Which Is Better for Your Vegetables: Vacuum Cooling or Forced-Air Cooling?

You know you need to remove field heat from your produce, but choosing the right method feels like a high-stakes decision. You’re looking at two primary technologies: vacuum cooling and forced-air cooling. Picking the wrong one can lead to operational bottlenecks, reduced product quality, and ultimately, lost profits.

This uncertainty is frustrating. You hear conflicting information, and the upfront cost of equipment makes you hesitant to make a move. You need a clear, honest comparison to understand which technology is not just a cost, but a strategic investment for your specific business.

Vacuum cooling is dramatically faster (under 30 minutes) and more uniform, making it the superior choice for high-surface-area produce like leafy greens. Forced-air cooling is a slower (3-12 hours), more versatile method suitable for a wider variety of produce, including dense items like apples or potatoes, but it comes at the cost of speed and efficiency.

I’ve spoken with hundreds of growers and processors, and this is one of the most common questions I get. The truth is, there isn’t one "best" answer for everyone. But by breaking down the comparison into the factors that matter most—speed, quality, operational impact, and cost—you can see which technology will deliver the best results for your products and your bottom line. Let’s dive in.

How Do They Compare on Cooling Speed?

The most immediate and dramatic difference between the two technologies is speed. But why does this speed matter so much? Because every minute your produce sits warm in the packing house is a minute it’s losing shelf life, freshness, and value.

Slow cooling creates a massive bottleneck. Your harvesting crews are fast, but your cooling process isn’t. This means pallets stack up, trucks wait, and your entire operation grinds to the pace of your slowest link. You’re paying for time that is actively working against your product quality.

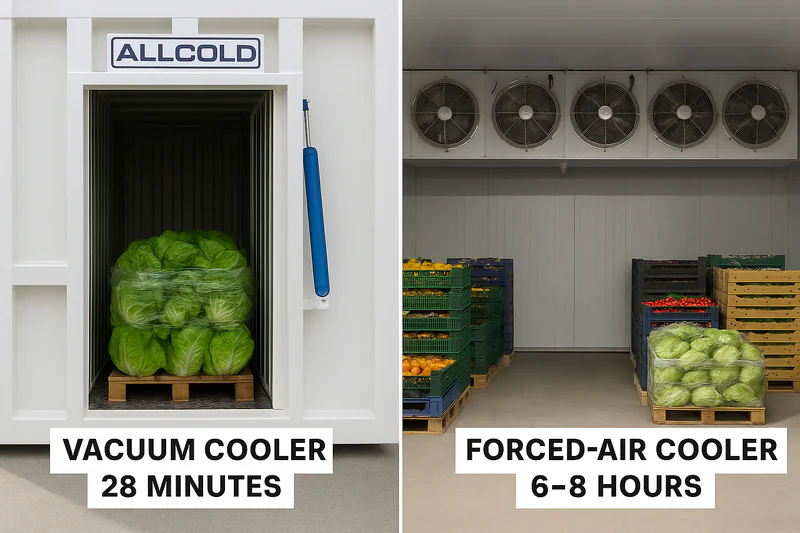

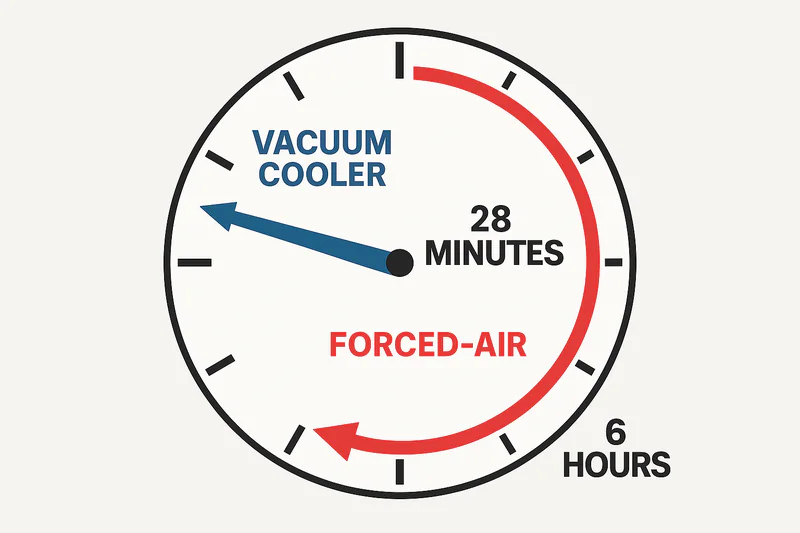

A vacuum cooler cools a pallet of lettuce from 30°C to 2°C (86°F to 36°F) in just 20-30 minutes. A forced-air cooler takes 4 to 10 hours to achieve a similar result. This is the single greatest operational difference between the two systems.

The Physics of Heat Removal

The reason for this incredible speed difference lies in the fundamental physics of how each system removes heat. For a hands-on owner like Carlos, understanding this "why" is key to trusting the technology.

How Forced-Air Cooling Works

Forced-air cooling is a process of convection1. It works by pulling cold air from a refrigeration unit and actively forcing it through the gaps in stacked pallets of produce. It’s like a very powerful, very cold wind. The system slowly removes heat from the outside of the product inward. This means the vegetables on the outside of the box cool first, while the produce in the center of the pallet can remain warm for hours. It’s a slow, steady, and often uneven process.

How Vacuum Cooling Works

Vacuum cooling, on the other hand, is a process of evaporation2. The machine seals a chamber and rapidly pumps out the air, lowering the atmospheric pressure. At a very low pressure, water boils at a very low temperature. The water on the surface of the vegetables begins to boil away, and this phase change from liquid to gas requires a massive amount of energy, which it pulls from the vegetable itself in the form of heat. This cools the entire product—inside and out—simultaneously and uniformly. Because it’s not waiting for cold to penetrate from the outside, the process is incredibly fast and predictable.

| Factor | Vacuum Cooling | Forced-Air Cooling |

|---|---|---|

| Mechanism | Phase Change (Evaporation) | Convection (Air Flow) |

| Typical Cycle Time3 | 20-30 Minutes | 4-10 Hours |

| Cooling Uniformity4 | Excellent (Entire product cools at once) | Poor to Fair (Outside cools much faster than inside) |

Which Method Better Preserves Product Quality and Shelf Life?

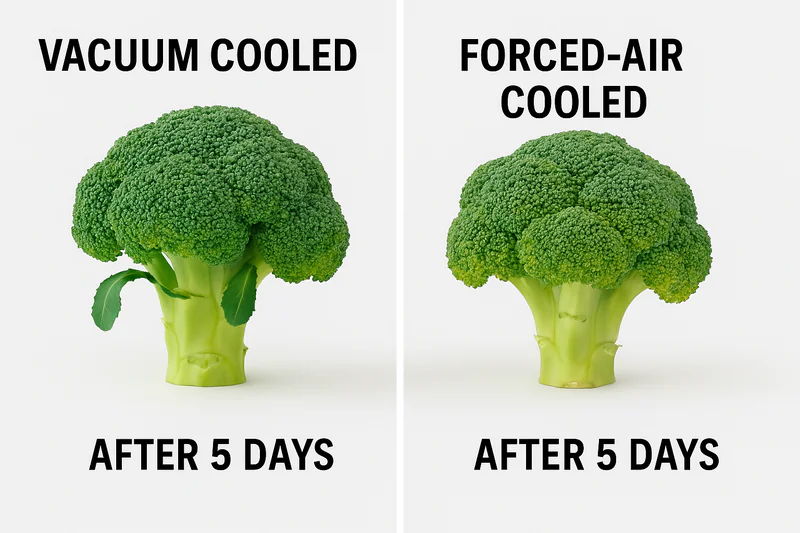

Speed is impressive, but the real goal of pre-cooling is to preserve the quality of your product and extend its marketable shelf life. A product that looks tired, wilted, or is already showing signs of decay upon arrival will be rejected by buyers or sold at a steep discount.

The "danger zone" for produce is the period right after harvest when field heat is accelerating respiration and microbial growth. Any cooling method that leaves your product in this danger zone for hours is actively reducing its value. It’s a race against time, and a slow start means you can never catch up.

Vacuum cooling’s rapid temperature drop immediately halts respiration and microbial growth, preserving the "just-picked" freshness, crispness, and color. The slower process of forced-air cooling allows for several hours of continued degradation, resulting in a shorter shelf life and potential quality loss.

The Biological Impact

For a quality-sensitive procurement manager like Sophia, consistency and a long code date are non-negotiable. She needs to know that the lettuce arriving at her central kitchen is as crisp and safe as possible.

Stopping Respiration and Wilting

A vegetable is still alive after harvest, and it respires—it breathes. This process burns sugars and moisture, causing the product to lose weight and become limp. Vacuum cooling5 brings the core temperature down so fast that this process is effectively put into hibernation mode within minutes. Forced-air cooling, by contrast, subjects the produce to hours of dry, moving air while it is still warm and respiring heavily. This can lead to significant moisture loss (dehydration), resulting in wilting and a lower salable weight. While vacuum cooling does cause a small, controlled moisture loss (around 1.5-2.5%), this is often less than the uncontrolled moisture loss from hours of respiration in a forced-air system.

Preventing Microbial Growth

Food safety is paramount. The bacteria and fungi that cause rot thrive in the warm, moist conditions of freshly harvested produce. A vacuum cooler plunges the temperature below the microbial growth threshold in minutes, giving these pathogens no time to establish themselves. A forced-air cooler leaves the product in the ideal temperature zone for bacterial growth for a significant period. For a HACCP-certified facility6 like Sophia’s, starting with the lowest possible microbial load is a massive advantage, reducing risks throughout her production line. The uniform cooling of the vacuum method ensures there are no "hot spots" in the center of the pallet where bacteria can multiply unnoticed.

| Quality Factor | Vacuum Cooling | Forced-Air Cooling |

|---|---|---|

| Shelf Life | Maximally Extended (e.g., Lettuce 14-21 days) | Moderately Extended (e.g., Lettuce 7-10 days) |

| Moisture Loss | Minimal and controlled | Can be significant and uncontrolled, causing wilting |

| Microbial Safety | Superior (Instant halt to growth) | Good (But allows a window for initial multiplication) |

What Is the Impact on Packing House Operations and Efficiency?

Your packing house should be a smooth, efficient production line, not a chaotic storage yard. The choice of cooling technology has a profound impact on your entire workflow, from labor allocation to the physical footprint of your facility.

A slow, unpredictable cooling process creates bottlenecks that ripple through your entire operation. It dictates your harvesting schedule, ties up valuable refrigerated space, and requires significant labor to manage and move pallets. It puts a hard cap on your daily throughput and your potential for growth.

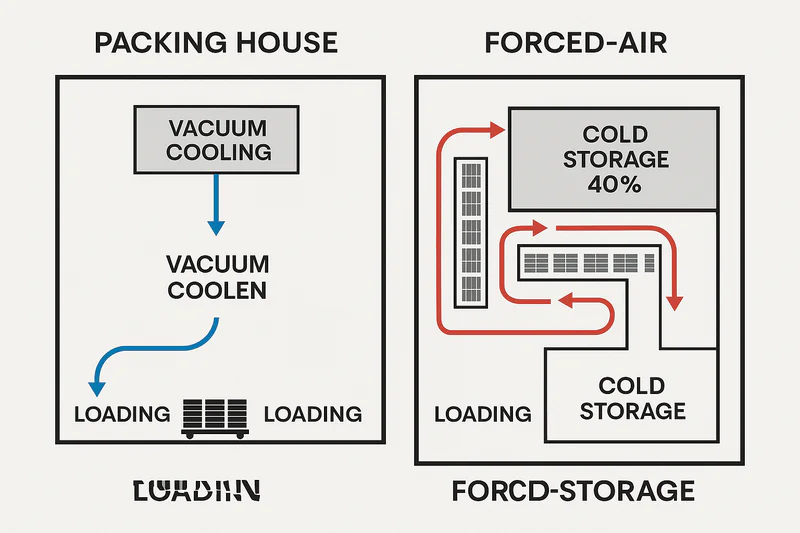

Vacuum cooling enables a "continuous flow" model, integrating seamlessly into a packing line with a small footprint and minimal labor. Forced-air cooling requires a "batch and wait" process, demanding a very large physical space and more labor to manage the inventory of cooling and cooled products.

Workflow, Labor, and Footprint

This is where the operational reality hits home for managers like Carlos and Sophia. They need a system that is predictable, lean, and scalable.

Workflow: Continuous Flow7 vs. Batch

With a vacuum cooler, a pallet is harvested, cooled in 28 minutes, and can be immediately loaded onto a truck or moved to a standard cold storage room. The cooling step is a quick, predictable part of the line. With forced-air, pallets are harvested and then must be staged in a large, specialized cooling room for many hours. This creates a disconnect. You end up with a huge amount of "work-in-progress" inventory, making first-in, first-out (FIFO) logistics difficult. It forces the entire operation to work in large, slow batches.

Labor and Footprint8

A forced-air cooler is essentially a very large, specialized room. It can occupy thousands of square feet. Managing it requires workers to shuttle pallets in, arrange them correctly for airflow, and then remove them hours later. A two-pallet vacuum cooler that can process 4 pallets per hour (over 90 pallets per day) has a footprint smaller than a car. It requires one worker to simply load a pallet, push a button, and unload it 28 minutes later. The labor and space savings are immense, especially for facilities in high-cost areas or those looking to maximize their processing capacity without expanding their building. For Sophia, whose central kitchen is likely in a dense urban area, a compact, automated system is far more practical.

| Operational Factor | Vacuum Cooling | Forced-Air Cooling9 |

|---|---|---|

| Workflow | Continuous Flow1 (In-line) | Batch Process (Requires staging) |

| Daily Throughput | High and predictable | Limited by room size and long cycle times |

| Footprint | Very Compact | Very Large |

| Labor | Low (simple load/unload) | High (Inventory management and pallet shuffling) |

What Is the True Cost Comparison and Return on Investment?

For any business owner, the final decision often comes down to money. It’s not just about the sticker price of the machine, but the total cost of ownership and, most importantly, the return on that investment (ROI).

Focusing only on the initial purchase price is a common mistake. It ignores the ongoing operational costs and, crucially, the revenue potential that each technology unlocks or fails to capture. A cheaper machine that costs you more in spoiled product, labor, and missed opportunities is the most expensive machine you can own.

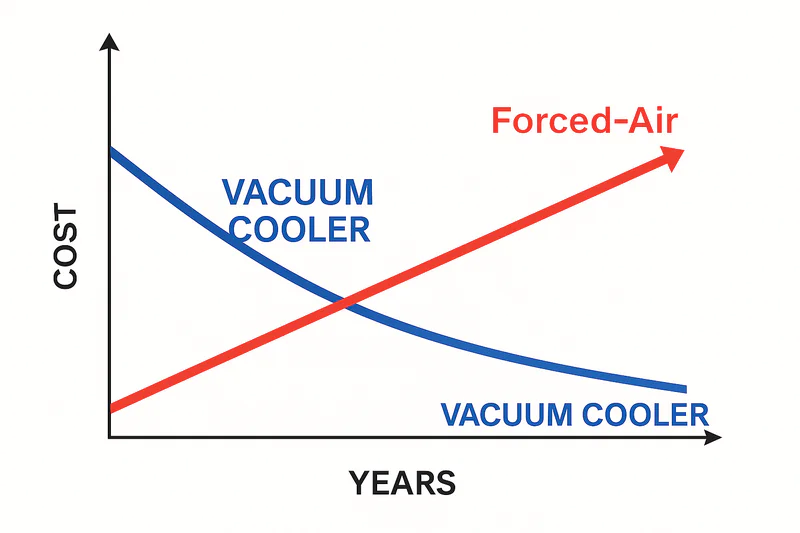

While forced-air systems have a lower initial capital cost, vacuum coolers often deliver a much faster and higher ROI. This is driven by significantly reduced product spoilage, lower labor costs, increased throughput, and the ability to command premium prices for higher quality produce.

A Financial Breakdown

This is the analysis that a professional buyer like Norman needs to see. It’s about moving beyond the price tag to the profit-and-loss impact.

Capital vs. Operating Costs

- Capital Expenditure (CapEx)10: Forced-air cooling is generally cheaper to install. It consists of a well-insulated room, fans, and refrigeration units. A vacuum cooler is a more complex piece of machinery (vacuum chamber, vacuum pumps, refrigeration system) and has a higher upfront cost.

- Operating Expenditure (OpEx): This is where the story changes.

- Energy: A vacuum cooler uses a lot of power for a very short time. A forced-air cooler uses less power per hour, but runs for 10-20 times as long. The total energy cost per pallet is often comparable or even lower for vacuum cooling.

- Labor: As discussed, the labor savings with a vacuum cooler’s automated process are significant and ongoing.

- Spoilage: This is the biggest factor. Reducing spoilage from 12% down to 3% (a common result) by using a vacuum cooler translates directly into saved revenue. For a medium-sized farm, this can be hundreds of thousands of dollars per year.

Return on Investment (ROI)11

The ROI for a vacuum cooler is built on tangible gains. Let’s say Norman is sourcing from a supplier who invests in one. That supplier can now reduce their spoilage losses, require less labor, and ship higher quality produce that justifies a 10% price premium. They can also now ship to more distant, higher-value markets. When you add up these financial gains—less waste, lower labor, higher price—the initial investment in the vacuum cooler is often paid back in under 24 months, after which it becomes a pure profit-generating machine. Norman knows that a supplier with this technology is more reliable and provides a better product.

Conclusion

For leafy greens and high-value, high-respiration produce, the vacuum cooler is the clear winner in speed, quality preservation, and operational efficiency. While forced-air cooling has its place, the ROI and competitive advantages offered by vacuum cooling are simply transformative for the right products.

-

Understanding convection is crucial for grasping how forced-air cooling effectively removes heat. ↩ ↩

-

Exploring evaporation in vacuum cooling reveals the science behind its rapid and uniform cooling process. ↩

-

Knowing the typical cycle time for vacuum cooling can aid in efficient planning for food storage and distribution. ↩

-

Learning about cooling uniformity helps in selecting the best cooling method for preserving produce. ↩

-

Explore the advantages of vacuum cooling, which can significantly enhance the shelf life and quality of your produce. ↩

-

Discover the significance of HACCP certification in ensuring food safety and quality in production environments. ↩

-

Explore how Continuous Flow can enhance efficiency and reduce waste in your operations. ↩

-

Understanding Labor and Footprint can help optimize your facility’s layout and workforce management. ↩

-

Discover the limitations of Forced-Air Cooling to make informed decisions for your cooling needs. ↩

-

Understanding CapEx can help you make informed investment decisions and optimize your financial strategy. ↩

-

Learning about ROI calculation is crucial for evaluating the profitability of your investments and making better financial choices. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But