How Does Vacuum Cooling Actually Improve Vegetable Shelf Life and Quality?

You’ve done the hard work. Your harvest is in, and the vegetables look perfect—crisp, vibrant, and full of life. But a clock has started ticking, and it’s counting down fast. Every minute that field heat remains in your produce, a silent process of decay is accelerating. It’s a race you can’t afford to lose.

This decay is a relentless thief, stealing the value of your crop. It shows up as wilted leaves, lost weight, dull colors, and, ultimately, spoilage. Relying on slow, conventional cooling methods is like giving this thief a multi-hour head start, resulting in lost revenue from customer rejections and a shorter window to sell your product.

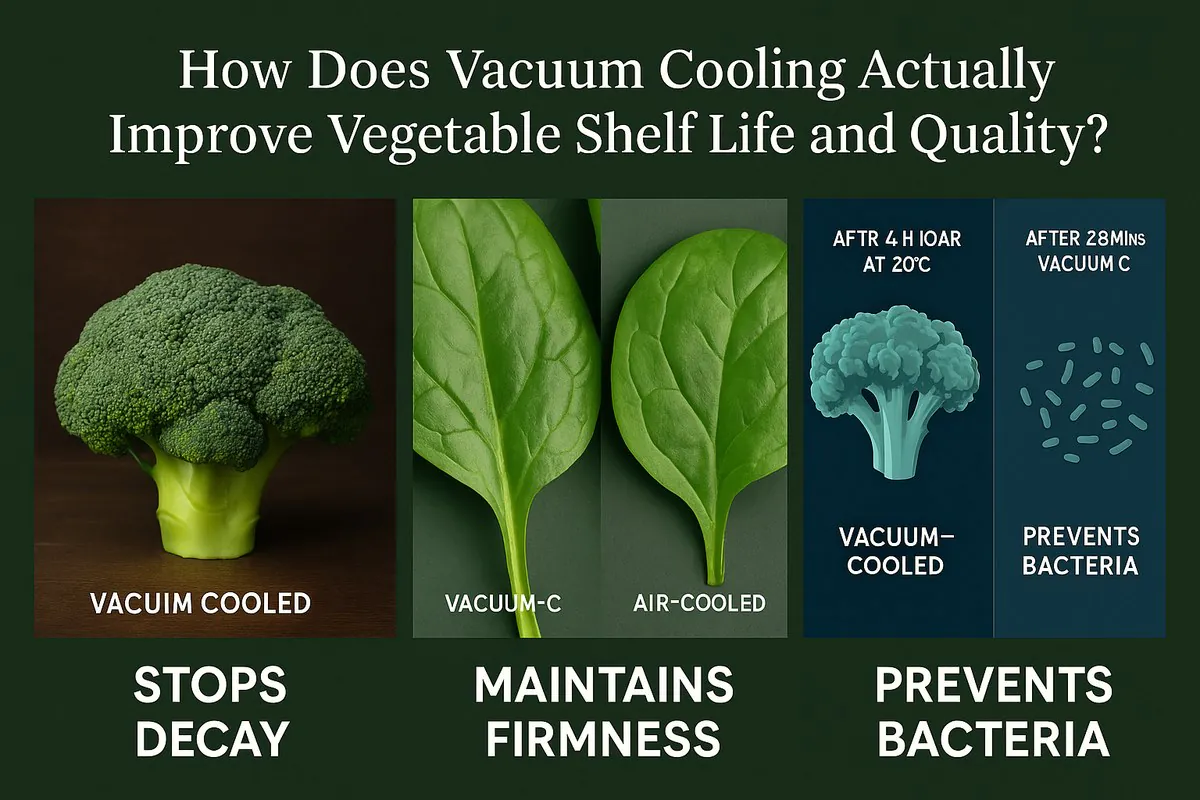

Vacuum cooling directly improves shelf life and quality by instantly halting the two primary drivers of decay: respiration and microbial growth. By rapidly dropping the core temperature in under 30 minutes, it preserves the vegetable’s cellular structure, moisture, and "just-picked" freshness, adding days or even weeks to its marketability.

As someone who works with growers and food processors every day, I’ve seen firsthand how post-harvest handling determines profit or loss. The difference isn’t magic; it’s science. A vacuum cooler gives you precise control over the biological processes that either preserve or destroy the quality of your product. Let’s explore exactly how this technology works to protect your investment and enhance your reputation for quality.

How Does Rapid Cooling Stop the Biological Aging Process?

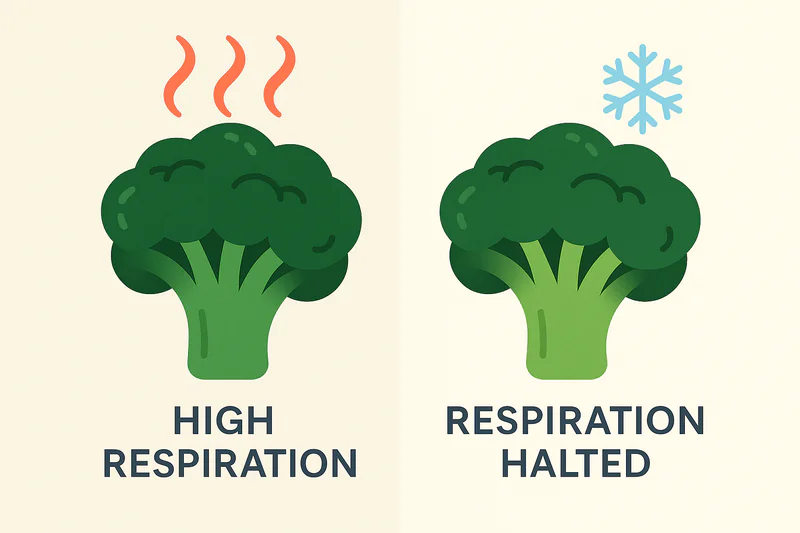

A harvested vegetable doesn’t know it has been picked. It continues to live, breathe, and age. This biological process, called respiration, burns the vegetable’s stored sugars and nutrients for energy. Field heat acts like a turbocharger for this process, making the vegetable burn through its own life force at an incredible rate.

Slow cooling methods leave your produce in this accelerated aging state for hours. It’s like forcing your vegetables to run a marathon in a hot room before they can finally rest. By the time they are finally cool, they are already exhausted, have lost significant nutrient value, and are days closer to the end of their life.

By dropping the product temperature from 30°C to 2°C (86°F to 36°F) in minutes, vacuum cooling slams the brakes on respiration. This metabolic shutdown preserves vital sugars and nutrients, effectively pausing the aging process and keeping the vegetable in a state of suspended animation, dramatically extending its life.

The Science of Respiration and Ethylene

For a farm owner like Carlos, understanding this science is what builds trust in the investment. He needs to know why he can now ship his produce on a 4-day journey and have it arrive fresher than a competitor’s produce shipped for one day.

Putting Respiration on Ice

Respiration is the enemy of shelf life1. It is the cellular process where the vegetable consumes its stored sugars and moisture to live. This process generates heat, which in a packed pallet, creates a vicious cycle of self-heating and faster decay. A vacuum cooler2 deals a decisive blow to this cycle. The rapid pressure drop forces water to evaporate from the vegetable’s surface, a process that requires a huge amount of energy. This energy is pulled from the vegetable itself in the form of heat. The result is an incredibly fast and uniform drop in temperature, deep to the product’s core. This temperature shock reduces the respiration rate3 by as much as 80-90%. The vegetable essentially stops "breathing" and consuming itself. This means it retains its sugars (which contribute to taste) and its stored water (which contributes to weight and crispness), and it stops generating additional heat. This state of metabolic hibernation is the foundational secret to a long shelf life.

Shutting Down Ethylene Production

Another critical aspect of aging is ethylene, a natural plant hormone that triggers ripening, aging, and eventually, decay. For many vegetables, especially leafy greens and broccoli, ethylene is the signal that says, "It’s time to turn yellow and die." Production of ethylene is highly temperature-dependent. Produce left warm after harvest continues to produce this damaging gas, which not only causes it to age but also triggers its neighbors in the box to age faster. It’s a chain reaction of spoilage. Because vacuum cooling takes the product below the temperature threshold for ethylene production4 so quickly, this "spoilage signal" is never sent. The vegetable is locked in its pre-ripened, pre-senescent state. This is why vacuum-cooled broccoli remains deep green and why lettuce doesn’t develop brown edges for much longer.

| Temperature | Respiration Rate | Ethylene Production | Aging Process |

|---|---|---|---|

| 25°C (77°F) | High | Active | Very Rapid |

| 10°C (50°F) | Moderate | Slowing | Moderate |

| 2°C (36°F) | Very Low | Negligible | Effectively Paused |

Why Does Vacuum-Cooled Produce Look and Feel Superior?

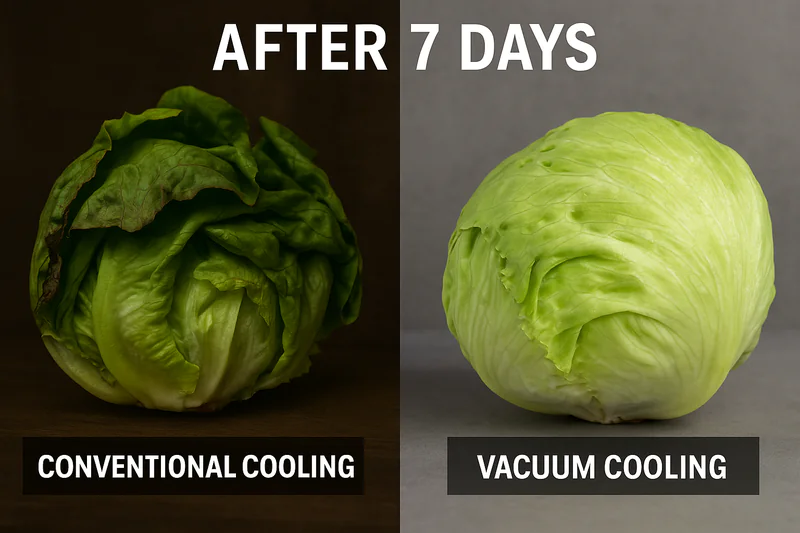

Quality is more than the absence of spoilage. It’s the crisp texture, the vibrant color, and the fresh weight that customers see and feel. This is what separates a premium product from a discount one. A head of lettuce can be perfectly edible but limp and dull, and it will be rejected by a quality-conscious buyer.

The slow dehydration and cellular breakdown that occurs during hours of conventional cooling is the main culprit behind this loss of quality. The dry, moving air in a forced-air cooler slowly wicks moisture away, and the ongoing respiration breaks down the very structures that give a vegetable its satisfying crunch and color.

Vacuum cooling preserves the physical quality of a vegetable by locking in its internal moisture and cellular integrity. This results in a product that maintains a higher turgor pressure (crispness), retains its chlorophyll (color), and has a higher salable weight compared to produce cooled by slower methods.

Preserving Cellular Turgor and Pigments

For a professional buyer like Norman, visual and textural quality is non-negotiable. He knows that produce that looks fresher sells faster and for a higher price. He can spot the difference between vacuum-cooled produce and conventionally cooled produce from a distance.

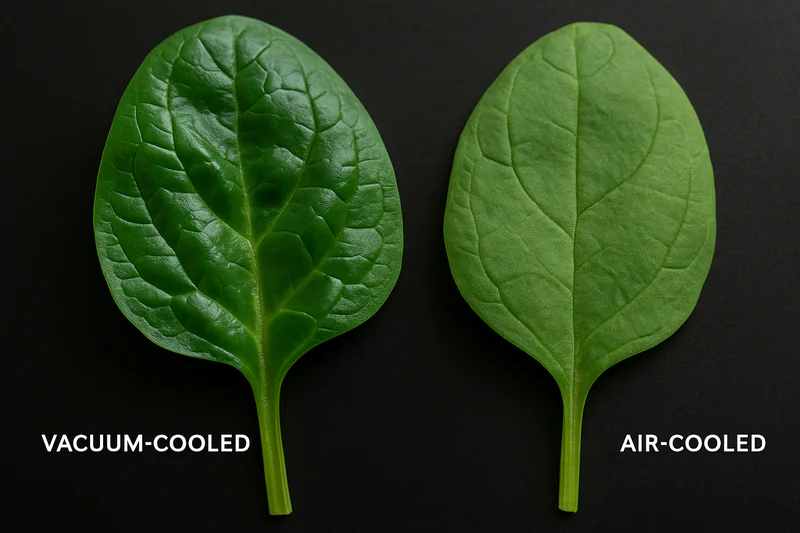

The Secret of Crispness: Turgor Pressure

The "snap" of a fresh green bean or the crunch of a crisp lettuce leaf is due to water pressure within the plant’s cells, known as turgor pressure5. Think of it as each cell being a tiny water balloon; when they are all full, the entire leaf or stem is firm and rigid. When a vegetable wilts, it’s because these cells have lost water and the pressure has dropped. Slow cooling methods, especially forced-air cooling, contribute to this by bombarding the product with dry air for hours while it’s still warm and respiring heavily, causing it to lose precious moisture. Vacuum cooling has a unique effect. While it does use evaporation (a loss of about 1.5% of moisture), this process is so fast (under 30 minutes) that it prevents the systemic, slow dehydration that causes wilting. It cools the product before the cells have a chance to lose their internal pressure. The result is a vegetable that retains its turgor, feeling significantly crisper and fresher to the touch. This textural superiority is a key indicator of quality for end consumers.

Locking in Color and Maximizing Weight

The vibrant green of broccoli, spinach, and lettuce is due to chlorophyll6. Enzymes within the plant, which are highly active at warmer temperatures, are responsible for breaking down this chlorophyll, leading to yellowing. Vacuum cooling’s rapid temperature drop instantly deactivates these enzymes, effectively "locking in" the green color. This is why vacuum-cooled broccoli stays green for days longer in the supermarket. Furthermore, while it seems counterintuitive, vacuum cooling7 can lead to a higher final salable weight. A vegetable losing 3-5% of its weight to uncontrolled respiration and dehydration over 12 hours in a cold room is common. The controlled, one-time moisture loss[^] of 1.5-2.5% during a vacuum cycle is often significantly less than this slow, continuous loss. For Carlos, selling thousands of tons of produce, a 2% difference in salable weight translates directly into tens of thousands of dollars of pure profit.

What Is the Impact on Food Safety and Microbial Control?

Quality and safety are two sides of the same coin. The same conditions that cause a vegetable to lose its visual appeal—warmth and moisture—are also the perfect breeding ground for the bacteria and molds that cause spoilage and potential food safety issues.

When produce sits in the "danger zone" (roughly 4°C to 40°C) for an extended period, it’s a dinner bell for microbes. A traditional cold room can take 12-24 hours to cool the core of a pallet, giving these pathogens a massive head start to multiply. This increases the risk of spoilage in transit and raises the microbial load of the final product.

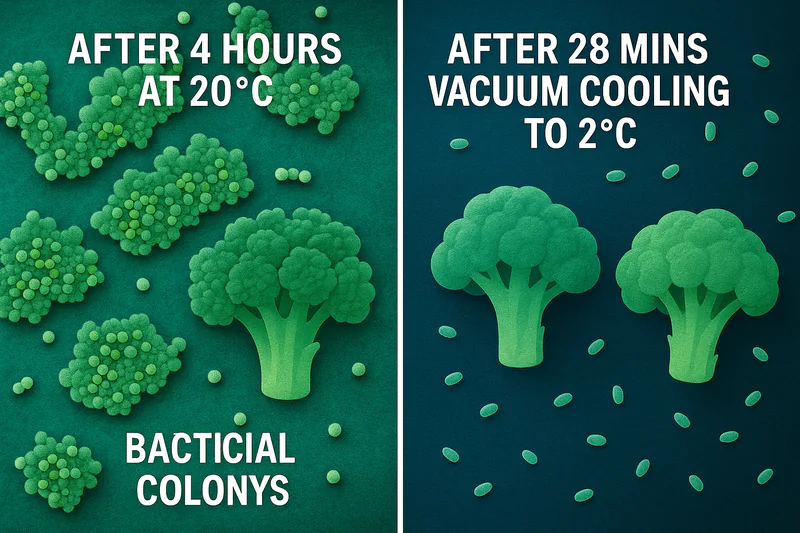

By pulling the product through the microbial danger zone in minutes, vacuum cooling acts as a powerful sanitation step. It gives bacteria and mold spores no time to activate and multiply, resulting in a safer product with a significantly lower microbial count, which is a critical factor for food processors and retailers.

A Critical Control Point for Food Safety

For a procurement manager like Sophia, who operates a HACCP-certified central kitchen8, starting with ingredients that have a low microbial load is not just a preference; it’s a requirement. It is a critical control point that impacts the safety and shelf life of every product her kitchen produces.

Winning the Race Against Spoilage Organisms

The surfaces of freshly harvested vegetables are naturally covered in the spores of common spoilage organisms9 like Botrytis (grey mold) and Erwinia (bacterial soft rot). In the warm, humid environment of a packed pallet, these spores activate and begin to multiply rapidly. A conventional cooler, which slowly removes heat, allows this incubation to proceed unchecked for hours. It’s like putting a petri dish in an incubator. A vacuum cooler10 is the opposite. The rapid drop in temperature is a form of thermal shock to these microorganisms. It plunges them into a dormant state before their reproductive cycle can even begin. This doesn’t sterilize the product, but it ensures that the starting microbial count is as low as physically possible. This advantage is carried through the entire cold chain. Less spoilage in the box, a longer code date at the store, and a safer final product for the consumer are all direct results of this initial microbial control.

The Unseen Benefit: Uniform Cooling Prevents Hidden Rot

One of the biggest hidden dangers of slow cooling methods is the creation of "hot spots." In a forced-air cooler, air flows around the outside of a pallet, cooling the outer boxes first. The produce in the center of the pallet can remain warm for many additional hours. This warm, moist core becomes a perfect incubation chamber for rot. This leads to the nightmare scenario for a buyer like Norman: receiving a pallet that looks fine on the outside but is decayed and rotting from the inside. Vacuum cooling’s mechanism of evaporative cooling is fundamentally different and prevents this. Because the cooling is driven by a drop in pressure that affects the entire chamber equally, every single leaf on every head of lettuce—whether it’s on the outside or in the very center of the pallet—cools at the same rate. This absolute uniformity guarantees that there are no hidden hot spots, eliminating the risk of internal pallet rot and ensuring the integrity and safety of the entire shipment.

Conclusion

Improving shelf life and quality is not just about making vegetables last longer; it’s about preserving their value. Vacuum cooling is a powerful tool that delivers a scientifically proven, multi-faceted advantage. It locks in freshness, crispness, color, and safety, creating a premium product that commands a higher price and builds a reputation for excellence.

-

Discover the key factors that affect shelf life and how to maximize it for your produce. ↩

-

Explore how vacuum coolers revolutionize produce shipping by extending shelf life and maintaining freshness. ↩

-

Understand the significance of respiration rates in vegetables for optimal storage and freshness. ↩

-

Learn about ethylene’s role in ripening and how to manage it for better produce quality. ↩

-

Understanding turgor pressure is crucial for anyone interested in plant health and quality, as it directly affects freshness. ↩

-

Discover the significance of chlorophyll in plants and how it affects their visual appeal and health. ↩

-

Explore the benefits of vacuum cooling to learn how it enhances produce quality and extends shelf life. ↩

-

Understanding HACCP certification can enhance your knowledge of food safety standards and practices. ↩

-

Learning about spoilage organisms can help you understand their impact on food safety and shelf life. ↩

-

Exploring vacuum cooling technology can provide insights into effective methods for preserving food quality. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But