Why Are Commercial Bakeries Worldwide Racing to Adopt Vacuum Cooling?

You watch your competitors deliver fresher bread faster while you are still stuck waiting for racks to cool in the hallway. You feel the pressure of rising energy costs and strict delivery deadlines, knowing that your traditional cooling method is the bottleneck slowing down your entire business.

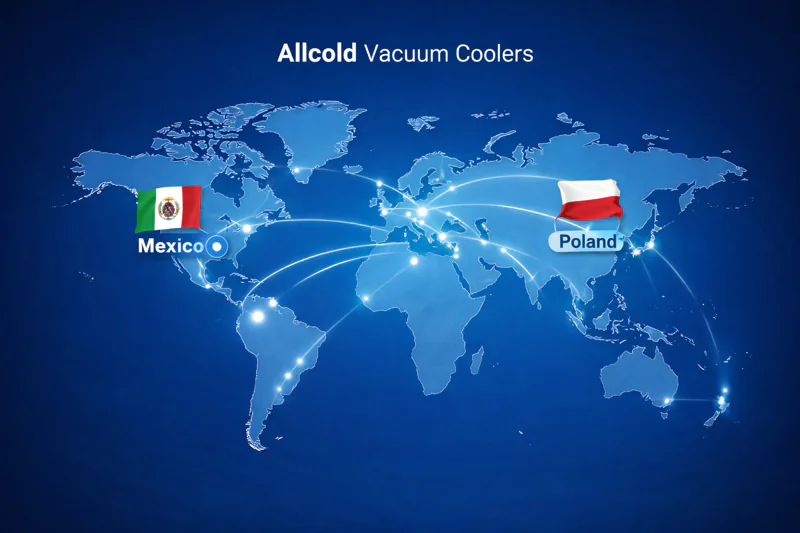

Bakeries from Mexico to Poland are adopting vacuum cooling because it slashes cooling times while securing quality. With systems capable of handling 150kg to 200kg per cycle and designed for ambient temperatures up to +52°C, this technology is transforming from a luxury to a necessity for high-volume production.

I have been working with clients across different continents, from the heat of Mexico to the busy industrial hubs of Europe. In the past, vacuum cooling was seen as a luxury experiment. Today, it is becoming a standard requirement for high-volume production. When I look at our recent orders—whether it is for Dr. Baker in the bakery sector or food processors in Eastern Europe—I see a clear pattern. Owners are no longer asking "what is this?"; they are asking "how fast can I install it?". Let’s dive into the specific technical reasons driving this global adoption trend.

Is Speed the Only Reason for the Global Shift?

You might think that saving time is the only benefit, but you worry that speed comes at the cost of quality. You fear that rapid cooling will dry out your bread or ruin the texture you worked so hard to perfect.

Recent data from our European projects shows that a single trolley system can process massive loads per cycle, bringing temperatures down to safe packing levels instantly. This throughput matches the high-speed demands of modern industrial ovens, ensuring no bottleneck exists.

The Business Case for Speed and Capacity

When we analyze the adoption rates, we have to look at the "Cycle Time1." In traditional baking, cooling is dead time. It uses space, it uses air conditioning energy, and it delays revenue. In our recent project in Poland, the requirement was very specific: handle a processing capacity of 150kgs per cycle (1 Trolley).

In a standard room, cooling this amount of dense product takes hours. With our AVCF-1502 model, the system is engineered with a powerful 5.5kW vacuum pump and a 13.6kW compressor to handle this load efficiently. The target is to reach a finished temperature of +28°C or even lower, which allows for immediate slicing. This isn’t just about speed; it’s about matching your cooling speed to your baking speed. The "Dr. Baker" project is another prime example where adoption is driven by the need for reliable, plug-in-ready solutions. The vacuum chamber size is optimized to fit standard trolleys without wasting energy on empty space. By reducing the cooling window, bakeries also reduce the time bacteria have to grow, making the product safer and extending its shelf life significantly.

| Feature | Specification (European Case) | Impact on Adoption |

|---|---|---|

| Model | AVCF-150 | Optimized for single trolley workflow. |

| Capacity | 150kg / Cycle | Matches industrial oven output rates. |

| End Temp | +28°C | Reaches slicing temp instantly. |

| Power | 5.5kW Pump / 13.6kW Comp | High power for rapid pressure drop. |

Can This Technology Survive in Hot Climates like Mexico?

You operate in a region with scorching summers, and you are terrified that sensitive European-style machinery will overheat and fail. You cannot afford equipment that trips its safety breakers every time the afternoon sun hits your factory roof.

Adoption is rising in hot regions because we engineer for them. Our systems are designed to operate in maximum ambient temperatures of +45°C to +52°C. We use high-efficiency air-cooled condensers that allow the machine to run smoothly even during a heatwave.

Engineering for Extreme Environments

One of the biggest barriers to adoption in the past was reliability in hot climates. A machine designed for a cool German autumn will often fail in a Mexican summer. That is why we changed our standard. In our specifications for Mexico and other hot regions, we explicitly calculate the condensing temperature at +45°C, and our manuals warn users about residual gas pressure hazards, indicating robust sealing and pressure management even in extreme conditions.

This robust design is the reason we are seeing more clients in Latin America. We don’t just hope the machine survives; we build it to thrive. We use Bitzer compressors3 which are the industry standard for heavy-duty reliability. But we also include smart energy features4. When the vacuum cooler has not been operated for a period of time, the machine will stop running to save electricity, but it is ready to restart instantly via the Siemens Touch Screen. This combination of heavy-duty heat resistance and smart energy management makes the switch to vacuum cooling a safe financial decision for bakeries in warm regions.

| Climate Feature | Specification | Why it Drives Adoption |

|---|---|---|

| Condensing Temp | +45°C | Reliable in hot countries (Mexico/Middle East). |

| Compressor | Bitzer (Germany) | Proven durability under heavy load. |

| Phase Protection | Carlo Gavazzi (Swiss) | Protects against unstable grid power. |

| Controls | Siemens PLC | Stable operation in humid kitchens. |

Do You Need a PhD to Fix It If It Breaks?

You hesitate to buy advanced tech because you fear being dependent on a distant supplier for repairs. You worry that if a single part fails, your local mechanic won’t know how to fix it, leaving you stranded.

We drive global adoption by using universal, top-tier components. With parts from Bitzer, Siemens, Schneider, and Danfoss, any local engineer can service our machines. Plus, our systems are "plug-in ready," making installation as simple as connecting the power.

The "Universal Repair" Strategy

Why do bakery owners feel safe buying from China? Because they recognize the names inside the cabinet. We don’t hide obscure parts behind a locked panel. We proudly list our detailed Part List in our quotations. We use Siemens Touch Screens from Germany for the interface. We use Schneider AC Contactors and Relays5 from Germany for the electrics. We use Danfoss Expansion Valves6 from Denmark.

This "All-Star" component list removes the fear of adoption. If a relay burns out in five years, you don’t need to ship a part from us across the ocean; you can buy a Schneider relay at your local electrical supply store. Furthermore, we make the start-up easy. Our systems are delivered on a "plug-in ready and well piped basis." This means you don’t need a complex engineering project to get started. We also back this up with a 12-month guarantee from the installation date, and we provide 24/7 phone assistance. This support structure makes the technology accessible to family-owned bakeries, not just giant corporations.

| Component | Brand | Origin | Advantage for the Client |

|---|---|---|---|

| Vacuum Pump | Leybold | Germany | High performance and easy to service globally. |

| Emergency Stop | Schneider | Germany | Safety standard compliance. |

| Oil Separator | Frascold | Italy | Ensures long-term pump health. |

| Liquid Receiver | Frascold | Italy | Stable refrigerant flow. |

Is Maintenance Too Complex for Your Daily Staff?

You worry that your staff will neglect the machine, leading to expensive failures. You have heard horror stories about "milky oil" destroying vacuum pumps and fear adding a high-maintenance diva to your production line.

We simplified maintenance to ensure longevity. Our "Water Scraping" protocol removes moisture from the pump oil to prevent damage. Simple visual checks of the oil level ensure your team can easily keep the machine in top condition without advanced degrees.

Hygiene and Protocol

Adoption fails when machines are too hard to take care of. In the bakery world, moisture is the enemy. Bread releases steam, and steam kills vacuum pump oil. To solve this, we integrated a mandatory discipline into the machine’s logic. As detailed in our Manual Book, maintenance isn’t a suggestion; it’s a process. We require regular cleaning of the air condenser7 and consistent oil checks for the vacuum pump.

Specifically, preventing the oil from turning "milky" (emulsified) is key. We instruct users to check the oil level through the observation spot and ensure it is not contaminated. We also advise on regular maintenance such as checking the electricity cabinet and ensuring the refrigerant levels are sufficient. By clarifying these steps in the manual—and using clear alarm screens on the Siemens interface to notify of faults—we empower your staff to own the machine. It is not mysterious magic; it is a manageable asset. This clarity allows bakeries to adopt the tech without hiring specialized engineers for daily operations.

| Task | Component | Purpose |

|---|---|---|

| Oiling | Vacuum Pump | Prevent seizure and maintain seal. |

| Cleaning | Air Condenser | Maintain cooling efficiency in heat. |

| Monitoring | Alarm Screen | Immediate fault detection. |

| Power Check | Main Connection | Ensure 3-phase stability. |

Conclusion

The rise in vacuum cooling adoption across bakeries is driven by the undeniable production speed of processing hundreds of kilograms per cycle, supported by a global supply chain of trusted parts like Bitzer and Siemens. With systems designed for +45°C condensing temperatures and clear maintenance protocols, Allcold makes high-tech cooling a safe, standard choice for bakeries worldwide.

-

Understanding Cycle Time is crucial for optimizing baking processes and improving efficiency in production. ↩

-

Exploring the AVCF-150 will reveal how advanced cooling technology can enhance bakery operations and product quality. ↩

-

Explore how Bitzer compressors ensure reliability and efficiency in challenging climates, making them a top choice for heavy-duty applications. ↩

-

Learn about the advantages of smart energy features in reducing costs and enhancing performance, especially in warm regions. ↩

-

Explore this link to understand how Schneider components enhance safety and reliability in bakery operations. ↩

-

Learn about Danfoss Expansion Valves to see how they ensure efficient refrigerant flow in your bakery’s cooling systems. ↩

-

Exploring the role of air condensers can enhance your knowledge of maintaining optimal cooling efficiency in bakery machinery. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy