How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark. Investing tens of thousands of dollars is a major decision, and you are rightly concerned about getting it right and not overpaying for features you don’t need.

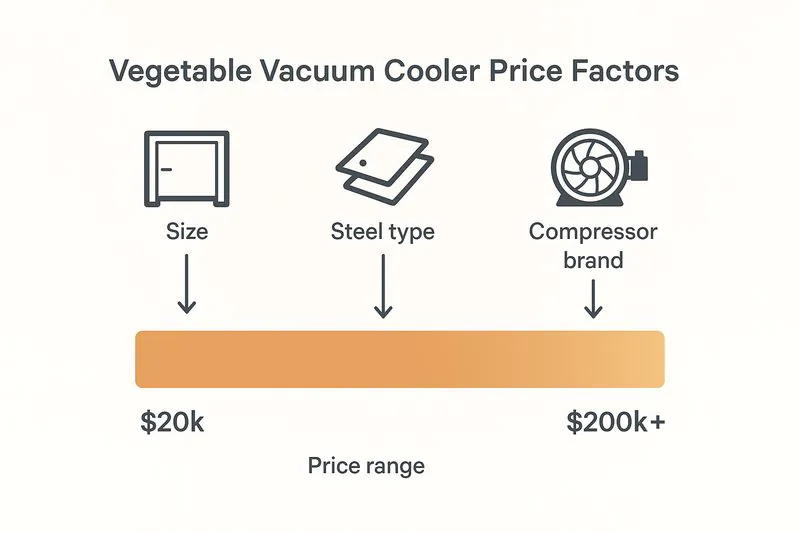

The price of a vegetable vacuum cooler can range from $20,000 for a small, basic model to over $200,000 for a large, automated industrial system. The final price depends entirely on its size (pallet capacity), construction materials (stainless steel vs. carbon steel), the quality of core components, and any customizations you require.

As the founder of ALLCOLD, this is the first question I get from nearly every potential client, from large farm owners like Carlos to professional buyers like Norman. The wide price range you see online can be confusing because you’re not just buying a machine; you are investing in a solution. In this guide, I will break down every element that contributes to the final cost, so you can build a realistic budget and understand exactly what you are paying for.

What Factors Determine the Upfront Machine Price?

You receive two quotes for a 4-pallet vacuum cooler, but one is $20,000 cheaper than the other. It’s tempting to go for the lower price, but this difference is a huge red flag. The cheaper option is almost certainly cutting corners on critical aspects that will cost you more in the long run.

The upfront price of the machine itself is determined by three main drivers: its physical size and capacity, the materials used to build it, and the quality of the "engine room" components like the vacuum pump and compressor. Each choice represents a trade-off between initial cost and long-term performance and reliability.

The primary cost factors for a vacuum cooler are its pallet capacity, the choice between painted carbon steel and more expensive 304 stainless steel, and the brands of the core components. A larger, stainless steel machine with premium German components will have a higher price but a lower total cost of ownership.

Deconstructing the Price Tag

A buyer’s journey often starts with a simple question: "How much for a 2-pallet machine?" But a professional knows the important questions come next. This is where we separate a mere purchase from a strategic investment.

Size and Capacity1: The Primary Cost Driver

This is the most straightforward factor. A machine built to cool 8 pallets of produce at once requires significantly more steel, a larger refrigeration system, and a more powerful vacuum pump than a machine designed for 2 pallets. It’s a simple matter of scale. A small, 1-pallet machine might be perfect for a central kitchen like Sophia’s, while a massive 12-pallet system is necessary for a large agricultural co-op. The price scales up accordingly. When requesting a quote, the number of pallets you need to cool per cycle is the first piece of information a manufacturer needs.

Material and Construction2: A Choice of Longevity

The choice between painted carbon steel and 304 food-grade stainless steel is a major price point. For many vegetable applications like lettuce or broccoli, a properly treated carbon steel chamber is perfectly adequate. At ALLCOLD, we use a multi-step process: sandblasting the steel to create an ideal surface, applying a zinc-rich primer for anti-corrosion, and finishing with multiple layers of marine-grade paint. This lasts for years. However, for direct food contact (like cooked food) or for clients demanding the best in hygiene and longevity, stainless steel is the only answer. For a manager like Sophia, whose facility is HACCP certified3, stainless steel isn’t a choice; it’s a requirement. This can add 20-40% to the chamber’s cost but guarantees rust-free operation for decades.

Core Components4: The Engine Inside

This is the hidden difference-maker. A quote might just say "50HP Refrigeration Unit." My quote will specify a "50HP German-made Bitzer Screw Compressor." This difference is everything. Premium components from brands like Bitzer (Germany)5, Copeland (USA), Leybold (Germany), and Siemens (Germany) have a global reputation for reliability, efficiency, and parts availability. A lower-priced machine will use domestic Chinese brands or even unbranded copycats. They work, but they are less efficient and far more likely to fail. For a grower like Carlos in the hot climate of Mexico, a robust Bitzer compressor that can perform in high ambient temperatures is a must-have, not a nice-to-have. This is where you are paying for peace of mind.

| Feature | Standard (Lower Price) | Premium (Higher Investment) |

|---|---|---|

| Capacity | 1-2 Pallets | 4-12+ Pallets |

| Material | Painted Carbon Steel | 304 Food-Grade Stainless Steel6 |

| Compressor | Generic or unbranded | Bitzer (Germany) or Copeland (USA) |

| Vacuum Pump | Obscure domestic brand | Leybold (Germany) or Busch (Germany) |

| Controls | Basic Relay Logic with Buttons | Siemens PLC with Touch Screen |

Are There Hidden Costs Beyond the Machine Price?

You have successfully negotiated a great FOB price for your new vacuum cooler. Your budget looks solid. But hold on—the machine price is only part of the story. A buyer’s biggest mistake is failing to budget for the "landed costs," the expenses required to get the machine from the factory floor to your facility and running.

These additional costs, from shipping to customs to installation, can be significant. Ignoring them can lead to project delays and serious budget overruns, turning a good deal into a financial headache. A professional buyer like Norman always plans for these costs from the very beginning.

Yes, you must budget for landed costs, which can add 15-30% on top of the machine’s price. These include international sea freight, insurance, customs duties and taxes in your country, inland transport from the port to your site, and potentially, installation and commissioning fees.

Budgeting for the Full Journey

When we provide a Proforma Invoice7 (PI), it will clearly state the Incoterms, usually FOB8 (Free On Board) or CIF9 (Cost, Insurance, and Freight). It’s crucial you understand what this means for your budget.

Shipping, Insurance, and Freight

If your price is FOB, it means we cover the cost of getting the machine to the port in China. You are responsible for the sea freight to your country, marine insurance, and all costs thereafter. If the price is CIF, we arrange and pay for the shipping and insurance to your destination port. CIF is more convenient for new importers, while experienced buyers often prefer FOB to use their own freight forwarders. A 40-foot container from China to North America or Europe can cost several thousand dollars, so this is a major line item.

Customs, Duties, and Taxes

Once the machine arrives, it must be cleared through your country’s customs. This involves paying import duties and taxes (like VAT or GST). These rates vary wildly by country and product classification. We provide the correct HS Code for the equipment, but you absolutely must consult a local customs broker. They will tell you the exact percentage you need to pay, preventing any nasty surprises. For a large industrial machine, these taxes can easily amount to tens of thousands of dollars.

Inland Transport and Installation

The journey isn’t over at the port. You need to arrange and pay for a truck to transport the machine from the port to your farm or facility. For larger systems, you will also need to hire a crane to offload the equipment from the truck and place it on its concrete pad. Finally, there is the installation itself. At ALLCOLD, we design our machines for easy installation. We provide detailed drawings and can guide your local electrician and refrigeration technician via video call for remote commissioning, which is the most cost-effective option. For complex industrial systems, you may budget for having one of our engineers fly to your site for on-site commissioning, which involves a daily fee plus travel expenses.

| Additional Cost Item | What It Is | Estimated Cost (as % of Machine Price) |

|---|---|---|

| Sea Freight & Insurance | Cost to ship the container from our port to yours. | 5-10% |

| Customs Duties & Taxes | Taxes levied by your government on the imported goods. | 5-20% (Varies Greatly) |

| Inland Transport10ation | Trucking from the port to your facility. | 2-5% |

| Installation Support11 | Remote guidance (free) or on-site engineer visit (paid). | 0-5% |

| Total Landed Cost | The sum of these can easily add… | 15-30%+ |

How Do I Calculate the Return on Investment (ROI)?

Looking at a quote for $80,000 can be intimidating. It’s easy to see it as a huge cost. But that’s the wrong way to look at it. The right way is to see it as an investment that generates a return. A vacuum cooler isn’t an expense; it’s a money-making machine.

If you don’t calculate the potential return, you can’t possibly justify the investment. You will be stuck comparing prices instead of comparing value. By running the numbers, you can prove to yourself, your partners, or your bank that this purchase will pay for itself, often much faster than you think.

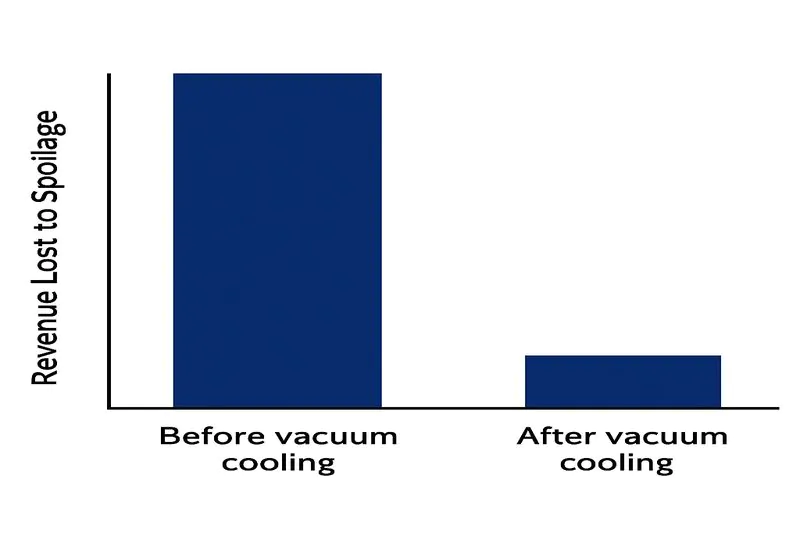

To calculate ROI, quantify the value of reduced spoilage, the higher prices you can command for premium quality, and labor savings. If a cooler prevents 5% spoilage on a $500,000 seasonal harvest, it has already generated a $25,000 return. The payback period is often just 1-3 seasons.

Finding Your Payback Period12

Let’s make this real with an example for a farm owner like Carlos. We will build a simple ROI model.

Step 1: Quantify Saved Revenue from Reduced Spoilage

Carlos harvests 40 tons of broccoli per day for a 90-day season. That’s 3,600 tons. Let’s say he sells it for $1,000/ton. His total seasonal revenue is $3,600,000. Without rapid pre-cooling, he experiences an average of 8% product loss from field heat, spoilage, and weight loss. That’s a loss of $288,000 per season. Our vacuum cooler can reduce that loss to just 2%.

- Annual Savings from Spoilage Reduction13: ($288,000 * (8% – 2%)/8%) = $216,000

Step 2: Quantify Revenue from Premium Market Access14

Many high-end supermarket chains only buy pre-cooled produce because it has a longer shelf life. By installing a vacuum cooler, Carlos can now access these buyers, who pay a 10% price premium. Let’s assume he can sell half his crop to these premium markets.

- Annual Gain from Premium Pricing: (1,800 tons $1,000/ton 10% premium) = $180,000

Step 3: Calculate Total Gain and Payback

Let’s say the total landed and installed cost of his industrial vacuum cooler is $180,000.

- Total Annual Gain15: $216,000 (Saved Loss) + $180,000 (Premium Price) = $396,000

- Payback Period: $180,000 (Investment) / $396,000 (Annual Gain) = 0.45 years

In this conservative example, the machine pays for itself in less than half a season. When you present the investment this way, the initial price no longer seems like a cost but a powerful tool for profitability.

| ROI Calculation Element | Your Farm’s Data (Example) | Annual Financial Impact |

|---|---|---|

| Total Seasonal Harvest | 3,600 Tons | – |

| Average Spoilage Rate | Before: 8%, After: 2% | +$216,000 (Saved Revenue) |

| Premium Price Access | 10% premium on 50% of crop | +$180,000 (New Revenue) |

| Total Annual Gain | – | $396,000 |

| Machine Investment | $180,000 | – |

| Payback Period | $180,000 / $396,000 | ~6 Months |

What Are My Financing and Payment Options?

You’ve calculated the ROI and you’re convinced the machine is a great investment. But you still face a practical problem: cash flow. Paying $80,000 or more upfront can be a major strain on any business, even a successful one.

Thinking you have to pay 100% in cash is a common misconception that stops many businesses from investing in the equipment they need to grow. The reality is that there are standard, secure payment structures and financing avenues available to make the purchase manageable.

Standard payment terms are a Telegraphic Transfer (T/T) of 30-50% as a deposit to begin production, with the balance due before shipment. For larger investments, an irrevocable Letter of Credit (L/C) at sight provides maximum security for both parties. Many buyers also secure loans from their local banks using the supplier’s Proforma Invoice.

Structuring Your Purchase

As a manufacturer exporting globally, we are flexible and familiar with several payment methods. Our goal is to make the transaction as smooth and secure as possible for both you and us.

Telegraphic Transfer (T/T)

This is the most common method for international trade. It’s a direct bank-to-bank wire transfer. The typical structure is a 30% to 50% deposit paid when you sign the purchase contract. This deposit allows us to start procuring the expensive raw materials and components (like the Bitzer compressor, which we have to order). The remaining 70% or 50% balance is then paid once the machine is built, tested, and ready for shipment. We provide photos and videos of the completed machine before you make the final payment. This method is fast, simple, and has lower bank fees than an L/C.

Letter of Credit (L/C)

For larger orders (typically over $100,000), or when dealing with a new supplier for the first time, a Letter of Credit offers the highest level of security. An L/C is a guarantee from your bank that we (the seller) will be paid as long as we meet the conditions specified in the L/C, such as providing proof of shipment (the Bill of Lading). It protects you because your bank will not release the funds until we have shipped the machine. It protects us because we have your bank’s guarantee of payment. While it is very secure, the process is more complex and involves higher bank fees (typically 1-2% of the transaction value).

Third-Party Equipment Financing

While we, as the manufacturer, do not offer direct financing or payment plans, we fully support our clients who seek it from their own banks or agricultural lending institutions. To apply for an equipment loan, your bank will need a detailed Proforma Invoice (PI) and technical specifications for the machine you are buying. We promptly provide all necessary documentation to support your loan application. This is a very common path for our clients in North America and Europe.

| Payment Method | How It Works | Best For | Pro / Con |

|---|---|---|---|

| Telegraphic Transfer (T/T) | Deposit to start production, balance before shipping. | Most transactions; buyers with trust in the supplier. | Pro: Fast, simple, lower bank fees. Con: Requires trust. |

| Letter of Credit (L/C) | Your bank guarantees payment upon our proof of shipment. | Large orders (> $100k); new relationships where trust isn’t established. | Pro: Maximum security for both parties. Con: Complex, slow, high bank fees. |

| Third-Party Loan | You get a loan from your local bank; you pay us via T/T. | Buyers needing to manage cash flow. | Pro: Preserves your working capital. Con: Requires a separate loan application process. |

Conclusion

Understanding the price of a vacuum cooler means looking beyond the sticker price. It’s about evaluating the investment based on capacity, quality, and landed costs, and then calculating its powerful return through saved produce and expanded market access. A vacuum cooler is one of the highest-ROI investments a produce business can make.

-

Understanding how size and capacity affect costs can help you make informed purchasing decisions. ↩

-

Exploring material options can ensure you choose a machine that meets your durability and hygiene needs. ↩

-

Understanding HACCP certification can help you ensure compliance and safety in your food operations. ↩

-

Learn why investing in high-quality components can lead to better performance and reliability. ↩

-

Find out why Bitzer compressors are renowned for their efficiency and reliability in demanding environments. ↩

-

Discover the significance of using food-grade materials to ensure safety and compliance in food processing. ↩

-

Understanding Proforma Invoices is essential for budgeting and ensuring clarity in shipping costs. ↩

-

Learn about FOB to understand your responsibilities and costs when importing goods. ↩

-

CIF can simplify your shipping process; explore its benefits for new importers. ↩

-

Understanding inland transport is crucial for budgeting the total cost of your import. ↩

-

Explore installation support options to ensure a smooth setup of your imported equipment. ↩

-

Discover the significance of the payback period in assessing the viability of agricultural investments. ↩

-

Explore how reducing spoilage can significantly boost farm profitability and sustainability. ↩

-

Learn how accessing premium markets can enhance revenue and market opportunities for farmers. ↩

-

Understand the concept of total annual gain and its importance in evaluating investment returns. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,