What Are the Real Benefits of a Vacuum Cooler in Your Bakery?

Your bakery is great at making delicious products, but your growth is stuck. The final step, cooling, takes hours and creates a huge bottleneck that slows down your entire operation, limits your output, and costs you money.

This inefficiency is deeply frustrating. Your factory floor is cluttered with endless racks, your staff is constantly waiting, and you know you could be producing more if only you could cool your products faster. It feels like you’re running a marathon with your legs tied together.

The primary benefits of vacuum cooling are a massive increase in production speed, superior and more consistent product quality, a natural extension of shelf life, and significant reductions in operational costs. These combine to make your bakery more profitable and scalable.

As someone who builds these machines, I’ve seen them transform businesses time and time again. The benefits aren’t just small improvements; they represent a fundamental shift in how a bakery can operate. Let’s break down these benefits one by one, so you can see the real-world impact they could have on your business.

How Can It Increase Your Bakery’s Daily Output?

You have expensive, high-capacity ovens that can bake hundreds of loaves per hour. Yet, your overall daily output is limited because your cooling racks are full. You are forced to stop baking until space clears up.

This situation is a huge source of inefficiency. Your most valuable assets and your skilled staff are forced into downtime. You have the potential to sell more, but your process is holding you back. It’s a constant struggle against time and space.

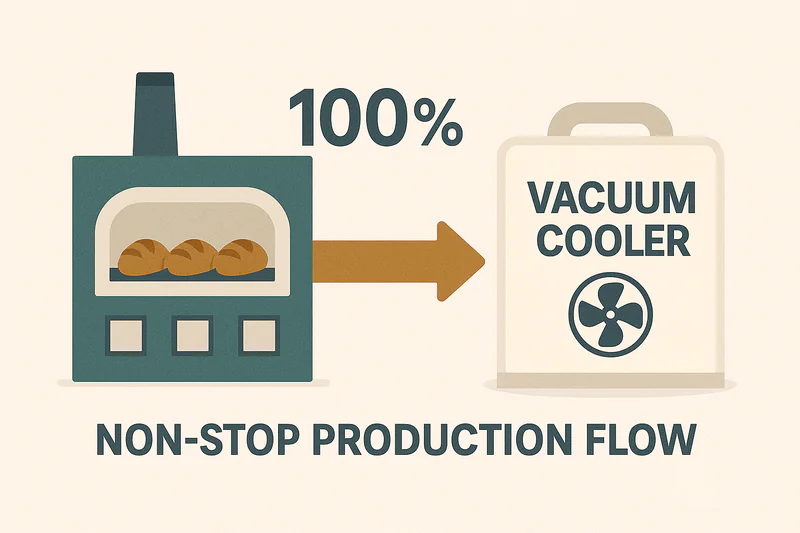

A vacuum cooler dramatically increases daily output by cutting the cooling time from 2-3 hours down to 3-6 minutes. This eliminates the production bottleneck and allows your ovens to run continuously, maximizing your throughput and overall capacity without adding new ovens.

The Power of Continuous Flow1 Production

This is the most immediate and revolutionary benefit. For a hands-on owner of a large farm and packing center like Carlos, maximizing throughput is everything. He understands that asset utilization is the key to profitability.

Moving Beyond "Batch-and-Wait"

The traditional bakery model is what I call "Batch-and-Wait." You bake a batch, then you wait. Then you bake another batch, and you wait. The cooling stage dictates the pace of the entire operation. With vacuum cooling, you shift to a "Continuous Flow" model. As soon as a trolley of bread leaves the oven, it enters the cooler. By the time the next trolley is ready to leave the oven, the first one is already cooled and on its way to packaging. The cooling process is no longer the slowest step; it’s one of the fastest. This simple change means you can run your ovens at their full, rated capacity all day long. For many bakeries, this can lead to a 20%, 30%, or even 50% increase in total daily output using the exact same baking equipment.

Meeting Demand and Maximizing ROI2

This increased output means you can say "yes" to bigger orders. It means you can meet seasonal peaks without stressing your system. Most importantly, it means you are getting the maximum possible return on investment (ROI) from your most expensive piece of equipment: your oven. An oven that is running is making you money. An oven that is sitting idle waiting for racks to clear is costing you money.

| Metric | Traditional Cooling ("Batch-and-Wait") | Vacuum Cooling3 ("Continuous Flow") | Impact on Your Bakery |

|---|---|---|---|

| Oven Utilization | Low (intermittent, forced stops) | High (can run at near 100% capacity) | Maximizes ROI on your most expensive asset. |

| Daily Throughput4 | Limited by cooling space and time. | Dramatically increased by 20-50% or more. | Generate more revenue from the same facility. |

| Production Planning | Complex, reactive, prone to delays. | Simple, predictable, and streamlined. | Makes scheduling easier and more reliable. |

How Does It Improve the Quality of Your Baked Goods?

You put so much effort into your recipe and baking process to create a product with a perfect, golden-brown crust and a soft interior. But then, as it sits on a rack for two hours, that beautiful crust slowly becomes soft, leathery, and disappointing.

It’s heartbreaking to see your product’s quality degrade at the very last moment. The inconsistency makes it difficult to package, slice, and deliver a premium product to your customers every single time. It undermines all the hard work you put in.

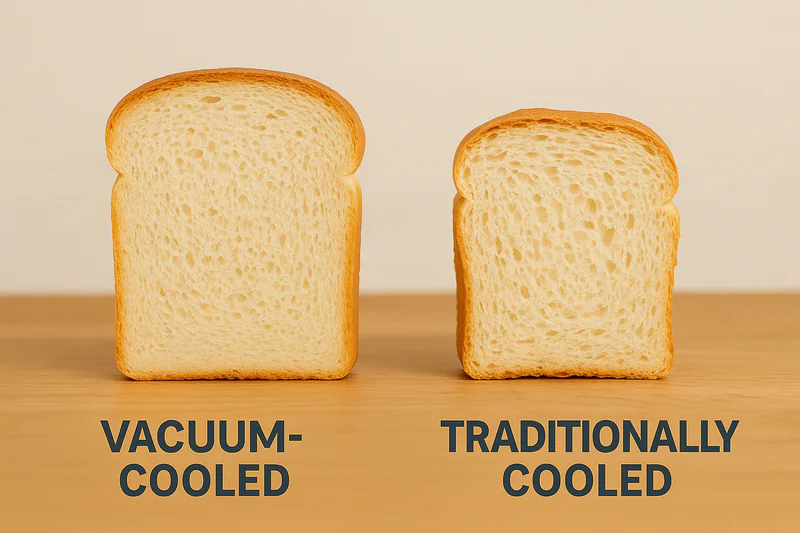

Vacuum cooling significantly improves product quality by creating an unmatched crispy crust and a more stable internal crumb structure. This ensures a consistently superior product that looks better, feels better, and holds up perfectly to slicing and handling.

The Science of a Better Loaf

This isn’t a subjective opinion; it’s a direct result of the physics of the cooling process. A quality-focused buyer like Norman, or a detail-oriented manager like Sophia, will immediately see the value in this consistency.

The "Gelatinization Stop" Effect

During baking, the starches in the flour absorb water and swell up, which is a process called gelatinization5. This creates the bread’s soft structure. When bread cools slowly, this process can partially reverse, the starches shrink, and the structure can weaken or collapse. Vacuum cooling is so rapid that it acts like a shock, instantly "freezing" the swollen starch structure in its perfect, just-baked state. This results in a loaf that has better volume, a stronger and more resilient crumb, and is far less likely to be damaged by automatic slicing machines. The result is a perfect, uniform slice from the first to the last.

The Crispiest Crust Imaginable

The reason a crust becomes soggy is simple: moisture from the hot interior of the bread slowly migrates outwards to the surface. Vacuum cooling turns this problem into a feature. The process physically pulls a small amount of moisture (about 1-2%) out of the entire loaf as vapor. This includes the surface moisture, which is evacuated from the chamber, leaving behind a perfectly dry, stable, and incredibly crispy crust6 that stays crispy for longer.

| Quality Attribute | Traditional Rack Cooling | Allcold Vacuum Cooling | Advantage for Your Business |

|---|---|---|---|

| Crust Texture | Becomes soft and leathery over time. | Incredibly crispy and stays crisp for longer. | Delivers a premium eating experience to the end customer. |

| Crumb Stability | Prone to collapsing, tears easily. | Strong, stable, and resilient. | Perfect for slicing, reducing waste and creating uniform slices. |

| Product Volume | Can sink and lose volume as it cools. | Maintains its full, just-baked volume. | A better-looking product on the shelf. |

| Consistency | Can vary based on ambient conditions. | Identical perfect results in every batch. | Builds brand reputation for reliable, high-quality products. |

Can It Naturally Extend Your Product’s Shelf Life?

You are constantly fighting against the clock. Your packaged bread has a limited shelf life, which restricts how far you can ship it. This also leads to financial losses from products that go stale on store shelves and are returned.

To combat this, you might be forced to add chemical preservatives to your ingredient list. This complicates your label and goes against the consumer trend toward clean, natural products. You are stuck choosing between more waste or a less "clean" label.

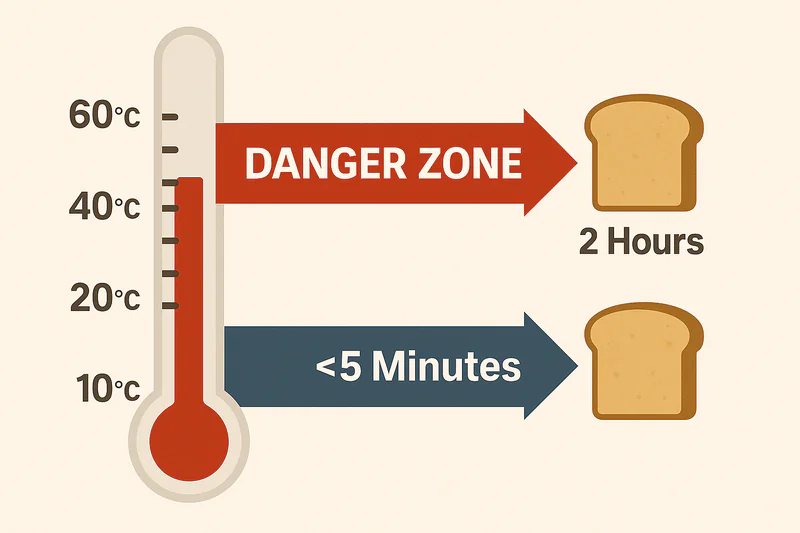

Yes, vacuum cooling is a powerful natural method to extend product shelf life, typically by 3 to 7 days. It achieves this by passing the product through the microbial "danger zone" in under five minutes, drastically inhibiting the growth of mold and bacteria from the very beginning.

The Hygienic Cooling Method

This is one of the most valuable benefits, especially for bakeries that supply supermarkets or other retailers. For a procurement manager like Sophia, who must meet strict HACCP hygiene standards7, this is not just a benefit—it’s a critical food safety feature.

Escaping the "Danger Zone"

The temperature range between 60°C and 10°C (140°F and 50°F) is the ideal environment for mold spores and other microbes to multiply. When a loaf of bread sits on a cooling rack, it can spend over an hour—sometimes two—slowly passing through this danger zone. This gives any microbes present on the bread a huge head start to grow and multiply. Vacuum cooling8 is so fast that the bread’s core temperature drops through this entire zone in just a few minutes. The microbes never get the warm, moist environment they need to get established. This is not a sterilization process; it is a "prevention" process.

The "Clean Label9" Advantage

Because you have so effectively inhibited the initial microbial growth, the product will simply last longer before it spoils. This allows you to achieve a longer shelf life10 without adding preservatives like sorbates or propionates. You can market your product with a "clean label," which is a powerful selling point for modern consumers. For a business owner like Carlos, this means he can supply large supermarket chains that have strict requirements for both shelf life and natural ingredients. It reduces waste, opens new markets, and improves your brand image simultaneously.

| Shelf Life Factor | Traditional Cooling | Vacuum Cooling | Benefit for Your Business |

|---|---|---|---|

| Time in Danger Zone | 1-2 Hours | < 5 Minutes | Massively inhibits initial mold & bacteria growth. |

| Resulting Shelf Life | Standard (e.g., 3-4 days) | Naturally Extended by 3-7 days | Reduces waste from stale returns, increases profitability. |

| Need for Preservatives | Often required for extended distribution. | Often eliminated. | Achieve a "Clean Label" to meet consumer demand. |

| Food Safety | Higher potential microbial load post-cooling. | More hygienic product, supports HACCP compliance. | Reduces risk and enhances your food safety program. |

How Does It Lower Your Bakery’s Operational Costs?

Beyond the product itself, running a bakery involves significant operational costs. You pay for every square foot of your facility. You pay for your staff’s time. You pay for the energy to run your equipment and keep your facility cool.

You may not realize it, but traditional cooling methods are secretly inflating all of these costs. The massive area required for racks is expensive, unproductive space. The time your staff spends moving racks is wasted labor. The heat radiating from hot bread drives up your energy bills.

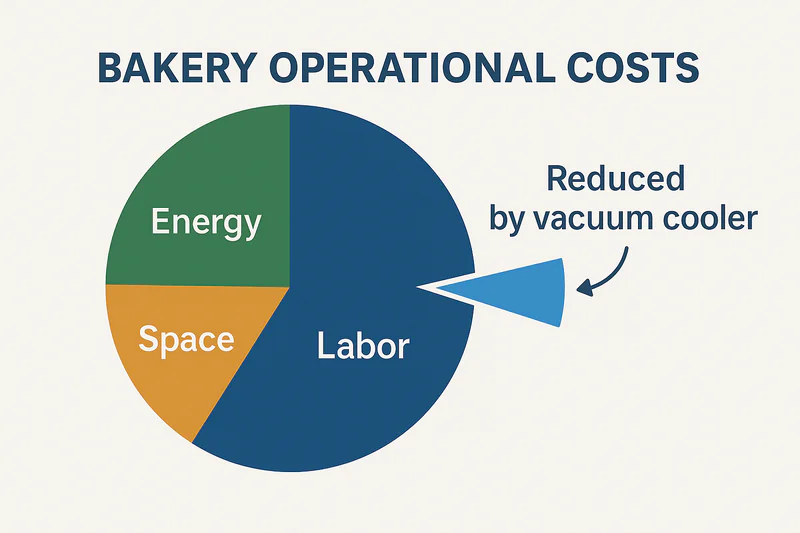

Vacuum cooling directly lowers your operational costs by freeing up huge amounts of valuable floor space, reducing unproductive labor hours, and cutting down on your facility’s energy consumption. It is a direct investment in a more lean and efficient operation.

The Hidden Savings of Efficiency

A savvy buyer like Norman is always looking for competitive prices, which means he appreciates suppliers who run a lean operation. Lowering your own costs allows you to be more competitive while maintaining healthy margins.

Space Savings = Financial Savings

A single vacuum cooler can replace 30, 40, or even more cooling racks. This can free up hundreds of square feet of floor space. You can calculate the cost per square foot of your facility lease and see this as a direct monthly saving. Better yet, you can repurpose that space for revenue-generating activities, like adding a new oven or packaging line. It transforms a cost center (storage) into a potential profit center (production).

Labor and Energy Efficiency

Think of the wasted motion in a traditional bakery. Staff are constantly pushing heavy, hot racks from the oven to the cooling area, and then to packaging. With vacuum cooling, that task is reduced to simply rolling a single trolley into a machine and pressing a button. This frees up your staff for higher-value work like quality control or sanitation. Furthermore, all that heat from the bread isn’t being radiated into your workspace for hours. This significantly reduces the load on your air conditioning system, leading to tangible savings on your monthly electricity bill, especially in warmer climates.

| Operational Cost | Traditional Cooling Method | Allcold Vacuum Cooling | Financial Impact |

|---|---|---|---|

| Floor Space | Very High. A massive "rack city". | Minimal. Up to 90% less space required. | Drastically lowers cost of unproductive space. |

| Labor | High. Staff wasted moving racks. | Low. Frees up labor for value-added tasks. | Improves productivity and reduces labor costs. |

| Energy (HVAC) | High. Radiates heat into the facility. | Low. Heat is contained and managed efficiently. | Reduces air conditioning load and lowers energy bills. |

| Maintenance | Racks are constantly being damaged and repaired. | A single, robust machine with low maintenance. | Lowers budget needed for repairs and replacements. |

Conclusion

The benefits are transformative. Vacuum cooling boosts your output, elevates your product quality, extends shelf life, and cuts your costs. It is the key to unlocking the full potential of your modern bakery, making you more efficient, profitable, and ready for growth.

-

Explore how Continuous Flow production can revolutionize your bakery operations and increase efficiency. ↩

-

Discover effective strategies to maximize ROI on your bakery equipment and boost profitability. ↩

-

Learn about the advantages of Vacuum Cooling and how it can enhance your baking process. ↩

-

Find out methods to significantly increase daily throughput in bakeries and improve overall productivity. ↩

-

Understanding gelatinization is key to mastering bread texture and quality, making this resource invaluable for bakers. ↩

-

Discover the secrets behind achieving a perfect crispy crust, essential for elevating your baking skills. ↩

-

Understanding HACCP standards is crucial for food safety and compliance, especially for businesses in the food industry. ↩

-

Learn how vacuum cooling technology can enhance food safety and extend shelf life, benefiting your business. ↩

-

Exploring the Clean Label concept can help businesses meet consumer demand for transparency and natural ingredients. ↩

-

Discover the key factors influencing shelf life to optimize your product offerings and reduce waste. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy