Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and energy rising. But have you ever calculated how much money is evaporating while your bread sits on a cooling rack?

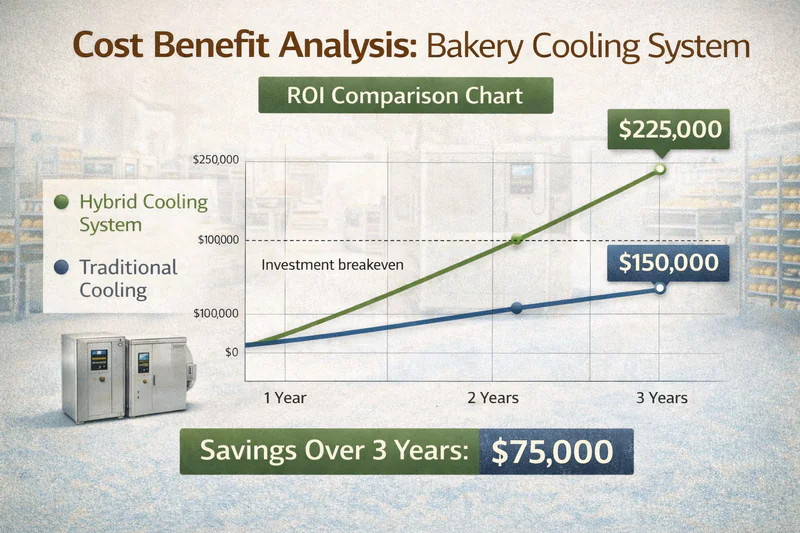

While conventional cooling systems have a lower initial sticker price, their long-term operational costs are significantly higher due to energy inefficiency and extended labor hours. Vacuum cooling, despite a higher upfront investment, offers a faster Return on Investment (ROI) by cutting energy bills, reducing waste, and freeing up valuable floor space.

It is easy to get stuck on the "purchase price" of a machine. However, smart business owners like Norman in the USA or Sophia in Singapore look at the "Total Cost of Ownership." Let’s break down the real numbers behind vacuum cooling versus traditional methods to see where the smart money really goes.

Does the Speed of Vacuum Cooling Justify the Price Tag?

Imagine if you could bake, cool, slice, and ship your order in the time it usually takes just to bake it. How would that change your cash flow?

Traditional ambient or air-blown cooling takes 90 to 120 minutes to bring bread from 100°C to slicing temperature. Vacuum cooling does this in just 3 to 10 minutes. This massive speed difference allows for "just-in-time" production, reducing inventory costs and labor waiting time.

The Financial Value of Time

When we talk about speed, we are actually talking about labor efficiency and production capacity. In my factory, Allcold, we often analyze the workflow of our clients before recommending a machine like the AVCF-150.

The Conventional Cost Trap:

In a standard bakery, racks of hot bread sit on the floor for up to two hours.

- Labor: Your packing staff might be standing idle, waiting for product. Or, you have to pay for an extra shift just to handle the cooling backlog.

- Bottlenecks: You cannot bake more bread because you have run out of rack space or floor space to cool it. Your ovens sit empty; your potential profit is stalled.

The Vacuum Profit Booster1:

With a vacuum cooler, the cycle time is roughly 10 minutes to cool bread from 100°C down to 28°C or 30°C.

- Continuous Flow: As soon as the trolley comes out of the oven, it goes into the vacuum chamber. Ten minutes later, it goes to the slicer.

- Labor Optimization2: Your bakers and packers work in a synchronized flow. There is no downtime.

- Capacity Increase: Because you are clearing racks instantly, you can run more oven cycles per day without buying more racks or expanding your floor.

For a client producing 150kg of bread per cycle, saving 110 minutes per batch translates to thousands of additional loaves produced per week with the same staff. That is where the machine pays for itself.

| Metric | Conventional Cooling | Vacuum Cooling (AVCF-150) |

|---|---|---|

| Cooling Time | 90 – 120 Minutes | ~ 10 Minutes |

| Labor Flow | Stop-and-wait | Continuous |

| Inventory | High work-in-progress | Low work-in-progress |

| Shipment Speed | 3+ hours after baking | 30 mins after baking |

Is Vacuum Cooling Really More Energy Efficient?

"Mila, vacuum pumps look powerful. Won’t my electricity bill explode?" This is the most common question I get. It is a logical fear, but the physics tells a different story.

Conventional cooling requires fans and air conditioning to run continuously for hours to fight ambient heat. Vacuum coolers only consume peak power for the short 10-minute cycle and feature automatic "power save" modes that shut down motors when not in use, resulting in lower total energy consumption per kg of bread.

Analyzing the Utility Bill

Let’s look at the engineering data from our machines to understand the costs.

The "Always-On" Cost of Traditional Methods:

If you use a spiral cooler or an air-conditioned cooling room, those compressors and fans are marathon runners. They run constantly. If your bakery is 35°C (which is common in places like Vietnam or Mexico), your cooling system is fighting a losing battle against the environment. It burns energy just to maintain a temperature.

The "On-Demand" Efficiency of Vacuum Cooling3:

Vacuum cooling is a sprinter.

- Short Duration: The machine, such as our AVCF-150 model, has a total power rating of roughly 20.6kW. However, it only runs this load for the 10 to 15 minutes of the cooling cycle.

- Intelligent Control: We equip our machines with a "Start sequence/power save" facility. If the vacuum cooler is not operated for a period, it automatically shuts down. It doesn’t sit there idling and wasting money.

- High-Efficiency Components: We use high-efficiency evaporators and air-cooled condensers specifically designed to minimize the kilowatt rating of the refrigeration compressors (like the Emerson or Bitzer units we install).

The Calculation:

You are paying for "Kilowatt-Hours4" (kWh).

- Traditional: 15kW motor x 2 hours = 30 kWh per batch.

- Vacuum: 20.6kW motor x 0.16 hours (10 mins) = ~3.3 kWh per batch.

Even if the vacuum cooler uses more "power" instantly, it uses far less "energy" over time. The savings on your monthly utility bill can be substantial, often covering the lease cost of the machine.

How Does "Plug and Play" Design Reduce Installation Costs?

Construction costs are a nightmare. Building a new cooling tunnel or an insulated room requires permits, contractors, and shutting down your factory. Who can afford that disruption?

Modern vacuum coolers are skid-mounted, "plug and play" units. They require no specialized foundation or complex drainage. With compact footprints (some indoor units are only 1.6m x 1.45m), they fit into existing layouts easily, saving you tens of thousands of dollars in facility renovation costs.

The Hidden Costs of Infrastructure

When you buy equipment, you must calculate the "landing cost5"—the cost to get it running.

The Infrastructure Burden of Traditional Systems:

- Space: Spiral coolers are massive. They often require structural changes to the building or even a building extension. In cities like Singapore or Hong Kong, where rent is astronomical, wasting 50 square meters on a conveyor belt is financial suicide.

- Construction: You need insulated panels, dedicated drainage, and HVAC ducting.

The Vacuum Advantage:

We design our machines, like the AVCF-150 and AVC-600 series, to be compact and mobile.

- Small Footprint: The indoor unit of a 150kg capacity machine is approximately 1600mm x 1450mm. It takes up less space than a standard office desk.

- Skid-Mounted: The machine comes as a complete unit on a steel base. You can move it with a forklift.

- Minimal Setup: As stated in our technical proposals, the requirements are simple: a flat concrete floor and a 380V/3-phase power supply.

Customization for Existing Lines:

We offer "tailor-made" options to fit your current trolley sizes. For example, if your trolley is 640x800x1750mm, we adjust the chamber size to 1000x1500x2000mm to fit it perfectly. You don’t need to buy new racks. You don’t need to knock down walls. This flexibility drastically lowers your initial setup cost compared to rigid conveyor systems.

Can Better Quality Reduce Financial Losses from Waste?

How much bread do you throw away? Whether it is due to mold, poor crust texture, or collapsing loaves, every discarded product is money straight out of your pocket.

Vacuum cooling extends shelf life by uniformly cooling the product and eliminating the "danger zone" for bacterial growth. Features like "Vacuum Delay" ensure delicate structures aren’t damaged, significantly reducing returns and waste, which directly improves your bottom line.

Quality as a Financial Metric

We often think of quality as subjective, but in the bakery business, it is purely financial.

The Cost of "Hot Core":

In conventional cooling, the crust cools fast, but the core stays hot. This heat gets trapped in the bag.

- Condensation: This leads to soggy crusts and, more dangerously, mold.

- Returns: If a supermarket rejects your delivery because of mold, you lose the sale, the transport cost, and your reputation.

The Financial Gain of Vacuum Tech:

Our machines allow you to control the process precisely via a Siemens touch screen.

- Uniformity: The readout shows you exactly when the core hits 28°C. There is no guessing. You pack with confidence.

- Vacuum Delay6: For products with high water content, we use a "Vacuum delay facility." This prevents the pressure from dropping too fast, which ensures the bread doesn’t explode or crack. It keeps the product beautiful.

- Shelf Life7: By cooling in a sterile, sealed chamber and skipping the warm bacterial growth zone, you can often add days to your shelf life.

For a high-volume producer, reducing waste by just 2% can equate to tens of thousands of dollars a year. That is pure profit that was previously going into the trash bin.

| Issue | Conventional Cost | Vacuum Solution | Financial Impact |

|---|---|---|---|

| Mold | High risk due to condensation | Zero condensation | Reduced Returns |

| Staling | Occurs during slow cooling | Gelatinizes starch instantly | Longer Shelf Life |

| Structure | Risk of collapse | Sets structure immediately | Consistent Product |

Conclusion

When you analyze the total cost—energy, labor, rent, and waste—vacuum cooling is not an expense; it is a savings strategy. It transforms your bakery from a slow, energy-hungry operation into a fast, efficient, and profitable business.

-

Exploring the Vacuum Profit Booster can reveal innovative ways to increase production and profitability in your bakery. ↩

-

Understanding Labor Optimization can help you enhance efficiency and reduce costs in your production processes. ↩

-

Explore the advantages of Vacuum Cooling to understand how it can significantly reduce energy costs and improve efficiency. ↩

-

Learn how to accurately calculate Kilowatt-Hours to better manage your energy expenses and optimize your utility bills. ↩

-

Understanding landing cost is crucial for budgeting and financial planning in equipment purchases. ↩

-

Understanding Vacuum Delay can enhance your baking process, ensuring better product quality and longer shelf life. ↩

-

Exploring shelf life extension techniques can significantly reduce waste and increase profitability in your bakery. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy

Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the