What Are the Power Requirements and Electrical Specifications for Bakery Vacuum Cooling Machines?

You are ready to upgrade your bakery. You have looked at the brochures, you like the cooling speeds, and you have calculated the ROI. But there is one critical question that often gets left until the very last minute: "Can my factory actually power this machine?"

It happens more often than you think. A customer orders a machine, it arrives, and then they realize their main breaker isn’t big enough, or they don’t have the right voltage, or they forgot about the compressed air supply. This leads to panic, delays, and expensive emergency electrical work.

Vacuum cooling machines for bakeries typically require a 3-Phase industrial power supply (380V-480V). The total power consumption ranges from approximately 20kW for a small unit to over 60kW for large systems, but the critical factor is understanding Peak Load versus Running Load to size your breakers correctly.

As a factory owner, I want to make sure your installation is boring. "Boring" is good. Boring means you plug it in, and it works. Let’s dive into the specific electrical and utility requirements you need to prepare for a professional vacuum cooling system.

How Much Power Does a Vacuum Cooler Actually Use?

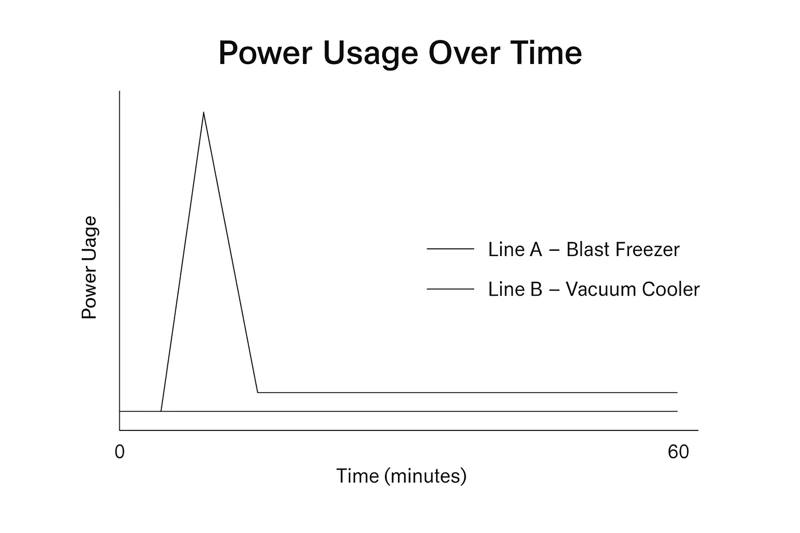

There is a misconception that vacuum coolers will double your electricity bill. This is not true. While they are powerful machines, they are also incredibly fast. A blast freezer might run for 60 to 90 minutes to cool a batch of bread. A vacuum cooler does it in 10 minutes.

So, while the intensity (kW) is high, the duration is short. This means the total energy consumed per loaf of bread is actually very efficient. However, your electrical infrastructure must be built to handle that short, intense burst of power.

For a standard 2-trolley bakery system, you generally need a connection capable of supporting 30kW to 40kW of Total Installed Power. This power is primarily consumed by the vacuum pump motor and the refrigeration compressor, which must run simultaneously during the peak of the cycle.

Analyzing the Load Components

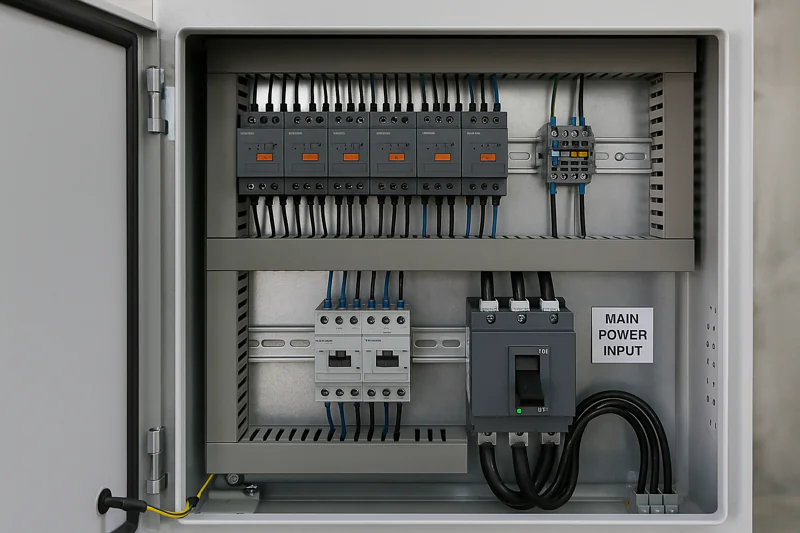

To understand what you are paying for (and what you are powering), we need to look inside the cabinet. For a buyer like Norman, who calculates every cent of operational cost, understanding where the power goes is essential for planning.

The Two Main Consumers

- The Vacuum Pump1 (The Muscle): This is the motor that fights against atmospheric pressure. In the first few minutes of the cycle, it works the hardest to evacuate the air. On a standard machine, this might be a 7.5kW to 11kW motor.

- The Refrigeration Compressor2 (The Shield): This component (usually a Bitzer) powers the "cold trap." It must keep the internal coils at -10°C or lower to catch the steam. This is usually the largest consumer, often rated between 15kW and 25kW depending on the machine size.

Peak Load vs. Running Load

Your electrician needs to know the "Full Load Amps" (FLA).

- Start-up: When you press start, if the motors start directly (Direct-on-Line), there is a massive spike in current.

- Operation: Once running, the amp draw drops.

- Peak: The highest demand happens when the vacuum gets deep (around 500mbar) and the refrigerator is working at maximum capacity to condense vapor.

We design our machines with this in mind. For example, we don’t start all motors at the exact same second. The control system staggers the start-up sequence by a few seconds to prevent a massive surge that could trip your factory’s main breaker.

| Component | Function | Approximate Power (Mid-Size Unit) | Why it needs power? |

|---|---|---|---|

| Vacuum Pump | Removes air | 7.5 kW – 15 kW | High torque needed to pull deep vacuum. |

| Compressor | Freezes vapor | 12 kW – 25 kW | Compressing refrigerant gas requires high energy. |

| Condenser Fans | Cools refrigerant | 1 kW – 3 kW | Moving large volumes of air. |

| Control System | Brain/HMI | 0.5 kW | Electronics and sensors (negligible). |

Why Are Voltage and Frequency Critical for International Buyers?

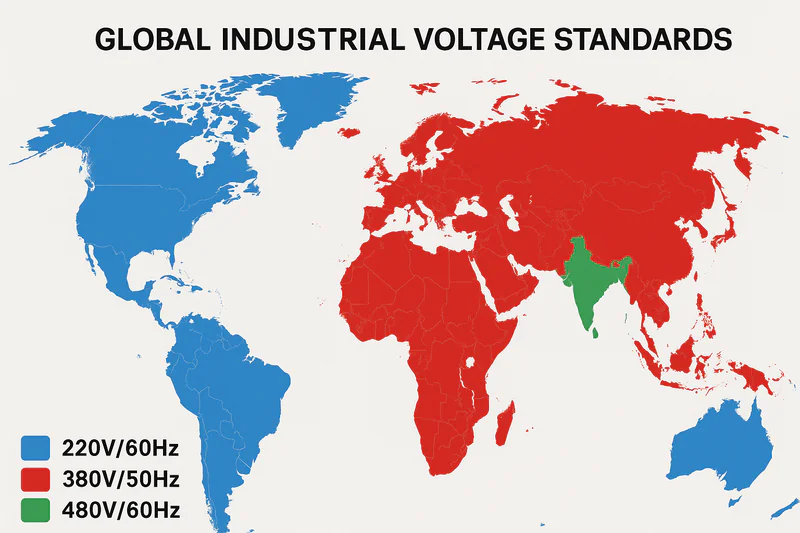

I export machines to the USA, Europe, Southeast Asia, and the Middle East. The biggest technical challenge is not the language; it is the electricity. A machine built for Germany will burn out in the USA. A machine built for the USA will run slowly in Singapore.

You cannot just use a simple travel adapter. These are industrial motors. If the frequency (Hertz) is wrong, the physical speed of the motor changes, which alters the cooling performance and can destroy the pump.

We must customize the motors and electrical components to match your local grid—specifically 60Hz for North America and parts of Asia, versus 50Hz for Europe and the rest of the world. Using the wrong frequency will cause motors to overheat or underperform.

The 50Hz vs. 60Hz Danger

This is a section specifically for my international customers like Carlos in Mexico or Norman in the USA.

The Physics of Rotation

AC motors rotate based on the frequency of the power supply.

- 50Hz (Europe/China)3: A standard 4-pole motor spins at roughly 1450 RPM.

- 60Hz (USA/Korea)4: The same motor spins at roughly 1750 RPM.

What Happens if You Mix Them?

- 50Hz Machine in a 60Hz Country (e.g., European machine in USA): The motors will spin 20% faster.

- Vacuum Pump: It might pump faster, but it will run much hotter. The bearings might fail because they are not rated for that speed. The amp draw will increase drastically, likely tripping the overload protection.

- Compressor: The refrigerant pressure will rise, potentially causing safety valves to blow.

- 60Hz Machine in a 50Hz Country (e.g., US machine in China): The motors spin 20% slower.

- Result: Performance drops by 20%. Your "fast" cooling cycle becomes slow. The cooling fans on the motors also spin slower, leading to overheating because they can’t cool the motor windings effectively.

The "Transformer" Myth

Many people ask, "Can I just buy a transformer?" A transformer changes Voltage (e.g., 220V to 480V), but it does not change Frequency (Hz). To change frequency, you need an expensive frequency converter.

- The Allcold Solution: We don’t use converters. We build the machine with native components. If you are in Texas, we install 480V/60Hz motors and contactors from the start. It is the only way to guarantee longevity.

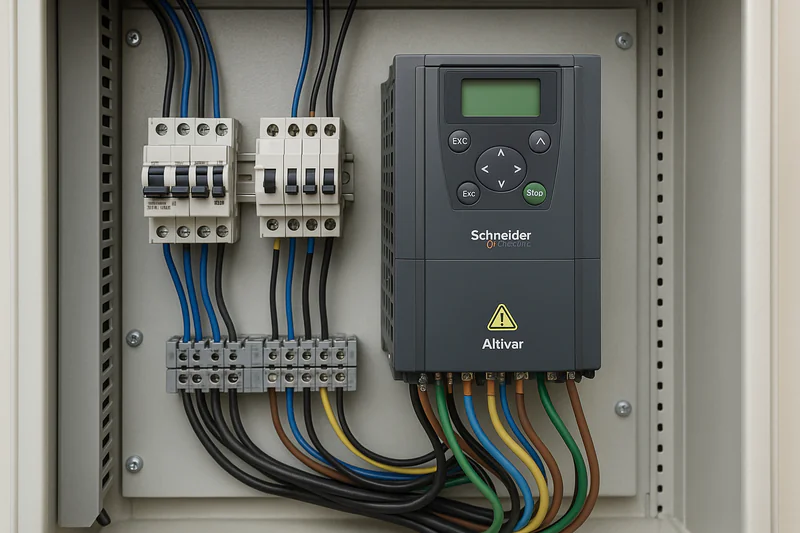

How Can Variable Frequency Drives (VFD) Save You Money?

In the past, industrial motors were "dumb." You turned them on, and they ran at 100% speed until you turned them off. This is inefficient and creates huge electrical spikes called "Inrush Current" that can dim the lights in your building.

Modern technology offers a better way. By using Variable Frequency Drives (VFDs), also known as Inverters, we can control the speed of the motors intelligently. This is not standard on all machines, but it is a feature we highly recommend for professional setups.

A VFD allows the vacuum pump and compressor to start gently (‘Soft Start’), eliminating massive power spikes. It also allows the motors to ramp down when full power is not needed, significantly reducing energy consumption and wear on the mechanical parts.

Intelligent Power Management

For a large-scale factory manager like Sophia, who monitors "Peak Demand Charges5" on her utility bill, VFD6s are a game changer.

Eliminating the "Inrush" Spike

When a large 15kW motor starts instantly, it can draw up to 600% of its rated current for a fraction of a second. If you have three machines starting at once, this can blow your main factory fuse or result in fines from your electricity provider.

- With VFD: The motor starts at 0 RPM and slowly accelerates to full speed over 5 or 10 seconds. The current never exceeds the rated limit. This means you might be able to install the machine without upgrading your main building transformer.

Process Control

VFDs give us control over the quality of the bread, not just the power.

- Gentle Cooling: For delicate products like Sponge Cake or Soufflé, pulling a vacuum too fast can make the product explode or collapse. With a VFD on the vacuum pump, we can program the machine to pull the air out slowly and gently.

- Energy Saving: In the final stages of the cooling cycle, the load decreases. A VFD can slow the compressor down, using less electricity while maintaining the target temperature.

| Feature | Standard Contactor (Old School) | VFD / Inverter (Modern) | Benefit |

|---|---|---|---|

| Startup Current | 500-600% Spike | 100% (No Spike) | Protects grid, no dimming lights. |

| Motor Speed | Fixed (100%) | Variable (0-100%) | Better control for delicate bread. |

| Wear & Tear | High Mechanical Shock | Smooth Acceleration | Longer belt and bearing life. |

| Cost | Low | Higher Initial Cost | Lower Long-term Electricity Bills. |

What About Compressed Air and Water? (The Hidden Utilities)

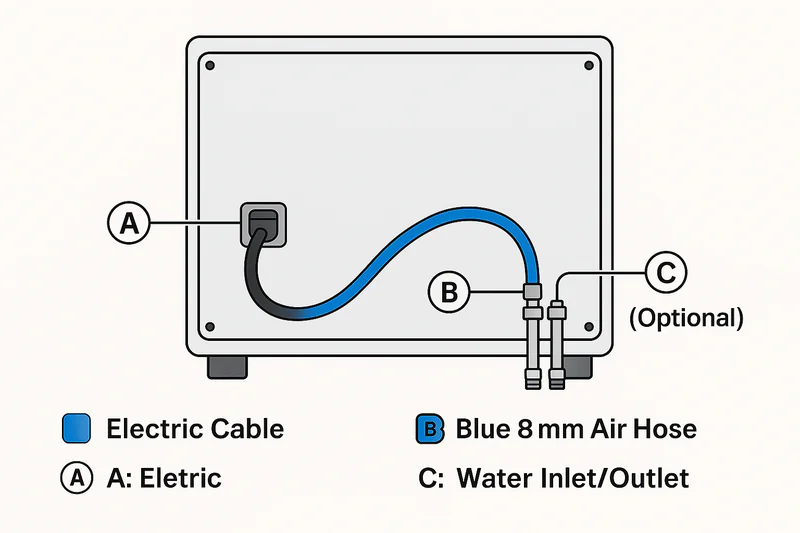

Electricity is the main utility, but it is not the only one. If you prepare the electrical cable but forget the air hose, your machine will sit silent on installation day.

Almost all vacuum coolers use pneumatics (compressed air) for movement. Why? Because pneumatic cylinders are cleaner, faster, and more reliable than electric motors for opening and closing heavy doors and large valves.

You must provide a clean, dry compressed air line (typically 6 to 8 bar pressure) to operate the door seals and vacuum valves. Additionally, if you opt for a water-cooled condenser, you must plumb in a cooling tower loop with adequate flow rates.

Planning Your Infrastructure

This section is for the facility manager or the contractor installing the machine.

1. The Compressed Air Requirement

You don’t need a massive industrial compressor just for this machine, but you do need a consistent supply.

- Pressure: We standardly require 0.6 – 0.8 MPa (6-8 bar).

- Volume: The volume usage is low. We only use air to inflate the door seal gasket and to flip the valves open/closed. A standard shop compressor with a receiver tank is usually sufficient.

- Quality: The air should be dry. If your air has a lot of water in it, it can rust the solenoid valves inside the machine over time. We install a small filter/regulator on the machine, but a dryer on your compressor is a good idea.

2. Water Cooling vs. Air Cooling

This is a major decision you make before you buy.

- Air-Cooled (The Standard): The machine has a built-in radiator and fans on top or behind.

- Requirement: Good ventilation. The machine spits out hot air (just like an AC unit). If you put it in a tiny, closed room, the room will get very hot, and the machine will stop working. You need high ceilings or an exhaust fan.

- Water-Cooled (The Heavy Duty): The machine has a compact heat exchanger (shell and tube).

- Requirement: You must connect it to an external cooling tower or chiller loop.

- Why choose this? If your bakery is in a tropical climate (like Singapore or Dubai) where the ambient air is 40°C+, air cooling struggles. Water cooling is much more efficient and keeps your factory floor cool. However, it requires plumbing work and a water pump.

Conclusion

Powering a professional vacuum cooler requires more than just an extension cord. You need to plan for 3-Phase power, understand your local Voltage and Frequency, consider using VFDs for efficiency, and don’t forget the Compressed Air.

By addressing these four points with your electrician early in the process, you ensure that when the machine arrives, you can turn it on immediately and start cooling bread on day one. It is about preparation, not luck.

-

Understanding the role of a vacuum pump can help optimize energy use and improve operational efficiency. ↩

-

Exploring the workings of a refrigeration compressor can enhance your knowledge of energy consumption and system performance. ↩

-

Understanding the implications of using 50Hz equipment in a 60Hz environment can help prevent costly equipment failures. ↩

-

Exploring the impact of 60Hz on motor performance can enhance your knowledge of equipment efficiency and longevity. ↩

-

Understanding Peak Demand Charges can help you manage energy costs effectively and optimize your factory’s utility expenses. ↩

-

Exploring VFD technology can reveal significant energy savings and operational benefits for your manufacturing processes. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy