What Are the Key Features of a Professional Bakery Vacuum Cooling System?

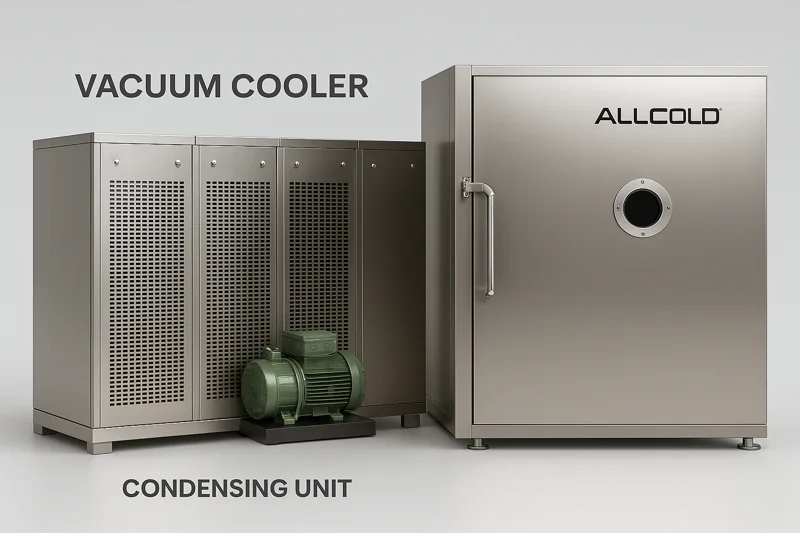

You are looking at brochures and websites, and every vacuum cooler looks like a big stainless steel box. But inside that box, there is a world of difference between a cheap, entry-level unit and a professional, industrial-grade system.

It can be confusing to tell them apart. You don’t want to spend money on a machine that breaks down in six months or ruins your bread’s crust. You need to know exactly what to look for under the hood to ensure you are buying a machine that will last.

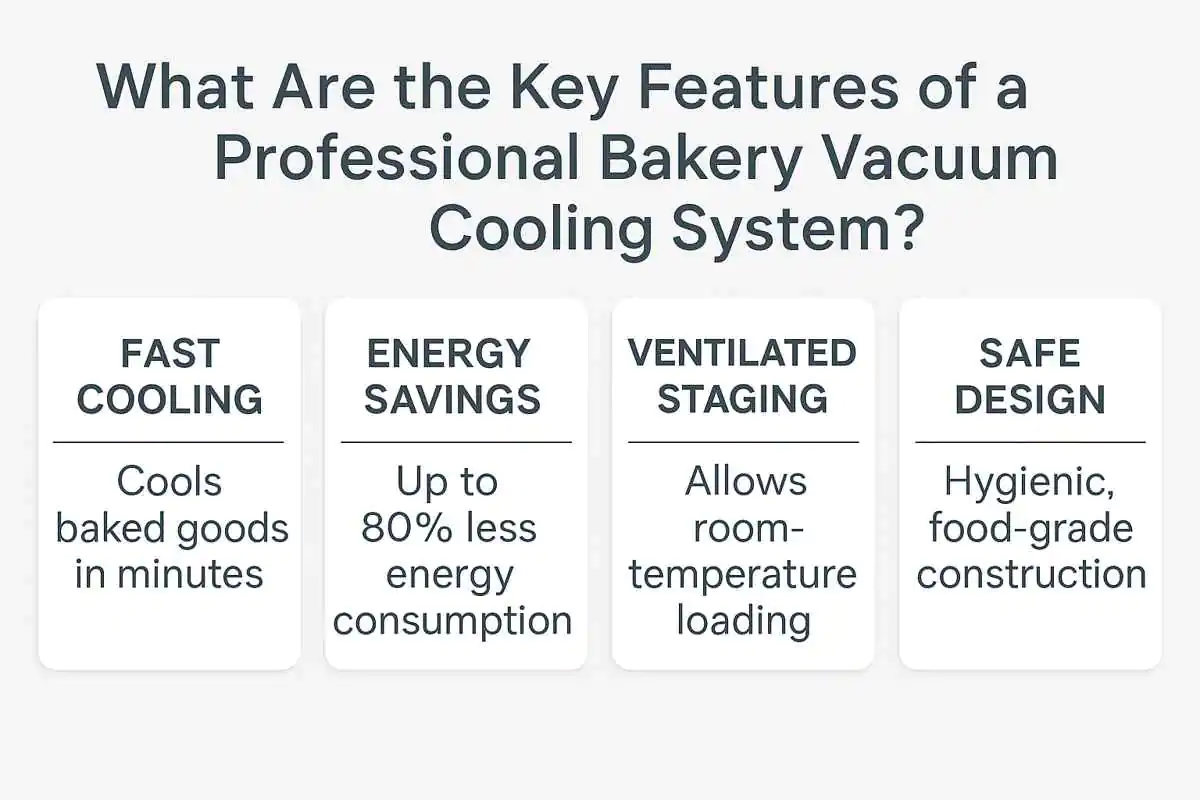

A professional bakery vacuum cooling system is defined by four key pillars: a world-class vacuum pump for speed, a robust refrigeration system for efficiency, an intelligent PLC control system for consistency, and a sanitary stainless steel construction for food safety.

As a manufacturer, I build these machines every day. I know that the quality of the components we choose determines the quality of the bread you bake. Let me take you on a tour inside a professional machine and explain the features that actually matter for your business.

Why Is the Vacuum Pump the Heart of the System?

The vacuum pump is the engine of the entire process. If the pump is weak or unreliable, the machine simply cannot do its job. A slow pump means slow cooling, which destroys your efficiency and leaves your bread in the "danger zone" for too long.

Many budget manufacturers use cheap, off-brand pumps to lower the price. These pumps are often noisy, prone to overheating, and struggle to reach the deep vacuum levels needed for perfect baking results.

Professional systems use top-tier German or American pumps, such as Leybold or Nash. These pumps are engineered for high speed and deep vacuum, ensuring your bread reaches the ‘flash point’ quickly for a crispier crust and a stable crumb structure.

The Difference Between "Running" and "Performing"

For a buyer like Norman, who is sensitive to quality, the brand of the pump is the first thing he checks. He knows that "generic" components are a gamble he can’t afford.

Speed is Quality

The goal of vacuum cooling is to reach the "flash point" (where water boils at low pressure) as fast as possible. A professional pump1, like the Leybold (Germany) or Nash (USA/Germany) units we use at Allcold, has a massive "pumping speed2." It evacuates the air from the chamber rapidly. Why does this matter?

- Crispiness: The faster you hit the flash point, the better the moisture evaporation from the surface, creating that perfect, shattering crust.

- Structure: Rapid pressure drop "freezes" the starch structure, preventing the loaf from collapsing.

A cheap pump might take 10 minutes to reach the vacuum level that a Leybold pump reaches in 3 minutes. That 7-minute difference is where you lose product quality.

Reliability and Maintenance

In a busy bakery, this pump might run 20 cycles a day, 365 days a year. Top-tier pumps are designed for this industrial workload. They run cooler and quieter. More importantly, spare parts and service for brands like Leybold are available globally. If a no-name pump fails, you might have to replace the whole unit. If a professional pump needs maintenance, you can just service it.

| Feature | Generic/Budget Pump | Professional Pump (Leybold/Nash) | Impact on Bakery |

|---|---|---|---|

| Evacuation Speed | Slow, struggles with full loads. | High-speed, consistent performance. | Faster cycles, better crust quality. |

| Vacuum Depth | Inconsistent, may fluctuate. | Deep, stable vacuum pressure. | Uniform cooling from core to crust. |

| Reliability | Prone to overheating/failure. | Industrial continuous duty rating. | No downtime during peak seasons. |

| Global Support | Non-existent parts network. | Worldwide service and parts. | Peace of mind for years. |

How Does the Refrigeration System Protect Your Pump?

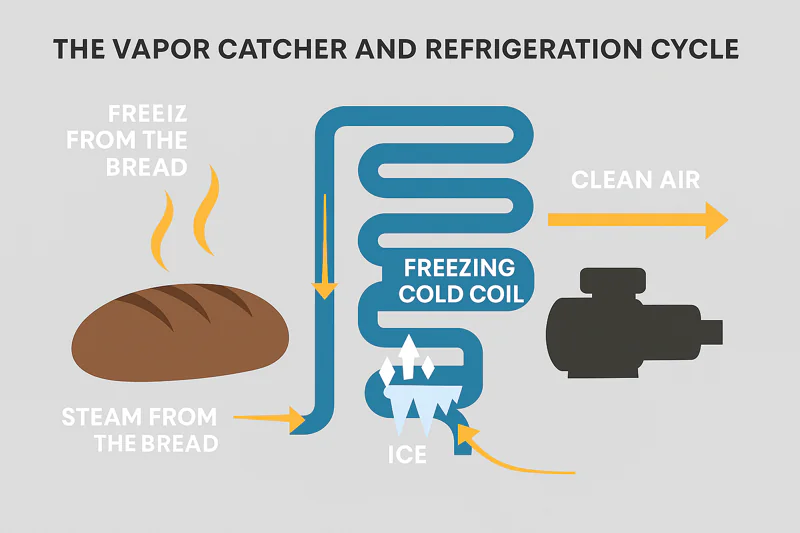

Creating a vacuum is only half the battle. When the water inside your hot bread boils, it turns into steam. A LOT of steam. If this hot steam gets sucked directly into your vacuum pump, it will destroy the pump oil and ruin the machine in weeks.

This is where the refrigeration system comes in. It acts as a shield. But if the refrigeration is undersized or inefficient, it can’t catch the steam fast enough, leading to "pump flooding" and longer cycle times.

A professional system uses a powerful refrigeration circuit, anchored by a Bitzer compressor, to drive a "cold trap" vapor catcher. This instantly freezes the steam before it reaches the pump, protecting your equipment and speeding up the cooling process.

The Muscle Behind the Machine

For a large-scale operator like Carlos, equipment failure is a nightmare. The refrigeration system is the muscle that keeps the machine running cycle after cycle without stalling.

The Bitzer3 Advantage

At Allcold, we standardize on Bitzer compressors (Germany). Bitzer is widely considered the gold standard for industrial refrigeration.

- Efficiency: They provide maximum cooling power with minimum energy input.

- Durability: They are built to handle the intense, fluctuating loads of vacuum cooling (where heat load spikes massively for a few minutes then drops).

- Protection: By pairing a Bitzer compressor with a high-efficiency evaporator (the cold trap), we ensure that the vapor is captured effectively.

The "Cold Trap4" Mechanism

Imagine the steam leaving your bread at 90°C. Inside the vacuum chamber, there is a radiator-like coil that is chilled to extremely low temperatures. As the steam passes over this coil, it condenses and freezes instantly. This does two things:

- Protects the Pump: Only dry air reaches the sensitive vacuum pump.

- Turbocharges Cooling: The act of condensing steam actually helps lower the pressure in the chamber even faster, acting like a secondary pump.

Cheap systems often undersize this component. The result? The pump sucks in water, the oil turns into a milky sludge (emulsification), and you have to change the expensive oil every week. With a professional design, your oil stays clean for months.

| Component | Standard/Budget Spec | Allcold Professional Spec | Benefit |

|---|---|---|---|

| Compressor | Local/Copycat Brand. | Bitzer (Germany). | High efficiency, long life, low noise. |

| Vapor Catcher | Undersized surface area. | Large surface area, high capacity. | Protects pump, speeds up cooling. |

| Components | Generic valves. | Danfoss (Denmark) / Frascold (Italy). | Leak-free, precise control. |

Why Is the Control System the "Brain" of Your Operation?

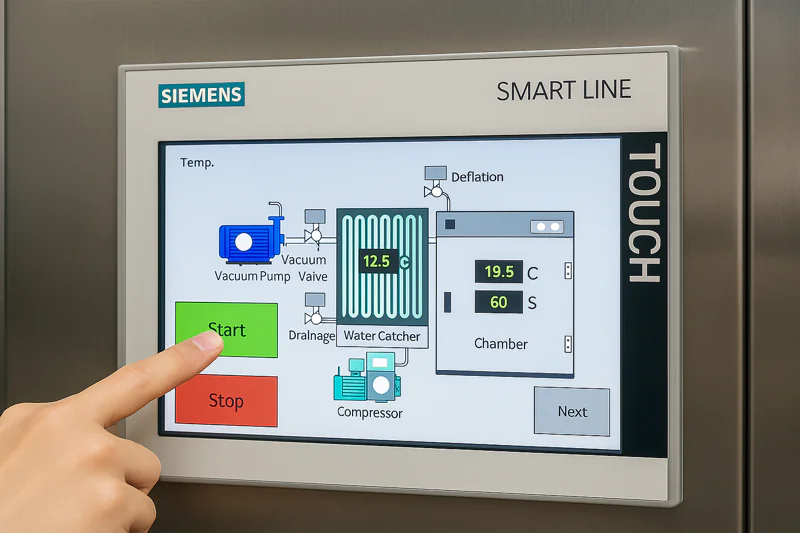

You might have the best mechanical parts in the world, but if the control system is difficult to use, your staff will make mistakes. Complicated buttons, confusing manuals, and lack of data can turn a high-tech machine into a headache.

In a busy bakery, you have different shifts and different operators. You cannot rely on everyone being an engineer. If the machine requires a "feeling" to operate, you will get inconsistent results—one batch perfect, the next one dried out.

Professional systems feature a Siemens PLC and Touch Screen interface with intelligent software. This allows you to store specific recipes (e.g., "Bagel" vs. "Sponge Cake"), offers one-touch operation, and provides built-in troubleshooting to keep production smooth.

Intelligence and Ease of Use

For a manager like Sophia in Singapore, who deals with tight schedules and staff turnover, the user interface is critical. She needs "plug and play" simplicity with "high-tech" control.

The Siemens5 Standard

We use Siemens (Germany) for our PLC (Programmable Logic Controller) and HMI (Human Machine Interface). Why Siemens? Because it is robust, stable, and user-friendly. The screen isn’t just a bunch of buttons; it’s a smart computer.

- Recipe Storage6: You can pre-program settings for every product you bake. A baguette needs a different cooling curve than a soft bun. Your baker just selects "Baguette" and hits "Start." The machine does the rest automatically.

- Multi-Language: We can program the interface in English, Spanish, Chinese, or any language your staff speaks, reducing communication errors.

- Intelligent Modes7: Our systems often feature temperature-based control. You insert a probe into the bread, and the machine stops exactly when the core reaches 30°C. No guessing.

Troubleshooting Assistant8

This is a game-changer. If the machine stops, a cheap system gives you a red light and you have to call a technician. Our Siemens system displays a clear message on the screen: "Door not sealed" or "Air pressure low." It tells the operator exactly what is wrong, often allowing them to fix simple issues instantly without downtime.

| Control Feature | Manual/Basic System | Allcold Intelligent System | Operational Benefit |

|---|---|---|---|

| Operation | Manual timers and gauges. | One-touch Recipe recall. | Eliminates human error. |

| Process Control | Time-based only (guessing). | Temp-probe or Time-based. | Perfect consistency every batch. |

| Diagnostics | Blinking red lights. | On-screen clear text guide. | Fast fixes, less downtime. |

| Electrical | Generic relays. | Schneider (France) & Carlo Gavazzi. | Stable power, safety protection. |

How Does Hygienic Construction Ensure Food Safety?

A bakery is a food factory. Your equipment must be easy to clean. If a vacuum cooler has rough welds, rusty screws, or corners that trap crumbs and water, it becomes a breeding ground for mold and bacteria.

This is a massive risk. You are using this machine to extend shelf life, but a dirty machine will infect your bread with mold spores before it even leaves the factory. "Industrial" does not always mean "Food Grade."

Professional vacuum coolers are constructed from 100% SUS304 food-grade stainless steel. They feature sanitary welding, rounded corners, and water drainage systems designed specifically for wash-down environments, meeting the strictest HACCP standards.

Built for the Food Industry

For Sophia and anyone exporting to major retailers, hygiene is non-negotiable. The machine must look and act like a piece of pharmaceutical equipment, not a garage tool.

The Material Matters: SUS304

We use SUS304 Stainless Steel for the chamber, the door, and even the internal piping.

- Corrosion Resistance: Bakeries are humid. Bread releases acidic steam. Carbon steel or lower-grade stainless (like 201) will eventually rust. SUS304 lasts forever.

- Cleanability: The surface is polished and smooth. Spores cannot stick to it. You can wipe it down or spray it out easily.

Smart Design Features

It’s not just the metal; it’s the shape.

- Sanitary Welds: We don’t leave gaps or rough spots where dough or crumbs can hide.

- Water Management: Vacuum cooling pulls moisture out of bread. That water has to go somewhere. Our machines have integrated drainage channels and reservoirs to collect this water so it doesn’t pool on the floor of the chamber.

- Door Configuration: We offer customized doors—sliding doors for tight spaces or "Pass-Through" (double door) systems. A pass-through is ideal for hygiene: raw/hot trolleys enter from the "High Risk" baking zone, and cool trolleys exit into the "Low Risk" packaging zone, preventing cross-contamination.

| Design Element | Standard Industrial Box | Allcold Hygienic Design | Food Safety Impact |

|---|---|---|---|

| Material | Painted Steel or SUS201. | 100% SUS304 Stainless. | Zero rust, easy to sanitize. |

| Flooring | Flat, hard to drain. | Sloped with drainage channel. | Prevents standing water/mold. |

| Door Type | Single hinged only. | Sliding or Pass-Through. | Optimizes workflow & hygiene zoning. |

Conclusion

A professional vacuum cooler is not just a collection of parts; it is an engineered solution. By insisting on top-tier components like Leybold pumps, Bitzer compressors, and Siemens controls, and housing them in a SUS304 sanitary chamber, you are investing in reliability, consistency, and safety. Don’t just buy a cooler; buy the peace of mind that comes with professional quality.

-

Discover the advantages of professional pumps, including speed, reliability, and quality in baking processes. ↩

-

Understanding pumping speed is crucial for achieving optimal vacuum cooling, ensuring product quality and efficiency. ↩

-

Explore the advantages of Bitzer compressors, known for their efficiency and durability in industrial refrigeration systems. ↩

-

Learn about the cold trap mechanism, crucial for protecting pumps and enhancing cooling efficiency in vacuum systems. ↩

-

Explore why Siemens is renowned for its robust and user-friendly PLC and HMI systems, perfect for efficient management. ↩

-

Learn how recipe storage enhances efficiency and consistency in baking, making operations smoother. ↩

-

Discover how intelligent modes optimize baking with precise temperature control, ensuring perfect results. ↩

-

Find out how troubleshooting assistants minimize downtime and enhance operational efficiency in machinery. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy