Is Vacuum Cooling Really More Energy Efficient Than Traditional Methods for Vegetables?

Worried about rising energy bills cutting into your profits from vegetable sales? Traditional cooling systems can run for hours, consuming significant electricity.

While vacuum coolers have powerful pumps, they cool produce extremely fast, often resulting in lower overall energy consumption per kilogram of vegetables cooled compared to traditional methods that run for extended periods. The key is total energy used for the job done, not just instantaneous power draw.

It’s a common question I get, and the answer isn’t always a simple yes or no without looking at the details. Let’s explore how these cooling methods stack up in terms of energy use so you can make an informed decision for your business.

How Much Energy Do Traditional Vegetable Coolers Really Use?

Think your old cold room is cheap to run just because it’s simple? The constant, lengthy operation can lead to surprisingly high energy bills over time, impacting your bottom line more than you realize.

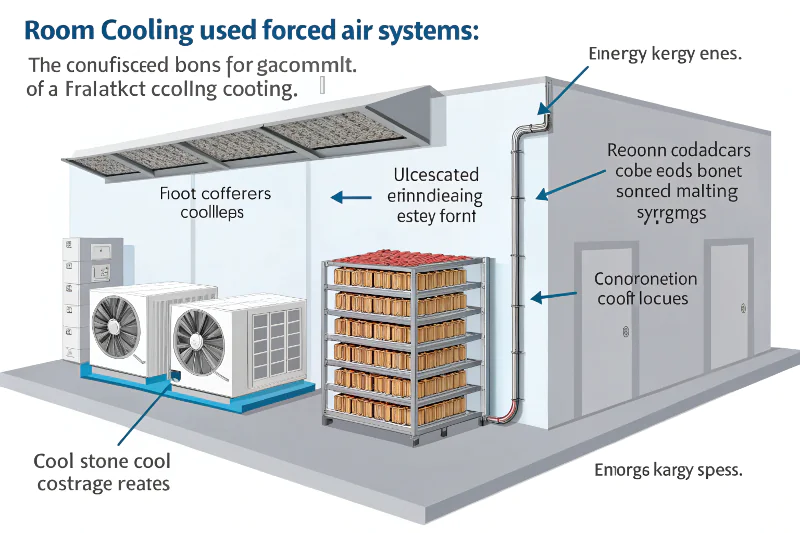

Traditional coolers like room coolers and forced-air systems often consume substantial energy because they operate for many hours to cool produce, and they cool the entire space, not just the product. Inefficiencies like poor insulation and air leaks add to this consumption.

I remember visiting a farm in [Placeholder for a region, e.g., the Central Valley, California] where they were using a very large, older forced-air cooling system. The owner, much like Norman in his pursuit of efficiency, was tracking his energy bills meticulously. He was shocked when we calculated how much of his electricity cost was going just to pre-cool his broccoli, largely because the system had to run almost continuously during peak harvest.

Understanding Energy Use in Traditional Systems

These systems rely on circulating cold air.

- Room Cooling1: This method is the most basic. A refrigeration unit cools a large insulated room, and the produce inside slowly gives off its heat to the cold air. The compressor and fans run for very long periods, often 12 to 72 hours, depending on the produce and how it’s stacked. Energy is lost through walls, door openings, and the constant need to remove heat from the product and the surrounding air and infrastructure.

- Forced-Air Cooling2: This is an improvement, where fans actively pull or push cold air through pallets of produce. While faster than static room cooling (typically 4-10 hours), the fans themselves consume energy, and the refrigeration system still has to work hard to remove the heat drawn from the produce. The longer the produce stays in the cooler, the more energy is consumed. Air often bypasses the product if not stacked perfectly, leading to wasted cooling energy.

Factors Driving Up Energy Consumption

Several factors contribute to higher energy use in these systems:

- Long Cooling Times3: The primary driver. The longer the refrigeration system and fans run, the more electricity is used.

- Cooling the Entire Space: A significant amount of energy is spent cooling the air, walls, floors, and ceiling of the cooler, not just the vegetables.

- Air Leakage & Insulation4: Poor seals on doors or inadequate insulation mean the refrigeration system has to work harder to maintain low temperatures.

- Ambient Temperature5: If the cooler is in a hot environment, more energy is needed to combat heat infiltration.

Here’s a look at their typical energy profiles:

| Cooling Method | Primary Energy Consumers | Typical Operational Duration for Pre-Cooling | Key Energy Inefficiency Factors |

|---|---|---|---|

| Room Cooling | Refrigeration compressor, Fans | 12-72+ hours | Very slow heat transfer, cooling entire room volume, heat leaks |

| Forced-Air Cooling | Refrigeration compressor, Powerful Fans | 4-10 hours | Air bypass, cooling room volume, fan energy, heat leaks |

| Hydrocooling | Water chillers, Pumps | 5-30 minutes (plus water chilling time) | Energy to chill large volumes of water, heat loss from water tank |

While hydrocooling can be fast, the energy to chill the water initially (and keep it chilled) can be substantial, and it’s not suitable for all products, as we’ve discussed. For air-based traditional methods, the extended run times are the main energy drain.

Is Vacuum Cooling More Energy Efficient for Vegetables?

Heard that vacuum coolers are power-hungry because of their large pumps? It’s true they have a high instantaneous power demand, but the incredibly short cooling cycles often mean less total energy consumed per batch.

Vacuum cooling can be significantly more energy-efficient per unit of produce cooled. Its rapid cooling cycles (15-30 minutes) mean the high-power components run for very short periods, focusing energy directly on product cooling through evaporative effects, rather than cooling large air volumes for hours.

This is a point I often discuss with clients like Carlos, who is very hands-on and technically minded. He was initially concerned about the electrical requirements for a vacuum cooler on his farm. But when we compared the total kilowatt-hours (kWh) needed to cool a ton of his lettuce with vacuum cooling versus his old forced-air system, the vacuum cooler used significantly less total energy for the same amount of cooling. The key is total energy consumed for the job, not just the peak power.

How Vacuum Cooling Uses Energy

The main energy consumers in a vacuum cooling system are:

- Vacuum Pump(s)6: These create the low-pressure environment. They are powerful but run only during the relatively short cooling cycle.

- Refrigeration System (Condenser)7: This system re-condenses the water vapor drawn from the vegetables, removing the heat. Its size and energy use depend on the amount of moisture to be removed (which relates to the amount of cooling).

Why It Can Be More Efficient

- Speed: The most significant factor. Cooling cycles of 15-30 minutes mean the system doesn’t run for long.

- Direct Cooling: Energy is primarily used to power the evaporation process, which directly removes heat from the product. There’s minimal energy wasted cooling the chamber walls or large volumes of air repeatedly.

- Targeted Action: The cooling is focused on the product itself. Once the cycle is done, the system stops.

- Energy per Unit Cooled (kWh/ton or kWh/kg): This is where vacuum cooling often wins. Because it cools a large batch very quickly, the total energy input divided by the weight of the produce cooled is often lower than traditional methods that run for many hours.

Consider this: a 100 kW vacuum pump running for 0.5 hours uses 50 kWh. A 10 kW forced-air cooling system running for 8 hours uses 80 kWh. If both cooled the same amount of produce, the vacuum cooler was more energy efficient in total kWh despite its higher power motor. This is a simplified example, but it illustrates the principle.

Let’s look at the energy dynamics:

| Feature | Vacuum Cooling | Traditional Air Cooling (Average) |

|---|---|---|

| Instantaneous Power Demand | High | Moderate to Low |

| Cycle Duration | Very Short (15-30 mins) | Long (4-72+ hours) |

| Energy Focus | Product cooling (evaporation) | Air & product cooling (convection) |

| Energy Loss to Environment | Minimal during short cycle | Significant (cooling space, air leaks) |

| Overall Energy/Kg Cooled | Often Lower | Often Higher |

| Primary Energy Consumers | Vacuum pump, refrigeration for condenser | Compressor, fans |

Of course, the exact energy efficiency depends on the specific design of the vacuum cooler, the type of vacuum pumps used (e.g., oil-sealed rotary vane vs. dry screw pumps), and the efficiency of the refrigeration system for the condenser. But for many leafy greens and suitable vegetables, the rapid cycle offers a clear path to lower overall energy use per unit.

What Factors Determine the True Energy Cost of Cooling Vegetables?

Simply looking at a motor’s horsepower or a system’s BTU rating doesn’t tell the whole story of energy costs. To truly compare, you need to dig deeper into how each system operates in your specific context.

The true energy cost is determined by the total kilowatt-hours (kWh) consumed to cool a specific quantity of vegetables from their initial field temperature to the desired storage temperature. This includes factors like cycle time, actual heat load, system efficiency, and even indirect savings from reduced spoilage.

When I work with clients, whether they are procurement managers like Sophia looking for HACCP compliance and efficiency, or farmers like Carlos needing raw speed, we always try to quantify these factors. It’s not just about the power rating on the machine; it’s about how intelligently that power is used. For instance, a well-designed vacuum cooler might have a higher initial power draw for its pumps, but if it cools three times the produce in one-tenth the time of a traditional cooler, its energy cost per pallet can be much lower.

Key Metrics for Real-World Energy Comparison

- Energy per Unit of Product (e.g., kWh/ton or kWh/pallet)8: This is the most crucial metric. Calculate total energy used for a cooling cycle and divide it by the amount of product cooled. This normalizes for different batch sizes and system capacities.

- Cycle Time vs. Continuous Operation: A vacuum cooler draws significant power but only for a short burst (e.g., 20-30 minutes). Traditional coolers draw less power at any given moment but run for many hours, often accumulating higher total energy use.

- Specific Heat Load: The actual amount of heat that needs to be removed. This depends on:

- Initial temperature of the produce.

- Target final temperature.

- Mass of the produce.

- Specific heat capacity of the vegetable (different veggies store different amounts of heat).

- System Efficiency9: This includes the efficiency of compressors, fans, pumps, motor efficiency, and how well insulated the system is (for traditional) or how efficient the vacuum and condensation process is (for vacuum cooling).

- Cooling the Product, Not Just the Air: Vacuum cooling excels here because the energy directly facilitates evaporation from the product. Traditional methods spend a lot of energy cooling the air around the product, which then slowly cools the product.

- Indirect Energy Savings from Reduced Spoilage10: This is often overlooked. If a faster, more effective cooling method like vacuum cooling reduces spoilage by, say, 5-10%, you’re saving all the energy that went into growing, harvesting, and initially handling that now-saved produce. This is a big win for sustainability and profitability.

Let’s summarize these critical factors:

| Evaluation Factor | Vacuum Cooling Consideration | Traditional Cooling Consideration | Importance |

|---|---|---|---|

| Energy per Unit Cooled | Typically lower due to speed & direct action | Can be higher due to long cycles & indirect cooling | Most critical direct comparison metric |

| Cycle Time | Very short (15-30 min) | Very long (hours to days) | Impacts total energy and throughput |

| Heat Load Removal | Efficiently removes specific heat via evaporation | Slower removal via convection, also cools surrounding mass | Determines fundamental energy requirement |

| System Losses | Primarily pump & condenser efficiency | Insulation, air leaks, fan efficiency, cooling entire volume | Reduces overall system efficiency |

| Ancillary Energy | Minimal beyond the cycle | Can include prolonged fan operation, defrost cycles | Adds to total consumption |

| Reduced Spoilage | Significant potential due to speed & uniformity | Higher risk of spoilage if cooling is slow or uneven | Indirect energy saving by preserving product value |

By focusing on kWh per ton (or per pallet) and considering the full operational cycle and benefits, you get a much clearer picture of true energy costs.

Conclusion

While vacuum coolers have a high initial power draw, their rapid cooling cycles often lead to lower total energy consumption per unit of vegetables cooled compared to slower, traditional methods. The key is efficient energy use over short periods.

-

Exploring this resource will provide insights into the efficiency and effectiveness of Room Cooling systems, helping you understand their impact on energy consumption. ↩

-

This link will help you discover how Forced-Air Cooling enhances energy efficiency, making it a crucial topic for anyone interested in refrigeration technology. ↩

-

Understanding the impact of long cooling times can help optimize energy efficiency in refrigeration systems. ↩

-

Exploring this topic can reveal strategies to improve insulation and reduce energy waste. ↩

-

Learning about the relationship between ambient temperature and energy use can guide better design and operation of coolers. ↩

-

Understanding the energy consumption of Vacuum Pump(s) can help optimize cooling efficiency and reduce costs. ↩

-

Exploring how a Refrigeration System (Condenser) operates can provide insights into energy efficiency and moisture management. ↩

-

Understanding this metric is vital for optimizing energy use in cooling processes, leading to cost savings and improved sustainability. ↩

-

Exploring ways to enhance system efficiency can lead to significant energy savings and better performance in cooling operations. ↩

-

This concept highlights the broader impact of efficient cooling methods on sustainability and profitability, making it worth investigating further. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not