Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is right for your specific crops. Investing in a vacuum cooler is a major decision, and you can’t afford to get it wrong by choosing a solution that doesn’t match what you grow.

Vegetables with a high surface-area-to-mass ratio are the absolute best candidates for vacuum cooling. This means leafy greens, broccoli, cauliflower, mushrooms, celery, and even sweet corn cool incredibly fast, providing the maximum return on investment and dramatic quality improvements.

This is one of the first questions I get from potential clients, and it’s the most important one. I remember speaking with a large-scale farmer in Mexico, Carlos, who was losing a significant portion of his lettuce harvest to spoilage before it even reached the distributors. He was using traditional cold rooms, but the lettuce would sit for hours, slowly cooling from the outside in, while the core stayed warm and continued to decompose. I explained that for a product like lettuce, with all its surface area, a vacuum cooler isn’t just a little better—it’s a complete game-changer. Within 25 minutes, it pulls the heat out from every single leaf at the same time. After installing one of our systems, he was able to extend the shelf life of his lettuce by an extra 7 to 10 days. That wasn’t just an improvement; it was a revolution for his entire business model, opening up new, more distant markets he couldn’t service before.

Why Do Some Vegetables Cool Better Than Others?

It seems strange that a powerful machine could work perfectly for one vegetable but be completely ineffective for another. You might think that cooling is just cooling, but you suspect there’s a deeper scientific reason behind it, and understanding it is key to making a smart decision that impacts your bottom line.

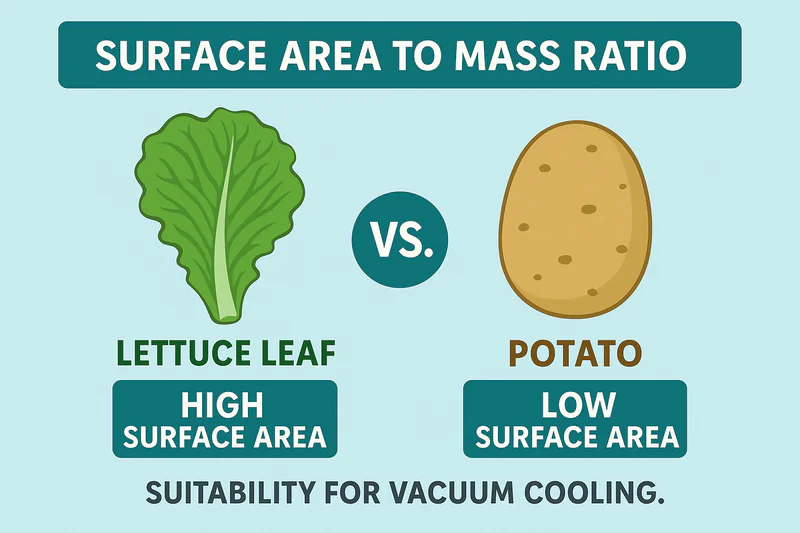

It’s all about physics: vacuum cooling works by making water evaporate, and this process is most effective on vegetables that can release water vapor easily. The key factor is a high ratio of surface area to total weight.

The Science of Evaporation

Imagine you have two wet towels. You leave one rolled up in a tight ball, and you spread the other one out flat. Which one will dry faster? The one spread out flat, of course. It has a much larger surface area exposed to the air, allowing water to evaporate quickly. Vacuum cooling operates on the exact same principle, but it accelerates the process dramatically. Inside the vacuum chamber, we lower the atmospheric pressure. This reduces the boiling point of water. At a very low pressure (around 6 to 8 millibars), the water on and inside the vegetables begins to boil at just 2°C or 3°C. This "cold boiling" requires a lot of energy, specifically thermal energy, which we call the latent heat of vaporization1. The process gets this energy by pulling heat directly from the vegetable itself. It’s like sweating for vegetables, but supercharged.

For this process to work efficiently, the water vapor must be able to escape.

- High Surface Area-to-Mass Ratio2: This is the most critical trait. A head of lettuce is a perfect example. It’s mostly leaves, with a massive amount of surface area for its relatively low weight. This allows water vapor to escape from everywhere at once, resulting in incredibly fast and uniform cooling.

- Low-Density Structure3: A product with a porous or open structure, like a mushroom or broccoli florets, allows water vapor to travel from the core to the surface with little resistance.

- Poor Candidates: Now consider a dense, solid vegetable like a potato or a carrot. They have a very low surface area for their weight, and their skin acts as a barrier. The water trapped deep inside simply cannot escape to evaporate. Trying to vacuum cool a potato is like trying to dry that tightly rolled-up wet towel—it’s incredibly inefficient and simply doesn’t work. For a buyer like Norman, who is extremely sensitive to quality control, understanding this principle is crucial for sourcing. It helps him identify suppliers who are using the right post-harvest technology4 for the right products, guaranteeing the quality he expects.

| Product Characteristic | Ideal for Vacuum Cooling | Poor for Vacuum Cooling | Example |

|---|---|---|---|

| Surface Area-to-Mass | Very High | Very Low | Lettuce vs. Potato |

| Product Density | Low / Porous | High / Solid | Mushroom vs. Carrot |

| Outer Skin | Thin / Permeable | Thick / Waxy | Spinach vs. Cucumber |

| Water Content | High | High | Celery vs. Sweet Potato |

| Structure | Leafy / Fibrous | Dense / Compact | Kale vs. Beetroot |

Leafy Greens: The Undisputed Champions of Vacuum Cooling?

You’re a large-scale grower of lettuce, spinach, and other greens. Your biggest challenge is the "cold chain clock" that starts ticking the second you harvest. You need to remove field heat as fast as possible, and you’re wondering if this is the technology that can finally win you that race.

Yes, without a doubt. Leafy greens are the perfect candidates. Their physical structure seems almost designed for vacuum cooling, allowing them to be cooled from 30°C to 2°C in as little as 15-25 minutes, a feat no other technology can match.

A Perfect Match for Structure and Speed

For produce like iceberg lettuce, romaine, spinach, and kale, vacuum cooling isn’t just an improvement; it’s the ideal technology. The benefits go far beyond just speed. Traditional cooling methods, like a walk-in cold room, cool produce from the outside in. This is a slow process that can take 8-12 hours for a full pallet. During this time, the warm core of the product continues to respire at a high rate, burning sugars, losing weight, and allowing bacteria to multiply. This is the primary cause of spoilage and reduced shelf life. Vacuum cooling turns this concept on its head. Because it works by evaporating moisture from every part of the product simultaneously, it cools the dense core and the outer leaves at the very same rate.

This uniform cooling5 is the secret to its success. It immediately shuts down the respiration process, preserving the texture, color, and nutritional value of the greens. For a central kitchen manager like Sophia, this means getting produce that meets strict HACCP standards6 by moving through the temperature danger zone in minutes, not hours. For a supermarket supplier, it means a longer shelf life, less waste, and a more visually appealing product on the shelf. The process is so effective that it can even add an extra 7-10 days of saleable life to the product, which is a massive financial benefit. Furthermore, the small amount of water loss (typically 1-3%) is known as "nature’s shrink-wrap," as it slightly wilts the outer leaves, making them more pliable and resistant to damage during packing and transport. It’s a win-win: faster cooling and a more durable product.

Cruciferous Vegetables: A Surprising and Powerful Application?

You grow broccoli and cauliflower, which are much denser than lettuce. You’ve heard vacuum cooling might not work for dense products, and you’re worried about making a bad investment. You need to know if it’s truly effective for your crops.

Absolutely. While denser than leafy greens, cruciferous vegetables like broccoli, cauliflower, and even cabbage are excellent candidates, especially when using the hydro-vac (pre-wetting) technique. This ensures thorough and rapid cooling.

Overcoming Density with a Simple Trick

It’s true that the dense heads of broccoli and cauliflower present a slightly different challenge than leafy greens. The water vapor from the core has a tougher journey to escape. If you try to cool a pallet of dry-harvested broccoli, you may find that the outer florets get cold while the inner core and thick stems remain warm. This temperature difference is a breeding ground for spoilage and is a major quality red flag. The solution is elegant and simple: we add water. This technique, called hydro-vacuum cooling7, involves lightly spraying the entire pallet with a fine mist of clean water right before it enters the vacuum chamber. We are not drenching the product, just adding about 1-2% of its total weight in water.

This added surface moisture does two critical things. First, it provides a ready source of "free" water that evaporates instantly when the vacuum is pulled, providing a powerful initial cooling effect on the surface. Second, and more importantly, this rapid surface chilling creates a significant temperature difference between the outside and the inside of the broccoli head. This temperature gradient8 actively helps to draw the trapped heat out from the core, allowing it to be removed by the system. By using this technique, we can achieve perfectly uniform cooling from floret to stem in about 25-35 minutes. It’s a simple, extra step that makes a world of difference, ensuring a premium-quality product with an extended shelf life. For growers of organic produce, this is especially important as it rapidly halts any insect activity without the use of chemicals.

Delicate Fungi: How Can You Vacuum Cool Mushrooms without Damage?

You’re a mushroom grower. Your product is high-value but incredibly delicate and susceptible to browning and weight loss. You’re intrigued by the speed of vacuum cooling but terrified that the powerful process could damage your fragile crop.

Mushrooms are an ideal, high-value candidate for vacuum cooling. Modern coolers with precise pressure control are specifically designed to cool them gently, stopping enzymatic browning in its tracks without causing any physical damage.

Speed, Precision, and Profitability

Mushrooms are over 90% water and have an extremely high respiration rate after harvesting. This is what causes them to turn brown, lose texture, and spoil so quickly. Getting their core temperature down to 2-3°C as fast as humanly possible is the single most important factor in preserving their quality and market value. This is where vacuum cooling excels. However, you are right to be cautious. The delicate structure of a mushroom can be damaged by a sudden, violent drop in pressure. This is why you cannot use a basic, old-fashioned vacuum cooler. You need a modern machine with sophisticated controls.

Our ALLCOLD systems, for instance, use a Siemens PLC and high-precision German-made pressure sensors. This allows us to program a special "mushroom cycle" with a feature called "soft-venting" or "ramp control." Instead of opening the vacuum pump’s valve fully, the PLC opens it gradually, lowering the pressure in a slow, controlled ramp over several minutes. This allows the water vapor to escape gently, preventing any cellular damage or bruising. This precise control allows us to cool a full pallet of mushrooms in about 20 minutes, a process that might take 10 hours in a conventional cold room. The result is a visibly whiter, firmer mushroom with a significantly longer shelf life, solving the biggest pain point for growers and processors in this industry and allowing them to command a premium price for a superior product.

What About Other Stars Like Celery and Sweet Corn?

Your farm grows a variety of produce, not just leafy greens. You need a versatile solution and want to know what other crops can benefit from this investment. You’re particularly interested in crops where freshness and sweetness are key selling points.

Absolutely. Vegetables like celery and sweet corn are also fantastic candidates. Celery stays crisper due to its high water content and fibrous structure, while sweet corn retains its sweetness thanks to rapid hydro-vac cooling.

The Crispness Factor: Celery

Celery’s value is all in its texture—that satisfying crunch. This crunch comes from turgor pressure, which is essentially the water pressure inside the plant’s cells. After harvest, as celery loses moisture and sits in the field heat, this pressure drops, and the stalks become limp and rubbery. Because celery has a very high water content and a fibrous structure that allows moisture to move easily, it responds exceptionally well to vacuum cooling9. The process cools it down so quickly (in about 25 minutes) that the cellular respiration and water loss are halted almost instantly. This locks in the turgor pressure10, keeping the celery crisp, fresh, and marketable for much longer.

The Sweetness Factor: Sweet Corn

For sweet corn, the enemy is time. The moment it’s picked, the natural sugars inside the kernels begin to convert into starch. This is why corn that’s a day old tastes bland and starchy compared to corn that’s fresh off the stalk. The key to preserving that sweetness is to drop the temperature immediately. Sweet corn, especially when pre-wetted, is a perfect fit for hydro-vac cooling. The water on the husks and silks provides the moisture for evaporation, rapidly chilling the entire cob, including the core. This process stops the sugar-to-starch conversion in its tracks. Growers who use vacuum cooling can deliver corn to the market that tastes like it was just picked, giving them a significant quality advantage over competitors using slower cooling methods.

Which Vegetables Are a Poor Fit for Vacuum Cooling?

You’re considering this technology, but you’re a practical business owner. Just as important as knowing what works is knowing what doesn’t. You don’t want to invest in a machine only to find it’s useless for half of your crops.

This is a critical point. Vacuum cooling is a specialized tool, not a universal solution. It is highly ineffective for dense, solid produce with a low surface area and a thick, waxy skin that acts as a vapor barrier.

The Science of Why It Doesn’t Work

Understanding the limitations is key to making a smart investment. Attempting to cool unsuitable produce will, at best, be a waste of time and energy and, at worst, could even slightly damage the product.

The Density Barrier: Root Vegetables

Vegetables that grow underground, like potatoes, carrots, sweet potatoes, and beets, are the worst possible candidates. They have an extremely low surface-area-to-mass ratio. They are thick, solid, and dense. The small amount of water that evaporates from their surface has a negligible effect on the internal temperature. The heat remains trapped deep inside the core. For these products, traditional methods like hydro-cooling (using chilled water) or simple refrigerated air are far more effective.

The Vapor Shield: Waxy-Skinned Produce

Many other popular vegetables are also poor fits because their skin acts like a raincoat, trapping moisture inside. This group includes cucumbers, tomatoes, bell peppers, zucchini, and eggplant. Their waxy, non-porous skin prevents water from evaporating, rendering the vacuum cooling process useless. You could run a cycle for an hour and the internal temperature would barely drop. It is always my policy to be completely transparent about this with clients. My goal is to sell you a solution that makes your business more profitable, not a machine that doesn’t fit your needs.

Conclusion

The secret to vacuum cooling’s success lies in the vegetable’s structure. High surface area is king. Leafy, light, and porous vegetables are the champions of this technology. By understanding not only what works, but also what doesn’t, you can confidently determine if this is the right investment to revolutionize your post-harvest process, enhance your product quality, and unlock new levels of profitability.

-

Learn about this essential energy concept that drives efficient cooling in various applications. ↩

-

Understanding this concept is key to optimizing vacuum cooling processes and improving food preservation. ↩

-

Explore how low-density structures enhance vapor escape, crucial for effective cooling in food technology. ↩

-

Stay updated on innovations that ensure quality and freshness in the food supply chain. ↩

-

Explore how uniform cooling enhances food preservation, ensuring freshness and quality for longer periods. ↩

-

Learn about HACCP standards to understand how they ensure food safety and quality in the supply chain. ↩

-

Explore this link to understand the science behind hydro-vacuum cooling and its benefits for preserving produce quality. ↩

-

Learn about the role of temperature gradients in cooling processes and how they enhance the freshness of fruits and vegetables. ↩

-

Exploring vacuum cooling reveals innovative methods to keep produce fresh, enhancing quality and marketability. ↩

-

Understanding turgor pressure is crucial for grasping how plant textures, like celery’s crunch, are maintained. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not