How Fast Will a Bakery Vacuum Cooler Pay for Itself?

You hesitate to buy a vacuum cooler because the initial price tag looks high. You worry that this investment will take years to recover, draining your cash flow instead of helping it.

Most commercial bakeries see a full return on investment (ROI) within 12 to 18 months. By combining energy savings, reduced labor costs, and extended shelf life, the machine generates daily cash savings that pay for the equipment faster than almost any other upgrade in your factory.

As a manufacturer at Allcold, I am not just selling machines; I am selling a business solution. When I talk to customers like Norman in the USA or Carlos in Mexico, I always tell them: "Do not look at the price tag. Look at the calculator." If a machine costs you $50,000 but saves you $4,000 every month, it is free after one year. After that, it is pure profit. Today, I want to break down exactly where that money comes from and how you can calculate your own payback period.

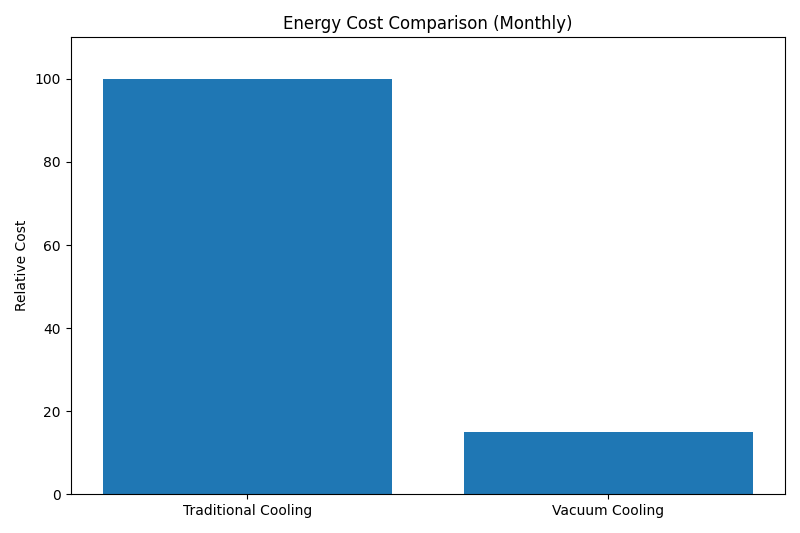

Will the Electricity Bill Savings Really Impact Your ROI?

You might think that running a powerful vacuum pump will increase your utility bill. You assume that "heavy machinery" equals "heavy costs," and you fear trading one expense for another.

Actually, vacuum cooling is about 60% cheaper to run than traditional air conditioning cooling. Because the cycle is so fast (minutes instead of hours), your total energy consumption drops drastically, putting thousands of dollars back into your pocket every year.

The Mathematics of Energy Reduction

Let’s look at the hard numbers. This is the first place you will see a return on your money.

I helped Carlos calculate this for his factory in Mexico. He was running huge fans and AC units to cool his bread because his climate is hot.

Here is the logic you need to use for your analysis:

In a traditional system, you are fighting physics. To cool bread from 95°C to 30°C, you have to run compressors for 2 hours.

Let’s say you have a cooling room1 pulling 40kW of power.

- Traditional Math: 40kW x 2 hours = 80 kWh per batch.

- Cost: If electricity is $0.15 per kWh, that batch costs you $12.00.

Now, look at the Allcold vacuum cooler2.

The machine might have a higher peak power, say 60kW. But it only runs for roughly 6 to 8 minutes (let’s say 0.15 hours) to do the exact same job.

- Vacuum Math: 60kW x 0.15 hours = 9 kWh per batch.

- Cost: At $0.15 per kWh, that batch costs you $1.35.

The Savings: You save $10.65 per batch.

If you bake 10 batches a day, you save $106.50 per day.

If you work 300 days a year, that is $31,950 per year in pure electricity savings.

This is just the direct electricity. You also have to consider the "Heat Load3." Traditional cooling dumps heat into your bakery, making your building’s air conditioning work harder. Vacuum cooling does not. So, your general facility electricity bill also goes down.

For many of my clients, the energy savings4 alone cover 30% to 50% of the machine’s cost in the first year. It is the most reliable part of the payback formula because it happens every single time you press the "Start" button.

| Cost Factor | Traditional Air Cooling | Allcold Vacuum Cooling | Annual Savings (Est.) |

|---|---|---|---|

| Cooling Time | 120 Minutes | 8 Minutes | — |

| Energy Used | 80 kWh / batch | 9 kWh / batch | — |

| Cost per Batch | $12.00 | $1.35 | — |

| Daily Cost (10 batches) | $120.00 | $13.50 | $106.50 / day |

| Annual Cost | $36,000 | $4,050 | $31,950 |

Can Reducing Labor Hours Shorten Your Payback Period?

You are paying staff to stand around waiting for bread to cool. You see the overtime hours on your payroll report, and you know that inefficiency is draining your bank account.

Vacuum cooling compresses your production schedule, often saving 2 to 3 labor hours per day. By eliminating the waiting time between baking and packaging, you reduce overtime and optimize shifts, which significantly accelerates your payback period.

The Cost of Waiting

Labor is usually the biggest expense for a bakery.

When I speak to Norman in the USA, he constantly complains about the cost of overtime. He pays his team time-and-a-half if they stay late.

Let’s analyze how vacuum cooling5 changes the labor equation.

In a standard bakery, the packaging team is held hostage by the cooling time.

If the last batch comes out of the oven at 2:00 PM, the packaging team cannot touch it until 4:00 PM. They have to stay until 5:00 PM to slice and pack it.

That gap—from 2:00 PM to 4:00 PM—is often "dead time" or low-productivity time. Yet, you are paying for it.

With vacuum cooling:

The last batch comes out at 2:00 PM.

It is cooled by 2:10 PM.

The packaging team packs it and is done by 3:00 PM.

You have just saved 2 hours of labor for your entire packaging line.

Let’s do the math on the payback:

- Imagine you have a team of 4 people in packaging.

- You pay them $20 per hour (including taxes and insurance).

- You save 2 hours per person, per day.

- Calculation: 4 people x 2 hours x $20 = $160 saved per day.

- Annual Calculation: $160 x 300 days = $48,000 saved per year.

Suddenly, the machine looks much cheaper.

If you add the energy savings ($31,950) to the labor savings6 ($48,000), you have already saved nearly $80,000 in one year.

For many industrial vacuum coolers, this amount covers the entire purchase price in just 9 to 12 months.

This does not even count the "intangible" benefits, like happier staff who get to go home on time. A stable workforce lowers your recruitment and training costs, which is another hidden financial return.

| Labor Variable | Standard Process | Optimized Vacuum Process |

|---|---|---|

| Wait Time | 2 Hours (Passive) | 10 Minutes (Active) |

| Shift End | Late (Overtime likely) | On Time / Early |

| Daily Hours Saved | 0 | 8 hours (4 staff x 2 hrs) |

| Daily Value | $0 | $160 |

| Annual Value | $0 | $48,000 |

Does Extended Shelf Life Convert to Real Cash?

You throw away bread that goes moldy too quickly. Or, you lose potential sales because you cannot ship your products to distant cities due to short shelf life. This is lost revenue that should be in your pocket.

Vacuum cooling extends shelf life by reducing microbial contamination and locking in moisture. This allows you to reduce returns of stale products and expand your sales territory, adding a powerful revenue stream to your ROI calculation.

Turning Waste into Profit

This is the most exciting part of the analysis because it is not just about "saving" money; it is about "making" money.

Sophia in Singapore faced a huge problem with mold. The humidity there is high. Her bread would mold after 3 or 4 days.

This limited her business model. She could only sell to local shops. If she tried to ship to Malaysia, the bread would spoil before it sold.

Vacuum cooling7 helps in two critical ways:

- The "Kill Step": The bread passes through the "danger zone" (60°C to 30°C) instantly. This is the temperature where bacteria and mold spores thrive. By skipping this zone, your bread is almost sterile when it reaches the packing room.

- Flash Drying: The surface of the bread is dried instantly by the vacuum. Mold needs moisture to grow. A dry crust protects the loaf.

Sophia found that her shelf life8 went from 4 days to 7 days (without adding preservatives).

How does this affect the Payback Period?

- Reduced Returns: If you usually accept 5% returns of stale/moldy bread from supermarkets, and you cut that to 2%, that is 3% of your total revenue saved.

- Example: If you sell $1,000,000 of bread a year, saving 3% is $30,000.

- New Markets: With 7 days of shelf life, you can reach customers 500km away. If this allows you to gain just one new supermarket chain account, that could be worth $50,000 or $100,000 a year in profit.

When you add this to the equation, the ROI9 becomes incredibly fast.

Let’s recap the potential annual gains:

- Energy: $31,950

- Labor: $48,000

- Total Year 1 Benefit: ~$110,000.

If the machine costs $60,000 or even $80,000, you have paid it off in roughly 7 to 9 months. The rest of the year is pure bonus. This is why I tell buyers that a vacuum cooler is not an expense; it is a high-yield savings account.

| Revenue Factor | Short Shelf Life (Traditional) | Long Shelf Life (Vacuum) | Financial Impact |

|---|---|---|---|

| Mold Onset | Day 3-4 | Day 7-10 | Lower waste |

| Product Returns | 5% | 2% | +3% Revenue retained |

| Market Reach | Local Only | Regional / National | Potential +10-20% Sales |

| Preservative Cost | High | Low / None | Lower ingredient cost |

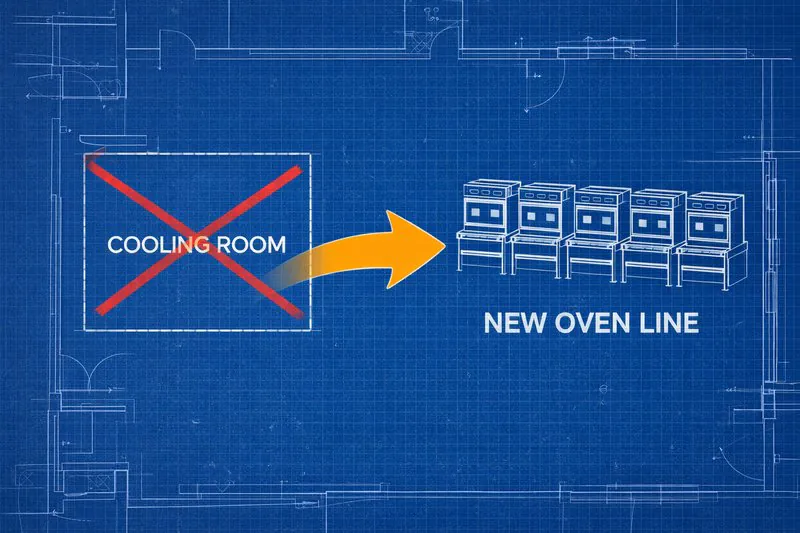

Can You Monetize the Space You Save?

You think you need to rent a bigger factory to grow. You are looking at expensive real estate contracts, not realizing that you already have the space you need—it is just filled with cooling racks.

By replacing large cooling rooms with a compact vacuum cooler, you reclaim up to 80% of your cooling floor space. You can use this area to add more production equipment, effectively "paying back" the machine by avoiding the cost of a new building.

The Real Estate Calculation

Real estate is expensive. This is true for Sophia in Singapore (where land is gold) and for Carlos in Mexico (where building a new facility is a headache).

Space has a dollar value. You are paying rent (or mortgage) on every square meter of your factory.

Let’s analyze the "Phantom Rent" you are paying for cooling.

- The Scenario: To cool your production naturally, you need a room of 100 square meters to hold all the racks.

- The Solution: An Allcold vacuum cooler takes up roughly 15 square meters.

- The Gain: You free up 85 square meters of high-quality, food-safe production floor.

How does this pay back the machine?

Method 1: Avoided Construction Costs.

If you were planning to build an extension to fit a new oven, that might cost $200,000.

By installing a vacuum cooler, you can put the new oven in the old cooling room.

You just saved $200,000 in construction. The machine paid for itself instantly—on Day 1.

Method 2: Increased Revenue per Square Meter.

If you use that reclaimed 85 square meters to install a second production line, you might double your output.

If your profit margin is $0.10 per loaf, and the new line produces 5,000 loaves a day, that is $500 of extra profit daily.

$500 x 300 days = $150,000 per year.

This is the "Opportunity Cost" payback.

Many business owners forget this. They only look at the electricity bill. But the ability to double your production without moving to a new factory is often the biggest financial win of all. It makes the payback period calculation look almost too good to be true, but the math is solid. You are trading low-value storage space for high-value production space.

| Space Variable | Cooling Room | Vacuum Cooler | Financial Implication |

|---|---|---|---|

| Footprint | 100 sqm | 15 sqm | 85 sqm reclaimed |

| Cost to Build | High (Insulation, AC) | Included in machine price | — |

| Usage | Passive Storage | Active Processing | — |

| Value of Space | ~$0 revenue generation | Can house new Oven/Mixer | High revenue potential |

Conclusion

The payback period for a bakery vacuum cooler is rarely longer than 18 months, and for high-volume bakeries, it can be as short as 6 months. When you add up the electricity savings, the labor reduction, the lowered waste, and the reclaimed floor space, the numbers are undeniable. It is an investment that stops your factory from leaking money.

-

Learn about the role of cooling rooms in food production and how they impact efficiency and product quality. ↩

-

Explore the advantages of the Allcold vacuum cooler for energy efficiency and cost savings in cooling processes. ↩

-

Understand the concept of Heat Load and its implications for energy consumption and cooling efficiency. ↩

-

Discover strategies and technologies that can help businesses significantly reduce energy costs in their cooling systems. ↩

-

Explore how vacuum cooling can revolutionize your bakery’s efficiency and reduce labor costs significantly. ↩

-

Discover innovative strategies that bakeries can implement to maximize labor savings and improve profitability. ↩

-

Explore this link to understand how vacuum cooling can extend shelf life and reduce waste in food products. ↩

-

Learn effective strategies to enhance bread shelf life, which can significantly boost your business profitability. ↩

-

Discover the financial benefits and ROI of vacuum cooling technology for food businesses. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy