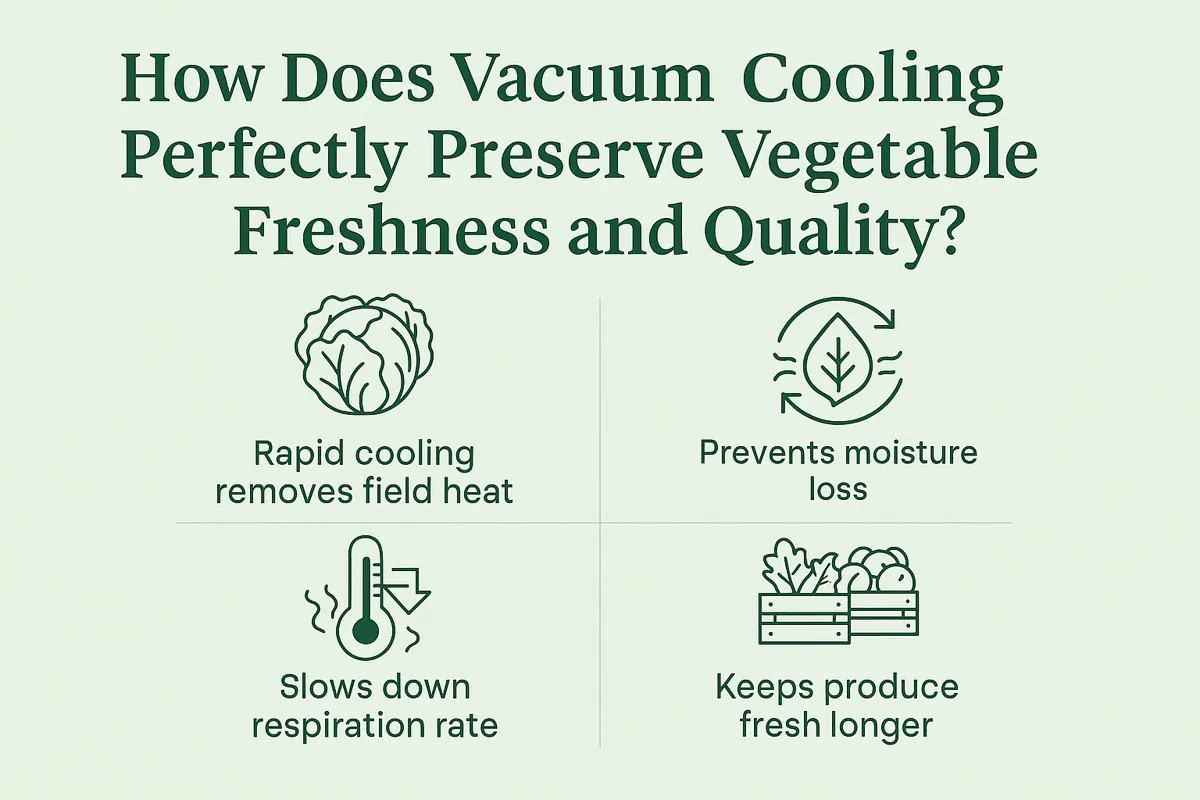

How Does Vacuum Cooling Perfectly Preserve Vegetable Freshness and Quality?

Your vegetables lose freshness with every minute they sit in a slow cooler. This lost time translates directly into lost

Vacuum Cooling vs. Traditional Cooling: Which is Better for Your Fresh Produce?

Your traditional cold room is slow. It takes hours to cool your fresh produce, and with every passing minute, field