Why Are Your Delicate Pastries Losing Volume During Cooling?

You bake a perfect sponge, light as air and tall in the pan. But halfway through the cooling process, it sinks. All that volume, gone in minutes. It is frustrating, isn’t it?

Vacuum cooling for cakes requires a gentle touch. Unlike hearty breads, pastries need the "Vacuum Delay" mode to lower pressure gradually. This prevents the delicate gluten structure from exploding, ensuring your cakes stay tall, moist, and ready for icing in under 10 minutes.

As a manufacturer at Allcold, I have seen pastry chefs hesitate to use vacuum cooling. They fear the "explosion." They are right to be worried—if they use a machine designed only for vegetables. But with the right parameters, we can change the physics of your bakery.

Why Do Cakes Need a Different Cooling Strategy Than Bread?

Treating a sponge cake like a sourdough loaf is a recipe for disaster. One is tough and resilient; the other is fragile and sugar-heavy. Mixing up their cooling methods costs you money.

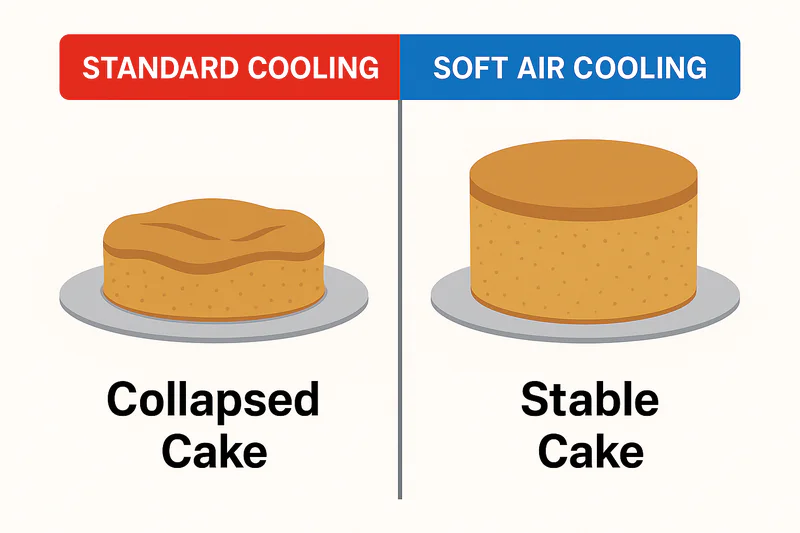

Cakes have a weaker structure and higher sugar content. Standard vacuum cooling pulls moisture too fast, causing the crumb to collapse or "mushroom." You need a machine that understands "gentle extraction" to preserve the volume you worked so hard to create.

The Physics of Delicate Structures vs. Durable Loaves

For a technical decision-maker like Carlos, understanding the "why" is as important as the "how." It is not just about "cooling"; it is about managing the State of Matter1 change inside your product. To truly optimize your production, we need to look at three critical scientific factors: Starch Retrogradation2, Structural Tugging3, and Water Activity.

1. The Battle Against Retrogradation (Staling)

One of the biggest hidden enemies in baking is starch retrogradation. This is the process where starch molecules (amylose and amylopectin) realign and crystallize as the product cools, pushing water out of the structure. This is what makes the crumb turn hard and dry (staling).

- The Critical Zone: Retrogradation happens fastest between 60°C and 20°C.

- The Traditional Problem: In a standard ambient cooling room, your cakes might sit in this "staling danger zone" for 2 hours. This gives the starch plenty of time to crystallize, reducing the shelf life of your product before you even package it.

- The Vacuum Advantage: Our systems flash-cool the product through this danger zone in just minutes. By minimizing the time spent between 60°C and 20°C, we keep the starch structure more amorphous (softer). This directly translates to a product that stays fresh for 2-3 days longer than air-cooled pastries.

2. Structural Integrity: Gluten vs. Egg Foam

Bread relies on a strong gluten network developed during kneading. It is like a rubber band; it can stretch and snap back. Cakes, however, often rely on egg protein coagulation and sugar for structure (like a Soufflé, Sponge, or Chiffon).

- The "Explosion" Risk: If the pressure in the vacuum chamber drops too quickly (e.g., from 1000 mbar to 30 mbar in 2 minutes), the water inside the cake turns to steam instantly. This steam expands roughly 1,600 times in volume. A strong bread crust can hold this expansion, but a delicate cake surface cannot.

- The Result: The steam blows out the cell walls. The cake might look fine in the chamber, but once you open the door and equalise pressure, it collapses into a dense, gummy puck. This is what we call "structure failure."

3. Comparing the Parameters

To give you a clear picture of how we customize our machines, here is how we program our Siemens PLCs4 differently for these two product categories:

| Feature | Bread / Rolls / Baguettes | Sponge Cake / Mousse / Muffins |

|---|---|---|

| Primary Structure | Strong Gluten Network | Fragile Protein / Foam-based |

| Cooling Speed5 | Fast (Aggressive, 3-8 mins) | Slow (Stepped, 8-15 mins) |

| Vacuum Mode | Continuous Linear Pull | Vacuum Delay / Step-down |

| Final Pressure | ~15-20 mbar (very cold) | ~30-40 mbar (moderately cold) |

| Risk Factor | Low (Crust hardness) | High (Total collapse, shape distortion) |

| Moisture Loss | 3% – 4% | 2% – 3% (Controlled) |

By understanding these differences, we configure the Variable Frequency Drive (VFD)6 on our pumps to adjust the extraction speed, ensuring we treat a croissant like a croissant, and a muffin like a muffin.

Now that we understand the structure, we need to look at the specific technology that prevents these collapses.

How Does the "Vacuum Delay" Feature Save Your Production?

Watching a batch of soufflés or cheesecakes implode in a vacuum chamber is a nightmare. It happens in seconds. But it doesn’t have to happen at all.

The Vacuum Delay Facility acts like a parachute. Instead of free-falling into a vacuum, the system pauses at specific pressure points (e.g., 500 mbar). This allows the cake’s internal heat to dissipate slowly, setting the structure before the deep cooling begins.

Engineering the Perfect Cooling Curve

For a QA manager like Sophia, this feature is the difference between a premium product and waste. This is not just a "slower" setting; it is an intelligent process managed by our advanced algorithms. It transforms the vacuum cooler7 from a "brute force" machine into a precision instrument.

The "Step-Down" Logic Explained

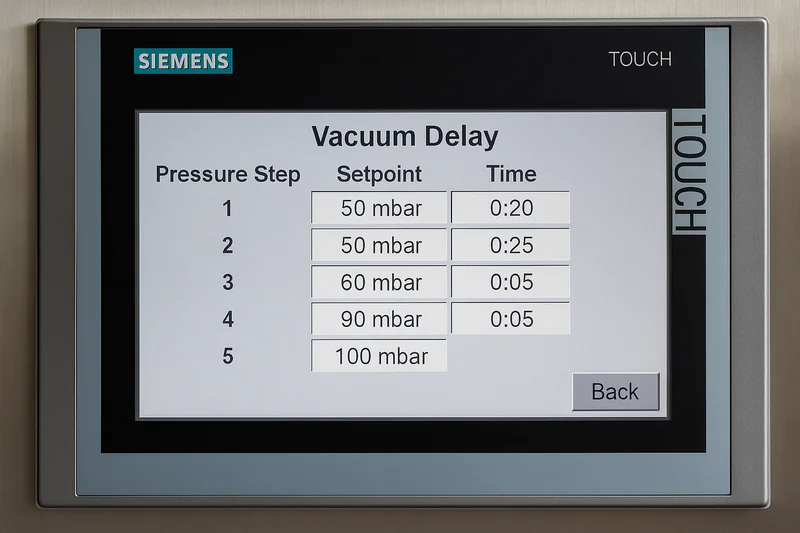

We use a technique called "Flash Point Detection8." Here is what happens inside an Allcold machine equipped with this technology:

- Initial Venting (1000 mbar to 800 mbar): The pump removes the bulk air from the chamber. This has no cooling effect yet; it just prepares the environment.

- The Stabilization Pause (The "Green Light"): As the pressure approaches the boiling point of water at the product’s current temperature (around 500-600 mbar for hot cakes), the machine detects the first signs of evaporation.

- The Magic Moment: Instead of continuing to pull, the system pauses. It holds the pressure steady.

- Why? This allows the heat from the core of the cake to travel to the surface without violent boiling. The structure (the crumb walls) begins to firm up and set. It balances the internal pressure with the chamber pressure.

- Gentle Ramp Down: After a set time (e.g., 60 seconds), the VFD slows the pump down. We gently lower the pressure to 200 mbar.

- Final Cooling: Only when the structure is stable does the machine go to full power to drop to the final target pressure (around 30 mbar) to reach the target temperature (e.g., 10°C or 25°C).

Visual Control via HMI

We use Siemens Touch Screens9 because they allow you to visualize and customize this process completely.

- Recipe Management: You can save a "Cheesecake" recipe (heavy delay) and a "Muffin" recipe (light delay).

- Operator Simplicity: Your staff doesn’t need to be physicists. They just press the picture of the cake, and the PLC handles the complex delay steps automatically.

Real-World Success: The "Flying Muffin" Case

I recall working with a client in South Korea who produced high-volume blueberries muffins.

- The Problem: When they used a competitor’s standard vacuum cooler, the blueberries would literally explode out of the top of the muffin due to rapid expansion, and the muffin tops would detach (we call this "Flying Tops"). The rapid pressure drop caused the air pockets inside the batter to expand faster than the crust could harden.

- The Fix: We implemented a 3-stage Vacuum Delay10 using our Allcold custom software.

- Stage 1: Hold at 700 mbar for 30 seconds (Skin formation).

- Stage 2: Linear pull to 300 mbar over 2 minutes (Gentle core cooling).

- Stage 3: Final pull to 30 mbar.

- The Result: The muffins retained their perfect dome shape, the blueberries stayed intact, and the cooling time11 was still only 12 minutes—compared to 90 minutes in their ambient spiral cooler. This saved them thousands of dollars in rejected products.

Once your product is cooled safely, the next challenge is getting it ready for sale.

Can Vacuum Cooling Speed Up Your Decorating Workflow?

The bottleneck in a pastry shop isn’t usually the baking; it is the waiting. Waiting for cakes to cool so the buttercream doesn’t slide off. How much time are you wasting right now?

Vacuum cooling brings cakes to 30°C (or lower) in minutes, not hours. This means you can slice and ice immediately. There is no warm core to melt your ganache, allowing for a streamlined, continuous production line from oven to packaging.

Hygiene, HACCP, and Operational Efficiency

For an owner like Norman, speed translates directly to the bottom line: faster turnaround means fresher products on the shelf. But for Sophia, the safety aspect is paramount. Let’s dig into how vacuum cooling changes the entire hygiene profile of your bakery.

The "False Cool" Phenomenon

Traditional cooling is deceptive. You touch the outside of a sponge cake after 40 minutes, and it feels cool.

- The Reality: The core might still be at 45°C.

- The Consequence: You apply the buttercream or fondant. Ten minutes later, the heat from the core radiates outward. The fat in the icing melts. The decoration slides off, or the fondant becomes sticky and "sweats."

- The Vacuum Solution: Vacuum cooling works from the inside out. It guarantees the core temperature is exactly what you set (e.g., 25°C). If the core is cold, the whole cake is stable. You can decorate with 100% confidence immediately. This eliminates the need for "buffer stock" waiting on racks.

Mastering the "Danger Zone"

Pastries are often rich in nutrients—eggs, milk, cream, sugar. This makes them a perfect breeding ground for bacteria (like Salmonella or Staphylococcus).

- The Danger Zone: Bacteria multiply fastest between 60°C and 20°C.

- Rule of Thumb: The longer your product stays in this temperature range, the higher the bacterial count (CFU).

- Speed is Safety: By crossing this danger zone in 8-10 minutes (Vacuum) instead of 120 minutes (Ambient), you effectively shock the bacteria and prevent them from multiplying.

- Shelf Life: This rapid cooling, combined with the sterile environment of the vacuum chamber (air is removed, so airborne contaminants are removed), can often double the mold-free shelf life of moist cakes without adding chemical preservatives.

The "Clean Room" Advantage

Traditional cooling usually happens on open racks in a hallway or a designated room.

- Risk: These racks are exposed to dust, flies, and yeast spores floating in the bakery air. Cross-contamination is a constant risk.

- Solution: A vacuum cooler is a sealed chamber. Once the door is closed, the product is isolated. The cooling air is filtered (or non-existent in deep vacuum).

- Maintenance: Our chambers are made of food-grade stainless steel (SUS304) and are designed to be washed down. The Zero Load Protection feature helps dry out the pump after a shift, ensuring that moisture and sticky sugar residues don’t degrade your equipment. For clients in tropical climates (like Singapore or Mexico), this moisture management is critical to preventing mold inside the machine itself.

Speed and quality are great, but does the math actually work for your business?

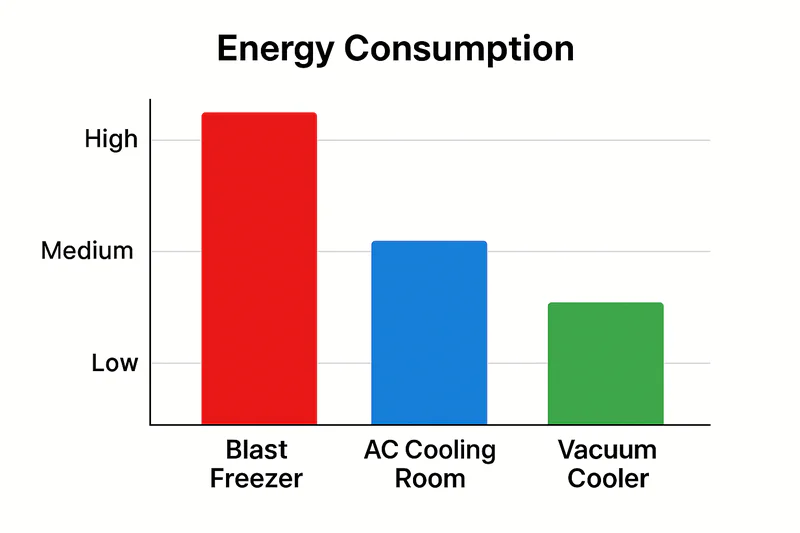

Is the Investment in Vacuum Cooling Justified by Energy Savings?

You might think vacuum cooling is an expensive luxury. But have you calculated the cost of running large blast freezers or holding rooms? Or the cost of the floor space they occupy?

Vacuum cooling is surprisingly energy-efficient because it only targets the product, not the room. It uses ~60% less energy than blast freezing and frees up 90% of your floor space, giving you a faster ROI than traditional cooling tunnels.

The ROI Calculation and Cost Analysis

Let’s break down the financials. Norman, this section is for you. We need to look at the Total Cost of Ownership (TCO), not just the machine price. Many buyers focus on the sticker price, but the operational savings of vacuum cooling are where the real profit lies.

1. Energy Consumption: Physics is on Your Side

- Traditional Cooling (AC Room / Spiral): You are cooling the air in a massive room. You are fighting against the heat of the oven, the heat of the summer, and the heat of the product. The fans run constantly. It is an inefficient heat transfer method.

- Vacuum Cooling: You are only removing energy from the bread/cake itself via evaporation. The vacuum pump only runs for the 10-minute cycle. When the machine is idle or loading, it consumes almost zero power (thanks to our Smart Standby mode).

- The Data: On average, cooling 100kg of product from 95°C to 25°C requires about 1.0 – 1.5 kWh of electricity with our vacuum systems. A comparable blast chiller or spiral freezer system would use 3.0 – 4.0 kWh for the same load due to inefficiencies and fan motors. Over a year, this electricity difference alone can amount to tens of thousands of dollars.

2. The Value of Floor Space (Real Estate)

- The Problem: A spiral cooling tower for a medium-sized bakery takes up a massive amount of footprint—often 30 to 50 square meters. Plus, you cannot use that vertical space for anything else.

- The Solution: A standard 2-rack vacuum cooler takes up about 4 to 5 square meters.

- The Gain: What could you do with that extra 40 square meters? Add another oven? Add a packaging line? Or simply reduce your rental costs? For a factory in a high-rent city like Singapore or New York, the space savings alone can pay for the machine in 2 years.

3. Labor and Workflow Optimization

- Touch Points: With rack cooling, workers have to move racks to a cooling area, wait, check temperatures manually, move them to slicing, wait again…

- Streamlined Flow: Oven -> Vacuum (10 mins) -> Slicing/Packaging.

- Shift Reduction: Because you don’t have to wait 2 hours for the bread to cool, your packaging team can start working almost immediately after the baking team finishes. You can potentially reduce your total shift hours or eliminate the need for a "night cooling shift."

4. Maintenance and Longevity

Some buyers worry about the vacuum pumps.

- Reality Check: High-quality pumps (like the Busch or Leybold pumps we use) are industrial workhorses. They are designed to run 24/7.

- Cost: The main consumable is oil and filters. Compared to the cost of maintaining a complex spiral conveyor system (belts breaking, motors failing, difficult cleaning), a vacuum cooler is mechanically simpler with fewer moving parts.

| Cost Factor | Spiral / Tunnel Cooler | Vacuum Cooler | Winner |

|---|---|---|---|

| Electricity | High (Fans + Compressors) | Low (Pump + small compressor) | Vacuum |

| Floor Space | Huge (30-50 m²) | Compact (4-6 m²) | Vacuum |

| Cooling Time | 60 – 120 mins | 8 – 15 mins | Vacuum |

| Sanitation | Difficult (Belt cleaning) | Easy (CIP Washdown) | Vacuum |

| Initial Cost | High ($$$) | Medium ($$) | Vacuum |

Conclusion

Cooling pastries is an art form that requires the right science. By utilizing the Vacuum Delay Facility, precise Siemens control systems, and understanding the structural needs of cakes, you can achieve volume, stability, and speed. Moreover, when you analyze the energy savings and space efficiency, the investment makes sense for any growing bakery.

Don’t let your profits collapse on the cooling rack. Give your cakes the gentle treatment they deserve.

-

Understanding the State of Matter is crucial for optimizing baking processes and improving product quality. ↩

-

Learn about Starch Retrogradation to enhance the freshness and shelf life of your baked products. ↩

-

Explore Structural Tugging to understand how it impacts the texture and integrity of baked items. ↩

-

Discover how Siemens PLCs can optimize baking processes for better product consistency and quality. ↩

-

Understanding Cooling Speed can help you achieve the perfect texture and freshness in your baked goods. ↩

-

Find out how VFD technology can improve the efficiency and effectiveness of baking operations. ↩

-

Discover the advantages of vacuum coolers for food production and how they can improve product quality. ↩

-

Understanding Flash Point Detection can enhance your knowledge of advanced cooling techniques and improve product quality. ↩

-

Explore how Siemens Touch Screens can streamline operations and enhance user experience in industrial settings. ↩

-

Learn about the 3-stage Vacuum Delay to optimize cooling processes and prevent product damage. ↩

-

Understanding cooling time factors can help you optimize production processes and reduce waste. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy