How to Perfectly Match Chamber Size and Loading Capacity to Your Bakery?

You’ve decided to buy a vacuum cooler, but now you’re standing in your bakery with a tape measure, scratching your head. "Will my trolleys fit?" "Do I need a one-trolley or two-trolley machine?" "What if my racks are a weird size?"

These are the most common anxieties I hear from customers. Getting the size wrong is a nightmare—if the chamber is too small, your trolleys won’t fit, and the machine is useless. If it’s too big, you’re paying to vacuum empty air every single cycle, wasting energy and money for years.

The perfect vacuum cooler is sized by two critical factors: the physical dimensions of your specific trolleys (Width x Depth x Height) and the total weight of the product on those trolleys. We customize the internal chamber to fit your racks snugly, ensuring maximum efficiency and zero wasted space.

As a manufacturer, I believe you shouldn’t have to change your bakery to fit a machine; the machine should fit your bakery. Let’s walk through exactly how to measure your needs and choose the right configuration, so you can order with 100% confidence.

What Exactly is "Cycle Capacity" and Why Does It Matter?

You see machines labeled as "100kg," "200kg," or "300kg." This is the "Cycle Capacity," or the maximum weight of bread the machine can cool in one batch. But here is the trick: this number is just a guideline. The real capacity is determined by your trolleys.

If a machine is rated for 200kg but the chamber is only big enough for one trolley, and your trolley only holds 80kg of bread, then your real capacity is only 80kg. You are limited by volume, not weight.

You must calculate your capacity based on the number of trolleys you need to cool per hour. For example, a ‘2-trolley’ machine is designed to hold two standard racks per cycle. If your production line releases two racks every 15 minutes, this is the exact capacity you need to maintain a continuous flow.

Calculating Your Real-World Throughput

For a buyer like Carlos, who needs to maximize every dollar, understanding the difference between "rated weight" and "real throughput1" is vital.

The "Trolley Math" Formula

Don’t just look at the machine’s sticker. Do the math for your specific product.

- Weigh One Trolley: Weigh a fully loaded trolley of your baked product (subtract the weight of the metal rack itself). Let’s say it’s 80kg of bread.

- Determine Oven Output: How many of these trolleys come out of your ovens every hour? Let’s say 4 trolleys per hour.

- Calculate Required Cycle Speed: A vacuum cooling cycle takes about 15 minutes (including loading/unloading). That means one machine can run 4 cycles per hour.

- Match the Machine: To cool 4 trolleys in 4 cycles, you need a machine that holds 1 trolley per cycle.

- Calculation: 1 trolley x 4 cycles = 4 trolleys/hour.

- Machine Choice: You need a 1-Trolley Machine2 (often rated as 100kg or 150kg model).

If your ovens produced 8 trolleys per hour, a 1-trolley machine would be too slow. You would need a 2-Trolley Machine (running 2 trolleys x 4 cycles = 8 trolleys/hour).

| Your Oven Output | Required Machine Size | Typical "Rated" Capacity | Why This Fits |

|---|---|---|---|

| 2-4 Trolleys/Hour | 1-Trolley Machine | 100kg – 150kg | Perfect for small-medium bakeries. |

| 6-8 Trolleys/Hour | 2-Trolley Machine | 200kg – 300kg | Standard for commercial wholesale. |

| 12+ Trolleys/Hour | 3 or 4-Trolley Machine | 400kg+ | Industrial scale, often custom built. |

Does One Size Really Fit All? (Hint: No!)

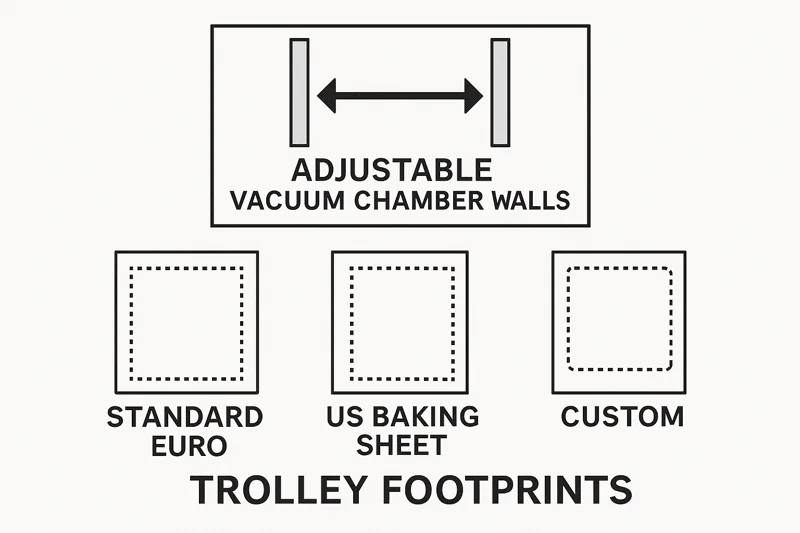

Trolleys in Europe are different from trolleys in the USA. A standard "Euro-Rack" is often 600x800mm. But in the US, baking racks are often wider, around 18×26 inches or larger.

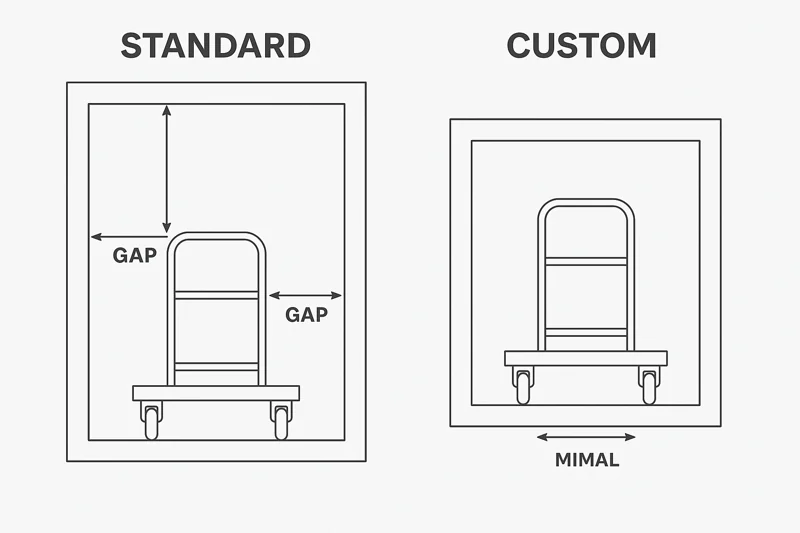

If you buy a standard "off-the-shelf" machine from a catalog, you might find that your racks are 2 inches too wide to fit through the door. Or, they fit, but there is 20cm of empty space on all sides. That empty space is an "energy vampire"—your pump has to work harder to remove air from that empty gap in every single cycle.

We customize the internal chamber dimensions (Width, Depth, Height) for every client. By building the chamber to fit your specific trolley size—whether it’s a slim Euro-rack or a wide American rack—we ensure a perfect fit that minimizes air volume and maximizes cooling speed.

The Importance of the "Snug Fit"

For a detail-oriented manager like Sophia, efficiency is everything. She knows that wasted space equals wasted energy.

Minimizing the "Free Air Volume3"

The science of vacuum cooling is simple: we pump air out of the chamber. The less air there is to start with, the faster we reach the vacuum state.

- The Problem: A standard machine designed for a 1000mm deep trolley will have a huge gap if you put in an 800mm deep trolley. That’s 200mm of useless air space.

- The Solution: We ask for your trolley dimensions before we build. If your trolley is 600mm x 800mm x 1800mm , we build the chamber to be something like 800mm x 1000mm x 2000mm . This leaves just enough room for easy loading (about 10cm clearance on sides) but minimizes the empty volume.

Handling "Non-Standard" Racks

Do you have double-width racks? Do you use short racks for cookies? No problem.

- Double-Width: We can build a wider chamber to accept double racks.

- Multiple Short Racks: If you have two short racks (e.g., 1 meter high), we can design the chamber height so you can stack them or load them side-by-side.

- Pallets: For large scale operations (like mushroom farms or huge bakeries), we even build chambers sized for standard industrial pallets (1.0m x 1.2m), allowing you to load with a forklift or pallet jack.

| Trolley Type | Typical Dimensions | Customization Strategy | Benefit |

|---|---|---|---|

| Standard Euro | 600 x 800 mm | Compact Chamber Design4 | Lowest energy consumption. |

| US Standard | 660 x 760 mm (approx) | Wider Door & Chamber | Fits US racks without modification. |

| Industrial Pallet | 1000 x 1200 mm | Heavy-Duty Pallet Floor | Allows forklift loading for heavy loads. |

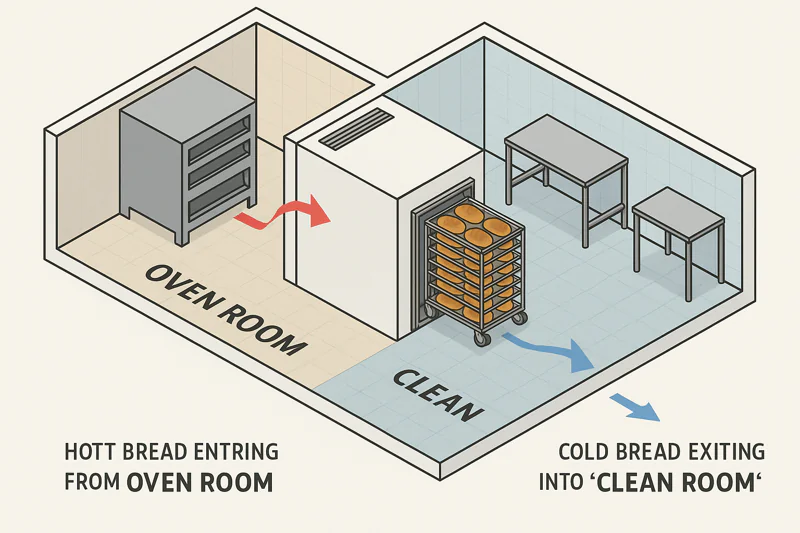

Single Door vs. Double Door: Which Flow is Right for You?

Most people assume a machine has one door: you put the bread in, cool it, and pull it out. But this "in-and-out" workflow can cause traffic jams in a busy factory.

In a linear production line, you want the product to keep moving forward. You don’t want the cooked food crossing paths with the raw food or the packaging staff entering the baking zone.

A "Pass-Through" (Double Door) configuration allows you to load hot trolleys from the oven side and unload cooled trolleys from the packaging side. This creates a straight-line workflow that strictly separates your "High Hygiene" (packaging) area from your "Low Hygiene" (baking) area.

Workflow and Hygiene Optimization

This feature is a major selling point for customers like Sophia or large factories like Carlos’s, where HACCP compliance5 and cross-contamination6 are major concerns.

The "Clean Room" Barrier

A vacuum cooler is often the bridge between the hot kitchen and the cold packaging room.

- Single Door (Standard): The operator has to walk into the "hot zone" to retrieve the trolley, or the baker has to walk into the "clean zone" to deliver it. This crossing of paths is a hygiene risk.

- Double Door (Pass-Through): We install a door on the front and the back. The machine sits in the wall separating the two rooms. The baker loads the hot bread from the oven room and closes the door. 15 minutes later, the packaging staff on the other side opens the back door and pulls the sterile, cold bread directly into the clean room. The two teams never interact, and the air from the dirty zone never enters the clean zone.

Speed and Traffic Control

Beyond hygiene, it’s just faster. You don’t have to wait for a trolley to be pulled out before you can stage the next one. You can have the next hot trolley ready at the entrance while the cooled one is being removed from the exit. It creates a seamless "flow" rather than a "stop-and-go" traffic jam.

| Configuration | Description | Best For… |

|---|---|---|

| Single Door (Hinged/Sliding) | One entry/exit point. | Small Bakeries / Tight Spaces. Simple and cost-effective. |

| Double Door (Pass-Through) | Entry at front, Exit at back. | Industrial Lines / HACCP Factories. Perfect for separating raw/cooked zones. |

| Vertical Sliding Door | Door slides up instead of swinging out. | Very Tight Spaces. Saves floor space needed for door swing. |

Conclusion

Don’t guess when it comes to size. By calculating your exact throughput in trolleys per hour and sharing your trolley dimensions with us, we can build a machine that fits your bakery like a glove. Whether you need a compact 1-trolley unit or a massive pass-through system, the right size means maximum efficiency and zero waste.

-

Understanding real throughput is crucial for optimizing production efficiency and maximizing profits in baking. ↩

-

Exploring the 1-Trolley Machine can help you choose the right equipment for your bakery’s output needs. ↩

-

Understanding Free Air Volume is crucial for optimizing vacuum cooling efficiency and reducing energy waste. ↩

-

Exploring Compact Chamber Design can reveal innovative strategies to enhance energy efficiency in industrial applications. ↩

-

Understanding HACCP compliance is crucial for maintaining food safety standards in your operations. ↩

-

Preventing cross-contamination is vital for food safety; explore effective strategies to ensure hygiene in your facility. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy