What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your reputation, and eat into your profits before your vegetables even leave the facility.

The best commercial vacuum cooler is defined by its core components, a simple operational process, clear maintenance needs, and reliable factory support. These factors deliver consistent performance and a strong return on investment.

I’ve spent years helping growers and processors find the perfect cooling solution. They all want the same thing: a machine that protects their harvest without causing headaches. Let’s break down the essential features that separate an average machine from the best possible investment for your business.

What core components define a reliable machine?

You see a stainless steel box, but its long-term performance comes from the parts inside. Choosing a machine with cheap components is a short-term saving that leads to long-term pain and costly downtime.

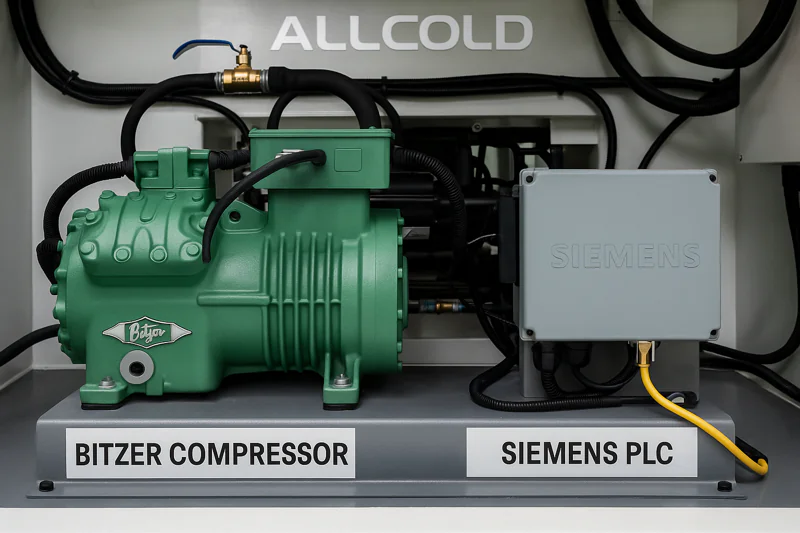

A top-tier vacuum cooler is built with world-class, brand-name components. Using parts from industry leaders like Bitzer (Germany) and Siemens (Germany) is the best indicator of a machine’s reliability and long service life.

Engineering for Peace of Mind

When I talk to professional buyers, the conversation always turns to component quality1. They know that the brand of the compressor or the PLC controller tells you a lot about the manufacturer’s commitment to quality. The heart of our cooler, the compressor, is from Bitzer in Germany, a brand known for its durability. The vacuum pump, which does the heavy lifting of lowering the pressure, is from Leybold, another German engineering leader.

The brain of the machine is just as important. That’s why we use Siemens for the touch screen, ensuring the operation is responsive and trouble-free. The electrical systems that manage the power safely use contactors from Schneider. Even supporting parts like the oil separator and expansion valve are sourced from respected brands like Frascold of Italy and Danfoss of Denmark. Using these premium, internationally recognized components isn’t the cheapest way to build a machine, but it’s the right way. It means you get a cooler that you can depend on, season after season.

| Component | Brand Used in Our Machines | Country of Origin |

|---|---|---|

| Compressor | Bitzer | Germany |

| Vacuum Pump | Leybold | Germany |

| Control System (PLC) | Siemens | Germany |

| AC Contactor | Schneider | Germany / France |

| Oil Separator | Frascold | Italy |

| Expansion Valve | Danfoss | Denmark |

How does a typical cooling cycle operate?

You need a machine that is powerful but also simple for your staff to operate safely and effectively. Complicated controls can lead to errors, inconsistent cooling, and lost time.

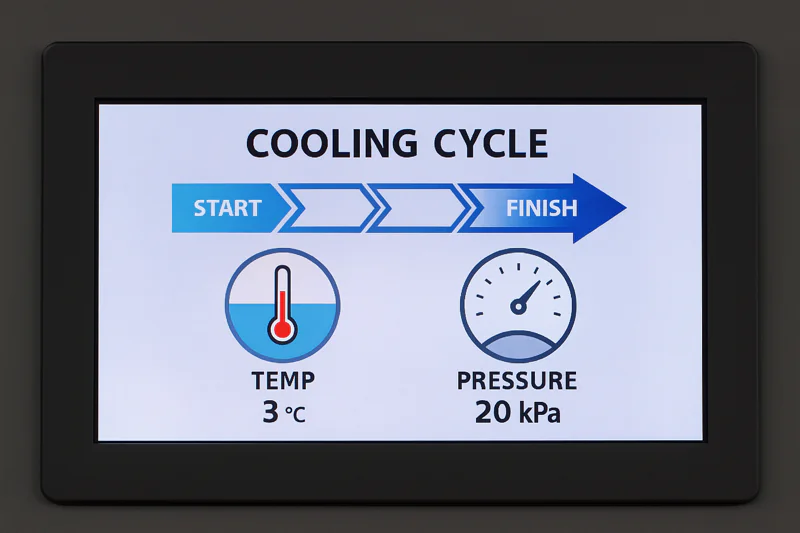

The cooling cycle is fully automatic. The operator presses ‘Start’ on the touch screen, and the machine runs the cooling process in sequence, stopping automatically when the target temperature is reached.

Automated for Simplicity and Consistency

I always emphasize to my clients how simple our machines are to use. We have designed the system so that achieving a perfect cooling result requires just one touch. Once the produce is loaded, your operator simply presses the ‘Start’ button on the Siemens touch screen2.

From there, the machine takes over completely. It automatically starts the necessary components in the correct order, including the vacuum pump and the refrigeration compressor. The system runs until the product reaches the target temperature you have set. At that point, the compressor and condenser fans stop automatically to save energy. The machine then begins the deflation process to bring the chamber back to normal pressure. As a final step to maintain the equipment, the vacuum pump3s continue running for a set period to remove any water from the pump oil, ensuring it’s ready for the next cycle. This level of automation means you get the same, consistent result every single time, regardless of who is operating the machine.

What routine maintenance keeps the cooler dependable?

To keep your investment running smoothly for years, you need a clear and manageable maintenance plan. Unexpected breakdowns are costly, but they can be avoided with simple, periodic checks.

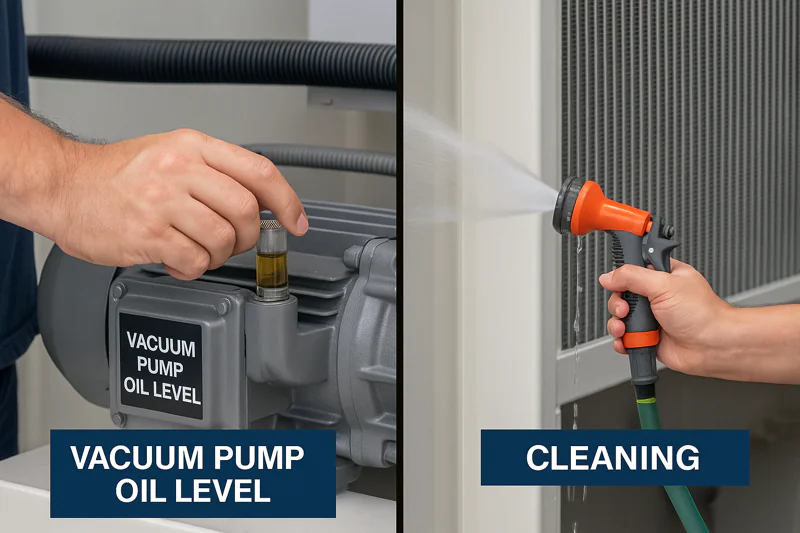

Dependability is maintained through straightforward, periodic checks. This includes a monthly inspection of the vacuum pump oil, an annual condenser cleaning, and changing the compressor oil every two years.

A Clear Schedule for Longevity

We design our machines not just for performance, but also for a long service life with easy maintenance. You don’t need to be a refrigeration expert to keep the machine in top condition. The routine tasks are very simple.

First, on a monthly basis, your operator should check the vacuum pump oil4. If the oil looks milky, it means it has emulsified with water and needs to be changed completely. Second, we suggest washing the condenser every year to keep it free of dust and debris, which ensures the refrigeration system runs efficiently. Third, the lubrication oil for the main Bitzer compressor5 should be changed by a professional every two years. Finally, for general cleanliness, we recommend an overall hygiene maintenance cleaning of the chamber every two seasons. Following this simple schedule will prevent most issues and ensure your machine remains a reliable asset for your business for years to come.

How can you ensure long-term support and warranty?

Buying a machine is a major investment. You need to know that the manufacturer will stand behind their product and provide help when you need it.

We provide a full 12-month guarantee on all our systems and back it up with a 24/7 technical support line. This ensures you have peace of mind and accessible help whenever you might need it.

A Partnership for the Long Haul

Your relationship with the manufacturer shouldn’t end after the machine is delivered. Lasting value comes from trust and dependable support. That’s why we provide a full 12-month / one-year guarantee6 on all our systems, starting from the B/L date or the date of installation. This covers the machine and its components, giving you confidence in your investment.

More importantly, we back it up with our technical support team. You can find our service line number and email in the machine’s manual and on our website. We know that problems don’t always happen during business hours, so we are here to help you diagnose any issues. This commitment to after-sales service7 ensures that your machine has minimal downtime and continues to be a productive part of your operation for many years to come. We don’t just sell you a machine; we build a long-term partnership.

Conclusion

The best vacuum cooler is a reliable, easy-to-use, and well-supported machine. It is an investment in quality components and a strong manufacturer partnership that protects your produce and your profits.

-

Understanding component quality is crucial for ensuring reliability and performance in engineering projects. ↩

-

Explore this link to understand how Siemens touch screens enhance user experience and operational efficiency. ↩

-

Learn about vacuum pumps and their crucial role in refrigeration systems for better performance and energy efficiency. ↩

-

Understanding the significance of vacuum pump oil maintenance can enhance your machine’s longevity and performance. ↩

-

Exploring maintenance tips for Bitzer compressors can help you ensure efficient operation and extend the life of your equipment. ↩

-

Understanding this guarantee can help you make informed decisions about your investments and ensure long-term support. ↩

-

Exploring this topic will reveal how after-sales service enhances customer satisfaction and product longevity. ↩

Mila

You May Also Like

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

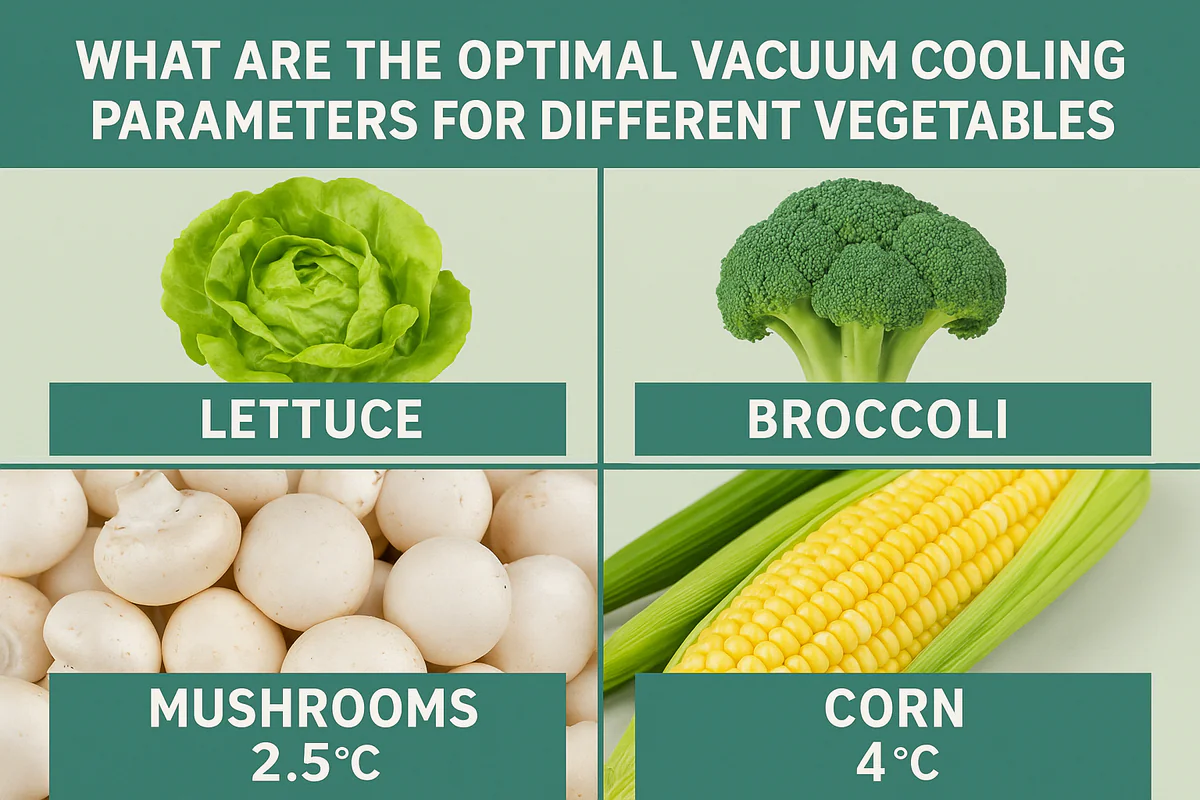

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

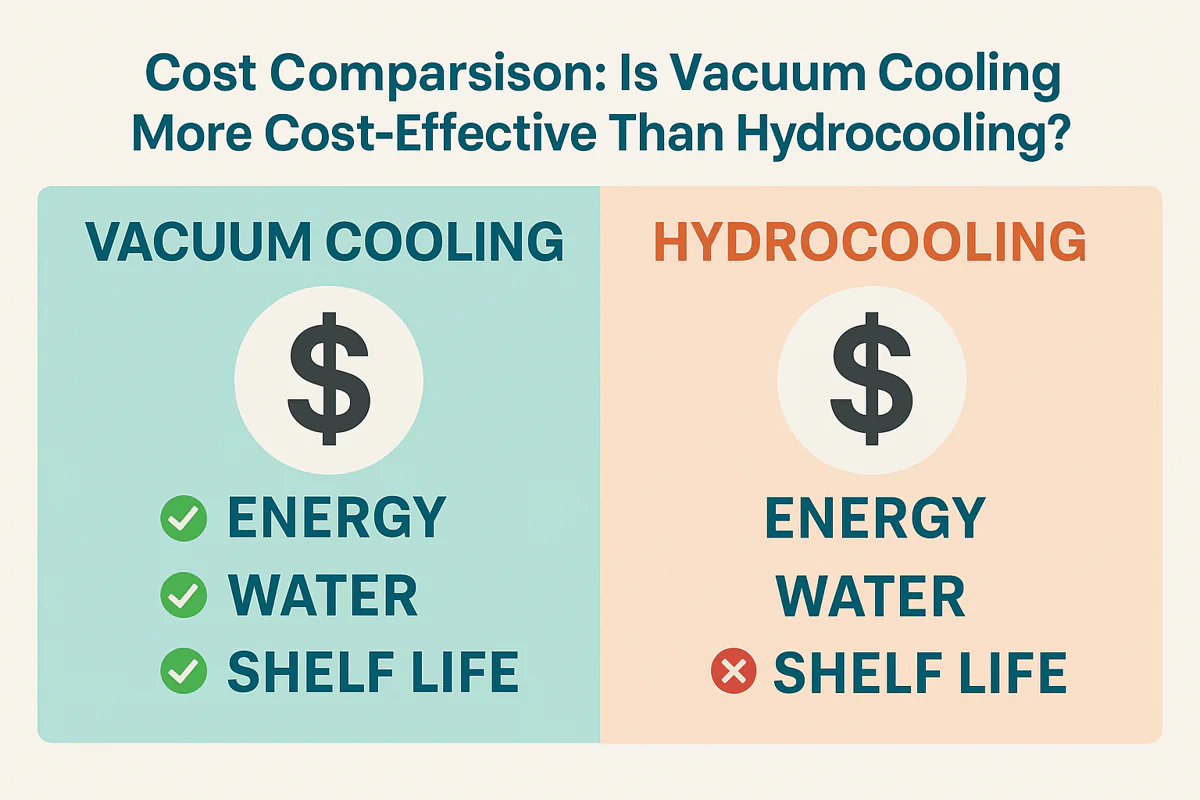

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are

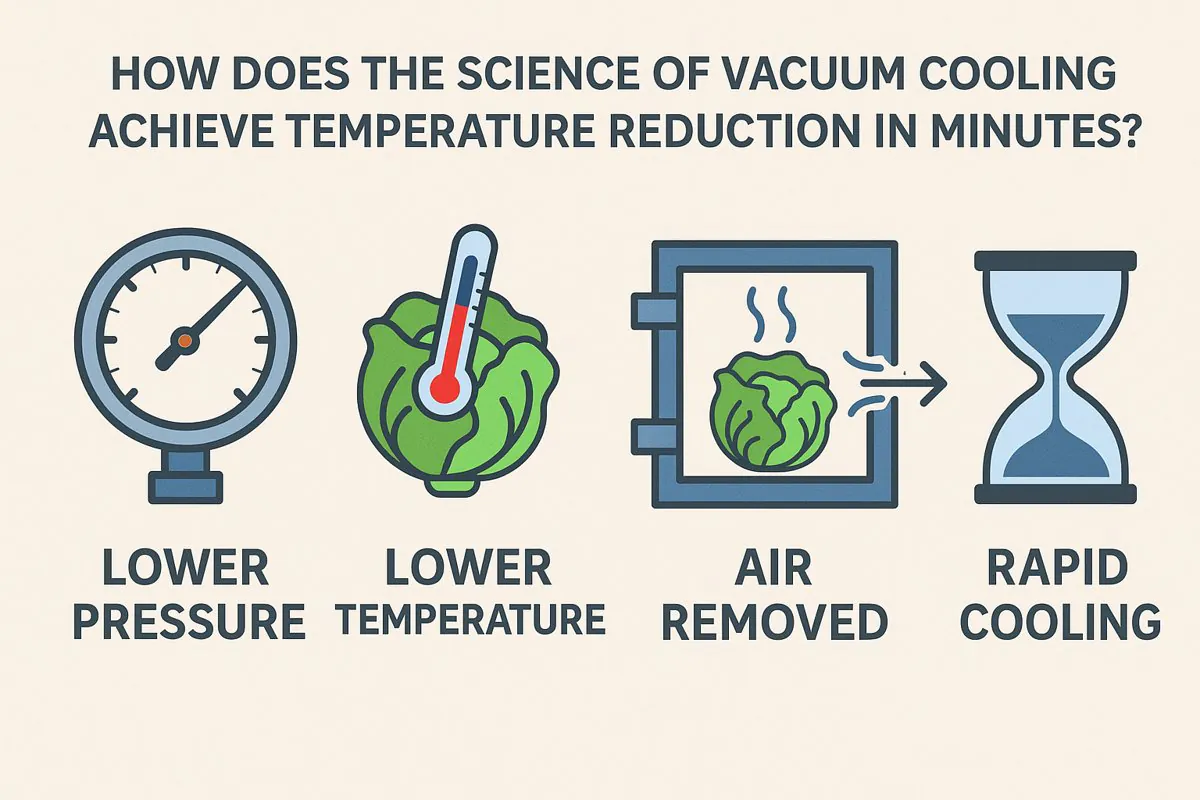

How Does the Science of Vacuum Cooling Achieve Temperature Reduction in Minutes?

You know that field heat is the enemy of fresh produce, but traditional cooling methods take hours to fight it,

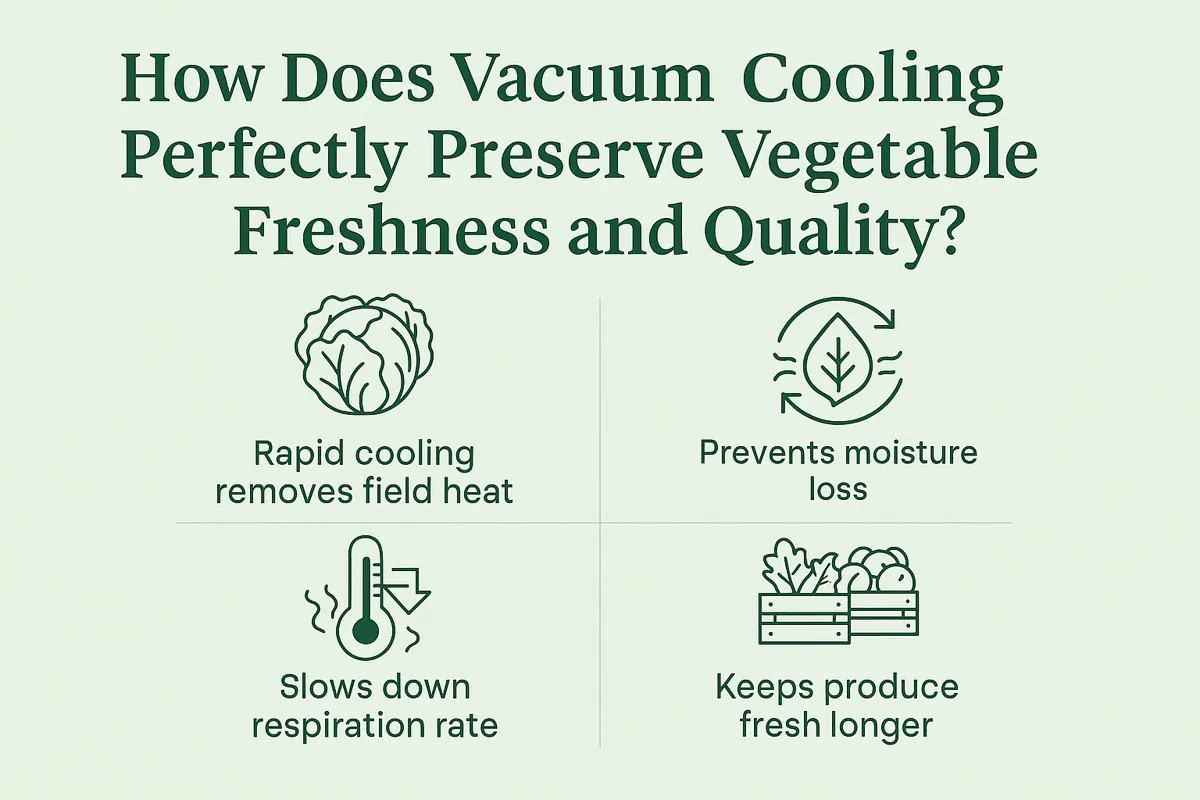

How Does Vacuum Cooling Perfectly Preserve Vegetable Freshness and Quality?

Your vegetables lose freshness with every minute they sit in a slow cooler. This lost time translates directly into lost

Vacuum Cooling vs. Traditional Cooling: Which is Better for Your Fresh Produce?

Your traditional cold room is slow. It takes hours to cool your fresh produce, and with every passing minute, field