What Are the Preservation Techniques for Ready-to-Eat Foods?

As consumers increasingly prefer ready-to-eat (RTE) foods, extending their shelf life effectively becomes a critical challenge.

Currently, the most effective preservation techniques for RTE foods include vacuum cooling, modified atmosphere packaging (MAP), high-pressure processing (HPP), and rapid freezing. These methods significantly prolong shelf life, ensuring food safety and freshness.

Let’s explore these methods in detail to see how they help extend the shelf life of RTE foods.

How Does Vacuum Cooling Preserve Ready-to-Eat Foods?

Slow cooling increases microbial growth risk, jeopardizing food safety.

Vacuum cooling quickly lowers food temperature, reducing time spent in dangerous temperature zones, thus substantially decreasing microbial growth and extending shelf life.

Dive Deeper into Vacuum Cooling

Vacuum cooling technology is especially effective for ready-to-eat foods that require quick and safe cooling. The method works by reducing atmospheric pressure in a vacuum chamber, which causes water inside the food to evaporate rapidly. This evaporation draws out heat very efficiently and much more evenly than surface-only cooling methods. Unlike traditional air cooling, where the surface may become cold while the interior stays warm for a long time, vacuum cooling ensures the entire product reaches the target temperature at almost the same time. This process is not only fast but also gentle, helping to preserve the texture, flavor, and moisture content of delicate foods like sandwiches, cooked rice, or bakery products.

One key advantage is safety. By reducing the time food spends in the "danger zone"—the temperature range (typically 20°C-50°C) where bacteria grow fastest—vacuum cooling drastically reduces the risk of foodborne illness1. This makes it especially valuable for central kitchens and food processors who supply schools, airlines, and convenience stores. Additionally, the technology is energy-efficient2; short, high-intensity cooling cycles use less energy than running a conventional blast chiller for hours. There is also less dehydration compared to open-air cooling, which means better product yield and less waste.

Vacuum cooling is highly scalable: it can be used for small meal packs or very large trays, supporting both batch and continuous production lines. Maintenance and operation are relatively simple, making it suitable for both industrial plants and medium-sized enterprises seeking higher food safety standards.

Is Modified Atmosphere Packaging Effective for Preserving RTE Foods?

Untreated packaging air accelerates food spoilage.

Modified atmosphere packaging replaces oxygen inside packaging with inert gases like nitrogen and carbon dioxide, effectively inhibiting oxidation and microbial growth, extending freshness.

Dive Deeper into Modified Atmosphere Packaging

Modified atmosphere packaging3 (MAP) is a modern preservation technology that changes the air composition inside food packaging to help slow down spoilage. Instead of using regular air, MAP replaces it with a carefully balanced mix of gases—usually nitrogen and carbon dioxide—that inhibit the growth of microbes and slow down oxidation. Oxygen, which causes food to spoil quickly, is either reduced to a very low level or eliminated entirely, depending on the product.

For example, in sliced deli meats or salads, too much oxygen will cause browning, off-flavors, and mold growth. Using MAP, these foods can remain fresh and visually appealing for days or even weeks longer than with standard packaging. This is because nitrogen acts as a filler that doesn’t react with food, while carbon dioxide inhibits the growth of many bacteria and fungi. For foods like bread or cheese, the right gas mixture prevents staleness and mold without the need for artificial preservatives.

Another benefit of MAP is its flexibility. Gas mixtures can be adjusted for different foods: red meat may need a little oxygen to maintain its color, while baked goods or cut fruits need a totally oxygen-free environment. MAP also improves logistics, as foods can be transported over long distances without significant loss of quality. In my own experience with export customers, adopting MAP has dramatically reduced spoilage and complaints during overseas shipments.

Implementing MAP requires specialized machinery and strict sealing standards, but the results—in terms of shelf life4, appearance, and customer satisfaction—make it a top choice for any food business dealing in RTE products.

Which Ready-to-Eat Foods Benefit from High-Pressure Processing?

Traditional thermal sterilization often damages food flavor and nutrition.

High-pressure processing (HPP) uses ultra-high pressure to eliminate microbes without significantly raising temperature, effectively preserving food’s flavor and nutritional content, thus extending shelf life.

Dive Deeper into High-Pressure Processing

High-pressure processing5 (HPP) is a cold pasteurization technology6 that preserves food by subjecting it to extremely high pressure—up to 600 MPa (about 87,000 psi)—for several minutes. Unlike traditional pasteurization, which uses heat and can destroy flavors, colors, and nutrients, HPP keeps food at or near room temperature. This means RTE foods, such as juices, guacamole, cooked meats, or ready meals7, retain their fresh taste and texture while still gaining an extended shelf life.

HPP is highly effective against bacteria, viruses, yeasts, and molds, including dangerous pathogens like Listeria or Salmonella. The process works by disrupting cell membranes and deactivating enzymes that cause spoilage, all without needing chemical preservatives. One of the biggest benefits for food processors is the flexibility to treat sealed, final-packaged products, reducing the risk of post-processing contamination. This is why HPP is increasingly popular for premium or clean-label RTE foods.

It’s also very gentle on food structure. For example, fresh juices treated with HPP can taste just-squeezed even after weeks of refrigerated storage. Sliced deli meats stay moist and keep their natural color. The technology is especially valued by brands that want to meet high standards in export markets with strict food safety laws. Although the equipment investment is significant, the return comes from higher product value, reduced recalls, and happier, safer customers. In my business experience, many clients have chosen HPP as a reliable way to enter new markets and deliver longer-lasting, better-tasting RTE foods.

Can Rapid Freezing Maintain Freshness of RTE Foods?

Slow freezing damages food cells, resulting in poor texture after thawing.

Rapid freezing quickly lowers food temperatures below -18°C, forming tiny ice crystals that minimize cellular damage and maintain food texture.

Dive Deeper into Rapid Freezing

Rapid freezing—also called quick freezing8 or flash freezing—is a preservation technique9 that locks in freshness by lowering the temperature of food to below -18°C very quickly, usually within 30 minutes. The faster food freezes, the smaller the ice crystals that form inside it. Small ice crystals cause less damage to cell walls, which helps maintain the original texture, moisture, and appearance of food once it is thawed. In contrast, slow freezing forms larger ice crystals, which rupture cells and make food mushy or dry after thawing.

For ready-to-eat foods such as seafood, dumplings, pizza, or pre-cooked rice, rapid freezing10 is especially important. It not only preserves quality but also helps control bacteria, as the quick temperature drop limits microbial activity. Foods frozen rapidly can be safely stored and shipped over long distances, giving suppliers more flexibility and reducing food waste. Another advantage is that rapid freezing allows for portion control—individual pieces do not stick together, making it easy for consumers to use only what they need.

Modern rapid freezers use powerful fans, very cold air, or contact plates to achieve ultra-fast freezing. In my own factory’s experience, adopting rapid freezing for certain product lines cut complaints about quality by half and boosted repeat orders. The up-front cost is quickly offset by higher customer satisfaction and reduced spoilage losses. As consumer demand for fresh-tasting, convenient foods grows, rapid freezing is an essential tool for any RTE food supplier.

Conclusion

Choosing suitable preservation techniques such as vacuum cooling, modified atmosphere packaging, high-pressure processing, or rapid freezing significantly enhances the quality and shelf life of ready-to-eat foods, meeting consumer demand effectively and improving market competitiveness.

-

Learn how vacuum cooling minimizes the risk of foodborne illness, ensuring safer food for consumers and suppliers alike. ↩

-

Discover why vacuum cooling is considered energy-efficient and how it can save costs in food processing operations. ↩

-

Explore this link to understand the science behind MAP and its benefits for food preservation. ↩

-

Learn how MAP can significantly enhance the shelf life of various food products, ensuring freshness and quality. ↩

-

Explore the advantages of High-pressure processing to understand how it enhances food safety and quality, making it a game-changer in the industry. ↩

-

Learn about cold pasteurization technology to see how it preserves food without compromising taste and nutrients, revolutionizing food safety. ↩

-

Discover the benefits of ready meals processed with High-pressure processing, ensuring freshness and safety for consumers seeking convenience. ↩

-

Learn how quick freezing preserves food texture and quality, ensuring a better culinary experience for consumers. ↩

-

Discover various preservation techniques that can help maintain food freshness and reduce waste, essential for food suppliers. ↩

-

Explore the advantages of rapid freezing to understand how it enhances food quality and safety, crucial for suppliers and consumers alike. ↩

Mila

You May Also Like

Is Your Cooling Process Holding Back Your Ready-Meal Business?

Your kitchen produces delicious, complex ready-meals, but the slow cooling process introduces food safety risks and production delays. This critical

How Can Vacuum Cooling Revolutionize Meat and Poultry Processing?

You’ve cooked a thousand kilograms of chicken perfectly, but now it sits for hours, slowly passing through the temperature danger

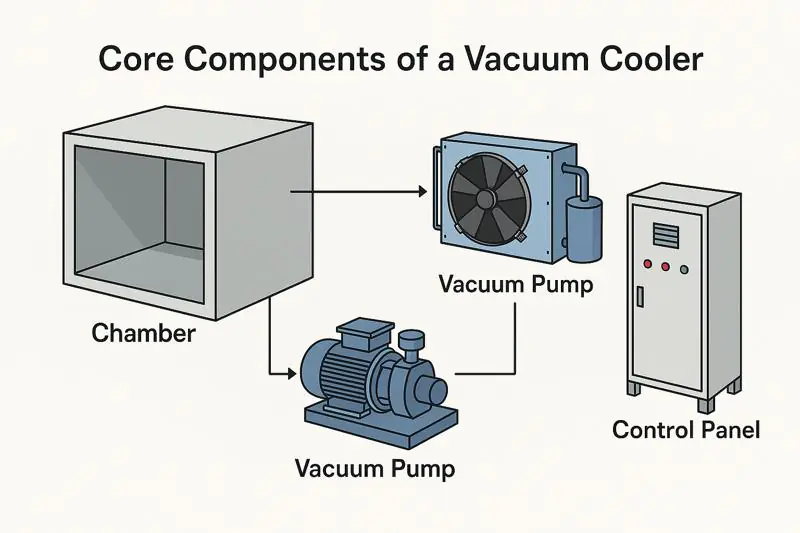

What's Really Inside Your Vacuum Cooler that Makes it Work?

Ever wondered what makes a vacuum cooler tick, transforming warm produce into perfectly chilled goods in minutes? It’s not magic,