Is Vacuum Cooling Too Big for Your Artisan Bakery?

You pour your heart into your sourdough. You nurture the starter, hand-shape the loaves, and bake them on stone hearths. But then, your precious bread sits on racks for hours, taking up space and slowly losing that "oven-fresh" magic. It feels like a waste, doesn’t it?

Vacuum cooling is no longer just for industrial giants. New compact, single-trolley systems are designed specifically for artisan bakers. They fit in small kitchens, preserve your signature crust, and allow you to pack and deliver fresh bread in under 15 minutes.

As a manufacturer at Allcold, I often hear small bakery owners say, "Mila, I am not a factory. I don’t need a machine that cools 1000 loaves." I understand this hesitation. But artisan baking is about quality, not just tradition. Today, I want to show you how scaling down our technology can actually scale up your quality.

Can Vacuum Cooling Preserve Your Signature Artisan Crust?

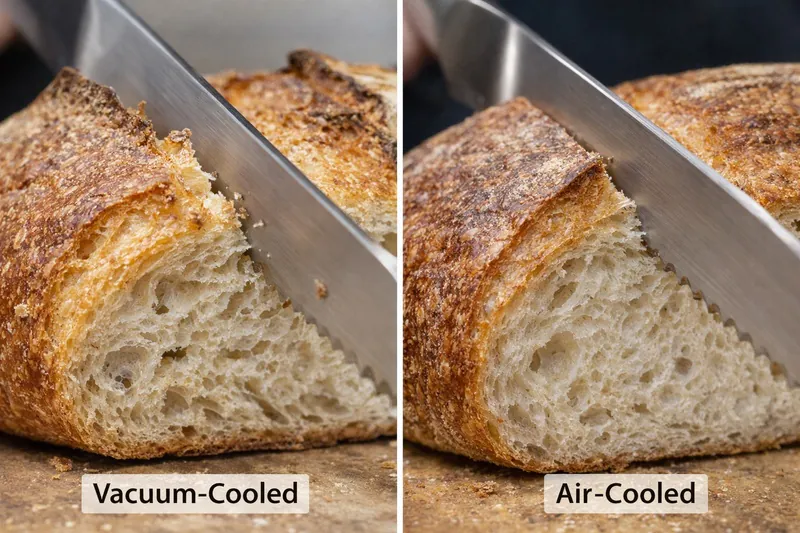

The soul of artisan bread is the crust. You worry that a machine might turn your crispy, singing baguette into something rubbery or soft. It is the number one fear I hear from master bakers.

Vacuum cooling actually improves crust structure. By controlling the pressure drop speed, we flash-off surface moisture while keeping the core moist. This creates a crust that is thinner, crispier, and shatters perfectly when bitten, staying crunchy far longer than air-cooled bread.

The Science of "The Song of the Bread"

For a baker who treats their product like art, the texture is non-negotiable. Let’s dig into the physics of why vacuum cooling1 is actually better for artisan crusts2 than leaving them on a rack. It comes down to managing moisture migration.

1. The Moisture Migration Problem3

In traditional cooling, heat escapes slowly from the core to the surface over a period of 90 to 120 minutes.

- The Process: Moisture travels from the hot, wet center to the cooler, drier crust. The crust acts like a barrier.

- The Result: As the bread sits, this migrating moisture softens the crust you worked so hard to bake. This is why a baguette feels amazing at 8:00 AM but gets chewy and tough by 2:00 PM. The crispness is literally dissolved by the bread’s own internal steam.

- The Vacuum Solution: We reverse this dynamic. The vacuum boils water at low temperatures throughout the entire loaf instantly. The moisture turns to steam and is extracted out of the chamber immediately, not re-absorbed by the crust.

2. Maillard Reaction and Flavor Retention4

Some bakers worry about flavor loss.

- Fact: The flavor compounds created by the Maillard reaction (the browning of the crust) are stable solids. Vacuum cooling removes water vapor and some volatile organic compounds (aromas), but the core flavor profile remains.

- The Aroma Trick: Because the cooling is so fast, we trap more of the fermentation gases inside the crumb structure before they can diffuse away over hours. When your customer cuts the bread, the aroma release is often more intense than with air-cooled bread.

3. Customizing the "Crunch"

At Allcold, we understand that a Sourdough needs a different treatment than a Brioche. We program our Siemens PLCs5 with specific profiles for artisan goods. We don’t use the same setting for a Rye loaf as we do for a Ciabatta.

| Bread Type | Artisan Challenge | Vacuum Strategy | Result |

|---|---|---|---|

| Sourdough | Needs a thick, blistered crust. | Aggressive final pull to dry the surface. | "Singing" crust, stays crisp for 12+ hours. |

| Ciabatta | High hydration (>80%), risks collapse. | Gentle, stepped pressure reduction. | Open crumb structure preserved, no collapse. |

| Baguette | Needs to be thin and shatter-crisp. | Fast cooling (3-4 mins). | Maximum crispness, zero "chewiness." |

4. The "Flash-Off" Effect

For artisan bread, we utilize a technique called "Flash-Off." This happens in the final 30 seconds of the cycle. We drop the pressure slightly below the equilibrium point. This forces the remaining surface moisture to evaporate instantly. It creates a micro-structure on the crust surface that resists humidity from the air. This is crucial for climates like Mexico (for customers like Carlos) or Singapore (Sophia), where humidity usually destroys crispy bread in minutes.

Now that we know the quality is safe, let’s talk about where to put the machine.

How Do You Fit Industrial Power into a Small Kitchen?

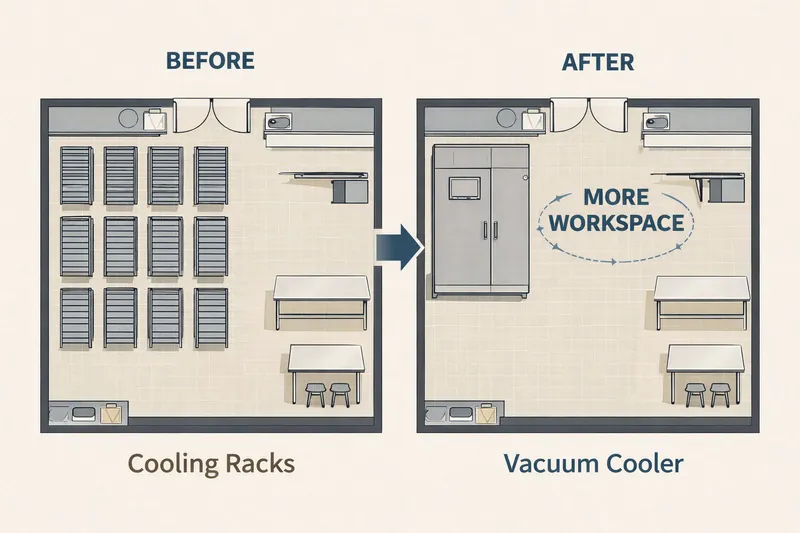

Rent in cities is expensive. You are fighting for every square meter of floor space. You cannot afford to lose half your kitchen to cooling racks that just sit there doing nothing.

A compact vacuum cooler occupies less than 4 square meters but replaces up to 20 cooling racks. It creates a continuous workflow: rack in, cool in 10 minutes, rack out to packaging. You reclaim your bakery floor for what matters—production and retail.

The "Allcold Mini" Logistics

For a business owner like Norman, "Space is Money." Let’s analyze the operational footprint of an artisan bakery and how a small-scale vacuum cooler changes the game. It is about flow, not just size.

1. The "Rack Jungle" Nightmare

In a typical artisan bakery producing 1,000 loaves a day:

- You need roughly 10-15 racks to hold that bread while it cools for 2 hours.

- The Space Cost: Each rack takes up space. Plus, you need walking paths between them to ensure airflow. A cooling area6 can easily eat up 30-40 square meters of prime real estate.

- The Operational Drag: Your bakers are constantly navigating this maze. Racks get bumped. Hot bread gets knocked over. It is chaotic and unsafe.

2. The Compact Solution: 1 or 2 Trolley Systems

Our small-scale models (like the Allcold PRO-17) are designed for this exact problem.

- Footprint: The machine is roughly 2.2 meters wide by 2.5 meters deep. It is built vertically to save floor space.

- Integration: The vacuum pump is often integrated on top of the chamber or tucked immediately behind it.

- The "One Rack" Flow: You don’t need 15 racks anymore. You only need enough racks to buffer the oven output.

- Oven -> Rack -> Vacuum Cooler (10 mins) -> Packaging/Storefront.

- The rack is empty and ready to be reused in 15 minutes. You might only need 4 racks total for the same production volume.

3. Installation Requirements for Small Spaces

Carlos often asks me about the difficulty of installing these machines in older buildings.

- Power: Our compact units8 run on standard 3-phase power. We use Variable Frequency Drives (VFDs)9 on our pumps. This means the motor ramps up slowly, so there is no massive "power spike" when the machine starts. This is gentle on your building’s electrical grid and usually requires no expensive upgrades.

- Water: We offer air-cooled condenser10 options. This means you don’t need a complex water tower or chiller system on your roof. It works just like a large air conditioning unit—simple and effective.

- Mobility: The smaller units are built on a rigid skid. If you move your bakery to a new location, you simply disconnect the power, load it on a truck, and move it. It is an asset that travels with you.

4. The "Open Kitchen" Aesthetic

Many modern artisan bakeries have open kitchens11 where customers can see the bakers.

- The Visual: A sleek, stainless steel vacuum cooler looks professional and high-tech. It signals to your customers that you invest in quality.

- The Theatre: Customers see steam venting (safely piped out) and fresh bread coming out ready to eat. It reinforces the message of "Freshness."

- Noise Control: We use low-noise pumps and sound insulation. The machine is often quieter than a large planetary mixer, so it won’t disturb your customers enjoying their coffee in the front of house.

If you have the space sorted, the next hurdle is your sleep schedule.

Can You Bake Today and Deliver "Fresh" Tomorrow?

The life of a baker is hard. Waking up at 2:00 AM to ensure fresh bread for the morning rush is exhausting. What if you could shift your production schedule without selling stale bread?

Vacuum cooling stabilizes bread instantly, stopping the aging process. This allows you to "Par-bake" or fully bake the day before. The bread retains its moisture and texture so perfectly that even after 24 hours, it tastes like it just came out of the oven.

The "Bake-Off" and Logistics Revolution

This section is vital for Sophia in Singapore, who manages tight delivery deadlines, and for anyone looking to wholesale their artisan bread to cafes or supermarkets. It is about unlinking "baking time" from "selling time."

1. The Science of Water Activity (aw) and Mold

Why does bread go moldy? It is usually because of free water and warm temperatures.

- Traditional Cooling: The bread sits in a warm, humid room for hours. Condensation often forms inside the bag if packed too early. This moisture is a swimming pool for mold spores.

- Vacuum Sterility: Vacuum cooling boils off moisture evenly from the core to the crust. It reduces the Water Activity (aw) to a safe level very quickly.

- The Clean Room Effect: As the air is sucked out of the chamber, so are airborne mold spores and bacteria. You are essentially packaging your bread in a much cleaner state. This can double your shelf life naturally, without adding any "anti-mold" chemicals that would ruin your "Artisan" label.

2. The "Par-Bake" Strategy

This is how small bakeries scale up to supply big chains or hotels.

- Step 1: Bake the bread to 80% or 90% completion. You get the volume, but the crust is pale.

- Step 2: Vacuum cool it immediately. This sets the structure so it doesn’t collapse, but keeps the inside very moist.

- Step 3: Pack and ship to the cafe/hotel. Because the moisture is locked in, it doesn’t dry out.

- Step 4: The cafe flashes it in their oven for 5 minutes.

- Result: The customer gets hot, fresh bread with a perfect crust. The texture is perfect because the vacuum cooling prevented the "double-baking" dryness effect that usually ruins par-baked goods.

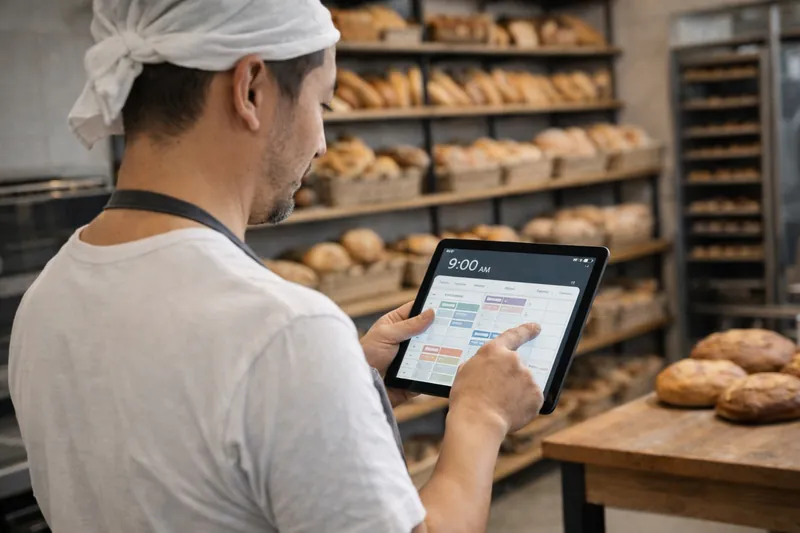

3. Shifting the Labor Clock

The biggest pain point for bakers is the "Graveyard Shift."

- Old Way: Bakers start at 10 PM. Bread cools from 4 AM to 6 AM. Deliveries start at 7 AM. Finding talented staff who want to work these hours is impossible.

- The Vacuum Way:

- Bakers start at 6 AM (Normal hours!).

- Bake all day.

- Vacuum cool and package immediately.

- Bread is stored for delivery the next morning.

- Quality Check: Because the bread passed the "Staling Danger Zone" (60°C to 20°C) in 3 minutes instead of 2 hours, the retrogradation of starch is halted. Bread baked at 4 PM today tastes fresher tomorrow morning than bread baked at 2 AM and air-cooled.

4. Reducing "Stales" and Waste

Every loaf you throw away is money burned.

- With vacuum cooling, you have better control. If you have a sudden rush order, you can bake and cool in 30 minutes total. You don’t need to guess and over-produce.

- Sliced Bread: For artisan sandwich loaves, you can slice them immediately after the 10-minute cooling cycle. No more waiting for the loaf to firm up while the crust gets soft. You get clean, perfect slices and can bag them instantly.

But does a small bakery really have the budget for this technology?

Is the Investment Worth It for a Boutique Bakery?

You look at the price tag of a machine and think, "I could buy a new oven for this." But an oven doesn’t save you labor, space, or waste. A vacuum cooler is an efficiency engine.

For a small bakery, the ROI comes from three places: 30% reduction in labor hours, 50% reduction in space rental needs, and a 20% increase in shelf-life that opens new wholesale markets. The machine typically pays for itself in 12 to 18 months.

The Economic Breakdown

Let’s do the math. I want to be transparent with you, just like I would be with Norman. We are looking at the Total Cost of Ownership (TCO) versus the Value Created.

1. Labor Costs: The Biggest Saver

In artisan baking, skilled labor is your highest cost.

- Scenario: You have 3 bakers earning $25/hour.

- Waiting Time: In a traditional process, there is a lot of "dead time" managing racks, moving product, and waiting for cooling before slicing/packing.

- The Saving: If vacuum cooling saves just 2 hours of combined labor per day (by streamlining the flow and allowing faster packing), that is $50/day.

- Annual Saving: $50 x 300 days = $15,000 per year purely in labor efficiency.

2. Energy: Cooling the Product vs. The Room

- The Myth: "Vacuum pumps use too much electricity."

- The Reality: The pump runs for 10 minutes per batch. An air conditioning unit for a cooling room runs 24/7.

- Calculation:

- Vacuum Cooling 100kg bread: ~1.2 kWh.

- Air Conditioning Room for 100kg bread (2 hours holding): ~3.5 kWh.

- You save roughly 60% on energy bills related to cooling.

3. Waste Reduction: The Hidden Profit

- Slicing Waste: Slicing warm bread ruins the shape and creates crumbs. Vacuum cooled bread is firm and slices perfectly. If you save 10 loaves a day from being damaged/unsellable:

- 10 loaves x $4.00 sales price = $40/day.

- Annual Saving: $12,000 per year.

4. Expanding Revenue (New Markets)

This is the most exciting part for entrepreneurs like Carlos.

- Without vacuum cooling, your delivery radius is limited to 1 hour. Any further, and the bread is stale by the time it reaches the shelf.

- With vacuum cooling, your bread stays "Day 1 Fresh" for 3 days (if packed well).

- Result: You can now sell to supermarkets or cafes in the neighboring city. You can double your potential customer base without building a second bakery.

5. Financing and Lifespan

- A quality vacuum cooler (like Allcold’s) is built with stainless steel and top-tier pumps (Busch/Leybold). It is designed to last 15-20 years.

- When you spread the cost over 15 years, the daily cost is negligible compared to the daily savings in labor and waste.

| Expense Category | Traditional Bakery | Vacuum Equipped Bakery |

|---|---|---|

| Cooling Space | 40 m² ($$$ Rent) | 5 m² ($ Rent) |

| Cooling Time | 120 Minutes | 10 Minutes |

| Shelf Life (Artisan) | 1 Day | 3 Days |

| Energy Use | High (AC constant) | Low (Per batch) |

| Labor Efficiency | Low (Waiting/Moving) | High (Continuous Flow) |

Conclusion

Small-scale vacuum cooling is not about changing your art; it is about protecting it. By integrating a compact solution like the Allcold Mini or PRO series, you can preserve that perfect crust, reclaim your kitchen space, and optimize your work-life balance.

You bake with passion. Let us help you cool with intelligence.

-

Explore how vacuum cooling enhances bread quality and texture for bakers. ↩

-

Find out expert techniques for achieving the perfect artisan crust in bread. ↩

-

Understanding moisture migration is key to improving bread texture and preventing crust softening. ↩

-

Explore the Maillard reaction to learn how it enhances flavor and aroma in baked goods. ↩

-

Discover how Siemens PLCs optimize baking processes for different bread types. ↩

-

Get insights on maximizing your bakery’s cooling area to improve workflow and productivity. ↩

-

Explore how the Allcold PRO-1 can revolutionize your bakery’s cooling process and save space. ↩

-

Explore the benefits of compact units for space-saving and operational efficiency in bakeries. ↩

-

Learn about VFDs and how they enhance energy efficiency and reduce operational costs in machinery. ↩

-

Discover the benefits of air-cooled condensers for simplifying installation and reducing maintenance. ↩

-

Find out how open kitchens can enhance customer experience and showcase your baking process. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy