Is a Bakery Vacuum Cooling Machine Worth the Investment?

You look at the price tag of a vacuum cooler. It shocks you. You wonder if this shiny machine is a luxury for giant factories or a necessity for your own survival. You need to know if the numbers make sense.

It is not an expense; it is a profit generator. By using a 5-minute cooling cycle to cut production time, reduce labor costs, and extend shelf life, most bakeries see a full Return on Investment (ROI) in just 12 to 18 months.

As a manufacturer at Allcold, I face this question every single day. A buyer like Norman will ask me, "Mila, this machine costs as much as a luxury car. You say it cools bread in 5 minutes, but how do I justify this price to my boss?" I love this question. It means we can stop talking about "features" and start talking about "money." I am going to walk you through the exact math I use with my clients to prove that this machine pays for itself.

How Does a 5-Minute Cycle Reduce Labor Costs?

Your biggest expense is your people. You pay skilled bakers to bake, not to stand around watching bread cool. Every minute they spend moving racks or waiting for bread to reach slicing temperature is money leaking out of your business.

A 5-minute cooling cycle creates a continuous workflow. It eliminates the 2-hour bottleneck of traditional cooling. By stopping the waiting, you can save roughly 2 to 3 labor hours per day, per shift, and reassign staff to value-adding tasks.

The "Dead Time1" Calculation

Let’s dig into the reality of a busy bakery. I want you to think about your current workflow. In a traditional setup, the bread comes out of the oven. A baker has to move it to a cooling area. Then, they wait. This is "Dead Time." This wasted time is a huge, hidden cost that destroys your efficiency.

For a customer like Sophia in Singapore, who runs a high-volume central kitchen, labor efficiency2 is the only way to survive. Her entire production line depends on a smooth, predictable flow. Any bottleneck creates chaos downstream. The old way of cooling is a guaranteed bottleneck. The bread comes out of the oven, and suddenly you need a person and a lot of floor space to manage dozens of hot, heavy racks. This person has to push racks, make sure they are not too close together, and then wait. The slicing and packing team also waits. With a 5-minute vacuum cooling cycle3, the flow is simple and perfect: Oven -> Cooler -> Slicer. It is a straight line with no waiting.

Let’s look at the math for a typical mid-sized bakery.

| Factor | Traditional Cooling Scenario | 5-Minute Vacuum Cooling Scenario |

|---|---|---|

| Workflow | Bake -> Move Racks -> Wait (90-120 min) -> Slice | Bake -> Cool (5 min) -> Slice |

| Handling | Multiple "touch points" per rack | One "touch point" per rack |

| Idle Time | Significant for bakers and slicers | Nearly eliminated |

| Labor Hours Wasted | 2-4 hours per shift | ~0.25 hours per shift |

The ROI Formula:

- Let’s be conservative and say you save 3 hours of labor per day.

- Your average labor cost (including wages, taxes, and benefits) is $25 USD per hour.

- Daily Saving: 3 hours/day × $25/hour = $75 saved per day.

- Annual Saving: $75 × 300 operational days = $22,500 USD saved per year.

This is just the direct labor saving. It does not account for the fact that your bakers are now less tired and more productive on the actual baking tasks. By removing the physical burden of managing hot, heavy racks across a large room, you also reduce the risk of workplace injury4, which is a hidden cost no one likes to talk about until it happens. A 5-minute cycle makes your bakery a safer and more efficient place to work.

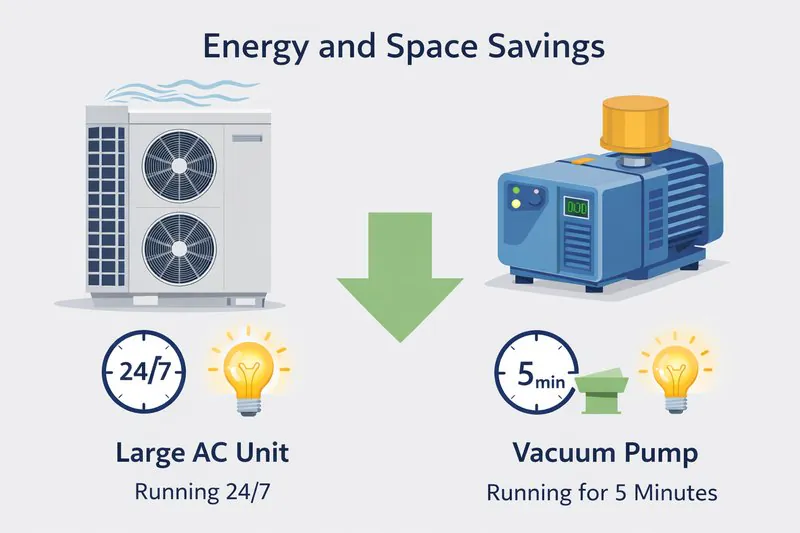

Can a 5-Minute Cycle Lower Your Energy and Rent Bills?

Real estate is expensive. Renting a large space just to store hot air and cooling racks is a waste of your budget. Furthermore, trying to cool that space with air conditioning is one of the most inefficient ways to use energy.

Yes. A 5-minute cycle cools only the bread, not the room. It cuts energy use per batch by over 80% and can reduce your physical cooling footprint by up to 90%, freeing up expensive space for more production.

The "Cost per Loaf" Energy Analysis

I often speak with Carlos in Mexico about this. He operates a large plant and his electricity bill is a major concern. He sees a big machine and assumes it uses big power. This is false when you look at the total energy consumed per batch. A 5-minute cycle is key to this efficiency.

Let’s analyze the physics.

Traditional Cooling Room:

- You have a room full of hot bread (95°C).

- You are trying to cool it with cold air from an Air Conditioning (AC) system. Air is a terrible insulator, so it’s a very poor conductor of heat.

- Your AC compressors must run constantly for hours to fight the heat load from the bread. They run for 2, 3, or even 4 hours to cool down one batch.

- You also cool the racks, the floor, the walls, and all the air in the room. This is wasted energy.

Allcold 5-Minute Vacuum Cooling5:

- Our machine uses a powerful pump, but it only runs for 5 minutes.

- All the energy is focused on one thing: making the water inside the bread evaporate. This evaporation is what removes the heat. We are not trying to cool the steel chamber or the air around it.

- Our systems use a Variable Frequency Drive (VFD)6, which acts like a dimmer switch for the motor. It only uses the exact amount of power needed. It might run at 100% for the first 2 minutes, then ramp down.

| Factor | Air Conditioning Room | Allcold 5-Minute Vacuum Cooler |

|---|---|---|

| What is Cooled? | Entire Room (Air, Walls, Racks) | Only the Product |

| Run Time per Batch | 2-4 hours | 5 minutes |

| Energy Transfer | Inefficient (Convection) | Highly Efficient (Evaporation) |

| Typical kWh/Batch | 20-30 kWh | 3-4 kWh |

The ROI Formula (Energy):

- Energy Saving per Batch7: ~18 kWh.

- If your electricity costs $0.15 per kWh, that is a saving of $2.70 per batch.

- If you produce 15 batches a day: $2.70 x 15 batches = $40.50 per day.

- Annual Energy Saving: $40.50 x 300 days = $12,150 USD per year.

The ROI Formula (Space):

For Sophia in Singapore, rent is extremely high.

- Old Way: She needed 40 square meters for cooling racks. At $50/sqm, this cost $2,000/month.

- New Way: She needs 8 square meters for the vacuum cooler and a small buffer area. This costs $400/month.

- Annual Rent Saving8: $1,600 x 12 months = $19,200 USD per year.

When you combine Energy ($12,150) and Space ($19,200), the operational savings are massive, often exceeding $31,000 per year.

How Does a 5-Minute Cool Down Increase Your Saleable Product?

Every loaf of bread you throw away is money you burned. Whether it is crushed during slicing because it was too soft, or it went moldy before you could sell it, waste destroys your bottom line.

The 5-minute cycle instantly firms the bread for perfect slicing, reducing waste. It also creates a more sterile product by passing through the bacterial danger zone in seconds, which can double the natural shelf life and cut returns from stores.

The Economics of Yield and Shelf Life

This is where the ROI calculation gets very powerful. We are no longer just saving costs; we are protecting the value of what you have already produced. A 5-minute cool-down is the key to locking in this value.

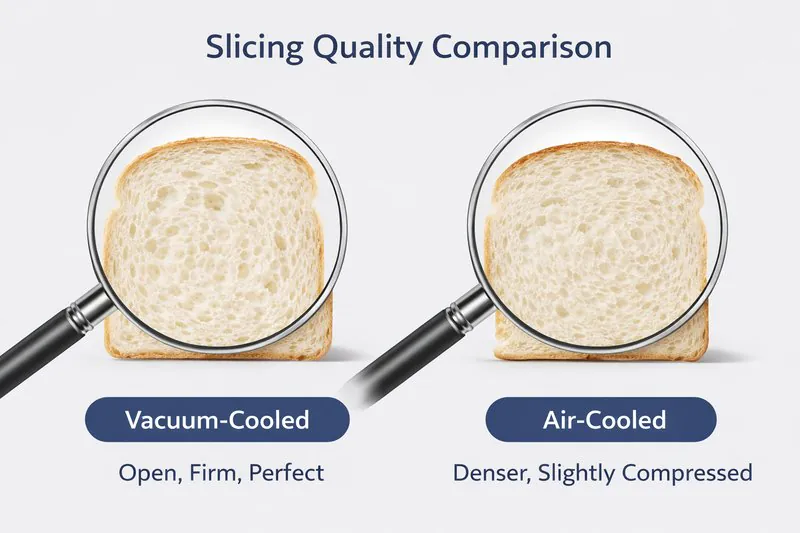

1. The Slicing Yield

Have you ever tried to slice a loaf of sandwich bread that is still 35°C in the center? The crumb is soft and sticky. The slicer blades tear the bread, or the loaf gets compressed. You end up with "dog ears" and crushed, unsellable slices. Most bakeries accept a 3% to 5% reject rate at the slicer as a normal "cost of doing business." It is not. With a 5-minute vacuum cycle, the bread is cooled uniformly to the core. The starch structure is perfectly set and stable. The loaf is firm and ready.

- The Gain: If you produce 2,000 loaves a day and sell them for $2.00 each, your daily production value is $4,000.

- Reducing rejects from 3% to just 0.5% means you save 2.5% of your production.

- Daily Value Saved: 2.5% of $4,000 = $100 per day.

- Annual Value Saved: $100 x 300 days = $30,000 USD per year. This alone is a huge return.

2. The Shelf Life Extension

This is the most important factor for Carlos, who distributes to large supermarket chains. Supermarkets hate returns.

- The Problem: In a normal bakery, bread cools on open racks where it is exposed to airborne mold spores. These spores get trapped in the packaging. The bread goes moldy in 4-5 days.

- The 5-Minute Solution: The vacuum process is a race against biology. First, the chamber is sealed and air is removed, sucking out spores. Second, the 5-minute cycle moves the bread through the bacterial growth "danger zone" (40°C to 4°C) in seconds, not hours. This creates a much more microbiologically stable product.

- The Result: Natural, un-preserved shelf life often extends from 4 days to 7 or 8 days. For a large bakery, reducing your "return rate" from supermarkets by even 1% can be worth tens of thousands of dollars per year. It also protects your brand reputation, which is priceless. For a buyer like Norman, this predictable quality is a massive selling point.

Can a 5-Minute Turnaround Actually Grow Your Business?

We have talked about saving money and protecting product. Now let’s talk about making more money. What is the value of being able to say "Yes" to an order you would usually have to refuse?

Yes. The 5-minute turnaround is a competitive weapon. It lets you accept rush orders your competitors can’t. It also extends your delivery radius by hours, opening up entirely new markets for daily fresh bread.

Opportunity Cost and Market Expansion

This part of the ROI calculator is about "Opportunity Cost." What money are you losing by being slow? Many business owners forget to calculate the cost of missed opportunities. The 5-minute cycle turns missed opportunities into new revenue streams.

1. The "Rush Order" Scenario

Imagine a hotel or a catering company calls you at 8:00 AM. Their regular supplier failed. They need 500 baguettes delivered by 11:00 AM for a lunch event.

- Without Vacuum: You bake (30 mins). You must cool the baguettes (at least 90 mins). Then you pack (30 mins). The total time is over 2.5 hours. You cannot meet the deadline. You have to say "No" and turn away the new customer.

- With a 5-Minute Cycle: You bake (25 mins). You cool the baguettes (5 mins). You pack (30 mins). The entire process takes one hour. The bread is on the truck at 9:00 AM. You easily say "Yes" and win a new, grateful client.

- The profit from capturing just one or two of these large, unexpected orders a month can often cover the entire monthly financing payment for the machine. This is how the machine starts paying for itself immediately.

2. Extending the Delivery Radius

Freshness is a ticking clock that starts the moment bread leaves the oven.

- If your bread takes 2 hours to cool before it’s ready for the delivery truck, that is 2 hours of precious shelf life lost. Your driver has a limited time to reach customers.

- With a 5-minute cycle, you gain back almost 2 full hours. Your delivery truck can leave 2 hours earlier. That means you can drive 2 hours further. This opens up new cities, new towns, and new supermarket chains that were previously "too far away" to service with fresh daily product. Expanding your market is the fastest way to grow your business, and this logistical speed is what makes it possible.

Conclusion

When we add it up—$22,500 in labor, $31,000+ in space and energy, $30,000 in reduced waste, plus new revenue—the annual return is massive. The 5-minute cycle is the engine that drives this ROI.

The question is not if you can afford to buy one. The question is: can you afford to keep losing that money every single year by not having one?

-

Understanding ‘Dead Time’ can help you identify inefficiencies in your bakery workflow and improve productivity. ↩

-

Learn why maximizing labor efficiency is essential for the success of your bakery operations. ↩

-

Explore how vacuum cooling cycles can revolutionize your baking process and enhance efficiency. ↩

-

Discover the risks of workplace injuries in bakeries and how to mitigate them for a safer environment. ↩

-

Find out how 5-minute vacuum cooling can enhance efficiency and reduce energy consumption in food production. ↩

-

Learn about VFD technology and its impact on energy efficiency and cost savings in machinery. ↩

-

Discover how optimizing energy savings can significantly reduce operational costs in industrial settings. ↩

-

Explore strategies for minimizing rent costs and maximizing space efficiency in your operations. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy