Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they have to choose one or the other, often compromising on either efficiency or product quality.

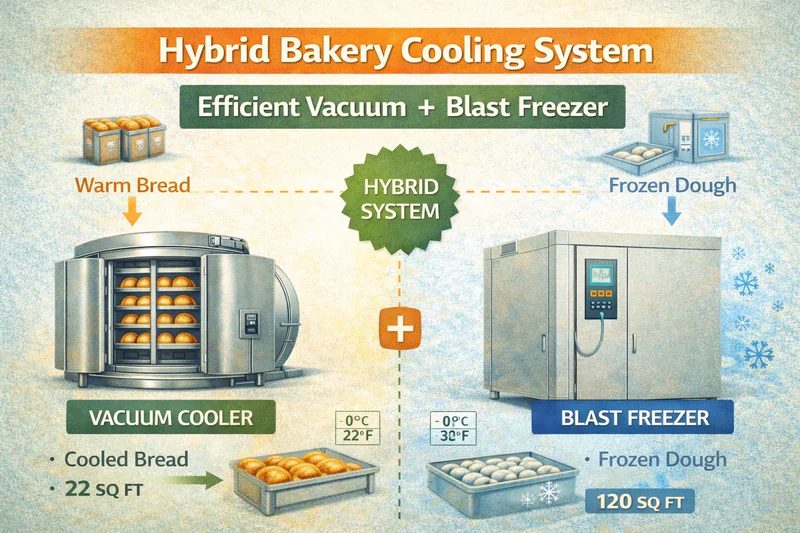

You do not have to choose. A hybrid cooling solution combines the rapid heat removal of vacuum cooling with the deep-freezing power of blast freezers. This approach maximizes energy efficiency, improves product texture, and significantly speeds up your production line by using each machine for what it does best.

In my years of running Allcold and helping clients from Vietnam to Mexico optimize their factories, I have seen that the "silver bullet" is often not a single machine. It is a smart combination of technologies. Let’s explore how merging these two worlds can transform your business.

Why Is the "Hybrid" Approach More Efficient Than a Blast Freezer Alone?

Have you ever watched your blast freezer struggle to bring down the temperature of steaming hot trolleys? It is like asking a sprinter to run a marathon; it works, but it is exhausting and inefficient.

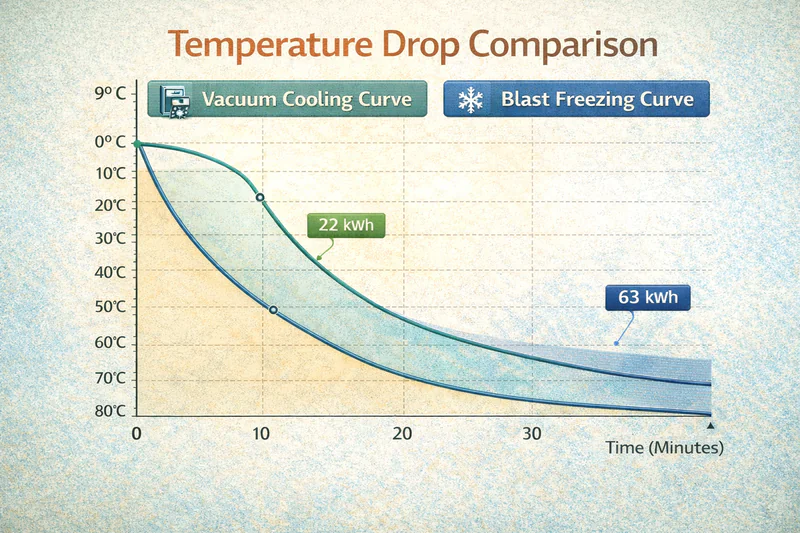

The hybrid method uses vacuum cooling to drop the temperature from 100°C to roughly 30°C in just 10 minutes. The blast freezer then takes over to freeze the product. This removes the massive "heat load" instantly, allowing your freezer to work much faster.

Understanding the Thermodynamics of Cooling

To understand why the hybrid method is superior, we need to look at the physics of heat removal.

The Limitation of Blast Freezers:

When you put a trolley of bread fresh from the oven (at nearly 100°C) directly into a blast freezer, you are asking the freezer to do two very different jobs:

- Remove Sensible Heat: Cooling the product from very hot to room temperature.

- Phase Change (Freezing): Turning the water inside the product into ice.

Blast freezers are designed primarily for the second job. When they are forced to do the first job, they consume huge amounts of electricity. The compressors have to run at maximum capacity to fight the intense heat radiating from the bread. This often causes ice to form on the evaporator coils, requiring frequent defrost cycles, which further slows down production.

The Role of Vacuum Cooling in a Hybrid System:

At Allcold, we design machines like the AVCF-150 specifically to handle that initial "heat crash." Vacuum cooling1 works by flash evaporation. We lower the pressure in the chamber, causing a small percentage of the water in the bread to boil off instantly.

- Result: The temperature drops from 100°C to around 28°C or 30°C in roughly 10 minutes.

- Efficiency: This process is incredibly efficient because it happens uniformly throughout the product.

By placing a vacuum cooler before your blast freezer, you are essentially pre-cooling the product instantly. Your blast freezer receives bread that is already cool. It can then focus entirely on freezing the product to -18°C. In my experience with a client in Vietnam, this simple change reduced their total freezing time by nearly 40%.

How Does This Combination Improve Product Quality?

Do you struggle with "freezer burn" or ice crystals destroying the texture of your delicate pastries? This often happens when the cooling process is too slow or uneven.

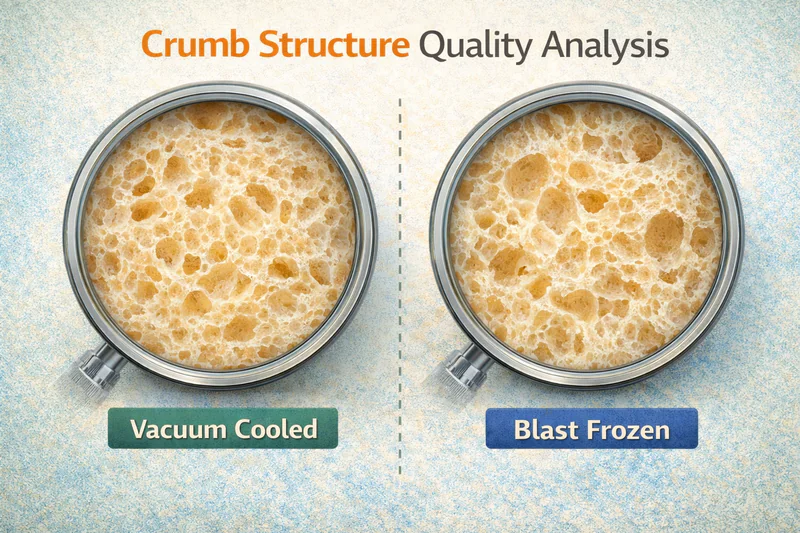

Hybrid cooling ensures the core of your product is cool before it enters the freezer. This prevents the "hot core" effect where internal steam migrates to the frozen crust, creating large ice crystals that ruin the crumb structure.

The Science of Moisture and Texture

Quality is the battlefield where you win or lose customers. If you are supplying high-end supermarkets or strict buyers like Norman, you cannot afford inconsistent texture.

The Problem with Direct Freezing:

When you put hot bread into a freezer, the outside freezes very quickly. However, the center is still hot. The heat from the center tries to escape, but it is trapped by the frozen crust. This trapped steam condenses and creates large, jagged ice crystals right under the crust or inside the crumb. When the customer thaws the bread later, these crystals melt, leaving the bread soggy or destroying its sponge-like structure.

The Hybrid Advantage2:

Our vacuum coolers, such as the AVC-600 series, come with a "Vacuum Delay" facility. This is a critical feature for quality. It allows the machine to pause or slow down the pressure drop to ensure that products with high water content do not cool too fast, which could damage the skin.

Once the product reaches 30°C uniformly through the vacuum process:

- Starch Gelatinization: The structure of the bread is "set" perfectly. The crumb is stabilized.

- Moisture Lock3: The moisture is evenly distributed.

- Clean Freezing: When this stable, cool product enters the blast freezer, it freezes evenly. You get micro-crystals instead of large ice crystals.

This results in a product that, upon thawing, tastes almost exactly like it was just baked. I have had clients tell me that their blind taste tests showed customers could not tell the difference between fresh bread and hybrid-cooled frozen bread.

Does a Hybrid System Save Money on Energy?

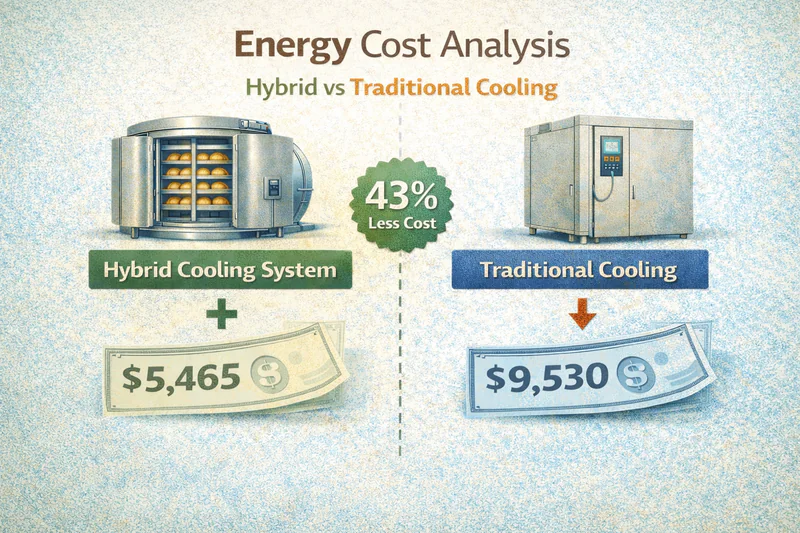

You might be thinking, "Mila, buying two machines sounds like it will double my electricity bill." It is a logical assumption, but the math actually works in your favor.

Vacuum coolers only use peak power for short bursts, and features like our "Start sequence/power save" minimize draw. By reducing the heavy load on your blast freezer compressors, you significantly cut their running time and maintenance costs.

Analyzing the Total Cost of Ownership4

Let’s break down the energy consumption5 using real data from our machines.

The Energy Hog:

A blast freezer must keep a large room at -30°C or -40°C. To do this while battling 150kg of hot bread requires the compressors to run continuously. A typical industrial freezer might draw 15kW to 20kW of power hour after hour.

The Energy Saver:

Our AVCF-150 vacuum cooler has a total power rating of around 20.6kW, but here is the key difference: it only runs for 10 to 15 minutes per cycle.

- Smart Features: We install a "Power Save" mode. If the machine has not been operated for a period, it automatically shuts down. It doesn’t sit there idling and wasting money.

- Component Efficiency: We use high-efficiency Bitzer compressors and air-cooled condensers that are sized specifically to minimize the kW rating.

The Calculation:

If you use a hybrid system:

- The vacuum cooler runs for 10 minutes to remove the bulk of the heat. This costs pennies.

- The blast freezer now has a much lighter load. It might only need to run for 40 minutes instead of 120 minutes to achieve the frozen state.

- You are saving 60+ minutes of high-energy freezer run time per batch.

Over a year, this reduction in energy consumption is massive. Furthermore, because your blast freezer isn’t working as hard, the compressors last longer, and you spend less on repairs. It is a classic case of working smarter, not harder.

Is Integrating Vacuum Cooling into Existing Lines Difficult?

Are you worried that installing a new system will require tearing up your factory floor or pausing production for weeks? This fear often stops owners from upgrading.

Modern vacuum coolers are designed to be "Plug & Play." Our units are skid-mounted, compact, and require minimal installation work—usually just a power connection and a flat concrete floor.

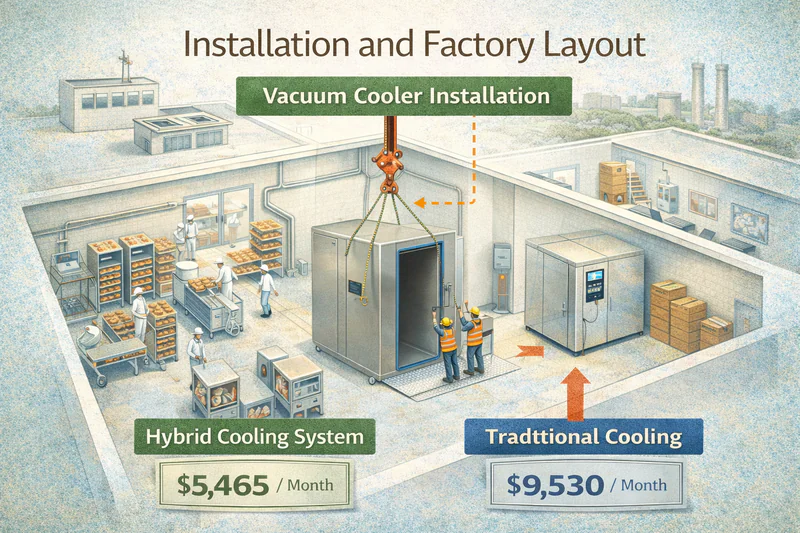

Installation and Space Management

I know that space is a premium for my clients. Whether you are in a crowded industrial park in Singapore or a large facility in the US, you don’t want to waste floor space.

Compact Design6:

We design our units to be surprisingly small for the work they do. For example, the indoor unit of our 150kg capacity model (AVCF-150) is approximately 1.6 meters wide by 1.4 meters deep. It takes up less space than a standard office desk. The noisy and hot parts—the cooling unit and condenser—can be placed outside or in a separate plant room (2.5m x 1.8m), keeping your production area quiet and cool.

Plug and Play7:

We build these machines on a steel skid base. This means:

- Mobility: You can move the machine with a forklift. If you rearrange your factory next year, the cooler moves with you.

- Simple Setup: You don’t need complex drainage or custom foundations. A standard concrete floor is sufficient.

- Power: You just need a standard 3-phase power supply (e.g., 380V/50Hz).

Operational Integration:

The system is controlled by a Siemens touch screen. It is designed for operators, not scientists. You roll the trolley in, insert the temperature probe, close the door, and press start. The screen displays the vacuum level, product temperature, and time elapsed. It is intuitive. This means your staff can start using the hybrid method on day one with minimal training.

Can You Customize a Hybrid Solution for Specific Needs?

Every bakery is different. Some of you bake baguettes, others bake heavy rye bread or delicate sponge cakes. A "one size fits all" machine rarely works perfectly.

We offer plenty of "tailor-made" options, from specific chamber sizes to accommodate your existing trolleys, to varying compressor brands like Bitzer or Emerson. This ensures the vacuum component fits seamlessly with your current freezing setup.

Tailoring the Technology to Your Product

At Allcold, we don’t just sell boxes; we sell solutions. When I speak to a potential client, I ask for their trolley dimensions, their production volume, and their specific product types.

Component Customization8:

We use top-tier components because reliability is non-negotiable.

- Compressors: We typically use Bitzer (Germany) or Emerson (USA) because they are robust and parts are available globally.

- Vacuum Pumps: We use brands like Leybold (Germany) or Nash (USA). These are the hearts of the machine.

- Electrical: Schneider (Germany) contactors and relays ensure the machine handles the power load safely.

Configuration Options:

- Door Types: We can install hinged doors for smaller units or sliding doors for automated lines.

- Trolley Capacity9: Whether you use a single rack or a double rack system, we adjust the internal chamber dimensions (e.g., 1000mm wide x 1500mm deep x 2000mm high) to fit your specific trolleys. You don’t need to buy new racks to fit our machine.

- Software Tuning: The "Vacuum Delay" and cooling curves can be programmed to match your recipe. If you are making a dense fruit cake, we program a gentler curve. If it is a light bun, we can go faster.

This level of customization means the hybrid system isn’t a disruption; it is an enhancement that feels like it was built specifically for your factory.

Conclusion

Combining vacuum cooling with your existing blast freezer isn’t just an upgrade; it is a strategic leap. You get the speed of flash cooling, the preservation power of freezing, and a lower energy bill. It is the smartest way to future-proof your bakery.

-

Explore this link to understand vacuum cooling’s efficiency and its role in enhancing cooling processes. ↩

-

Discover the Hybrid Advantage to learn how advanced cooling methods improve food texture and quality, crucial for high-end markets. ↩

-

Explore this link to understand how Moisture Lock enhances food quality and preserves texture, ensuring customer satisfaction. ↩

-

Understanding TCO helps businesses evaluate long-term costs and savings, making informed decisions on energy-efficient equipment. ↩

-

Exploring strategies to reduce energy consumption can lead to significant cost savings and improved operational efficiency. ↩

-

Explore how compact design can optimize space and efficiency in industrial settings, making it a smart choice for your operations. ↩

-

Learn about the advantages of plug and play systems, which simplify installation and enhance mobility in your facility. ↩

-

Explore this link to understand how component customization can enhance product reliability and performance. ↩

-

Learn about the importance of trolley capacity in optimizing production processes and maximizing space utilization. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the