Why Are Root Vegetables Like Carrots and Potatoes So Tricky to Cool Quickly?

Struggling to get your carrots or potatoes chilled to the core efficiently? You’re not alone. These dense, robust vegetables present unique challenges compared to their leafy green counterparts when it comes to rapid cooling.

Root vegetables are harder to cool quickly primarily due to their low surface area-to-volume ratio, dense flesh, and often lower accessible surface moisture. These characteristics hinder rapid heat transfer, especially for methods relying on surface evaporation like standard vacuum cooling.

Understanding these inherent properties is key to selecting the right cooling strategy and setting realistic expectations for preserving their quality post-harvest. Let’s dig into why these earthy treasures take their time to cool down.

Why is their Low Surface Area-to-Volume Ratio a Big Hurdle for Cooling Roots?

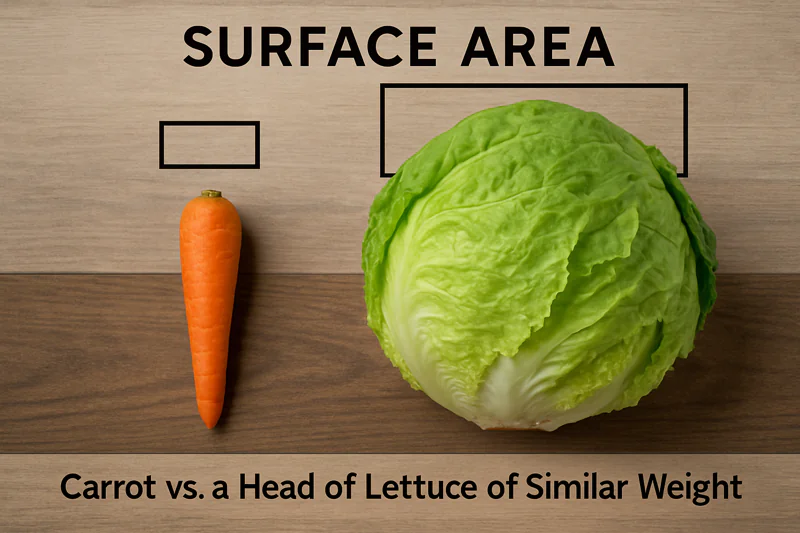

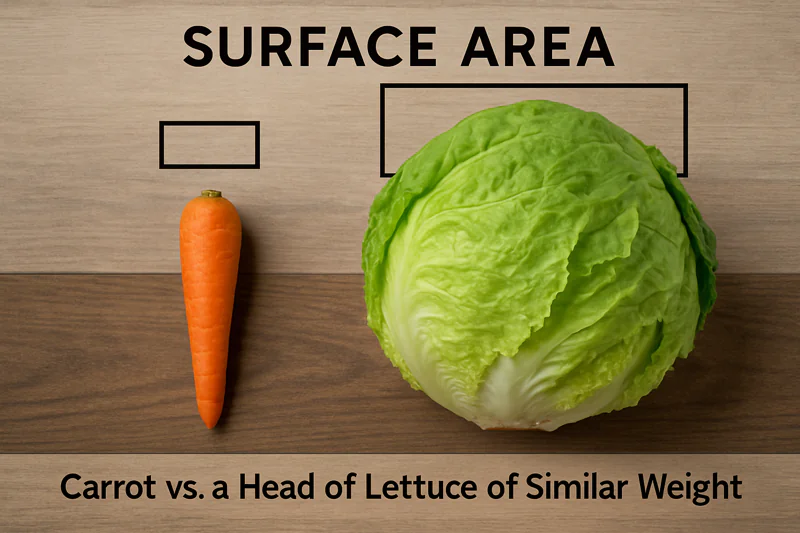

Ever wonder why a pile of carrots takes so much longer to chill than a bin of lettuce, even if they weigh the same? A major reason lies in their basic shape and how much of their "skin" is exposed.

Root vegetables typically have a compact, bulky shape with a relatively small outer surface compared to their total mass. This low surface area-to-volume ratio severely limits the area through which heat can escape, slowing down the cooling process.

I often explain this to clients like Norman, who sources various products and understands that different items need different handling. For leafy greens, vacuum cooling is incredibly effective because of their vast surface area. Each leaf offers a pathway for heat to escape. Now, consider a carrot or a potato. Their solid, rounded forms mean much less surface is available for heat exchange. Heat from the deep core has a longer, slower journey to the outside. This fundamental geometry is a primary reason they present a cooling challenge. For methods like vacuum cooling that rely heavily on surface evaporation, this limited "active" area is a significant bottleneck, meaning the cooling effect struggles to penetrate deeply and quickly.

Understanding Surface Area’s Impact

The key here is the ratio of surface area to the total volume1 (or mass) of the vegetable.

- High Ratio (e.g., Leafy Greens)2: Lots of surface relative to the total bulk. Heat can escape easily from many points. This is ideal for rapid cooling.

- Low Ratio (e.g., Potatoes, Carrots)3: Little surface relative to the total bulk. Heat from the interior has fewer and more distant escape routes.

Think of it this way:

| Vegetable Type | Shape Example | Surface Area relative to Volume | Implication for Cooling Speed |

|---|---|---|---|

| Leafy Green (Lettuce) | Many thin layers | Very High | Fast |

| Root Vegetable (Potato) | Compact, spherical | Low | Slow |

| Root Vegetable (Carrot) | Compact, cylindrical | Low | Slow |

This physical characteristic means that even if the cooling medium (air, water, or vacuum) is very efficient at removing heat from a surface, there’s just not enough surface on a root vegetable to allow for rapid cooling of its entire mass. The heat deep inside is "trapped" by the layers of dense flesh it needs to pass through to reach the limited exterior.

How Does the Dense Structure of Root Vegetables Slow Down Heat Removal?

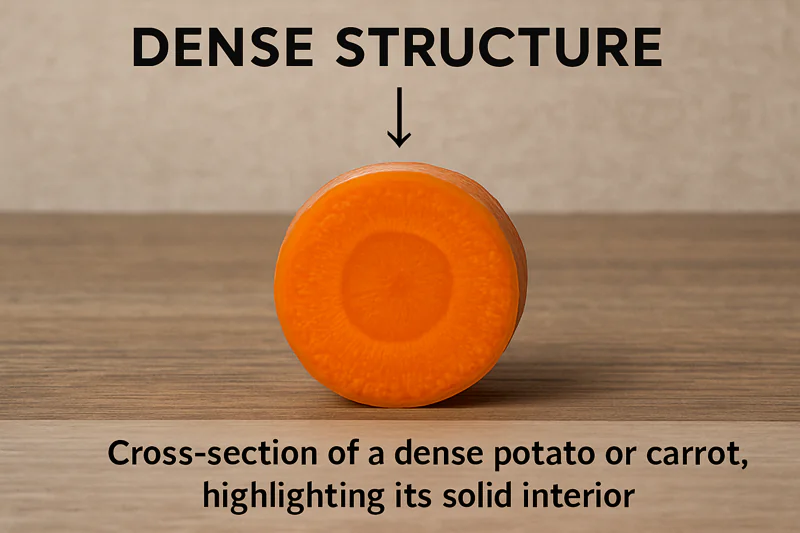

Beyond just their shape, what’s inside root vegetables also makes them tough customers for quick chilling. Their internal makeup isn’t designed for rapid temperature changes through methods that work wonders for more delicate produce.

The dense, tightly packed cellular structure of most root vegetables results in slower thermal conductivity. Heat energy from the warm core simply takes a longer time to move through these compact tissues to the cooler surface of the vegetable.

When I discuss cooling with technically-minded farm owners like Carlos, who values equipment durability and efficiency, we often touch upon how the product itself influences performance. The internal resistance of the product to temperature change is a key factor. Heat moves from the warmer core to the cooler surface via conduction. In dense materials like potatoes or beets, this molecular heat transfer is a slow process. These vegetables also have a high specific heat capacity, largely due to their water content, meaning a lot of energy must be removed to lower their temperature. It’s not just about reaching the surface; it’s about the slow journey of heat through the dense flesh. This internal bottleneck is why even if you rapidly cool the surface of a potato, its core can remain warm for a surprisingly long time.

Why Density Matters for Heat Transfer

The thermal properties of the vegetable flesh itself are critical:

- Thermal Conductivity: This measures how well heat passes through a material. Most vegetables, especially dense roots, are relatively poor conductors compared to, say, metals. Heat doesn’t "flow" easily through them.

- Specific Heat Capacity4: This is the amount of heat needed to change the temperature of a certain mass of the vegetable. Water has a high specific heat, and since roots are high in water, they need a lot of heat energy removed to cool down.

- Thermal Diffusivity: This combines conductivity, density, and specific heat to describe how quickly a material’s temperature will change when its surroundings change. Roots generally have low thermal diffusivity.

Consider these points:

| Property | Impact on Root Vegetable Cooling | Explanation |

|---|---|---|

| Low Thermal Conductivity5 | Heat moves slowly from core to surface. | The material itself resists rapid heat flow. |

| High Specific Heat | A large amount of energy must be removed to lower temperature. | Takes more "cooling power" and time to extract the necessary heat. |

| Dense Cellular Structure | Acts as an insulator, trapping heat within the core. | Fewer air pockets or easy pathways for heat to escape compared to porous items. |

This combination means that cooling a dense root vegetable is like trying to cool a well-insulated container from the outside – it takes a long time for the temperature change to reach the center.

Does the Lower Surface Moisture of Roots Impact Evaporative Cooling Speed?

We’ve talked about shape and density, but what about water? For vacuum cooling, which is our specialty at allcold, surface moisture is absolutely key. This is another area where many root vegetables present a challenge.

Many root vegetables have relatively dry, sometimes waxy or thick skins with less readily available surface moisture compared to leafy greens. This significantly limits the effectiveness of purely evaporative cooling methods like standard vacuum cooling, which rely on water turning to vapor to remove heat.

When I’m explaining vacuum cooling to potential clients, I always emphasize that water is the "refrigerant." The process works by lowering the pressure so water on the product’s surface boils at a low temperature, and this phase change draws heat from the product. If there’s little or no accessible water on the surface of a root vegetable, then this primary cooling mechanism is severely hampered. For leafy greens, their high surface moisture and vast surface area are a perfect combination. For a potato straight from dry soil, it’s a different story. Even if the root has high internal moisture content, if that moisture isn’t easily accessible at the surface, or if the skin is a barrier, then rapid evaporation simply can’t occur effectively to cool the entire mass.

The Role of Surface Water in Vacuum Cooling

The efficiency of vacuum cooling is directly tied to how much water can evaporate from the product’s surface.

- Abundant Surface Moisture6 (e.g., Leafy Greens): Leads to rapid and widespread evaporation, causing quick cooling.

- Limited Surface Moisture (e.g., Many Root Vegetables): Leads to slow, minimal, or surface-only cooling.

Here’s how surface characteristics affect things:

| Feature | Typical Root Vegetable (e.g., Potato, Carrot) | Impact on Standard Vacuum Cooling |

|---|---|---|

| Skin Type | Often thick, waxy, or suberized (corky) | Acts as a barrier to moisture evaporation7 from within. |

| Natural Surface Moisture | Generally Low (especially after some drying) | Insufficient "fuel" for effective evaporative cooling8 of the core. |

| Water Adhesion | Water may not cling as well to waxy surfaces | Pre-wetting might be less effective if water just runs off. |

This doesn’t mean vacuum cooling is impossible for all roots. Some smaller, more tender roots, or those that are thoroughly washed and still wet, might see some benefit. Techniques like "hydro-vacuum" (wetting before or during the vacuum cycle) can help by providing that necessary surface moisture. However, for large, dense roots with dry or impermeable skins, relying solely on standard vacuum cooling for core temperature reduction is often inefficient.

Are Alternative Cooling Methods More Effective for Some Root Vegetables?

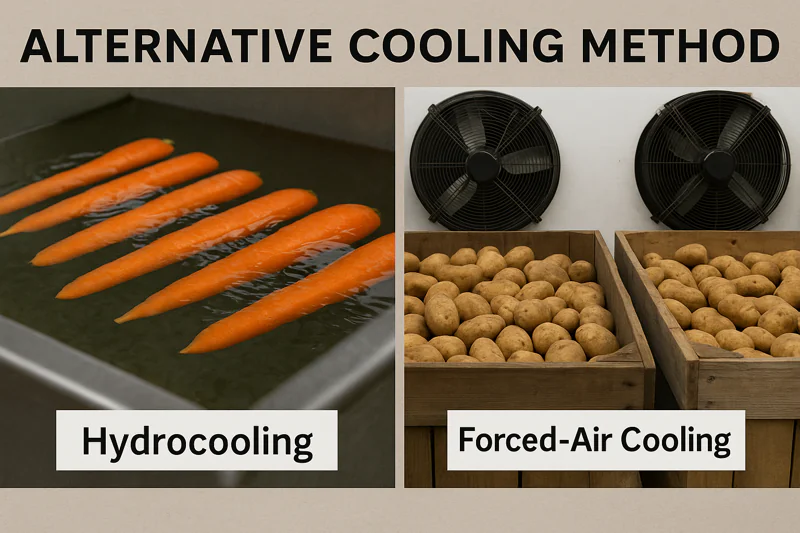

Given the challenges posed by their low surface area, dense structure, and often limited surface moisture, is vacuum cooling always the wrong choice for root vegetables? And what works better?

While standard vacuum cooling is often not ideal for many root vegetables, methods like hydrocooling (chilled water) or forced-air cooling are generally more effective for these dense products as they facilitate better heat transfer with their specific characteristics.

At allcold, we believe in providing the best solution, and sometimes that means acknowledging where other technologies might be more suitable. For our core products—leafy greens, mushrooms, many cooked foods—vacuum cooling is unbeatable. But for a farmer with tons of potatoes or large carrots, understanding alternatives is crucial.

Let’s look at why other methods can be better for roots:

- Hydrocooling: This involves immersing or drenching vegetables in chilled water. Water has a high thermal conductivity and makes excellent contact with the entire surface of the root, even irregular shapes. This allows for more efficient heat transfer from the root into the water. It’s often much faster than air cooling for dense items.

- Forced-Air Cooling (or Pressure Cooling): Here, cold air is actively forced through bulk bins or stacks of produce. This is much more effective than just placing roots in a cold room (room cooling) because it ensures consistent airflow over the product surfaces, increasing convective heat transfer. It’s good for large volumes.

Comparing Methods for Dense Roots:

| Cooling Method | Primary Heat Transfer | Suitability for Dense Roots | Key Advantages for Roots | Common Challenges for Roots |

|---|---|---|---|---|

| Standard Vacuum Cooling9 | Evaporation | Generally Poor to Fair | Very fast if sufficient surface moisture is present (rare for dry roots) | Slow core cooling; surface cools, core stays warm; moisture dependent. |

| Hydrocooling10 | Conduction/Convection | Good to Excellent | Rapid, uniform cooling; cleans product. | Water management, cost of chilling water, potential microbial issues. |

| Forced-Air Cooling11 | Convection | Good, especially for bulk | Effective for large volumes; can integrate with storage. | Slower than hydrocooling; potential for some moisture loss. |

| Room Cooling | Convection | Poor (Very Slow) | Simple, low initial equipment cost. | Extremely slow; non-uniform; significant moisture/quality loss. |

Sometimes, hybrid approaches are used, like hydro-vacuum cooling, where roots are wetted before entering the vacuum chamber to provide the necessary surface moisture for evaporation. This can improve outcomes for certain types of roots, but for the densest and largest varieties, direct water or enhanced air cooling often provides more reliable and thorough core temperature reduction. Understanding these differences helps producers like Carlos or buyers like Norman make informed decisions about their post-harvest handling.

Conclusion

Root vegetables, with their compact shapes, dense tissues, and often dry surfaces, pose significant cooling challenges. Their unique characteristics generally make them less suitable for standard vacuum cooling compared to more efficient methods like hydrocooling or forced-air cooling for achieving rapid and thorough temperature reduction.

-

Understanding this ratio can help you optimize cooling methods for different vegetables, enhancing freshness and quality. ↩

-

Discover the science behind why leafy greens cool more efficiently, which can inform your cooking and storage practices. ↩

-

Learn about the cooling properties of root vegetables to improve your food preservation techniques and cooking times. ↩

-

Exploring specific heat capacity helps in understanding how different substances respond to heat, crucial for cooking and material science. ↩

-

Understanding thermal conductivity is essential for grasping how heat moves through different materials, especially in cooking and food science. ↩

-

Understanding surface moisture is crucial for optimizing vacuum cooling processes, especially for different types of vegetables. ↩

-

Learning about moisture evaporation factors can help in selecting the right produce for effective vacuum cooling. ↩

-

Exploring evaporative cooling can enhance your knowledge of cooling systems and improve efficiency in food preservation. ↩

-

Understand the limitations of standard vacuum cooling, particularly its moisture dependency and slow core cooling issues. ↩

-

Explore the advantages of hydrocooling, which offers rapid and uniform cooling, essential for maintaining root quality. ↩

-

Learn about forced-air cooling, an effective method for large volumes that can enhance storage integration. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But