Is Your Cooling Process Holding Back Your Ready-Meal Business?

Your kitchen produces delicious, complex ready-meals, but the slow cooling process introduces food safety risks and production delays. This critical bottleneck stops you from meeting deadlines and growing your business.

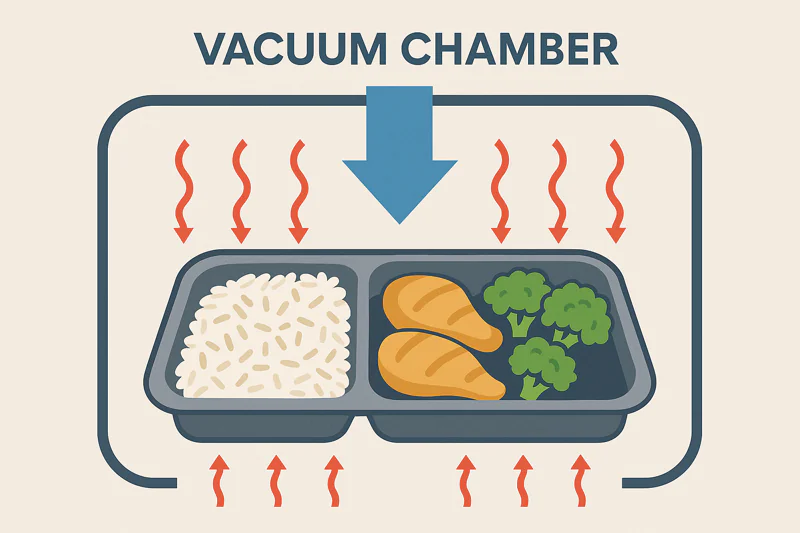

Vacuum cooling solves this by chilling hot ready-meal components like rice, pasta, and sauces from 95°C to below 10°C in minutes. This ensures HACCP compliance, dramatically boosts throughput, and perfectly preserves the individual quality of each ingredient for a superior final product.

As a factory solutions expert, I find ready-meal production fascinating. It combines the art of cooking with the science of high-speed manufacturing. However, the most common point of failure I see is the cooling stage. It’s where quality is lost and safety is compromised. We design our systems to fix this specific problem, turning your biggest liability into your greatest operational advantage.

How Can You Guarantee Food Safety in Multi-Component Meals?

You have a tray with dense pasta, a rich sauce, and delicate vegetables. Each one cools at a different rate, making it nearly impossible to ensure the entire meal passes through the temperature danger zone safely and quickly.

Vacuum cooling guarantees food safety by rapidly and uniformly cooling all components at once. It pulls the entire meal through the bacterial danger zone (60°C to 5°C) in under 30 minutes, acting as a powerful and validated Critical Control Point.

Acing Your HACCP Audit

For a central kitchen manager like Sophia, who lives by deadlines and HACCP regulations, inconsistent cooling is a nightmare. In a ready-meal tray, the dense core of a meatball or a scoop of lasagna might stay in the temperature danger zone for hours in a traditional blast chiller, even if the surface vegetables are cold. This creates a hidden risk that is difficult to monitor and control. It’s a failure waiting to happen during a microbiological test. The complexity of the product becomes your biggest enemy.

Vacuum cooling1 completely changes this dynamic. The process doesn’t rely on cold air penetrating from the outside. Instead, it uses a deep vacuum to trigger rapid evaporation from every water-containing component at the same time. This means the hot center of the pasta cools just as quickly as the sauce around it. You get unprecedented temperature uniformity across the entire batch. This speed and consistency transform cooling from a source of anxiety into your most reliable Critical Control Point (CCP). We can provide you with data logs from the Siemens PLC for every cycle, giving you a verifiable record that proves every batch was cooled safely, satisfying the most stringent auditors and customers.

| Cooling Method | Cooling Uniformity | Time in Danger Zone | HACCP Compliance2 |

|---|---|---|---|

| Blast Chilling | Poor (Hot core, cold surface) | 2 – 6 hours | Difficult to validate |

| Room Cooling | Very Poor | 6+ hours | Non-compliant |

| ALLCOLD Vacuum Cooling | Excellent (Uniform core-to-surface) | < 30 minutes | Easy to validate as a CCP |

Can You Cool Sauces, Rice, and Vegetables Without Ruining Their Texture?

You’re worried that this powerful process will damage your carefully prepared ingredients. Will it make the rice dry, the vegetables limp, or cause the sauce to separate? This is a major concern for product quality.

Yes, vacuum cooling actually enhances the texture and quality of ready-meal components. It instantly halts the cooking process in vegetables, keeps grains like rice and pasta perfectly firm, and stabilizes sauces for a premium final product.

Preserving the Perfect Bite

A professional buyer like Norman judges a product on its overall quality, and for ready-meals, that means every component must be perfect. Slow cooling is the enemy of texture.

Protecting Grains and Pasta

When rice, pasta, or other starches cool slowly, they continue to absorb moisture and steam in their own heat. The starch gelatinizes and then breaks down, resulting in a soft, mushy, and clumpy texture. Vacuum cooling3 avoids this entirely. The rapid evaporative process "locks in" the texture of the cooked grain at its peak. It stops the gelatinization process instantly, keeping individual grains separate, firm, and with a perfect al dente bite.

Keeping Vegetables Crisp and Colorful

A pile of hot, steamed broccoli or carrots in a blast chiller continues to cook due to its own residual heat. This overcooking destroys the vibrant color, breaks down the cell walls (making them soft and mushy), and reduces nutrient content. Vacuum cooling acts like an instant "off switch" for the cooking process. As it rapidly removes heat, it stops all enzyme activity and locks in the color, crispness, and nutritional value. Your vegetables look and taste like they were just prepared. This is a clear quality advantage your customers will notice.

| Ingredient | Effect of Slow Cooling | Effect of Vacuum Cooling |

|---|---|---|

| Rice / Pasta | Becomes mushy, clumpy | Stays firm, separate, al dente |

| Vegetables | Overcooks, becomes soft, loses color | Stays crisp, vibrant, and nutritious |

| Sauces / Curries | Can separate, form a skin | Remains smooth, homogenous, stable |

What’s the Key to Eliminating Production Bottlenecks?

Your kitchen has high-capacity cookers and packaging lines, but everything grinds to a halt while you wait for products to cool. This buffer time kills your efficiency and limits your daily output.

The key is to match your cooling speed to your cooking speed. A vacuum cooler processes a full batch in about 20 minutes, turning cooling from a multi-hour stop into a fast, continuous step in your production line.

Designing a Continuous Flow4 Kitchen

A hands-on owner like Carlos thinks in terms of throughput and an efficient workflow. The traditional "cook, then wait" model is fundamentally broken for high-volume production. Imagine your cooking line produces 1,000 kg of cooked rice or sauce per hour. A blast chiller would require a massive, energy-hungry room and hours of time to handle that volume. You’re constantly running out of space and time.

A vacuum cooler is designed to be a "flow-through" machine. You cook a batch. You roll the trolley of hot trays directly from the cooker into the vacuum chamber. You press start. Twenty minutes later, that batch is cooled and ready for the assembly line. While that batch is cooling, you are already cooking the next one. The cooling process is no longer the slowest step; it’s a fast, reliable, and predictable part of the line. One of our vacuum coolers can often handle the output of several large steam kettles. This allows you to centralize your cooling operation, reclaim huge amounts of floor space, and drastically increase the number of batches you can produce in a single shift. It enables a true "just-in-time" production philosophy for your kitchen.

| Metric | Blast Chilling Room | ALLCOLD Vacuum Cooler5 |

|---|---|---|

| Cycle Time | 2 – 6 hours | 20 – 30 minutes |

| Production Flow | Batch-and-Wait (Bottleneck) | Continuous Flow |

| Floor Space | Huge Footprint | Compact, single machine |

| Labor | High (moving racks, managing space) | Low (Roll in, press start, roll out) |

How Does a Vacuum Cooler Fit into an Assembly Line?

You have an established ready-meal assembly line. You’re worried about how a new, large piece of equipment would physically fit and integrate with your existing process of portioning, sealing, and labeling.

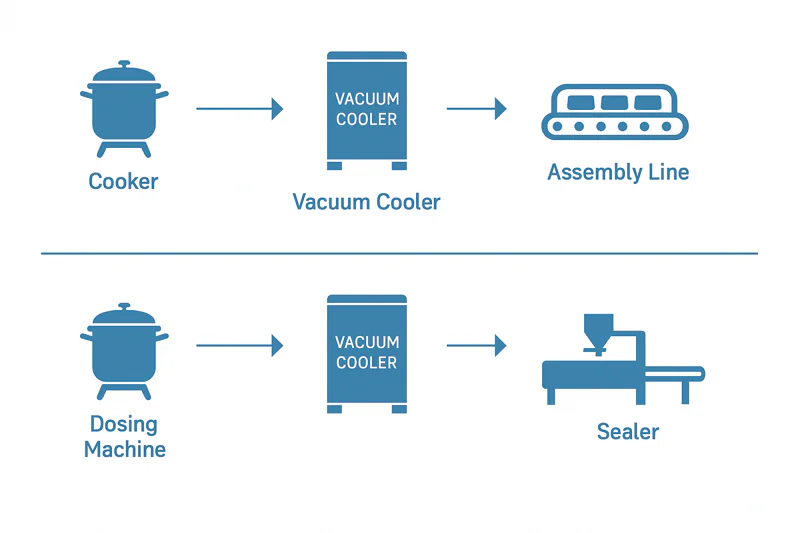

We design our vacuum coolers to integrate seamlessly. Hot components are cooled first in bulk trays, then dispensed onto your assembly line. Or, for some products, cooling can happen after portioning, just before sealing.

pre-cooling the bulk components6.

pre-cooling the bulk components6.

Here’s the process: You cook 500 kg of curry sauce in a kettle. You transfer it to shallow stainless steel trays and load them onto a trolley. This trolley is rolled into the vacuum cooler. Thirty minutes later, the curry is at a safe 8°C. This trolley is then taken to the start of your assembly line, where the cooled sauce is dosed into meal trays along with other pre-cooled components like rice and vegetables. This method is fast, safe, and allows for maximum efficiency at the assembly stage.

For some specific workflows, we can even provide systems with double doors, creating a true clean-room pass-through7. You load the hot product from the "raw" cooking side, and after the cycle, unload the cold, safe product on the "high-care" packaging side. We build our machines to order, so we can customize the chamber size to match your batch volume from one to six trolleys. With high-quality, reliable components like Leybold pumps and Siemens controls, the system becomes a dependable workhorse in your line, not a complication.

Conclusion

For ready-meal producers, vacuum cooling is the key to unlocking higher throughput, superior food safety, and better product quality. It professionalizes your cooling process, directly boosting your capacity and profitability.

-

Explore how Vacuum cooling enhances food safety and compliance, ensuring consistent quality and reducing risks. ↩

-

Learn effective strategies for achieving HACCP Compliance, crucial for maintaining food safety standards. ↩

-

Explore this link to understand how vacuum cooling enhances food quality and texture, ensuring freshness and taste. ↩

-

Explore how a Continuous Flow kitchen can enhance efficiency and productivity in high-volume cooking environments. ↩

-

Learn about the advantages of using a Vacuum Cooler for rapid cooling and space-saving in commercial kitchens. ↩

-

Explore this link to understand how pre-cooling enhances food safety and efficiency in production. ↩

-

Learn about clean-room pass-through systems and how they ensure hygiene and safety in food manufacturing. ↩

Mila

You May Also Like

How Can Vacuum Cooling Revolutionize Meat and Poultry Processing?

You’ve cooked a thousand kilograms of chicken perfectly, but now it sits for hours, slowly passing through the temperature danger

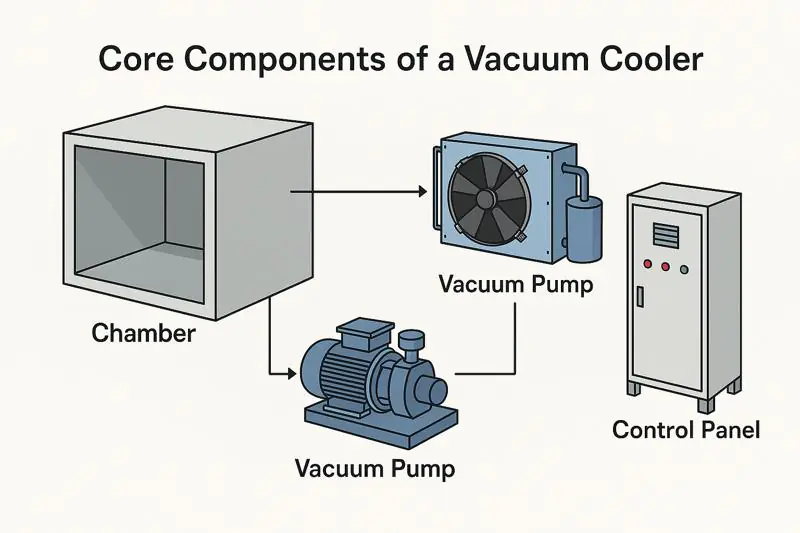

What's Really Inside Your Vacuum Cooler that Makes it Work?

Ever wondered what makes a vacuum cooler tick, transforming warm produce into perfectly chilled goods in minutes? It’s not magic,

What Are the Preservation Techniques for Ready-to-Eat Foods?

As consumers increasingly prefer ready-to-eat (RTE) foods, extending their shelf life effectively becomes a critical challenge. Currently, the most effective