Is Your Cooling Process Costing You More Than You Think?

At your scale, you move hundreds of pallets a day. A small, nagging inefficiency isn’t small anymore—it’s a massive, hidden drain on your profits, multiplying with every box you ship.

Yes, your conventional cooling process is likely a major hidden cost. The true expense isn’t just the energy bill; it’s in lost throughput, excessive labor, wasted space, and the constant risk of rejection from your most important buyers.

For a large commercial farm, success is measured in cents per pound and pallets per hour. An investment in equipment isn’t about adding a capability; it’s about re-engineering a core process for maximum profitability. Let’s analyze how vacuum cooling transforms the economics of a large-scale operation.

How Can You Double Your Shipping Capacity Without Doubling Your Space?

During peak harvest, the race is relentless. Your biggest bottleneck isn’t in the field; it’s at the cold room door where pallets stack up, waiting for hours to cool down. This is capping your daily revenue.

You increase capacity by changing the unit of measurement. Stop thinking in terms of a 12-hour cooling day and start thinking in terms of 25-minute cooling cycles. This boosts throughput exponentially.

Traditional forced-air or room cooling is fundamentally a batch process limited by time and space. Even with multiple large rooms, you can only cool so much produce in a 24-hour period. A vacuum cooler operates on a continuous flow model. Imagine a single machine processing two pallets every 30 minutes. That’s 32 pallets in one 8-hour shift from one machine. To match this with a traditional cold room would require a massive, expensive footprint and a complex pallet-shuffling operation. For a large farm that needs to match cooling speed with harvest speed, this isn’t just an improvement; it’s a paradigm shift. It allows you to confidently schedule more trucks, fulfill larger last-minute orders, and maximize your output during the most profitable days of the season.

The Math of Throughput

The economic advantage comes from removing the primary constraint on your growth. You are no longer limited by how much you can cool, but only by how much you can harvest and sell. This is how market leaders scale their operations.

| Metric | Conventional Cold Rooms | Single Vacuum Cooler System1 |

|---|---|---|

| Time per Pallet | 12 to 24 hours | ~25-30 minutes |

| Effective Daily Capacity2 | Capped by room size & cycle time. | High; easily processes 30-60+ pallets. |

| Workflow | Disjointed batch processing; bottleneck. | Continuous flow3; matches harvest speed. |

| Operational Result | Growth is physically constrained. | Growth is enabled and scalable. |

Where Are the Hidden Operational Costs in Your Current System?

You meticulously track your energy and labor bills, but those numbers don’t tell the whole story. The real financial drain is in the inefficiencies that your accounting software can’t see.

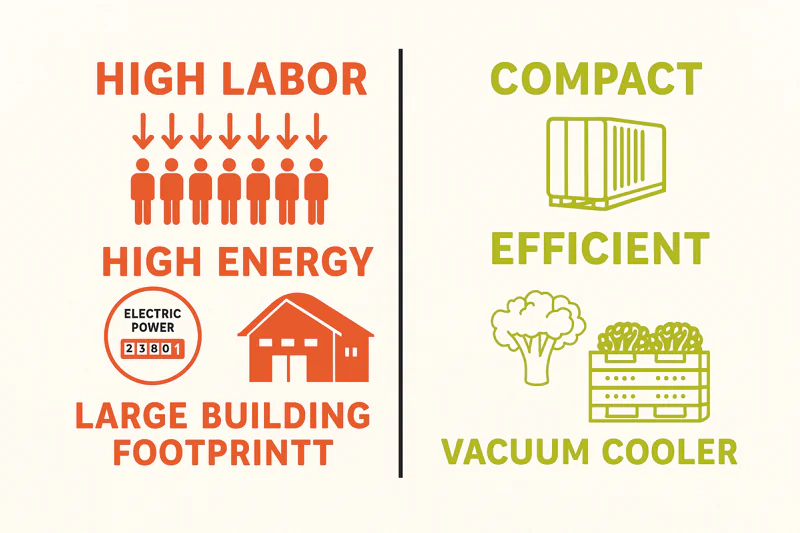

The biggest hidden costs are in wasted labor from re-handling pallets, peak energy demand to maintain massive cold spaces 24/7, and the enormous capital expenditure required for the building footprint itself.

Let’s do a quick audit of a single pallet’s journey. With a cold room, a worker moves it from the packing line to a staging area. Then another moves it into the room. Later, it might be moved again within the room. Finally, it’s moved out for shipping. That’s multiple labor touchpoints. Now, consider a vacuum cooler: load, press button, unload. Two touchpoints. At your scale, that saved labor per pallet adds up to thousands of hours per year. Now think about energy. A vacuum cooler has a high-power draw, but only for about 20-25 minutes. A massive cold room facility draws significant power continuously, 24/7. The total energy cost (kWh) to cool a pallet is often substantially lower with vacuum cooling. Finally, the physical space itself is a massive capital cost. You can achieve more throughput with a compact vacuum cooler than you can with a refrigeration warehouse five times its size.

Optimizing Cost-Per-Pallet

For a large operation, victory is won by lowering the cost-per-unit4. A vacuum cooler attacks and reduces the three primary cost drivers in post-harvest handling.

| Cost Driver | Conventional Cold Rooms | Vacuum Cooler System5 |

|---|---|---|

| Labor Cost6 | High (multiple moves per pallet). | Low (load-and-go process). |

| Energy Cost | High (constant 24/7 operation). | Efficient (short, powerful cycles). |

| Capital (Space) | Very High (large building required). | Low (compact, efficient footprint). |

Why Is ‘Good Enough’ Quality a Direct Threat to Your Brand?

You don’t just sell produce; you sell a promise of consistency to major retail and export partners. Their standards are absolute, and your brand’s reputation is your most valuable asset.

"Good enough" quality leads to variable shelf life, which professional buyers like Norman will not tolerate. One inconsistent load damages your brand’s reputation and can jeopardize multi-million dollar contracts.

When a major supermarket chain buys from you, they are buying predictability. They need every box of your broccoli to look and last exactly the same. Traditional cooling methods are notoriously inconsistent. Pallets on the outside cool faster than those in the middle of the room. Heat from respiration can keep the core of a pallet several degrees warmer, drastically reducing its shelf life. A vacuum cooler solves this physics problem. By lowering the boiling point of water, it pulls heat out from the very core of every single product, on every part of the pallet, at the same time. The result is perfectly uniform cooling. This level of consistency is the foundation of a premium brand. It’s how you become the preferred, trusted supplier who can command higher prices and secure the most lucrative, long-term contracts.

The Technology of Trust

Your brand is built on the trust you earn with every shipment. This technology provides the documented proof of quality that top-tier clients demand for their HACCP and food safety programs.

| Quality Factor | Conventional Cooling | Vacuum Cooling |

|---|---|---|

| Temperature | Inconsistent, core remains warm. | Perfectly uniform throughout the pallet. |

| Shelf Life | Variable, unpredictable. | Consistent, maximized, and predictable. |

| Client Perception | A commodity supplier with some risk. | A professional, premium, trusted partner. |

How Do You Insure Your Harvest Against Catastrophic Loss?

At your scale, risk isn’t just about a few bad boxes. A single rejected shipment is a five-figure disaster that impacts inventory, logistics, and client relationships.

Your best insurance policy is a bulletproof process. Vacuum cooling virtually eliminates temperature-related rejections, protecting you from the catastrophic financial and reputational losses that can derail a profitable quarter.

Imagine a truckload of high-value produce, worth $30,000, being rejected at a distribution center because its core temperature is two degrees too high. You instantly lose the entire value of the product. But the real loss is larger: you’ve also lost the labor to harvest it, the cost of the packaging, and the freight charges to ship it. Plus, you now have a major problem with a key customer. These events are the biggest financial risks in the produce business. A vacuum cooler is the most effective operational control you can implement to prevent this. Its speed and efficiency mean that product goes from field to optimally-cooled in under an hour. This rapid removal of field heat stops degradation and bacterial growth in its tracks, ensuring you meet even the strictest international import and food safety standards. The investment in the machine can often be justified by preventing just one or two of these catastrophic rejection events.

From Risk Management to Business Continuity7

This isn’t just about preventing a loss; it’s about ensuring your business can operate smoothly and fulfill its commitments without interruption, protecting your cash flow and market position.

| Risk Category | Without Vacuum Cooling8 | With Vacuum Cooling |

|---|---|---|

| Shipment Rejection | High risk, especially with top clients. | Virtually eliminated. |

| Food Safety | Slower cooling allows bacterial growth. | Rapid cooling inhibits bacterial growth. |

| Financial Impact9 | Catastrophic potential from one failure. | Predictable outcomes, secure cash flow. |

Conclusion

For a large commercial farm, a vacuum cooler is not an expense. It is a strategic investment in operational excellence that drives profitability through superior throughput, lower costs, brand dominance, and powerful risk mitigation.

-

Explore how a Single Vacuum Cooler System can revolutionize your food processing efficiency and scalability. ↩

-

Understanding Effective Daily Capacity can help optimize your cold storage operations for better productivity. ↩

-

Learn why continuous flow is crucial for maximizing efficiency and reducing bottlenecks in production. ↩

-

Understanding strategies to lower cost-per-unit can significantly enhance operational efficiency and profitability. ↩

-

Exploring the benefits of a Vacuum Cooler System can reveal innovative solutions for reducing costs and improving efficiency in handling. ↩

-

Learning about best practices to reduce Labor Cost can lead to substantial savings and improved operational workflows. ↩

-

Understanding Business Continuity is crucial for maintaining operations and protecting your market position. Explore this resource to learn more. ↩

-

Discover how Vacuum Cooling technology enhances food safety and minimizes risks, ensuring smoother operations and better financial outcomes. ↩

-

Learn about the financial implications of effective risk management strategies to secure your business’s cash flow and stability. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But